If you’ve ever wondered “how thick are plywood sheets?”, you’re in the right place. Plywood is a versatile building material used in furniture, construction, and more. In this article, we’ll explore the various thickness options available for plywood and help you understand which one suits your needs. So, let’s dive in and unravel the mysteries of plywood thickness!

Now, you might be thinking, “Why does plywood come in different thicknesses?” Well, the thickness of plywood sheets plays a crucial role in determining their strength and application. From thin and flexible sheets to thick and sturdy ones, plywood offers a wide range of options. So whether you’re planning a DIY project or a professional construction job, understanding plywood thickness is essential.

But how thick can plywood sheets be? Sit tight and get ready for a wild ride as we explore the world of plywood thicknesses. By the end of this article, you’ll be equipped with the knowledge to confidently tackle any woodworking or construction project that comes your way. So let’s get started and unravel the mystery of plywood thickness together!

How Thick Are Plywood Sheets? – Unraveling the Mysteries

When it comes to plywood, one question that often arises is how thick the sheets are. It’s an important consideration, as the thickness of plywood can determine its strength, durability, and suitability for different projects. In this comprehensive guide, we will delve into the various thickness options available, their applications, and other factors to consider when choosing plywood sheets. Whether you’re a DIY enthusiast or a seasoned professional, this article will provide you with the knowledge you need to make informed decisions about plywood thickness.

The Importance of Plywood Thickness

Before diving into the specifics, it’s essential to understand why plywood thickness matters. Plywood is composed of several layers of wood veneers glued together, creating a strong and versatile material for construction and woodworking projects. The thickness of these veneers plays a crucial role in determining the overall strength and stability of the plywood sheet. Depending on the intended use and load-bearing requirements, selecting the right thickness can make or break the success of your project.

