Are you curious about how strong a lathe is? Well, let me tell you, my friend! A lathe is a mighty machine that can handle some serious power. In fact, it’s known for its strength and durability, making it a favorite tool among craftsmen and engineers alike.

But wait, what exactly is a lathe? Imagine a spinning wheel, like the ones you see on pottery shows. Now, imagine that instead of clay, this wheel is used to shape metal or wood with precision and finesse. That’s a lathe! It’s like having a superhero in your workshop, ready to transform raw materials into incredible creations.

You might be wondering, how does a lathe get its strength? Well, it all comes down to its robust construction and powerful motor. With a sturdy frame and heavy-duty components, a lathe can handle the toughest tasks without breaking a sweat. So rest assured, when it comes to strength, a lathe is an unstoppable force to be reckoned with!

So there you have it! A lathe is not only a versatile and precise tool but also a powerhouse in terms of strength. Whether you’re working on a small hobby project or undertaking a massive industrial task, a lathe will be by your side, ready to take on anything you throw at it. Get ready to unleash your creativity because with a lathe, the possibilities are endless!

How Strong is a Lathe? Exploring the Power and Capability

Powerful Motors and Torque

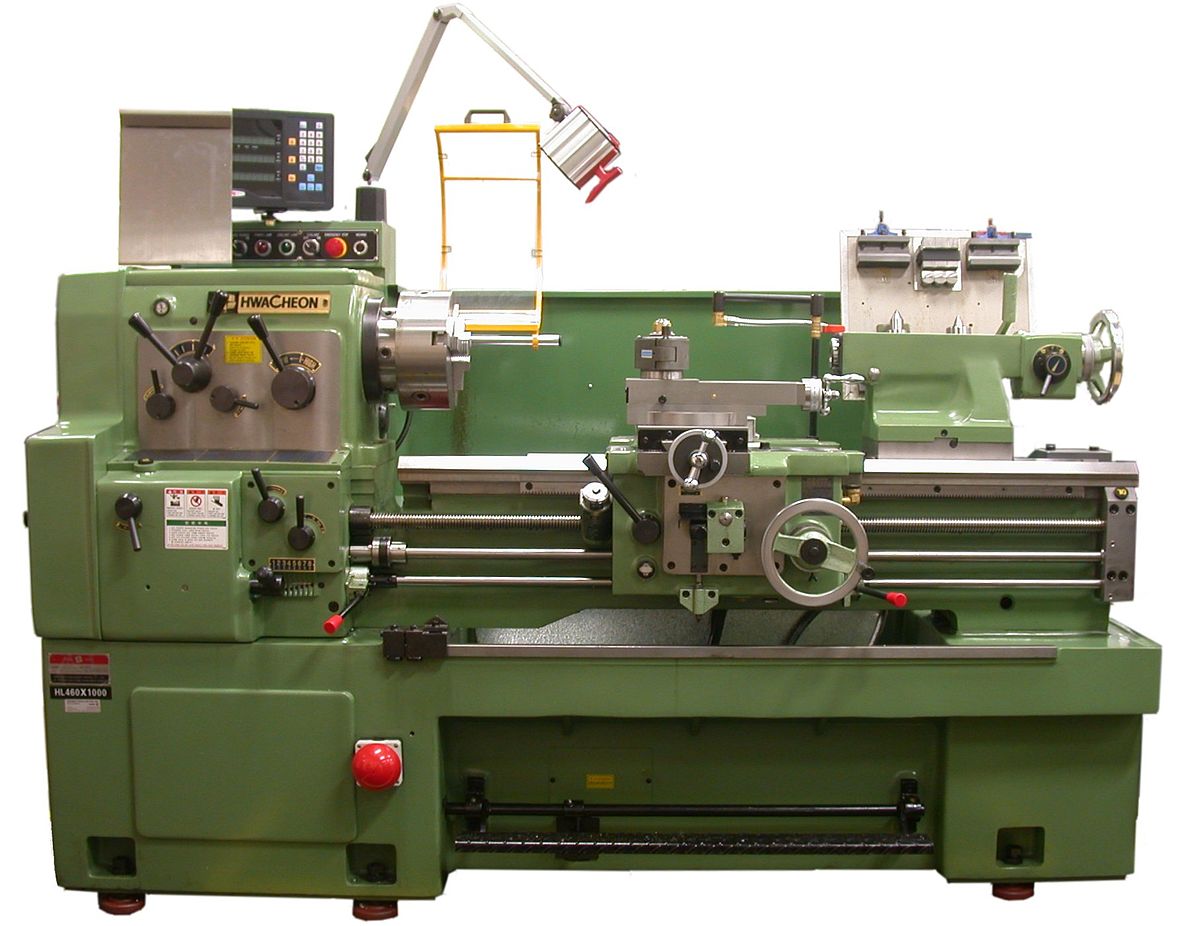

A lathe is a machine tool commonly used in machining operations to shape and cut materials with precision. One of the primary factors that determine the strength of a lathe is its motor power. Lathes are equipped with electric motors that provide the necessary power to drive the spindle and rotate the workpiece. The strength of a lathe’s motor is typically measured in horsepower (HP) or kilowatts (kW). The higher the horsepower or kilowatt rating, the more powerful the lathe motor will be. A powerful motor not only ensures the smooth and consistent rotation of the workpiece but also allows the machine to handle heavier loads and perform more complex operations.

In addition to motor power, torque is another crucial aspect that contributes to the strength of a lathe. Torque measures the rotational force generated by the lathe’s motor. It determines how effectively the lathe can overcome resistance and maintain a consistent cutting speed. A lathe with high torque can handle tough materials and maintain stability even when subjected to heavy cutting forces. Torque is influenced by factors like the motor’s power, gearing system, and overall design of the lathe. To determine the strength of a lathe, it is essential to consider both the motor power and torque capabilities.

Robust Construction and Bed Design

