Are you curious about how thick a bandsaw can cut? Well, you’ve come to the right place! Today, we’re going to dive into the world of bandsaws and explore the limits of their cutting capabilities. So, whether you’re a woodworking enthusiast or simply interested in the mechanics of this versatile tool, buckle up and let’s get started!

Imagine having a bandsaw at your disposal, a tool that can effortlessly slice through different materials like butter. From wood to metal, this powerhouse of a machine can handle it all. But have you ever wondered just how thick it can go? That’s the burning question we’re going to tackle in this article. So, get ready to uncover the maximum cutting thickness of a bandsaw and discover what it can do for your projects.

Now, I know you might be itching to find out the answer, but hold on tight because we’re about to take you on a thrilling journey into the world of bandsaw capabilities. Get ready to unlock the secrets of this fascinating tool and learn everything you need to know about how thick a bandsaw can cut. It’s going to be a wild ride, so let’s jump right in!

How Thick Can a Bandsaw Cut? A Comprehensive Guide

When it comes to woodworking, a bandsaw is an essential tool that allows for precise and curved cuts. One of the most common questions that arise for both beginners and experienced woodworkers is, “How thick can a bandsaw cut?” The ability of a bandsaw to handle different thicknesses of material is crucial, as it determines the range of projects you can take on. In this article, we will explore the factors that affect the cutting capacity of a bandsaw and provide you with a comprehensive guide to understanding just how thick a bandsaw can cut.

The Anatomy of a Bandsaw

Before delving into the depths of a bandsaw’s cutting capacity, it is important to understand its anatomy. A bandsaw consists of several key components, including the blade, wheels, table, guides, and motor. The blade, specifically, plays a significant role in determining the maximum thickness a bandsaw can handle. Bandsaw blades come in different lengths, widths, and tooth configurations, each designed for specific cutting applications. Understanding the various elements of a bandsaw will help you grasp its limitations and capabilities.

Factors That Affect Cutting Capacity

Several factors influence how thick a bandsaw can cut. Let’s explore these factors in detail:

1. Throat Capacity:

The throat capacity of a bandsaw refers to the distance between the blade and the vertical frame of the saw. It determines the maximum width of a workpiece that can be passed through the saw. Bandsaws come in various throat sizes, typically ranging from 10 to 36 inches. The larger the throat capacity, the wider the workpiece you can cut. However, it’s important to note that throat capacity alone does not dictate the maximum thickness that can be cut on a bandsaw.