Standard Plywood Thickness Options

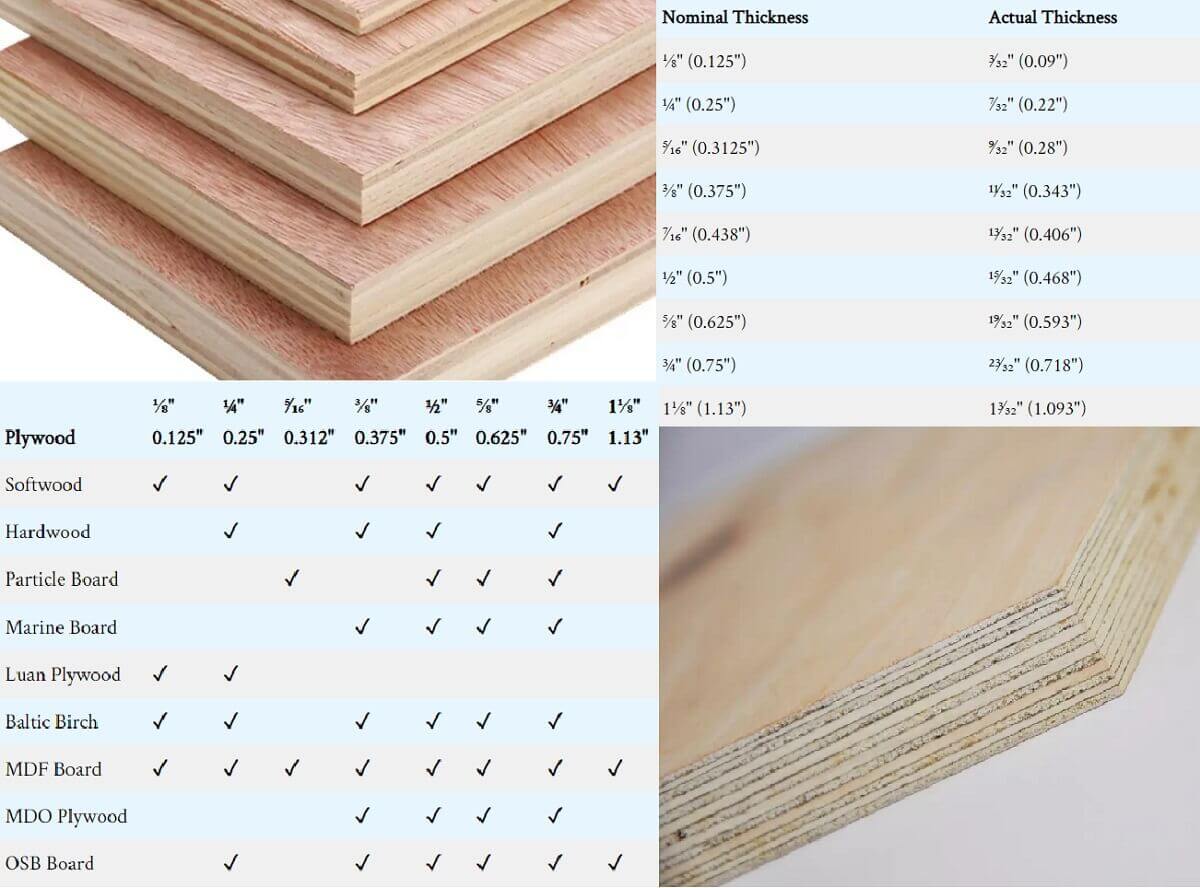

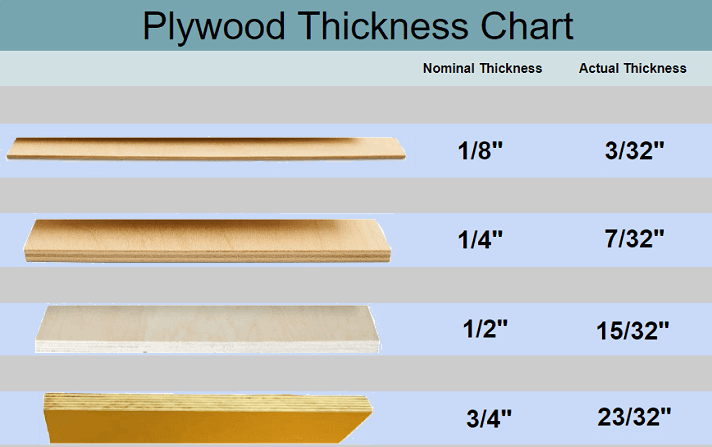

Plywood sheets are available in various thicknesses, with common sizes ranging from 1/8 inch to 1 1/4 inch. The most frequently used thicknesses are 1/4 inch, 3/8 inch, 1/2 inch, 5/8 inch, 3/4 inch, and 1 inch. Let’s explore the applications and characteristics of each thickness:

- 1/4 inch: This thin plywood is ideal for projects that require flexibility, such as making curved pieces or veneering. It’s not suitable for heavy-duty applications.

- 3/8 inch: Slightly thicker than 1/4 inch plywood, it provides more strength and stability while still maintaining flexibility. It’s commonly used for cabinet backs and drawer bottoms.

- 1/2 inch: This mid-range thickness is one of the most versatile options. It can be used for various applications, including subflooring, roofing, and furniture construction.

- 5/8 inch: The increased thickness of 5/8 inch plywood offers enhanced durability and strength. It’s suitable for heavy-duty projects like flooring and wall sheathing.

- 3/4 inch: Often considered the go-to thickness for general construction, 3/4 inch plywood is sturdy and can support significant weight. It’s commonly used for cabinets, furniture, and structural applications.

- 1 inch: This thick plywood is reserved for specialized applications that require maximum durability and load-bearing capacity, such as heavy-duty flooring and industrial projects.

It’s important to note that the actual thickness of plywood may slightly vary due to manufacturing processes and factors like moisture content. Always consult with suppliers or refer to the manufacturer’s specifications for accurate measurements.

The Impact of Plywood Thickness on Different Projects

The appropriate plywood thickness for a specific project depends on various factors, including the type of project, the desired level of strength, and the load-bearing requirements. Here are a few examples that highlight the impact of plywood thickness on different applications:

Construction Projects

In construction projects, plywood is commonly used for subflooring, wall sheathing, and roof decking. The thickness of the plywood will depend on the specific application. For subflooring, a thickness of 3/4 inch is often recommended to ensure stability and support heavy loads. Wall sheathing may require a slightly thinner plywood, such as 1/2 inch or 5/8 inch, depending on local building codes and structural requirements. Roof decking, on the other hand, may utilize 1/2 inch or 3/4 inch plywood, depending on factors like the roof slope and anticipated snow load.

Cabinet Making and Furniture Construction

Plywood is a popular choice in cabinet making and furniture construction due to its strength and affordability. The appropriate thickness will depend on the specific piece being built. For cabinet backs, a thinner plywood like 1/4 inch or 3/8 inch may suffice. However, for sturdy cabinet frames and furniture pieces that need to support weight, 3/4 inch plywood is often preferred. It’s important to consider the weight-bearing requirements and the overall design and functionality of the piece.

DIY and Craft Projects

If you’re into DIY and craft projects, plywood can be a versatile material to work with. Depending on the specific project, you might need thinner plywood sheets, such as 1/4 inch or 3/8 inch, for making small decorative items or intricate cutouts. These thicknesses offer flexibility and ease of handling during intricate cuts. However, if you’re creating larger installations or furniture pieces, a thicker plywood like 1/2 inch or 3/4 inch may be more appropriate to provide stability and durability.

Considerations When Choosing Plywood Thickness

While the general guidelines discussed above can help you determine the appropriate plywood thickness for your projects, it’s important to consider the following factors as well:

Safety and Load-Bearing Requirements

Safety should always be a priority when selecting plywood thickness. If a project requires the plywood to support heavy loads or structural elements, opting for a thicker sheet provides added safety and stability. Consult local building codes and structural engineers when necessary to ensure compliance.