Another critical factor that determines the strength of a lathe is its construction and bed design. The lathe’s bed is the foundation of the machine and provides support to the various components. A sturdy and well-built bed ensures stability and reduces vibrations during machining operations, allowing for accurate and precise work. Lathe beds are commonly made from cast iron, known for its excellent durability, rigidity, and vibration-dampening properties. The quality of the casting and the overall design of the bed play a significant role in determining a lathe’s strength.

Moreover, the geometry of the bed also affects the lathe’s strength. Common bed designs include flat beds, V-beds, and gap beds. Flat beds provide a stable platform for the workpiece but may have limitations when accommodating larger materials. V-beds, on the other hand, offer increased rigidity and are suitable for heavy-duty applications. Gap beds have a removable section to accommodate larger workpieces. By choosing a lathe with a robust construction and a bed design that aligns with the intended applications, one can ensure optimal strength and performance.

Spindle and Chuck Strength

The strength of a lathe is also determined by the performance of its spindle and chuck. The spindle is a crucial component responsible for rotating the workpiece and transferring power from the motor. A high-quality spindle is made from durable materials, such as hardened steel, that can withstand heavy loads and resist wear over time. The design of the spindle, including its bearings and lubrication system, also contributes to its strength and longevity.

Similarly, the chuck, which holds the workpiece securely in place, plays a vital role in the lathe’s strength. The chuck needs to provide a firm grip on the workpiece without any slippage or movement during machining operations. A strong chuck ensures precise and accurate cuts, even when working with challenging materials. High-quality lathe chucks are typically made from hardened steel or other robust materials to withstand the forces exerted during machining.

Overall, the strength of a lathe relies on several factors, including the power of its motor, the torque generated, the construction and bed design, and the quality of the spindle and chuck. By considering these aspects and selecting a lathe that aligns with the specific machining requirements, one can ensure optimal strength and performance for a variety of applications.

Key Factors to Consider When Assessing Lathe Strength

1. Workpiece Size and Material

In determining the strength of a lathe, it is crucial to consider the size and type of materials you will be working with. Different lathes have varying weight capacities and capabilities, so choosing the right lathe for your intended applications is essential. Heavy-duty industrial lathes are designed to handle large and heavy workpieces, while smaller benchtop lathes may have limitations in terms of weight capacity.