2. Blade Width and Tooth Configuration:

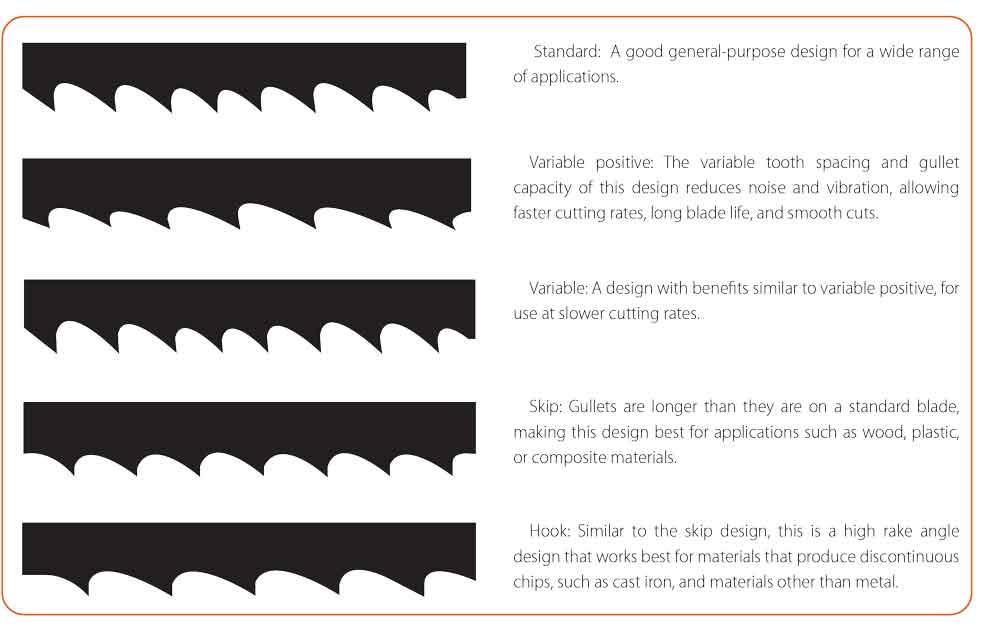

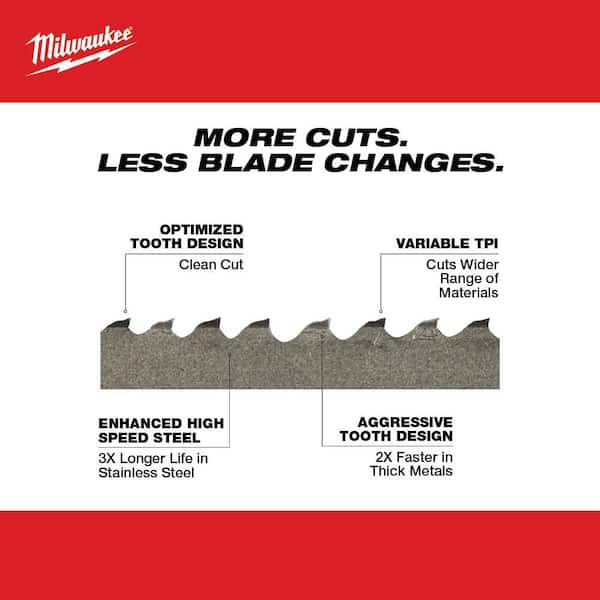

The width and tooth configuration of the bandsaw blade directly impact its ability to cut through different thicknesses of materials. Generally, bandsaw blades range from 1/8-inch to 1-inch in width. Narrower blades are suitable for making intricate, detailed cuts, while wider blades are more ideal for resawing or cutting thicker stock. The tooth configuration, such as a regular tooth or skip tooth pattern, also affects how efficiently the blade cuts through the material.

3. Motor Power:

The power of the bandsaw’s motor is another critical factor in determining its cutting capacity. A more powerful motor enables the blade to cut through thicker materials with ease. Motors are typically rated by horsepower (HP), and bandsaws can range from 1/4 HP for smaller, hobbyist models to 3 HP or more for professional-grade saws. The power of the motor directly affects the bandsaw’s ability to maintain a consistent cutting speed and handle the resistance encountered when cutting thicker stock.

4. Blade Tension:

Proper blade tension is crucial for achieving clean and accurate cuts on a bandsaw. Insufficient tension can result in blade deflection and a decrease in cutting capacity. The bandsaw’s tensioning system allows you to adjust the tightness of the blade, ensuring it stays aligned and straight during the cutting process. Maintaining the right amount of tension for the thickness of the material being cut is essential for maximizing the cutting capacity of a bandsaw.

Now that we have explored the factors that affect a bandsaw’s cutting capacity, let’s dive into the details of how thick a bandsaw can cut in various scenarios.

Understanding the Cutting Capacity of a Bandsaw

Now that we’ve discussed the factors that play a role in determining the cutting capacity of a bandsaw, let’s take a closer look at the capabilities of different types of bandsaws:

1. Benchtop Bandsaws:

Benchtop bandsaws are compact and portable, making them suitable for smaller woodworking projects. These saws typically have a maximum cutting capacity of around 3 to 4 inches, allowing them to handle thinner materials such as boards, small logs, or detailed cuts on thin stock. Benchtop bandsaws are perfect for hobbyists or those with limited space.

2. 14-Inch Bandsaws:

The 14-inch bandsaw is a popular choice among woodworking enthusiasts. These versatile machines offer a throat capacity of approximately 14 inches and can handle stock up to 6 inches in thickness. With the ability to make both intricate cuts and resawing, a 14-inch bandsaw is well-suited for a wide range of projects, including furniture making and cabinetry.

3. 17-Inch and Larger Bandsaws:

As the width of the bandsaw increases, so does its cutting capacity. Bandsaws with throat capacities of 17 inches or more can handle stock up to 12 inches thick or even thicker in some cases. These larger bandsaws are commonly found in professional woodworking shops and are capable of handling heavy-duty resawing, slicing thick slabs, and other demanding tasks.

It’s important to note that while these general guidelines provide an idea of the cutting capacity of different bandsaws, the exact capabilities can vary depending on the specific model and blade being used. Always consult the manufacturer’s guidelines and recommendations to ensure you are operating within the limits of your bandsaw.

Key Takeaways: How thick can a bandsaw cut?