Environmental Conditions

Consider the environment in which the plywood will be used. Moisture and humidity can affect the stability and longevity of plywood. In high-moisture areas or applications like outdoor furniture, it is advisable to choose moisture-resistant plywood or consider applying appropriate sealants and finishes to protect the wood.

Budget and Availability

Plywood is available in different prices range depending on the thickness and quality. Consider your budget and the availability of the desired thickness in your area. If a specific thickness is not readily available, consult with suppliers or consider alternative options that meet your project requirements.

Project Complexity

The complexity of your project can also influence the plywood thickness choice. If you are undertaking a complex build with intricate joints or require precise fitting, thinner plywood may be easier to work with. However, if the project involves heavy loads or requires structural integrity, opting for a thicker plywood sheet is advisable.

In Conclusion

Understanding plywood thickness is crucial for any project involving plywood sheets. By considering the specific application, load-bearing requirements, and other factors mentioned in this guide, you can confidently choose the appropriate plywood thickness for your projects. Remember to consult with professionals and suppliers when needed and prioritize safety and quality in your construction or woodworking endeavors.

Key Takeaways: How Thick Are Plywood Sheets?

- Plywood sheets come in various thicknesses, typically ranging from 1/8 inch to 1 1/4 inch.

- The most common plywood thicknesses are 1/4 inch, 1/2 inch, and 3/4 inch.

- The thickness of plywood affects its strength and durability, with thicker sheets being more durable and able to withstand heavier loads.

- Thinner plywood sheets are often used for lighter-duty applications like crafting and cabinetry.

- It’s important to consider the intended use and requirements of your project when choosing the appropriate plywood thickness.

Frequently Asked Questions

When it comes to plywood sheets, thickness is an important consideration. Here are some commonly asked questions about the thickness of plywood sheets.

1. What are the standard thicknesses available for plywood sheets?

The standard thicknesses of plywood sheets vary, but some commonly available options are 1/4 inch, 3/8 inch, 1/2 inch, 3/4 inch, and 1 inch. These thicknesses serve different purposes and can be used for various applications.

Thinner plywood sheets like 1/4 inch are suitable for projects that require flexibility, such as curved surfaces or lightweight constructions. On the other hand, thicker plywood sheets like 3/4 inch or 1 inch are ideal for projects that require sturdiness and structural support.

2. What factors should be considered when choosing the thickness of plywood sheets?

There are a few factors to consider when choosing the thickness of plywood sheets. One important factor is the intended application of the plywood. If it will be used for sheathing or subflooring, thicker sheets are usually recommended for added durability.

Another factor to consider is the spacing between the supporting studs or joists. Plywood sheets should have enough thickness to span the distance between the supports without sagging or flexing excessively. Lastly, the weight-bearing capacity of the plywood and the load it needs to bear should also be taken into account.

3. Can plywood sheets be custom-cut to specific thicknesses?

Yes, plywood sheets can be custom-cut to specific thicknesses. If the standard thicknesses available do not meet your requirements, you can request a custom cutting service. However, keep in mind that there may be limitations depending on the supplier or manufacturer.

Custom-cut plywood sheets might incur additional costs, as the process involves special equipment and precision cutting. It’s recommended to inquire with the supplier or manufacturer about the feasibility and cost of custom-cutting plywood sheets to the desired thickness.

4. How does the thickness of plywood sheets affect their weight?

The thickness of plywood sheets directly affects their weight. Thicker plywood sheets are generally heavier than thinner ones. For example, a 3/4-inch plywood sheet will be heavier than a 1/4-inch plywood sheet of the same dimensions. This weight difference can impact the ease of handling and transporting the plywood.

When planning a project, it’s important to consider the weight of the plywood sheets, especially if they need to be moved or carried by hand. Thicker plywood sheets may require additional assistance for transportation or lifting, while thinner sheets are generally easier to handle.

5. Are there any general guidelines for matching plywood thickness to specific applications?

While there are no strict rules, there are general guidelines for matching plywood thickness to specific applications. For sheathing and subflooring, 3/4 inch plywood is commonly used due to its strength and load-bearing capacity. For wall and roof panels, 1/2 inch or 5/8 inch plywood is often suitable.

Thinner plywood like 1/4 inch or 3/8 inch is often used for cabinet backs, lightweight furniture, or crafts. If you’re unsure about the appropriate thickness for your specific application, consulting with a professional or researching specific guidelines for the project is recommended.

Summary

So, to sum it up, the thickness of plywood sheets can vary depending on what you need it for. The most common thickness is 3/4 of an inch, but there are thinner and thicker options available.

When choosing plywood, consider the project and its requirements. Thinner sheets are lighter and more flexible, while thicker ones are sturdier but heavier. Understanding the different options will help you make the right choice for your needs.