If you’ve ever wondered how much lathes weigh, you’re in the right place! In this guide, we’ll dive into the weight of lathes and why it matters. So, let’s grab our tools and start exploring!

Lathes, those fascinating machines used to shape and carve wood, metal, and other materials, come in various sizes and types. But have you ever stopped to think about how much these hefty machines actually weigh? Well, we’re here to satisfy your curiosity, my young builder!

Now, let’s embark on a weighty adventure together and uncover the secrets behind the fascinating world of lathes. Are you ready to discover the surprising numbers behind their weight? Let’s jump right in!

How Much Do Lathes Weigh?

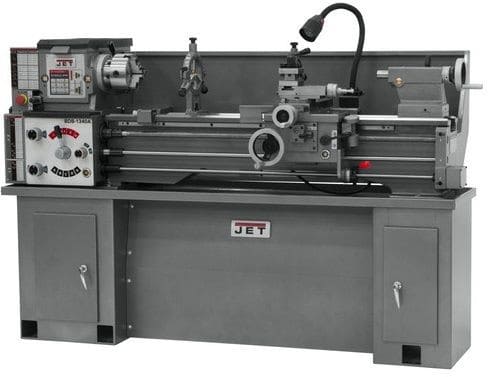

A lathe is an essential tool in many industries, used for shaping wood, metal, and other materials. If you’re considering purchasing a lathe, one important factor to consider is its weight. The weight of a lathe can affect its portability, stability, and overall performance. In this article, we will explore the factors that determine the weight of a lathe and provide detailed information to help you make an informed decision.

1. Types of Lathes and Their Weight

There are different types of lathes available in the market, each with its own weight. The weight of a lathe depends on its size, design, and the materials used in its construction. For example, smaller benchtop lathes designed for hobbyists and small-scale projects are generally lighter, weighing around 50 to 150 pounds (22 to 68 kilograms). On the other hand, larger industrial lathes used in professional settings can weigh anywhere from 500 to 10,000 pounds (227 to 4,536 kilograms) or even more.

Factors Affecting Weight

The weight of a lathe is determined by several factors, including the size and dimensions of the lathe, the material it’s made of, and the additional components it may have. Cast iron is a common material used in lathe construction due to its durability and stability. However, it also adds significant weight to the machine. The size of the lathe, particularly the length of the bed, also affects its weight. Larger lathes with longer beds will generally be heavier compared to smaller models.

Table of Lathes and Their Weights

Here is a table comparing the weights of different types of lathes:

| Lathe Type | Weight Range |

|——————|————————|

| Benchtop Lathe | 50-150 pounds |

| Mini Lathe | 100-300 pounds |

| Industrial Lathe | 500-10,000 pounds |

| CNC Lathe | 1,000-20,000 pounds |

2. Considerations When Choosing a Lathe Based on Weight

When choosing a lathe, it’s important to consider the weight and how it will impact your work. Here are some key considerations:

Portability

If you often need to move your lathe from one location to another, such as for on-site projects or workshops, a lighter and more portable lathe would be a better choice. Benchtop and mini lathes are highly portable, making them suitable for hobbyists and those with limited space.

Stability

On the other hand, if stability and precision are essential for your work, a heavier and more robust lathe will provide better results. Industrial lathes, with their substantial weight, offer excellent stability and are suitable for larger-scale projects that require precision.

Workspace

Consider the available space in your workshop or workspace. Larger lathes require more space to accommodate their size and weight. Ensure that you have enough room for the lathe and allow for easy access and maneuverability around the machine.

3. Tips for Handling and Moving Heavy Lathes

Moving a heavy lathe can be challenging, but with proper precautions, it can be done safely. Here are some tips to help you handle and move a heavy lathe:

1. Prepare a suitable workspace:

Ensure that the area where the lathe will be placed is clean, level, and can support the weight of the machine. Remove any obstacles that may hinder movement.

2. Seek assistance:

Lathes are heavy, and attempting to move them alone can lead to injuries. Enlist the help of others to ensure safe lifting and moving.

3. Use proper lifting equipment:

Consider using lifting equipment such as a forklift or hoist to safely lift and move the lathe. Make sure the lifting equipment is suitable for the weight of the lathe and follow all safety guidelines.

4. Disassemble if needed:

If the lathe is too heavy to move as a whole, consider disassembling it into smaller parts for easier transportation. Take note of the proper disassembly and reassembly procedures to avoid any damage to the machine.

