If you’re wondering “how much does plywood expand?” when exposed to different conditions, you’ve come to the right place! Plywood is a versatile material commonly used in construction and woodworking projects. Understanding how it behaves under different circumstances can help you make informed decisions. So, let’s dive in and explore the fascinating world of plywood expansion!

Plywood, like many other materials, expands and contracts in response to changes in temperature, humidity, and moisture levels. This natural behavior occurs due to the structure of plywood, which consists of layers of wood veneers glued together. As temperature and humidity fluctuate, the individual wood fibers within the plywood can either absorb or release moisture, leading to expansion or contraction.

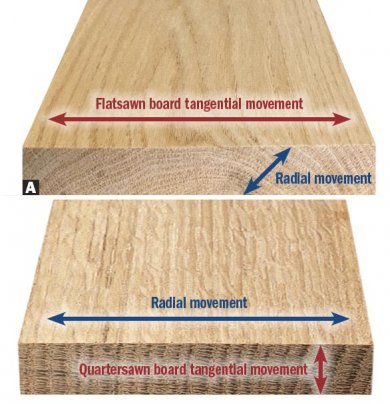

The amount of expansion that plywood experiences depends on various factors, such as the type of wood used, the environmental conditions, and the specific construction of the plywood itself. In general, plywood tends to expand more across the grain than along the grain. Understanding this expansion behavior is crucial when working with plywood to ensure the stability and longevity of your projects.

Now that we’ve set the stage, let’s dive deeper into the fascinating world of plywood expansion. In the following sections, we’ll explore different factors that influence plywood expansion and provide practical tips to help you work with plywood effectively. So, buckle up and get ready to expand your knowledge!

How Much Does Plywood Expand? Exploring the Factors and Considerations

When it comes to working with plywood, understanding how much it expands is crucial to ensure the success of your project. Plywood, being a wood-based material, is prone to expansion and contraction due to changes in temperature and humidity. In this article, we will explore the various factors that contribute to plywood expansion and provide you with valuable insights on how to deal with it.

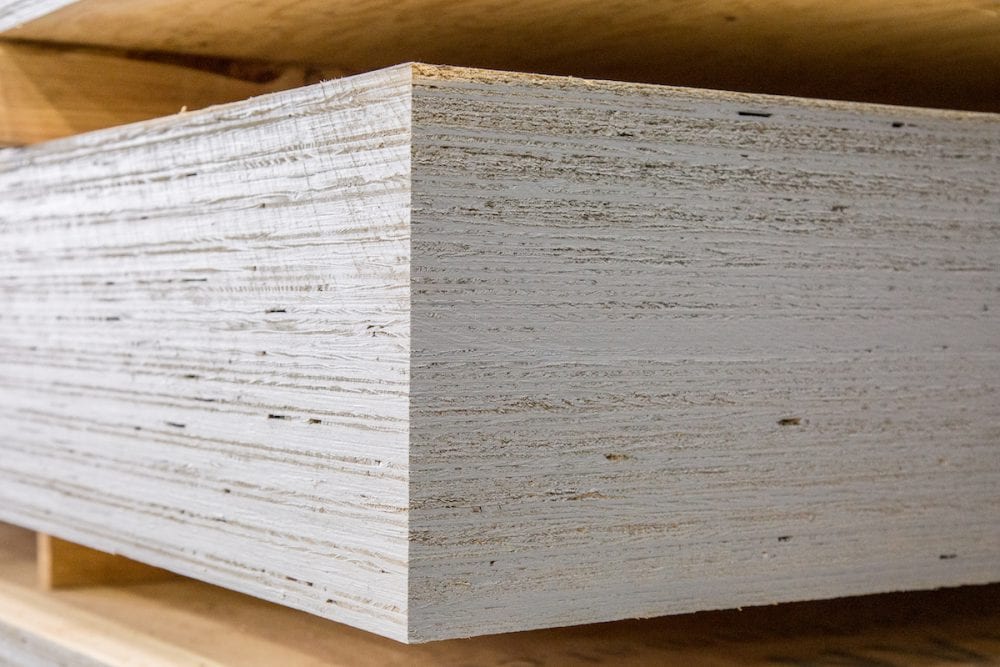

The Composition of Plywood

Plywood is made by gluing together several layers of thin wood veneers, with each layer being placed perpendicular to the grain direction of the one below it. This cross-laminated construction gives plywood its strength and stability. However, it also makes plywood susceptible to dimensional changes when exposed to different environmental conditions.

