Are you curious about how an orbital sander works? Wonder no more, because in this article, we’ll dive into the fascinating world of orbital sanders. If you’re unfamiliar with this handy power tool, don’t worry – we’ll explain everything in simple terms. From the basic principles to its practical applications, you’ll soon understand why an orbital sander is a must-have for any DIY enthusiast or professional woodworker.

So, let’s get started by answering the question on your mind: How does an orbital sander work? At its core, an orbital sander consists of a vibrating pad that moves in a circular motion. This unique motion allows the sander to efficiently remove material from surfaces, leaving them smooth and ready for finishing. But how does it operate, and what makes it different from other sanding tools? Well, hold on to your hats because we’re about to unveil the secrets of the orbital sander!

Now that we have a basic understanding of how an orbital sander works, let’s explore its practical applications. Whether you’re working on a wooden piece of furniture, refinishing a vintage dresser, or preparing a wooden deck for staining, an orbital sander is your trusty companion. Its versatility and ease of use make it ideal for a wide range of sanding tasks. So, grab your safety goggles and let’s dive into the world of orbital sanders!

Discover the inner workings of an orbital sander for smooth and precise sanding results. This power tool uses a circular sanding pad that moves in an elliptical or orbital motion. As it spins, it also oscillates, allowing it to create a swirl-free finish on various surfaces. With its unique mechanism, the orbital sander efficiently removes material while minimizing the risk of leaving sanding marks. Get ready to achieve professional-level sanding with an orbital sander!

How Orbital Sander Works: A Comprehensive Guide

Orbital sanders are essential tools in the woodworking industry, capable of smoothing surfaces and removing unwanted materials effectively. Whether you’re a DIY enthusiast or a professional woodworker, understanding how orbital sanders work is crucial to achieve the desired results. In this in-depth guide, we’ll explore the inner workings of an orbital sander, its components, and how it operates. By the end, you’ll have a comprehensive understanding of how to use this tool effectively and efficiently.

Types of Orbital Sanders

Before delving into the mechanics of how orbital sanders work, let’s first explore the different types available in the market. There are three main types of orbital sanders: random orbital sanders, sheet sanders, and finish sanders.

Random orbital sanders are the most versatile type, incorporating both random orbit and circular motions. This design ensures a flawless finish while minimizing swirl marks. Sheet sanders, on the other hand, use rectangular sheets of sandpaper, making them ideal for large, flat surfaces. Finish sanders, also known as palm sanders, are specifically designed for final finishing touches and delicate projects.

Understanding the Mechanics of an Orbital Sander

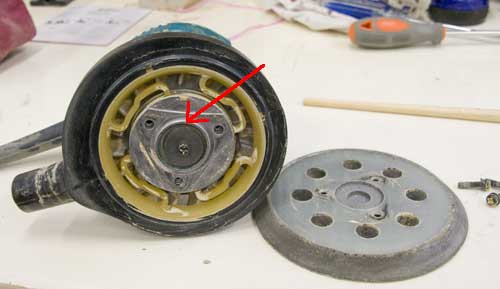

Orbital sanders consist of several key components that work together to deliver the desired sanding action. These components include a motor, sanding pad, dust collection system, and variable speed control.

The motor is the heart of the orbital sander, providing the necessary power to drive the sanding pad. The sanding pad, typically made from rubber or foam, connects to the motor and holds the sandpaper securely in place. The dust collection system, which may include a dust bag or a vacuum attachment, helps keep the work area clean by capturing the generated dust particles. Finally, the variable speed control allows users to adjust the speed of the sanding pad, providing greater control over the sanding process.

How Does an Orbital Sander Work?

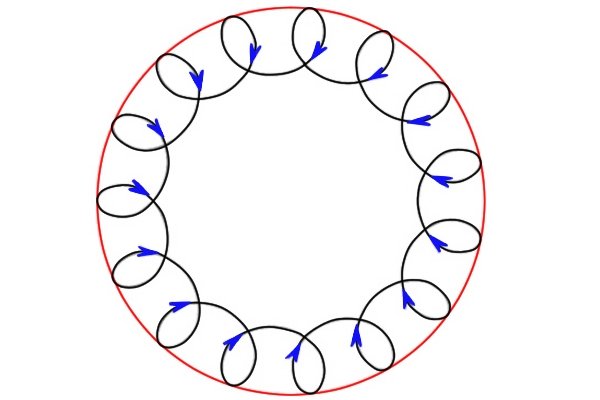

When the orbital sander is turned on and placed on the surface to be sanded, the motor transfers rotational motion to the sanding pad. However, unlike traditional rotary sanders that spin in a continuous circular motion, the sanding pad of an orbital sander moves in an elliptical or orbital pattern. This unique motion, combined with the random movement of the pad in random orbital sanders, minimizes sanding marks and prevents the sandpaper from becoming clogged.

