Wondering how thick a 10 bandsaw can cut? Let’s dive right in and explore the capabilities of this powerful tool!

If you’re a woodworking enthusiast or just starting out, a bandsaw can be your best friend. But how thick can it really slice through? We’ll answer that question and more in this article, providing you with all the information you need to know.

When it comes to a 10 bandsaw, its cutting capacity refers to the maximum thickness of the material it can handle. So, if you’re curious about what this versatile tool is capable of, keep reading to discover its limits and unleash your creativity!

How Thick Can a 10 Bandsaw Cut?

Introduction: Have you ever wondered how thick a 10 bandsaw can cut? Whether you’re a DIY enthusiast or a professional woodworker, understanding the capabilities of your equipment is crucial for achieving accurate and precise cuts. In this article, we will explore the maximum cutting depth of a 10 bandsaw, the factors that influence it, and tips for optimizing your cutting performance.

Understanding the Cutting Capacity of a 10 Bandsaw

A 10 bandsaw, also known as a 10-inch bandsaw, refers to the diameter of the wheels that drive the blade. However, the cutting capacity of a 10 bandsaw is not solely determined by wheel size. The throat capacity, which is the distance between the blade and the vertical frame of the bandsaw, also plays a significant role.

The cutting depth of a 10 bandsaw typically ranges from 4 to 6 inches. That means the maximum thickness of material you can cut in a single pass is around 4 to 6 inches, depending on the specific model. It’s important to note that this measurement refers to the distance from the table surface to the upper blade guide, which is the limiting factor when it comes to the cutting depth.

Factors That Influence Cutting Capacity

Several factors can affect the cutting capacity of a 10 bandsaw:

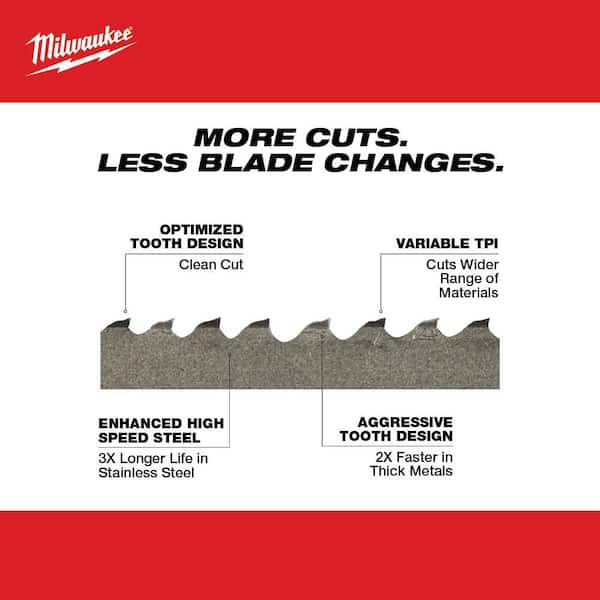

1. Blade Size and Tension: A larger blade will have a smaller kerf (the width of the cut), allowing for thicker cuts. Proper blade tension is crucial for maintaining cutting accuracy and preventing blade drift.

2. Motor Power and Speed: A more powerful motor and adjustable speed settings can improve cutting performance, especially when dealing with dense or thick materials.

3. Throat Capacity: The wider the throat capacity, the larger the workpieces you can maneuver around the blade. This provides more freedom to cut thicker materials.

4. Blade Guides and Bearings: High-quality blade guides and bearings play a significant role in maintaining a straight cutting path and reducing blade deflection.

5. Cutting Techniques: Skillful blade control, proper feed rate, and utilizing appropriate cutting techniques can maximize the cutting capacity of a 10 bandsaw.

Optimizing Cutting Performance

To get the most out of your 10 bandsaw and achieve the maximum cutting depth, consider the following tips:

1. Select the Right Blade: Choose a blade with the appropriate tooth configuration and width for the desired thickness of your cuts. A wider blade with fewer teeth is ideal for thick cuts, while a narrower blade with more teeth is better for intricate cuts.

2. Maintain Blade Tension: Regularly check and adjust the tension of your bandsaw blade to ensure optimal cutting performance.

3. Optimize Blade Guides: Ensure that your blade guides and bearings are properly adjusted and lubricated for smooth and accurate cuts.

4. Feed Rate: Pay attention to the feed rate at which you push the material through the blade. Too slow or too fast can lead to poor cutting results. Experiment with different speeds to find the optimal feed rate for each material.

5. Keep the Blade Sharp: A dull blade will not only reduce cutting capacity but also produce rough cuts. Sharpen or replace the blade regularly for clean and precise results.

6. Take Safety Precautions: Always wear appropriate safety gear, such as safety glasses and ear protection, when operating a bandsaw. Follow the manufacturer’s guidelines for safe usage.

In conclusion, a 10 bandsaw typically has a cutting depth ranging from 4 to 6 inches. The actual cutting capacity depends on factors such as blade size, tension, motor power, throat capacity, blade guides, and cutting techniques. By understanding these factors and implementing the optimization tips mentioned above, you can maximize the cutting performance of your 10 bandsaw and achieve accurate and precise cuts. So, get ready to unleash the full potential of your bandsaw and take your woodworking projects to new heights!

Key Takeaways: How Thick Can a 10 Bandsaw Cut?

- A 10 bandsaw can typically cut through materials up to 6 inches thick.

- The actual cutting thickness may vary depending on the type of material being cut.

