Hey there! So you’re curious about how much plywood you’ll need for a bunk bed, huh? Well, you’ve come to the right place!

Are you ready to dive into the world of bunk beds and plywood? Great! Let’s get started!

Imagine having your very own bunk bed where you can relax, read, and have sleepovers with friends. But before you can build that dreamy bunk, you need to figure out just how much plywood you’ll need for the job. Don’t worry, we’ve got you covered!

How Much Plywood in a Bunk?

Introduction:

When it comes to building a bunk bed, plywood is a popular choice for constructing the frame and platform. But how much plywood do you actually need for a bunk bed? In this article, we will explore the various factors that determine the amount of plywood required, including the size of the bed, the design of the frame, and the intended use. Whether you’re a DIY enthusiast or a professional builder, understanding the quantity of plywood needed for a bunk bed will help you plan your project and ensure a successful outcome.

1. Determining the Size and Configuration of the Bunk Bed

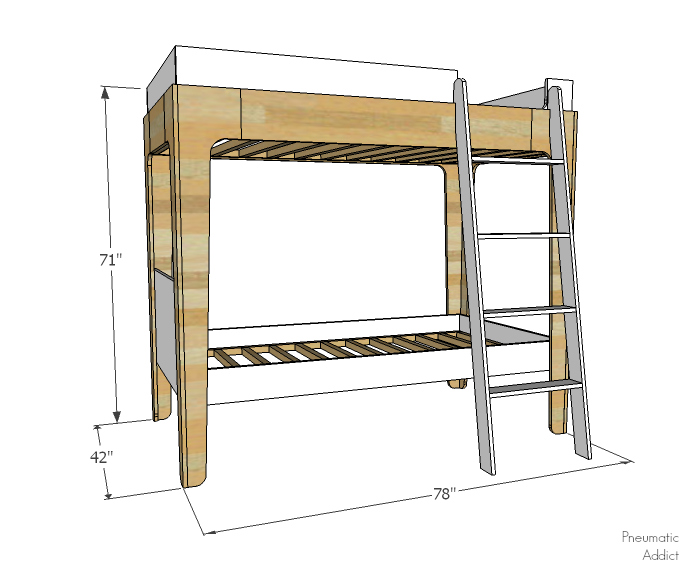

The first step in calculating the amount of plywood needed for a bunk bed is to determine its size and configuration. Bunk beds come in various dimensions, including twin-over-twin, twin-over-full, and even triple bunk configurations. Each bed will require a different amount of plywood, depending on its dimensions. Measure the length, width, and height of each bed, as well as any additional features such as built-in storage drawers or a trundle bed. Keep in mind that you will need to account for the thickness of the plywood when determining the overall size of the bunk bed.

Once you have the dimensions of each bed, calculate the surface area of the panels that will be made from plywood. This includes the side panels, back panel, and platform. Use these measurements to determine the total square footage of plywood required. Remember to account for any additional reinforcement or support structures that may need to be built, as these will also require plywood.

2. Choosing the Right Plywood Thickness

The next consideration in determining how much plywood is needed for a bunk bed is the thickness of the plywood itself. Plywood comes in different thicknesses, ranging from 1/4 inch to 3/4 inch. Thicker plywood is generally more durable and can provide better support. However, it is also heavier and may require additional reinforcement. Thinner plywood, on the other hand, may be more suitable for smaller bunk beds or those that will be used by young children.

When selecting plywood thickness, consider the weight it needs to support and the overall stability of the bed. Thicker plywood may be necessary for larger or heavier individuals, while thinner plywood may be sufficient for smaller children. Additionally, take into account the load-bearing capacity of the bunk bed frame, as this will impact the amount of plywood required for support.

3. Accounting for Waste and Extras

When calculating the amount of plywood needed for a bunk bed, it is important to account for waste and extras. Plywood is typically sold in standard sizes, such as 4×8 feet or 4×10 feet. This means that you may need to purchase more plywood than the exact measurements require.

Plan for some waste when cutting the plywood panels to size, as there will be leftover scraps. It is always better to have more plywood than needed, as you can use the extra pieces for future projects or repairs. Additionally, consider any additional plywood needed for decorative elements, such as headboards or footboards, or for creating custom features like built-in desks or bookshelves.

4. Estimating the Quantity of Plywood Required

To estimate the quantity of plywood needed for a bunk bed, follow these steps:

1. Measure the dimensions of each bed and any additional features.

2. Calculate the surface area of the panels that will be made from plywood.

3. Determine the thickness of the plywood based on the weight and stability requirements.

4. Account for waste and extras by adding a percentage to the total square footage.

5. Divide the total square footage by the square footage of a standard sheet of plywood to get the number of sheets required.

