Have you ever wondered just how thick a circular saw can cut? Well, you’re in luck because we’re about to dive into this exciting topic and unravel the secrets of circular saw cutting depths!

So, how thick can a circular saw cut? We’re here to answer that burning question and provide you with all the information you need. Whether you’re a DIY enthusiast or a curious mind, this article will equip you with the knowledge to understand the limits of a circular saw’s cutting capacity.

Grab your safety goggles, roll up your sleeves, and let’s explore the fascinating world of circular saws and their cutting depths together! Get ready to be amazed by the power and precision of these versatile tools.

When it comes to the cutting thickness of a circular saw, it depends on factors such as the blade size and the power of the saw. Generally, a standard circular saw can cut up to 2-⅛ inches thick. However, some models offer deeper cuts, ranging from 2-½ inches to 3-⅛ inches. It’s important to choose a saw that matches your cutting needs to ensure optimal performance and safety.

How Thick Can a Circular Saw Cut?

Introduction: Circular saws are versatile tools that can make a variety of cuts in different materials. One common question that arises when using a circular saw is, “How thick can it cut?” In this article, we will explore the capabilities of a circular saw and shed light on the factors that determine its cutting depth. So, let’s dive in and discover the answer to this intriguing question!

Factors that Affect the Cutting Depth of a Circular Saw

When it comes to determining the maximum thickness a circular saw can cut, several factors come into play. These factors influence the efficiency and performance of the saw, allowing it to slice through various materials with varying depths. Let’s take a closer look at these crucial elements:

The Blade Size

The size of the circular saw blade plays a significant role in determining the cutting depth. Typically, circular saw blades range in size from 6 ½ inches to 10 inches. The larger the blade size, the deeper the cut it can make. For example, a 7 ¼-inch blade can cut through materials up to 2 ⅜ inches thick, while a 10-inch blade can handle cuts up to 3 ½ inches deep.

It’s important to note that using a blade larger than the recommended size for your circular saw may adversely affect the performance and safety of the tool. Always refer to the manufacturer’s guidelines for the appropriate blade size for your specific saw model.

Furthermore, different types of blades, such as those designed for specific materials like wood or metal, may have varying cutting depths. It’s crucial to choose the right blade for the job to achieve optimal results.

The Motor Power

The power of the circular saw’s motor also impacts its cutting depth. A higher-powered motor enables the saw to generate more torque and maintain consistent blade speed even when cutting through thicker materials. This increased power translates to the ability to make deeper cuts. It’s essential to consider the motor power when selecting a circular saw for your cutting needs.

However, it’s worth noting that the motor power alone does not determine the cutting depth. You must also consider the blade size, material being cut, and other factors mentioned in this article to accurately gauge the maximum cutting capacity of a circular saw.

The Material Being Cut

The type of material being cut greatly influences the cutting depth of a circular saw. Different materials have different densities and properties that determine how easily they can be cut. For example, a circular saw may effortlessly slice through plywood, but struggle with thicker and denser materials like hardwood or metal.

Moreover, certain materials may require specialized blades for optimal cutting performance. For instance, cutting through plastic may necessitate a blade specifically designed for plastics, which could have different cutting depth capabilities compared to a standard wood-cutting blade.

It’s essential to consider the thickness and density of the material being cut to determine if a circular saw is the appropriate tool for the job.

Choosing the Right Blade and Adjusting the Cutting Depth

Now that we understand the factors that affect the maximum cutting depth of a circular saw, let’s explore how to choose the right blade and adjust the cutting depth:

Selecting the Correct Blade

To achieve optimal cutting results, it’s crucial to choose the right blade for the material being cut. Different blades are designed for various purposes, including ripping, cross-cutting, and cutting specific materials like wood, metal, or plastic. Be sure to select a blade that matches your desired application and material to ensure clean and efficient cuts.

Beyond material compatibility, consider the number of teeth on the blade. Blades with more teeth provide smoother cuts, while blades with fewer teeth cut faster but with a slightly rougher finish. Choose the appropriate blade for your desired cut quality and speed.

Adjusting the Cutting Depth

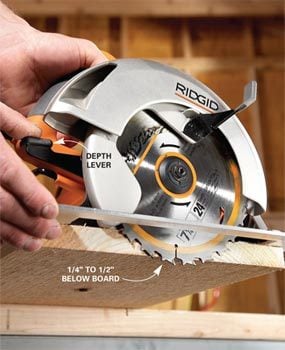

Most circular saws allow for adjusting the cutting depth to accommodate different materials and desired cut depths. Typically, there is a lever or knob near the blade housing that can be loosened to adjust the depth.

Prior to making any adjustments, ensure the saw is unplugged and the blade has come to a complete stop. Then, adjust the cutting depth by setting the desired measurement on the saw’s depth scale. Take care not to set a depth greater than the capacity specified by the manufacturer.

Always remember to tighten the depth adjustment mechanism securely before operating the circular saw to ensure the blade remains at the desired depth throughout the cutting process.

Benefits of Using a Circular Saw

Now that we understand the maximum cutting capacity of a circular saw, let’s explore some of its benefits:

1. Versatility:

Circular saws are highly versatile tools that can make a wide range of cuts, including straight cuts, bevel cuts, and even plunge cuts. This versatility makes them suitable for various woodworking and construction projects.

2. Portable:

Most circular saws are compact and lightweight, making them easy to transport and maneuver. This portability allows for greater flexibility on job sites and makes them suitable for DIYers and professionals alike.

3. Cost-Effective:

Compared to other power saws, circular saws are relatively affordable. They provide excellent value for money, as they are durable, versatile, and capable of handling a wide range of cutting tasks.