Due to its construction, plywood expands and contracts mostly along its width. This is because the layers of wood have different wood grain orientations, causing them to react differently to moisture and temperature changes. The outer layers, also known as the face and back veneers, have the most significant impact on expansion and contraction.

It’s important to note that plywood can expand and contract up to twice as much as solid wood, making it crucial to account for this movement when planning and installing plywood in various applications.

Factors Affecting Plywood Expansion

Several factors contribute to the expansion of plywood:

1. Moisture Content:

Plywood is highly sensitive to changes in moisture content. When exposed to high humidity or direct water contact, the moisture content of plywood increases, causing it to expand. Conversely, in drier conditions, plywood loses moisture and contracts.

It’s important to acclimate plywood to the environment where it will be installed by storing it in the area for a few days before installation. This allows the plywood to adjust to the moisture content of the surroundings, minimizing expansion or contraction after installation.

2. Temperature:

Temperature variations directly affect the dimensions of plywood. When exposed to high temperatures, plywood expands, and when subjected to low temperatures, it contracts. This thermal expansion and contraction can result in warping, buckling, or gaps between sheets if not accounted for during installation.

It’s recommended to install plywood with slight gaps between the sheets to allow for temperature-related expansion. These gaps can be filled with a flexible sealant that accommodates movement while maintaining a watertight finish.

3. Grain Orientation:

The direction of the wood grain in plywood plays a significant role in its expansion and contraction behavior. Plywood with alternating grain directions in its layers is less likely to expand or contract significantly compared to plywood with all layers oriented in the same direction.

When selecting plywood for a project, consider using plywood with cross-laminated construction, as it offers better stability and reduces the risk of excessive expansion or contraction.

Minimizing and Managing Plywood Expansion

While plywood will inevitably expand and contract, there are steps you can take to minimize and manage its movement:

1. Allow for Proper Ventilation:

Ensuring proper ventilation in the installation area helps regulate moisture levels and reduces potential expansion or contraction of plywood. Adequate air circulation helps maintain a more stable environment for the plywood.

2. Use Proper Fasteners:

Choosing the right fasteners is crucial when installing plywood. To accommodate for expansion and contraction, consider using fasteners with slight oversize holes. This allows the plywood to shift without inducing stress or damage, reducing the risk of splitting or buckling.

3. Apply Appropriate Finishes:

Finishing plywood with suitable sealants or coatings can help protect it from excessive moisture absorption or prolong exposure to high temperatures. These finishes create a barrier that slows down the plywood’s expansion or contraction process.

By understanding the factors that contribute to plywood expansion and implementing these strategies, you can effectively manage and minimize the movement of plywood in your projects, ensuring long-lasting and successful results. Remember to account for plywood’s unique characteristics and plan accordingly to achieve the desired outcomes.

Additional Considerations for Plywood Expansion and Proper Usage

Different Grades of Plywood

When selecting plywood for your project, it’s important to consider the specific grade of plywood. Different grades have varying levels of tolerance to expansion and contraction. Higher-grade plywood, such as Marine Grade plywood, is often more stable due to stricter quality control measures during manufacturing. This makes it a suitable choice for applications that require increased resistance to moisture and environmental fluctuations.

Lower-grade plywood, such as Construction Grade or Utility Grade plywood, may be more prone to expansion and contraction. However, it can still be used effectively in applications where precise dimensional stability is less critical.

Effect of Moisture Barrier Treatments

Applying a moisture barrier treatment to plywood can significantly reduce its susceptibility to moisture-related expansion and contraction. Various products are available that penetrate the wood, creating a shield against moisture absorption. This treatment helps maintain the integrity of the plywood and minimizes the risk of warping or distortion.

Before applying any moisture barrier treatment, ensure that the plywood is clean, dry, and free of any contaminants. Follow the manufacturer’s instructions for proper application and allow sufficient drying time before subjecting the plywood to moisture or temperature variations.

Understanding Plywood Grading System

The Plywood Grading System provides a standardized way to assess the quality and suitability of different plywood panels. Plywood grades are determined based on various factors, including the number of blemishes, the presence of voids, and overall structural integrity.