5. Use appropriate safety gear:

Wear proper protective gear, such as gloves and sturdy shoes, to avoid injuries during the lifting and moving process.

The Importance of Weight in Lathe Selection

When considering the purchase of a lathe, understanding its weight and how it can impact your work is crucial. The size, material, and components of a lathe all contribute to its overall weight. Whether you require a portable lathe for small-scale projects or a heavier, industrial-grade lathe for more demanding tasks, weighing your options and considering the factors discussed in this article will help you make an informed decision. Remember to prioritize safety when moving heavy lathes and seek professional assistance if needed.

Key Takeaways: How much does lathes weigh?

- Lathes can vary in weight depending on their size and type, but on average, they can range from a few hundred pounds to several thousand pounds.

- Mini lathes, commonly used for hobbyists and smaller projects, tend to weigh around 50 to 100 pounds.

- Benchtop lathes are larger and heavier, typically weighing between 150 and 300 pounds.

- Industrial-grade lathes, designed for heavy-duty use, can weigh anywhere from 1,000 to 10,000 pounds or more.

- It’s essential to consider the weight of a lathe when purchasing one, as it will determine the stability, portability, and support requirements needed for proper operation.

Frequently Asked Questions

Looking to find out how much lathes weigh? We’ve got you covered with the answers to commonly asked questions.

1. What factors determine the weight of a lathe?

The weight of a lathe can vary based on several factors, including its size, construction materials, and additional features. Generally, larger lathes tend to weigh more due to the increased amount of metal and components used in their construction. Lathes made with heavier materials, such as cast iron, are also likely to be heavier compared to those made with lighter materials like aluminum.

Additionally, special features like built-in accessories, multiple motors, or extended beds can contribute to the weight of a lathe. It’s important to consider your specific needs and workspace limitations when choosing a lathe with the appropriate weight.

2. How much does an average-sized lathe weigh?

An average-sized lathe typically weighs between 500 and 2500 pounds (227 to 1134 kilograms). However, these weight ranges can vary depending on the specific model, brand, and the features included. It’s recommended to check the product specifications or consult with the manufacturer to get the exact weight of a particular lathe model.

Remember, when considering the weight of a lathe, it’s essential to account for any additional equipment, such as chucks, tool rests, or stands, as these can also add to the overall weight and need to be factored in for transportation and installation purposes.

3. Can a lathe be too heavy for my workshop?

Yes, the weight of a lathe is an important consideration when planning for its installation in a workshop. While a heavier lathe is often more stable and can dampen vibrations, it may also require a sturdier and more reinforced workbench or floor to support its weight.

Before purchasing a lathe, it’s crucial to assess the load-bearing capacity of your workshop floor and any workbenches or stands you plan to use. If necessary, consult with a structural engineer to ensure that your workspace can safely accommodate the weight of the lathe you intend to purchase.

4. Are there portable or lightweight lathes available?

Yes, if portability is a priority or you have limited space available, there are portable or lightweight lathes that can be suitable for your needs. These lathes are typically smaller in size and made with lighter materials like aluminum, making them easier to transport and maneuver.

Portable lathes often come with features like foldable or telescoping stands, allowing for easy setup and storage. However, it’s important to note that portable lathes may have limitations in terms of their maximum turning capacity and may not be as stable as larger, heavier models.

5. How can I determine if my floor can support the weight of a lathe?

If you’re unsure whether your workshop floor can support the weight of a lathe, consider taking the following steps:

1. Consult a structural engineer or a professional with expertise in construction and load-bearing capacities to evaluate your workshop floor.

2. Determine the maximum weight capacity of your floor by referring to the original building plans, consulting the building’s specifications, or using load-carrying capacity calculators.

3. Consider reinforcing your floor by adding additional support beams or reinforcing existing structures if necessary.

It’s crucial to ensure the safety of your workshop and the structural integrity of your floor when installing heavy machinery like lathes.

What Size Lathe Should You Buy?

Summary

So, we learned about lathes and how much they weigh. Lathes are big machines used to shape materials like wood or metal. They can weigh anywhere from a few hundred pounds to several thousand pounds. The weight depends on the size and type of the lathe. It’s important to consider weight when buying a lathe, as it affects how it can be transported and used safely. Remember, lathes are heavy machines, so be cautious when operating or moving them.