The random motion of the sanding pad ensures that no single point on the sandpaper remains in contact with the surface for an extended period, resulting in a smoother and more even finish. Additionally, the elliptical or orbital motion reduces the risk of creating swirl marks, which can be challenging to remove.

The dust collection system plays an essential role in maintaining a clean work area. As the sanding pad removes material from the surface, dust particles are generated. The dust collection system sucks in the majority of these particles, preventing them from becoming airborne or settling on the work surface. This not only improves visibility during sanding but also protects your respiratory health.

Overall, understanding the mechanics and operation of an orbital sander allows you to harness its full potential. Whether you’re sanding hardwood floors, refinishing furniture, or tackling other woodworking projects, a thorough understanding of how orbital sanders work empowers you to achieve professional-grade results efficiently and safely. So grab your orbital sander, choose the appropriate sandpaper grit, and let its unique motion transform your woodworking projects.

Key Takeaways – How an Orbital Sander Works

- The orbital sander is a power tool used for sanding wood and other surfaces.

- It works by spinning a sanding pad in a circular motion while vibrating back and forth.

- This combination of motions helps to remove material quickly and evenly.

- The sanding pad uses sandpaper discs that attach to it with a hook-and-loop system.

- It’s important to move the sander in a smooth and even motion to avoid leaving marks or creating uneven surfaces.

Frequently Asked Questions

Are you curious about how orbital sanders work? Look no further – we have answers to your burning questions:

1. How does an orbital sander operate?

An orbital sander operates by spinning the sanding pad in small circles while simultaneously moving it in an elliptical motion. This unique dual-action movement helps to achieve a smooth and swirl-free finish. The elliptical motion ensures that no single section of the sanding pad remains in contact with the surface for too long, reducing the risk of leaving visible marks or sanding grooves.

The movements of an orbital sander are powered by an electric motor, which allows for consistent and efficient sanding. Additionally, many orbital sanders are equipped with variable speed settings, allowing users to adjust the speed based on the type of material being sanded or the desired level of finish.

2. Can I use an orbital sander for different types of materials?

Absolutely! One of the advantages of using an orbital sander is its versatility. Orbital sanders can be used on a variety of materials, including wood, metal, plastic, and even some types of composites. The key is to select the appropriate sandpaper grit for the material you are working with. Finer grits are typically used for finishing surfaces, while coarser grits are more suitable for removing material or shaping surfaces.

However, it’s important to keep in mind that orbital sanders are not suitable for every task. They may not be ideal for heavy material removal or for working on extremely delicate surfaces. In those cases, other sanding tools or techniques may be more appropriate.

3. What are the advantages of using an orbital sander?

Using an orbital sander offers several advantages. Firstly, its dual-action motion ensures a more even and consistent sanding result, reducing the risk of leaving visible marks or swirls on the surface. Additionally, the circular and elliptical movement helps to prevent the sandpaper from getting clogged with debris, allowing for longer continuous use.

Furthermore, an orbital sander is relatively easy to handle and control, making it suitable for both professionals and hobbyists. The sanding pads are typically replaceable, allowing users to switch to a different grit or replace a worn-out pad easily. Overall, an orbital sander can save time and effort while delivering a smooth and professional-looking finish.

4. Do I need special training to use an orbital sander?

No, special training is not usually required to operate an orbital sander. However, it is always recommended to read and follow the manufacturer’s instructions and recommendations to ensure safe and effective use of the tool. Additionally, wearing appropriate safety gear, such as safety glasses and a dust mask, is important to protect against flying debris and potentially harmful dust particles.

If you are new to using an orbital sander, it may be helpful to practice on a scrap piece of material before working on your desired project. This can help you get a feel for the tool and understand how to control it effectively. As with any power tool, it is essential to always exercise caution and work in a well-ventilated area.

5. Can an orbital sander be used for both large and small projects?

Definitely! Whether you have a large woodworking project or a small DIY endeavor, an orbital sander can be a valuable tool. For larger projects, such as sanding large wooden surfaces or refinishing floors, a larger orbital sander with a wider sanding pad can cover more area in less time. On the other hand, for smaller projects or working in tight spaces, a smaller orbital sander or a detail sander attachment can provide better maneuverability and precision.

The key is to select the right size and type of orbital sander based on the scale of your project and the specific requirements. Additionally, consider the type of sandpaper grit that is suitable for the task at hand. With the right equipment and approach, an orbital sander can be a versatile and efficient tool for projects of all sizes.

Summary

So, to sum it all up, an orbital sander is a tool that helps smooth surfaces. It has a round pad that spins in circles while moving back and forth, creating a smooth finish. The sandpaper attached to the pad helps remove imperfections and old paint. The sander’s design reduces the risk of leaving swirl marks on the surface. Overall, an orbital sander is a handy tool for DIY projects, woodworking, and refinishing furniture.