Understanding the grading system helps you choose the right plywood for your specific project needs. For projects where minimal expansion is desired, selecting higher-grade plywood with fewer imperfections can be beneficial.

By considering the grade of plywood, utilizing moisture barrier treatments, and understanding the grading system, you can better navigate plywood expansion challenges and ensure optimal results in your projects.

Key Takeaways: How Much Does Plywood Expand?

- Plywood expands and contracts with changes in humidity and moisture levels.

- The expansion and contraction of plywood can vary depending on the type and quality of plywood.

- On average, plywood can expand up to 1/8 inch for every 4 feet of length.

- Proper installation techniques, such as allowing for expansion gaps and using adequate fasteners, can help minimize the effects of plywood expansion.

- It is important to acclimate plywood to the environment in which it will be used to reduce the risk of excessive expansion or contraction.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section. Here, we will address common queries related to the expansion of plywood. Whether you’re a DIY enthusiast or a professional, understanding how much plywood expands can help you make informed decisions for your projects. Read on to find the answers you’re looking for.

1. How does plywood expansion occur?

Plywood tends to expand due to changes in moisture content and temperature. As a natural material, plywood absorbs and releases moisture depending on the environment it’s in. When exposed to high humidity or moisture, plywood absorbs the water and expands. Similarly, when the moisture content decreases, plywood loses moisture and contracts.

The expansion and contraction of plywood result from the movement of water molecules in its individual veneer layers. This movement causes the layers to push against each other, leading to changes in dimensions.

2. What factors influence plywood expansion?

Several factors affect how much plywood expands. One key factor is the type of plywood itself. Different plywood grades and compositions can have varying expansion rates. Additionally, the thickness of the plywood can influence how much it expands. Thicker plywood tends to expand and contract less compared to thinner plywood sheets.

Environmental conditions also play a significant role. Humidity levels, temperature fluctuations, and exposure to water or moisture can all impact the expansion of plywood. It’s essential to consider these factors when selecting and installing plywood to ensure it performs as expected in different environments.

3. Can plywood expansion be prevented?

While it’s not possible to entirely prevent plywood from expanding and contracting, there are steps you can take to minimize the effects. One approach is to acclimate the plywood to the environment in which it will be used. By storing the plywood in the same space for a few days before installation, it can adjust to the temperature and humidity of the area.

Another effective strategy is to seal the plywood with a suitable finish or coating. Sealing the surface helps protect the plywood from absorbing excess moisture, reducing its expansion potential. However, it’s important to note that even with these preventative measures, some level of expansion may still occur.

4. How much does plywood typically expand?

The amount plywood expands can vary depending on multiple factors, such as the type of plywood and environmental conditions. On average, plywood can expand by around 1/8 inch per foot of width. This expansion can lead to noticeable changes, especially on larger surfaces.

It’s crucial to account for this expansion when planning and installing plywood to avoid issues such as buckling, warping, or gaps. Consulting with a professional or knowledgeable supplier can help you select the right plywood type and provide guidance on accommodating its expansion.

5. How can plywood expansion affect my project?

Plywood expansion can have various impacts on your project, depending on the specific circumstances. Excessive expansion can cause the plywood sheets to push against each other or surrounding materials, leading to warping or buckling. This can result in uneven surfaces or compromised structural integrity.

Additionally, if plywood expands and contracts significantly, it can create gaps between the sheets or along joints. These gaps can be problematic for aesthetics or functional aspects such as water penetration or insulation. Being aware of plywood expansion and taking necessary precautions during installation can help mitigate these potential issues.

5 Mistakes Buying Plywood – Don’t Waste Your Money!

Summary

Plywood can expand when exposed to moisture, causing it to swell and potentially warp. The amount of expansion depends on the type of plywood and the level of moisture it is exposed to. It is important to take this into consideration when using plywood in construction or woodworking projects.

When plywood is properly sealed, with a finish or sealant, it can help prevent moisture absorption and reduce the risk of expansion. It is also important to store plywood in a dry environment to avoid any unnecessary expansion. By understanding how plywood reacts to moisture, you can make informed decisions about its use and take appropriate steps to prevent unwanted expansion.