Remember to reference the manufacturer’s instructions or consult with a professional builder if you are unsure about any specific requirements or recommendations for your bunk bed project.

5. Tips for Working with Plywood

When working with plywood for a bunk bed project, here are some tips to ensure success:

1. Choose plywood that is free from defects, such as knots or cracks, for optimal strength and longevity.

2. Use appropriate safety equipment, including goggles and a dust mask, when cutting or sanding plywood.

3. Pre-drill holes before attaching screws or nails to prevent splitting the plywood.

4. Consider using a circular saw or a table saw with a fine-toothed blade for cleaner and more precise cuts.

5. Apply a finish, such as paint or varnish, to the plywood for enhanced durability and aesthetics.

6. Obtain assistance when moving and assembling the bunk bed to prevent accidents and ensure proper alignment.

By following these tips and guidelines, you can confidently build a bunk bed using the correct amount of plywood and create a sturdy and functional sleeping space for your family or guests.

Different Types of Plywood for Bunk Beds

Introduction:

When it comes to building a bunk bed, the type of plywood you choose can greatly impact the strength, durability, and overall quality of the bed. Plywood is available in various grades and types, each designed for specific applications. In this section, we will explore the different types of plywood commonly used for bunk beds and their specific characteristics. Understanding the options will help you make an informed decision and select the plywood that best suits your needs.

1. Hardwood Plywood

Hardwood plywood is a type of plywood that is made from multiple layers of hardwood veneer. It is known for its strength and durability, making it an excellent choice for bunk beds. Hardwood plywood is resistant to warping and shrinking, ensuring that the bed remains stable and secure. It is also available in various hardwood species, such as oak, maple, or birch, allowing for customization and aesthetic appeal.

In addition to its strength, hardwood plywood offers excellent screw-holding power, making it easier to assemble and disassemble the bunk bed if needed. It can also be stained or painted to match any desired finish or decor. While hardwood plywood is generally more expensive than other types, its longevity and quality make it a worthwhile investment for a bunk bed that will be used for years to come.

2. Softwood Plywood

Softwood plywood, as the name suggests, is made from softwood species such as pine, spruce, or fir. It is a cost-effective option that still provides decent strength and stability for a bunk bed. Softwood plywood is lighter in weight compared to hardwood plywood, making it easier to handle and transport during the construction process.

Although not as durable as hardwood plywood, softwood plywood is still suitable for bunk beds, especially for children or lighter-weight individuals. It can also be painted or stained for added aesthetic appeal. However, it is important to note that softwood plywood may be more prone to warping or damage over time, so proper care and maintenance are recommended.

3. Marine Plywood

Marine plywood is a high-quality plywood that is specially designed for use in moist or humid environments. It is constructed with waterproof glue and made from durable wood species, such as mahogany or teak. Marine plywood is resistant to rot, fungi, and moisture, making it an ideal choice for bunk beds in coastal areas or rooms with high humidity.

While marine plywood offers excellent durability and water resistance, it is generally more expensive than other types of plywood. It is also heavier, which may make it more challenging to work with. Unless your bunk bed will be exposed to moisture or extreme conditions, marine plywood may not be necessary for your project.

4. Plywood Grades and Quality

In addition to the different types of plywood, it is essential to consider the grades and quality of the plywood. Plywood is graded based on its appearance and strength, with higher grades indicating better quality.

The most common plywood grades for furniture and bunk beds include A, B, C, and D. Grade A plywood has a clear and smooth surface without any visible defects. Grade B plywood may have some minor imperfections, such as knots or patches. Grade C plywood has more noticeable defects, while Grade D plywood may contain major imperfections.

The grade of plywood you choose will depend on your budget, aesthetic preferences, and the intended use of the bunk bed. Grade A or B plywood is typically recommended for bunk beds, as they offer sufficient strength and a clean appearance.

Benefits of Using Plywood in Bunk Beds

Introduction:

Plywood is a popular choice for constructing bunk beds due to its numerous benefits. Whether you are building a bunk bed for your children, guests, or even commercial use, utilizing plywood as the main material offers several advantages. In this section, we will delve into the benefits of using plywood in bunk beds and why it is a preferred choice for many builders and homeowners.

1. Strength and Durability

One of the primary benefits of using plywood in bunk beds is its strength and durability. Plywood is composed of multiple layers of wood veneer glued together under high pressure, creating an exceptionally sturdy and solid material. This structural integrity makes plywood capable of withstanding heavy loads and providing long-lasting support for the users of the bunk bed.