2. Cutting Speed and Feed Rates

The strength of a lathe can also be evaluated based on its cutting speed capabilities and feed rates. Higher horsepower or kilowatt ratings allow the lathe to maintain consistent cutting speeds even when working with hard or dense materials. Additionally, lathes with stronger motors can withstand heavier feed rates, resulting in faster material removal and increased productivity.

3. Rigidity and Vibration Dampening

A robust and well-built lathe will exhibit excellent rigidity and vibration dampening properties. This ensures stability during machining operations, minimizing vibrations that can affect the accuracy and surface finish of the workpiece. When assessing lathe strength, look for features such as solid cast iron construction, reinforced bed designs, and advanced damping systems that contribute to enhanced rigidity and reduced vibrations.

4. Cutting Tool Compatibility

The strength of a lathe should also be evaluated based on the compatibility and adaptability of cutting tools. Different lathe models may have varying tool post designs and tool holder options. Ensure that the lathe you choose can accommodate a wide range of cutting tools, including those suitable for heavy-duty cutting, threading, and facing operations.

5. Precision and Accuracy

Strength is not solely determined by the physical robustness of a lathe but also by its ability to deliver precise and accurate results. Look for lathes with features like high-quality spindle bearings, precise alignment mechanisms, and advanced control systems that contribute to exceptional accuracy and repeatability.

6. Manufacturer Reputation

When assessing the strength of a lathe, it is essential to consider the reputation and reliability of the manufacturer. Well-established and reputable manufacturers are more likely to produce high-quality machines with superior strength and durability. Research customer reviews, seek recommendations, and choose a lathe from a trusted manufacturer known for their commitment to excellence.

7. Maintenance and Support

Finally, when evaluating lathe strength, it is crucial to consider the maintenance and support services provided by the manufacturer. A well-maintained lathe will not only last longer but will also maintain its strength and performance over time. Look for a manufacturer that offers comprehensive maintenance guidelines, readily available spare parts, and reliable customer support to ensure the longevity and continuous strength of your lathe.

Maximizing Lathe Strength: Tips and Best Practices

1. Choose the Right Lathe for the Job

To maximize lathe strength, it is essential to select the right lathe for your specific applications. Consider the size and type of materials you will be working with, as well as the desired cutting speed and feed rates. By choosing a lathe with adequate power and capabilities, you can ensure that it can handle the demands of your machining projects effectively.

2. Ensure Proper Maintenance and Lubrication

Regular maintenance and proper lubrication are crucial to maintaining the strength and longevity of a lathe. Follow the manufacturer’s maintenance guidelines, including scheduled inspections, cleaning, and lubrication of critical components. This will help prevent premature wear and ensure optimal performance.

3. Use High-Quality Cutting Tools

Invest in high-quality cutting tools that are appropriate for the materials and operations you will be performing. Dull or improper tools can exert excessive force on the lathe, leading to decreased strength and potential damage. Properly sharpened and maintained cutting tools will not only improve performance but also extend the life of your lathe.

4. Optimize Cutting Parameters

To maximize lathe strength, it is crucial to optimize cutting parameters such as cutting speed, feed rate, and depth of cut. Adjust these parameters based on the material being machined and the desired outcome. Operating within the recommended ranges will ensure efficient material removal without stressing the lathe.

5. Prioritize Operator Training

Providing proper training to operators is essential for maximizing lathe strength. Ensure that operators are well-versed in lathe operation, safety practices, and routine maintenance procedures. Well-trained operators will have a better understanding of the lathe’s capabilities and limitations, enabling them to make informed decisions and maximize the machine’s strength.

6. Monitor Performance and Address Issues Promptly

Regularly monitor the performance of your lathe and address any issues promptly. Pay attention to signs of excessive vibration, unusual noise, or decreased precision. Timely maintenance and repairs will help maintain the strength and reliability of your lathe.

By following these tips and best practices, you can maximize the strength and performance of your lathe, ensuring efficient and accurate machining operations for years to come.