Safety Tips for Using a Circular Saw

When using a circular saw, it’s crucial to prioritize safety. Here are some essential tips to keep in mind:

1. Wear Safety Gear:

Always wear appropriate safety gear, including safety goggles, ear protection, and gloves, to protect yourself from potential hazards like flying debris and loud noise.

2. Secure the Workpiece:

Before cutting, ensure the workpiece is securely clamped or properly supported to prevent it from moving while using the circular saw. This will help maintain control and avoid accidents.

3. Follow Proper Techniques:

Use the appropriate techniques for cutting, such as keeping the saw blade aligned with the cut line, maintaining a firm grip on the saw, and applying consistent pressure throughout the cut. Avoid forcing the saw through the material, as this can lead to kickback and potential injuries.

4. Disconnect Power:

Before making any adjustments or blade changes, always disconnect the power source to prevent accidental starts and ensure your safety.

5. Store Properly:

After using the circular saw, store it in a safe and secure place, out of reach of children and away from any potential damage. Proper storage helps prolong the life of the saw and minimizes the risk of accidents.

In conclusion, the cutting depth of a circular saw depends on various factors, including the blade size, motor power, and the material being cut. By choosing the right blade and adjusting the cutting depth, you can achieve optimal cutting results for your desired application. Remember to prioritize safety and follow the recommended safety guidelines when operating a circular saw. Happy cutting!

Key Takeaways: How Thick Can a Circular Saw Cut?

- A circular saw can typically cut through materials up to 2 inches thick.

- Thinner materials like plywood or MDF are easier to cut with a circular saw.

- Thicker materials may require multiple passes and may result in rougher cuts.

- It’s important to choose the right blade for the material you’re cutting to achieve the best results.

- Always wear protective gear, such as goggles and gloves, when using a circular saw.

Frequently Asked Questions

Are you wondering about the cutting capacity of a circular saw? Look no further! We have compiled some frequently asked questions about how thick a circular saw can cut. Read on to find your answers.

What is the maximum cutting depth of a circular saw?

The maximum cutting depth of a circular saw depends on the blade size and the saw’s power. In general, a 7.25-inch circular saw can cut up to 2.5 inches deep, while a 10-inch saw can cut up to 3.5 inches deep. However, it’s important to note that the cutting depth may vary based on the material being cut.

Circular saws are commonly used for cutting materials such as plywood, MDF, and lumber. Keep in mind that cutting depth may be reduced if you’re using a guide rail or if the material is particularly dense. Always refer to the manufacturer’s guidelines for the specific saw you’re using to ensure safe and accurate cutting.

Can a circular saw cut through thick pieces of metal?

While circular saws are primarily designed for cutting wood and other softer materials, some models can also cut through thin pieces of metal. With the right blade, such as a carbide-tipped or abrasive blade, a circular saw can effectively cut through thin sheets of metal like aluminum or steel.

However, it’s important to note that cutting metal with a circular saw requires caution and proper safety measures. The saw should be equipped with a blade designed specifically for metal cutting, and the material being cut should be properly secured. It’s also crucial to wear appropriate safety gear, including gloves and eye protection, to avoid any potential hazards.

What factors can affect the cutting capacity of a circular saw?

Several factors can impact the cutting capacity of a circular saw. The main factors include the blade diameter, motor power, and the material being cut. Larger blades, such as 10 inches, generally have a greater cutting capacity compared to smaller blades. Likewise, a saw with a higher motor power will typically have a higher cutting capacity.

The type of blade being used also plays a role. Blades designed for specific materials, such as plywood or metal, will have different cutting capacities. Additionally, the condition of the blade, such as its sharpness or whether it’s appropriately installed, can affect the saw’s cutting capacity. It’s crucial to use the right blade for the job and ensure it is in good condition to achieve optimal cutting results.

Can a circular saw cut through concrete or other masonry materials?

Circular saws are not typically designed for cutting through concrete or other heavy masonry materials. The hardness and density of these materials require specialized tools such as a concrete saw or a masonry saw. These tools are equipped with diamond blades that can withstand the rigors of cutting through tough materials.

While a circular saw may be able to make shallow scores or cuts on concrete, it is not recommended for deeper or extensive cutting. Attempting to cut through concrete with a circular saw can cause damage to the saw and potential injuries. For cutting concrete or masonry, it’s best to use the appropriate tool designed specifically for those materials.

What safety precautions should be taken when using a circular saw?

When using a circular saw, it is essential to prioritize safety. Start by wearing appropriate personal protective equipment (PPE), including safety glasses or goggles, hearing protection, and gloves. Ensure your work area is well-lit and clear of any potential hazards.

When making cuts, secure the material being cut firmly in place to prevent it from shifting or being thrown by the saw. Use clamps or other securing methods if necessary. Keep your hands away from the blade and use a push stick or guide whenever possible to maintain a safe distance. Lastly, always disconnect the saw from the power source when not in use and store it in a safe place, out of reach of children or unauthorized users.

How to Cut Thick Wood with Circular Saw

Summary

Circular saws are great for cutting through wood, but the thickness they can handle depends on a few factors. The size and power of the saw, as well as the type of blade used, affect how deep a circular saw can cut. It’s essential to choose the right blade for the material you’re cutting, and be aware of the saw’s limitations.

Another important factor is the diameter of the blade. The larger the blade, the deeper it can cut. However, keep in mind that as the blade gets bigger, the saw’s motor needs to provide more power to maintain efficient cutting. Safety should always be a priority, so be sure to follow the manufacturer’s guidelines and wear protective gear when using a circular saw.

In conclusion, circular saws can cut through different thicknesses of wood, but the depth will depend on the size and power of the saw, the type of blade used, and safety precautions taken. It’s important to choose the right equipment for the job and use it responsibly.