If you’ve ever wondered, “how much does plywood shrink?” you’re in the right place! Plywood is a versatile building material, but it’s important to understand its characteristics. So, let’s dive in and explore the fascinating world of plywood shrinkage.

Picture this: you’ve just completed a woodworking project using plywood, and now you’re faced with the question, “Will my plywood shrink?” Well, fear not! In this article, we’ll unravel the mystery of plywood shrinkage and give you the answers you seek.

Plywood shrinkage can be influenced by various factors, such as moisture content, environment, and the type of plywood used. So, whether you’re a curious DIY enthusiast or an aspiring builder, get ready to discover the secrets behind how much plywood can shrink. Let’s get started!

The Science of Plywood: Understanding How Much it Shrinks

Plywood is a versatile and widely used building material known for its strength, durability, and affordability. However, one common concern among builders and DIY enthusiasts is how much plywood actually shrinks. Understanding the extent of shrinkage is crucial for accurately planning and executing construction projects. In this article, we will delve into the factors that influence the shrinkage of plywood, explore the typical amount of shrinkage to expect, and provide practical tips to mitigate potential issues.

Factors Affecting Plywood Shrinkage

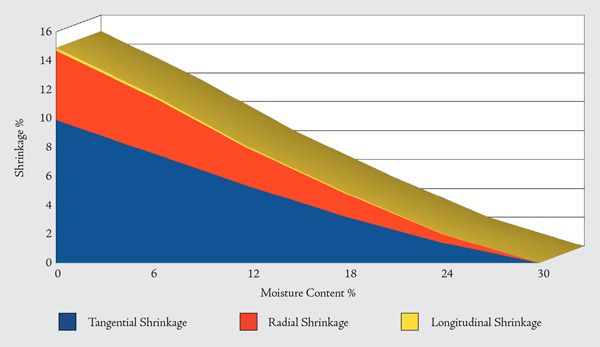

Before diving into the exact amount of shrinkage, it’s essential to understand the factors that can influence the dimensional changes in plywood. Moisture content and environmental conditions play a significant role in how much plywood shrinks.

Moisture Content:

Plywood is made by gluing together several thin layers of wood veneer with adhesive. On a microscopic level, the wood fibers are like straws that absorb and release moisture depending on the environment. Moisture content significantly affects the size of plywood, as it expands when exposed to high humidity and contracts when the moisture content decreases. Plywood manufacturers typically produce and sell plywood with moisture content within a specific range to minimize shrinkage issues.

Environmental Conditions:

The environment in which plywood is installed or stored also impacts its dimensional stability. Rapid or extreme changes in temperature and humidity can cause the wood to shrink or expand abruptly, leading to warping, cupping, or buckling. For example, exposure to direct sunlight or proximity to heat sources can accelerate moisture loss and result in excessive shrinkage. Similarly, areas with high humidity or moisture can cause the plywood to absorb water, leading to swelling and expansion.

Wood Species:

Different types of wood species have varying amounts of natural shrinkage due to their unique cellular structure. Softwoods, such as pine or fir, tend to shrink more compared to hardwoods, such as oak or maple. However, plywood is manufactured using various wood species, and each may have its own properties in terms of shrinkage. It’s important to consider the specific type of plywood being used and its corresponding shrinkage characteristics when planning a project.

Understanding Plywood Shrinkage

The amount of plywood shrinkage varies depending on the factors mentioned above. While it is challenging to provide a precise measurement due to the myriad of variables involved, a general estimate can be made.

Typical Shrinkage Range:

On average, plywood can shrink by approximately 1/8 inch per foot of width. For example, a standard 4-foot wide plywood sheet may experience shrinkage of about 1/2 inch in total width when exposed to dry conditions or low moisture content. However, it’s important to note that this is just an estimated value, and actual shrinkage can vary based on the specific circumstances.

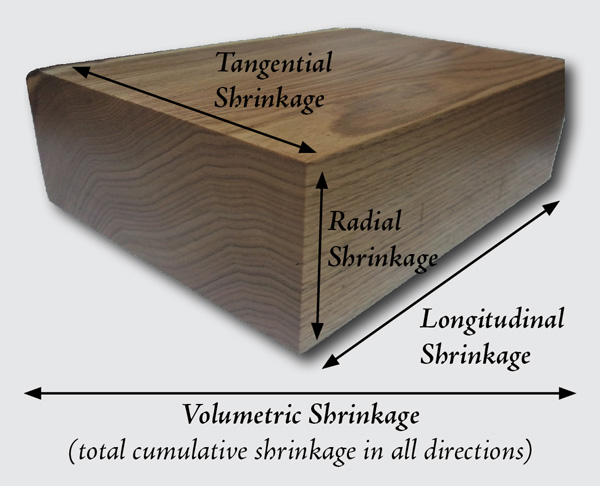

Grain Orientation:

Another aspect that affects plywood shrinkage is the grain orientation. Plywood consists of multiple layers, with the grain of each layer alternating in direction. The opposing grain pattern helps to counteract the natural tendency of wood to shrink or expand in one direction. This cross-grain construction minimizes the overall change in size and makes plywood more dimensionally stable compared to solid wood.

Length and Thickness Factors:

It is worth mentioning that shrinkage is predominantly observed in the width of the plywood sheet rather than the length or thickness. The dimensional fluctuations in length and thickness are relatively minimal and tend to have a negligible impact on overall dimensions. Nonetheless, it is essential to consider all dimensions when planning for a project, especially if precise measurements are crucial.