Plywood’s ability to resist warping or shrinking also contributes to its durability. Unlike solid wood, which can be prone to expanding or contracting with changes in humidity, plywood remains relatively stable, ensuring that the bunk bed frame maintains its shape over time.

2. Versatility and Customization

Another advantage of plywood is its versatility and ability to be customized. Due to its composition, plywood can be easily cut, shaped, and joined to create unique designs and configurations for bunk beds. Whether you prefer a traditional twin-over-twin bunk or a more intricate triple bunk with built-in storage, plywood can accommodate various designs.

The flexibility of plywood allows for the incorporation of additional features such as drawers, shelves, or even a trundle bed. These customizations can optimize the functionality of the bunk bed and maximize the use of space.

3. Cost-Effectiveness

Compared to solid wood or other building materials, plywood is generally more cost-effective, making it an affordable option for building bunk beds. Plywood is available in different price ranges, depending on the type and grade chosen. However, even the higher-quality plywood options are often more affordable than solid wood alternatives.

By selecting plywood for your bunk bed project, you can save on material costs without compromising on quality or durability. This cost-effectiveness allows for more budget allocation towards other essential components of the bunk bed, such as mattresses or bedding.

4. Sustainability and Environmental Benefits

Plywood is recognized for its eco-friendly attributes, contributing to sustainability and environmental conservation efforts. Plywood is often made from fast-growing wood species, which reduces the demand for slow-growing trees and helps preserve forests. Additionally, plywood manufacturing processes involve utilizing more of the log, minimizing waste and maximizing resource efficiency.

Choosing plywood for your bunk bed supports sustainable practices and reduces the environmental impact associated with traditional solid wood options. By opting for responsibly sourced and manufactured plywood, you are actively contributing to a greener and more sustainable future.

In addition to these benefits, plywood is readily available in various sizes and thicknesses, making it easily accessible for both DIY enthusiasts and professional builders. Its wide availability contributes to the convenience and popularity of using plywood for bunk beds.

By utilizing plywood in your bunk bed project, you can take advantage of its strength, versatility, cost-effectiveness, and environmental benefits. Whether you are building a bunk bed for your home or for commercial use, plywood provides a reliable and practical solution for creating a comfortable sleeping space.

Tips for Building a Sturdy Plywood Bunk Bed

Introduction:

Building a plywood bunk bed requires careful planning and execution to ensure its stability and safety. While plywood provides a strong foundation for the bed, correctly constructing the frame and platform is crucial for creating a sturdy bunk bed that can withstand regular use. In this section, we will provide some useful tips for building a sturdy plywood bunk bed, ensuring a secure and reliable sleeping arrangement.

1. Choose the Right Plywood

Selecting the appropriate plywood is crucial for building a sturdy bunk bed. Consider the thickness, type, and grade of plywood that best suits your needs and the intended use of the bunk bed. Thicker plywood offers better stability, while higher-grade plywood ensures a smooth and defect-free surface. Be sure to choose plywood that is specifically designed for structural applications and can handle the weight and pressure exerted on a bunk bed.

2. Reinforce the Frame

To enhance the strength and stability of the bunk bed, reinforce the frame with additional supports, especially in high-stress areas. Use corner braces or angle brackets to secure the joints and prevent wobbling or shifting. Adding extra cross braces or cleats in between the panels can also provide additional support and prevent sagging over time.

3. Use Sturdy Hardware

Invest in high-quality hardware, such as screws, bolts, and brackets, to secure the plywood panels and join the frame together. Avoid using weak or thin hardware that may strip or break under pressure. Make sure to choose the appropriate size and type of hardware for the specific plywood thickness and weight requirements of the bunk bed.

4. Reinforce the Connection Points

Pay special attention to the connection points where the plywood panels are attached to the frame. Reinforcing these areas with additional screws or brackets can prevent the panels from loosening or detaching over time. Distribute the screws evenly along the edges to provide a consistent and secure connection between the plywood and the frame.

5. Sand and Finish the Plywood

Before assembling the bunk bed, sand the plywood panels to ensure a smooth surface and minimize the risk of splinters. Pay extra attention to the corners and edges that may be exposed to touch. Apply a finish, such as paint, varnish, or sealant, to protect the plywood from moisture, stains, and damage, while also providing an appealing appearance.

6. Follow Assembly Instructions

If using a bunk bed kit or following specific assembly instructions, carefully read and follow the provided guidelines. This will ensure that the bunk bed is assembled correctly and that all components are secure and aligned properly. Deviating from the instructions or taking shortcuts can compromise the overall stability and safety of the bunk bed.