Closing Thoughts

In summary, the strength of a lathe depends on various factors, including motor power, torque, construction, bed design, spindle and chuck strength. Assessing these aspects can help you determine if a lathe is capable of handling your specific machining needs. Considering factors like workpiece size, cutting speed, rigidity, cutting tool compatibility, precision, and the reputation of the manufacturer will guide you in making an informed decision when choosing a lathe. By maximizing lathe strength through proper maintenance, tool selection, optimization of cutting parameters, operator training, and prompt issue resolution, you can ensure optimal performance and longevity. Ultimately, selecting a lathe that aligns with your requirements and implementing best practices will enable you to unlock its full strength and unleash its machining potential.

Key Takeaways: How Strong is a Lathe?

In simple terms, a lathe is a machine that can handle significant amounts of force.

Lathe machines are designed to withstand the pressure and vibrations generated during machining operations.

With proper maintenance and care, lathes can be incredibly durable and long-lasting.

Strength of a lathe can vary depending on its size and design, so it’s important to choose the right lathe for each specific task.

It is advisable to consult with professionals or experts when considering the strength and capabilities of a lathe for a particular job.

Frequently Asked Questions

Welcome to our FAQ section where we answer common questions about the strength of a lathe. Learn more below!

What kind of materials can a lathe handle?

A lathe is a versatile tool that can handle a wide range of materials. It is commonly used for working with wood, metal, and even some plastics. Whether you’re crafting a wooden bowl, turning metal parts, or creating intricate designs, a lathe can handle the task with ease.

However, it’s important to note that the strength of a lathe can vary depending on its size and power capabilities. Larger lathes with more horsepower tend to be able to handle heavier and tougher materials compared to smaller, less powerful lathes.

Can a lathe handle large projects?

A lathe is designed to handle projects of various sizes, including large ones. With the right lathe and accessories, you can work on projects like furniture legs, stair railings, or even baseball bats. The size of the lathe and the distance between centers determines the maximum length of the projects it can handle.

Keep in mind that when working on larger projects, it’s essential to consider the weight distribution and stability of the lathe. Ensure that the lathe is securely mounted to a stable surface and use appropriate support systems to prevent any imbalances or vibrations during the turning process.

Is a lathe capable of precision work?

Absolutely! Lathes are renowned for their ability to produce precise and intricate shapes. Whether you’re turning intricate details on a wooden spindle or creating perfectly round metal components, a lathe allows you to achieve remarkable accuracy.

The precision of a lathe is influenced by various factors, such as the quality of the lathe’s construction, the skill level of the operator, and the selected cutting tools. With proper technique and attention to detail, you can achieve remarkable precision in your lathe work.

How strong is the motor of a lathe?

The strength of a lathe motor depends on its size and power rating. Larger lathes generally have more powerful motors, allowing them to handle heavier and more demanding projects. These lathes are capable of generating enough torque to effortlessly turn large or dense materials.

Additionally, modern lathe motors often come with variable speed controls, allowing you to adjust the speed according to the material being worked on. This versatility in motor strength and speed control provides flexibility and ensures that the lathe can handle a wide range of projects with ease.

Can a lathe withstand repeated use?

Yes, a well-maintained lathe is designed to withstand repeated use. However, like any tool, regular maintenance and proper care are essential to ensure its longevity and performance. Lubricating moving parts, regularly checking for wear and tear, and cleaning the lathe after each use can significantly extend its lifespan and reliability.

If you plan on using a lathe frequently, investing in a high-quality lathe made from durable materials is crucial. Additionally, following proper safety procedures and using the appropriate accessories and tools for each project will help maintain the lathe’s strength and ensure its continued functionality over time.

what lathe should I buy?

Summary

So, how strong is a lathe? Well, a lathe is a pretty strong machine. It can shape and cut through tough materials like metal and wood. It uses different tools called cutters to make precise shapes and designs.

The strength of a lathe comes from its motor, which powers the spinning of the workpiece. The motor generates a lot of force, allowing the lathe to carve out intricate details. However, it’s important to use caution and follow safety guidelines when operating a lathe to avoid accidents. Remember, safety first!