Tips for Managing Plywood Shrinkage

While some shrinkage is inevitable when working with plywood, there are several measures you can take to minimize potential issues and ensure the best possible results. Here are some practical tips to manage plywood shrinkage:

Allow for Acclimation:

Prior to installation, it is important to allow the plywood to acclimate to the environment in which it will be installed. This means storing the plywood in the area where it will be used for at least 48 hours, allowing it to adjust to the temperature and humidity of the space. This helps to minimize the potential for abrupt dimensional changes after installation.

Proper Sealing and Coating:

Applying a high-quality sealant or coating to the plywood can help protect it from excessive moisture absorption or moisture loss. A sealant acts as a barrier against moisture, reducing the chances of warping or swelling. Be sure to choose a sealant that is compatible with plywood and suitable for both interior and exterior applications.

Strategic Fastening:

When fastening plywood, especially in applications where shrinkage may be a concern, it’s important to use strategic fastening techniques. This involves leaving a small gap (1/8 to 1/4 inch) between adjacent sheets to accommodate potential shrinkage. Additionally, using screws or nails with slightly larger holes can allow for limited movement without compromising the structural integrity.

By implementing these techniques, you can minimize the impact of shrinkage and ensure the plywood remains stable and dimensionally accurate throughout its lifespan.

Conclusion

Plywood shrinkage is an inherent characteristic of the material, influenced by factors such as moisture content, environmental conditions, and wood species. While it is challenging to provide precise measurements due to the numerous variables involved, plywood can shrink by approximately 1/8 inch per foot of width. By understanding these factors and implementing proper techniques for managing shrinkage, builders and DIY enthusiasts can mitigate potential issues and ensure successful construction projects. Remember to allow for acclimation, apply sealants or coatings, and use strategic fastening techniques when working with plywood. With careful planning and attention to detail, plywood shrinkage can be effectively managed, leading to durable and visually appealing structures.

Key Takeaways: How Much Does Plywood Shrink?

- Plywood shrinkage depends on the moisture level and the type of plywood.

- On average, plywood tends to shrink between 1-2% in width and length.

- Thicker plywood tends to shrink less compared to thinner plywood.

- Plywood with proper sealing and moisture control can minimize shrinkage.

- It is important to understand plywood characteristics to prevent issues due to shrinkage in woodworking projects.

Frequently Asked Questions

Below are some commonly asked questions about the shrinkage of plywood and their answers:

1. Why does plywood shrink?

Plywood is made up of multiple layers or veneers of wood glued together, and these layers can absorb or release moisture depending on the environment. When plywood is exposed to dry conditions, the moisture content in the wood decreases, causing the wood fibers to contract and the plywood to shrink.

Conversely, when plywood is exposed to high humidity or moisture, the wood fibers absorb water and expand, causing the plywood to swell. Understanding the factors that affect moisture content can help prevent excessive shrinkage or swelling in plywood.

2. How much can plywood shrink?

The amount of shrinkage in plywood can vary depending on several factors such as the species of wood used, the thickness of the plywood, and the specific environmental conditions. On average, plywood can shrink between 0.1% to 1% of its original size. This means that a standard 4×8 feet plywood sheet could shrink anywhere from about 0.04 to 0.4 inches in width or length.

It’s important to note that these figures are only general guidelines, and actual shrinkage can vary. Moisture content, temperature, and humidity levels are crucial factors that influence the shrinkage of plywood. Utilizing appropriate acclimation techniques before installation can help minimize the shrinkage and ensure better long-term performance.

3. Is plywood shrinkage a problem?

While some degree of shrinkage is expected in plywood, excessive shrinkage can pose problems in certain applications. For example, if plywood is used for construction or woodworking projects where precise measurements are essential, significant shrinkage can result in gaps, warping, or structural instability.

To mitigate potential issues, it’s important to consider the moisture content of the environment where the plywood will be used and take appropriate measures to minimize shrinkage. This may include proper acclimation, sealing the edges of the plywood, and ensuring sufficient ventilation to control moisture levels.

4. Can plywood be prevented from shrinking?

While it’s not possible to completely eliminate shrinkage in plywood, there are steps that can be taken to minimize it. Proper acclimation is key, allowing the plywood to adjust to the moisture content of its intended environment before installation. This helps reduce the likelihood of significant shrinkage once the plywood is in place.

Sealing the edges and surfaces of the plywood with appropriate finishes or coatings can also help reduce moisture absorption or loss, thereby minimizing shrinkage. It’s important to consult with professionals or follow manufacturer recommendations for specific measures to prevent shrinkage based on your particular project or application.

5. Does all plywood shrink equally?

No, not all plywood shrinks equally. The shrinkage characteristics can vary depending on the type of plywood and the wood species used to manufacture it. Different wood species have different rates of shrinkage, so the amount of shrinkage can vary when using plywood made from different woods.

Additionally, the way the plywood is manufactured, including the bonding process and the quality of adhesive used, can also impact the shrinkage properties. It’s important to consider these factors when selecting plywood for a specific project and consult with experts or manufacturers to determine the most suitable plywood type and species that will minimize shrinkage for your intended application.

5 Mistakes Buying Plywood – Don’t Waste Your Money!

Summary

Plywood can shrink due to changes in moisture content. When plywood gets wet, it expands, and when it dries, it can shrink. This can affect its dimensions and cause warping. Different types of plywood shrink at different rates, so it’s important to consider this when using plywood in various projects. Plywood with more layers or thicker veneers tends to shrink less than plywood with fewer layers or thinner veneers. To minimize shrinkage, it’s essential to store plywood in a dry environment and to properly seal and finish it.

Overall, plywood is a versatile material widely used in construction and woodworking. While it may experience some shrinkage, understanding its properties and taking precautions can help mitigate these effects and ensure its durability. Keep in mind that moisture levels play a significant role, so it’s crucial to monitor and manage them to maintain the quality of plywood projects.