- A bandsaw is a powerful tool that can cut through various materials such as wood, metal, and plastic.

- The thickness that a bandsaw can cut depends on the size and power of the bandsaw.

- Generally, bandsaws can cut material up to a thickness of 6 inches or more.

- It’s important to choose the right blade for the material you’re cutting to ensure clean and accurate cuts.

- Always follow safety precautions when using a bandsaw, such as wearing protective gear and securing the material properly.

Frequently Asked Questions

Welcome to our FAQ section about bandsaw cutting! Here, we’ll answer some of the most common questions related to the thickness of cuts that a bandsaw can make. Let’s dive in and explore the world of bandsaw cutting capacities!

1. How deep of a cut can a bandsaw make?

When it comes to the depth of cut, bandsaws are quite versatile. The cutting capacity of a bandsaw is mainly determined by the distance between the tabletop and the upper blade guides. In general, a bandsaw can make cuts ranging from a few millimeters to several inches deep. However, the capacity can vary depending on the specific model and size of the bandsaw.

Bandsaws designed for woodworking typically have a capacity ranging from 6 to 24 inches, allowing you to cut through thick pieces of lumbers, plywoods, and even logs. Industrial-grade bandsaws with larger tables can handle even bigger cuts. It’s important to check the specifications of your bandsaw to determine the exact cut depth it can achieve.

2. What factors affect the thickness of the cut on a bandsaw?

The thickness of the cut on a bandsaw can be influenced by several factors. The blade type and width play a significant role. Thinner blades are better suited for intricate cuts with tighter curves, while wider blades are more appropriate for resawing thicker materials. Additionally, the power of the motor and the tension applied to the blade also impact the cut thickness.

It’s important to note that the type of material being cut can also affect the thickness. For instance, hardwoods may require slower feed rates or shallower cuts compared to softwoods. Experimenting and adjusting the settings on your bandsaw can help you achieve the desired cut thickness for different materials and projects.

3. Can a bandsaw cut through metal?

Yes, a bandsaw can cut through metal, but it requires a specific type of bandsaw known as a metal cutting bandsaw. These bandsaws are designed with specialized blades that are more rigid and have teeth specifically designed for metal cutting. They also typically have a slower blade speed to handle the heat generated during metal cutting.

Regular woodworking bandsaws are not suitable for cutting metal as they are not designed to withstand the rigors of metal cutting. Attempting to cut metal with a standard bandsaw can damage the blade and potentially cause safety hazards. If you need to cut metal, it’s recommended to invest in a dedicated metal cutting bandsaw.

4. Can a bandsaw cut curves?

Absolutely! Bandsaws are renowned for their ability to cut intricate curves with precision. The design of the bandsaw blade, with its continuous loop and narrow profile, allows for tight turns and curved cuts. Additionally, most bandsaws come equipped with a table that can tilt, making it even easier to create bevels and angled cuts.

Whether you’re working on detailed scrollwork or shaping rounded edges, a bandsaw can be your best friend. Just make sure to use an appropriate blade, with a narrower width for tighter curves, and adjust the blade tension and feed rate to suit your specific project.

5. Can a bandsaw cut thicker materials like solid metal bars or thick hardwood slabs?

While a bandsaw is predominantly used for woodworking, it can indeed cut through thicker materials like solid metal bars and thick hardwood slabs. The key factor in cutting thicker materials is the size and power of the bandsaw. Industrial bandsaws, designed for heavy-duty applications, have more robust frames and stronger motors that can handle cutting through thicker materials.

For cutting solid metal bars, you will need a metal cutting bandsaw with the appropriate blade. The same goes for thick hardwood slabs; a bandsaw with ample power, a wider blade, and an appropriate blade setting can handle the job. It’s important to consider the specific capacity of your bandsaw before attempting to cut extremely thick materials to ensure both safety and efficiency.

Summary

So, after learning about how thick a bandsaw can cut, here are the key points to remember:

Bandsaws are versatile tools that can cut through wood and metal with ease, but the thickness they can handle depends on the size and power of the machine.

For smaller bandsaws, they typically have a maximum cutting capacity of around 6 inches, while larger bandsaws can handle thicker materials, up to 12 inches or more.

It’s important to remember that the thickness of the blade and the tension applied to it also play a role in determining the cutting capacity.

So, if you want to cut thick materials, make sure to choose a bandsaw that is suitable for the job and has the power and specifications needed. Always follow safety guidelines and consult the manufacturer’s recommendations for the best results.