- Harder materials like hardwood and metal may require slower cutting speeds and multiple passes.

- It’s important to check the bandsaw’s maximum cutting capacity specified by the manufacturer.

- Proper maintenance and blade selection can also affect the bandsaw’s cutting capabilities.

Frequently Asked Questions

Welcome to our FAQ section where we address common questions about the cutting capabilities of a 10 bandsaw. If you’re wondering how thick this type of bandsaw can cut, you’ve come to the right place. Read on to find answers to your burning questions!

1. What is the maximum thickness that a 10 bandsaw can cut?

A 10 bandsaw has a maximum cutting capacity of around 4 to 6 inches thick. This measurement refers to the height of the material that can be cut with the bandsaw’s blade. Keep in mind that the actual thickness capacity may vary depending on the specific model and brand of the bandsaw.

It’s essential to check the manufacturer’s specifications for the particular bandsaw you are using to ensure you stay within the recommended cutting capacity. Trying to cut material thicker than what the bandsaw is designed for can lead to inaccurate cuts and potential damage to the machine.

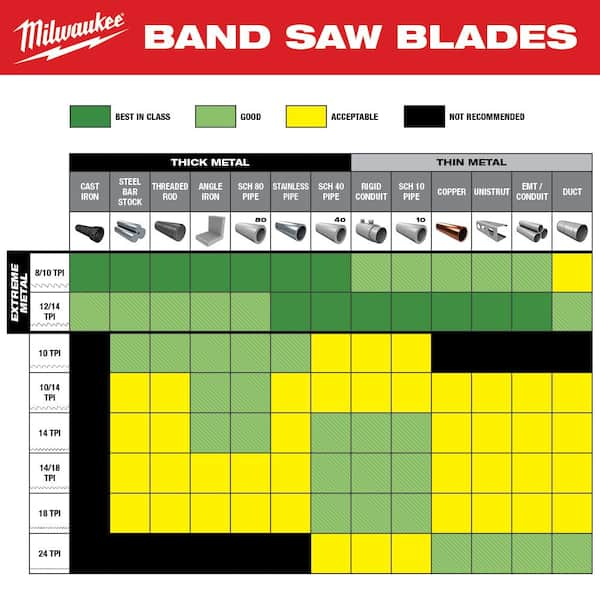

2. Can a 10 bandsaw cut through metal?

Yes, a 10 bandsaw can cut through metal, but the cutting capacity can vary depending on the type of metal. For softer metals like aluminum or brass, a 10 bandsaw can typically handle them with ease. However, when it comes to denser metals like steel or iron, it may be more challenging for the bandsaw to make clean cuts.

If you need to cut metal with a 10 bandsaw, it’s important to choose the appropriate blade designed for metal cutting. Additionally, using cutting fluids or lubricants can help improve the cutting performance and prolong the lifespan of the blade. Always follow the manufacturer’s recommendations and exercise caution when cutting metal with a bandsaw.

3. Are there any limitations to the length of material a 10 bandsaw can cut?

While a 10 bandsaw can handle a range of thicknesses, it does have limitations when it comes to the length of material that can be cut. The length capacity of a bandsaw is determined by the distance between the blade and the vertical support column, known as the throat depth.

For a 10 bandsaw, the throat depth is typically around 10 inches or slightly more, which means you can cut materials up to that width. However, keep in mind that the effective cutting length may be slightly less due to the space needed for blade tension and the guides. Check the manufacturer’s specifications for the exact throat depth of your bandsaw to determine the maximum length you can work with.

4. What type of blade should I use for cutting thick materials on a 10 bandsaw?

When cutting thick materials on a 10 bandsaw, it’s crucial to use a blade with a lower tooth count. A blade with fewer teeth per inch (TPI) is ideal for thick cuts as it allows for more efficient chip removal and reduces the chances of the blade getting stuck or overheated.

For thicker materials, such as hardwood or dense plastics, a blade with 2-4 TPI is recommended. This type of blade offers the necessary aggressiveness to tackle the thickness effectively. However, if you’re working with thinner and more delicate materials, you may need a blade with a higher TPI to achieve clean and precise cuts.

5. Can I cut curves with a 10 bandsaw?

Yes, a 10 bandsaw is capable of cutting curves, making it a versatile tool for various woodworking projects. The narrow width of the bandsaw blade allows for tighter turns, enabling you to create intricate curved designs and shapes.

When cutting curves with a bandsaw, it’s essential to use a smaller blade with a higher TPI, such as a 1/4-inch blade with 6-10 TPI. This type of blade provides the necessary control and precision for curved cuts. Additionally, adjusting the bandsaw’s blade tension and using appropriate guides can help enhance the overall performance when cutting curves.

Summary

So, how thick can a 10 bandsaw cut? Well, it depends on a few factors. Firstly, the size and power of the bandsaw will determine its cutting capacity. A 10 bandsaw is typically capable of cutting through wood or other materials that are up to 6 inches thick.

However, it’s important to note that the type of material being cut also plays a role. Harder materials, like metal, may require a more powerful bandsaw or specialized blades to achieve the desired thickness. Additionally, the condition and sharpness of the bandsaw blades can affect the cutting capacity.

Ultimately, it’s best to consult the manufacturer’s specifications and guidelines to determine the exact cutting capacity of your 10 bandsaw. Always prioritize safety and proper use of the equipment to ensure accurate and efficient cuts.