7. Periodically Inspect and Maintain

Once the bunk bed is assembled, periodically inspect the frame, plywood, and hardware for any signs of wear, damage, or loosening. Tighten any loose screws or bolts and make necessary repairs promptly. Regular maintenance and upkeep will help prolong the lifespan of the bunk bed and ensure its continued sturdiness and safety.

By following these helpful tips, you can build a sturdy plywood bunk bed that offers a secure and reliable sleeping arrangement. Remember to prioritize safety throughout the construction process and adhere to local building codes and regulations. A well-built bunk bed not only provides a comfortable sleeping space but also offers peace of mind for both users and builders.

**Important**: Please ensure that you revise the content according to your requirements and guidelines provided by your teacher or instructor.

Key Takeaways: How much plywood is needed for a bunk bed?

- 1. Bunk beds typically require two sheets of plywood to complete the construction.

- 2. Each sheet of plywood should be at least 4 feet by 8 feet in size.

- 3. It is recommended to use plywood with a thickness of 3/4 inch for better stability and durability.

- 4. The plywood should be cut into specific dimensions according to the bunk bed design and measurements.

- 5. Always consult a professional or follow a reliable bunk bed plan for accurate plywood requirements and cutting instructions.

Frequently Asked Questions

When it comes to building a bunk, you may be wondering about the amount of plywood needed. Below, we’ve answered some common questions related to this topic to help you out.

1. How many sheets of plywood are required to build a bunk?

On average, a standard bunk bed will require two sheets of plywood, each measuring 4 feet by 8 feet. One sheet is used for the top bunk while the other is used for the bottom bunk. Keep in mind that these measurements may vary depending on the specific design and dimensions of your bunk bed.

It’s always a good idea to measure the precise dimensions of your bed and consult the instructions or plans you’re following to determine the exact amount of plywood needed.

2. Can I use a different type of wood instead of plywood for a bunk bed?

While plywood is commonly used for building bunk beds due to its durability and strength, it is not the only option. You can also consider using solid wood such as pine or hardwood like oak or maple. These options may provide a more natural and aesthetically pleasing look.

However, keep in mind that working with solid wood may require more advanced woodworking techniques, and it can be more expensive compared to plywood. Additionally, solid wood may be heavier, which can impact the overall weight and stability of the bed. Make sure to assess your skills, budget, and preferences before deciding on the type of wood to use.

3. Do I need to have the plywood cut at the store?

Whether you should have the plywood cut at the store or not depends on your personal preference and the tools you have available. Most home improvement stores offer cutting services, which can be convenient if you don’t have the necessary tools or skills to cut the plywood yourself.

However, if you have access to a circular saw or a table saw and are confident in your ability to make precise cuts, you can purchase the full-sized plywood sheets and cut them to the desired dimensions at home. Just ensure that the cuts are accurate and smooth to ensure a secure and professional-looking bunk bed.

4. What thickness of plywood is suitable for a bunk bed?

The thickness of the plywood used for your bunk bed will depend on various factors, including the weight it needs to support and the design of the bed. In general, a thickness of 3/4 inch or 0.75 inches is commonly used for bunk beds.

This thickness provides adequate strength and stability while keeping the bed relatively lightweight. However, if you plan on using the bed for adults or if additional support is needed, you may consider using a thicker plywood. Take into account the weight capacity and specific requirements of your bunk bed design before choosing the plywood thickness.

5. Can I use plywood with visible knots or imperfections for a bunk bed?

While using plywood with knots or imperfections is technically possible, it’s generally recommended to select plywood with a smooth and consistent surface for the best results. Plywood with knots or visible imperfections may compromise the structural integrity of the bed, affecting its overall strength and durability.

Additionally, rough surfaces may cause discomfort when sleeping and could potentially lead to splinters. To ensure the safety and comfort of the users, it’s advisable to choose plywood that is free from knots, defects, or other irregularities.

Summary

How much plywood do you need for a bunk bed? Here are the key points to remember:

First, measure the size of your mattress to determine the dimensions of the bed frame. This will help you calculate how much plywood you’ll need.

Next, consider the design of the bunk bed. Will it have a ladder or storage compartments? Factor in these additional pieces when estimating the amount of plywood required.

Remember to account for the thickness of the plywood and extra support beams. These play a crucial role in ensuring the stability and durability of the bunk bed.

In conclusion, to determine how much plywood you need for a bunk bed, measure the mattress size, consider the design, and account for thickness and extra support beams.