Are you wondering just how thick a circular saw can cut? Well, you’ve come to the right place! Today, we’re going to dive into the exciting world of circular saws, exploring their cutting capabilities and the factors that can affect them. So let’s grab our safety goggles and get ready to learn about the power and precision of circular saws!

Now, you might be thinking, “Why should I care about circular saws and their cutting thickness?” Well, my curious friend, whether you’re a DIY enthusiast or a professional woodworker, understanding the cutting capacity of a circular saw is crucial. It determines the thickness of the material you can slice through like a hot knife through butter. And let me tell you, there’s something oddly satisfying about watching a circular saw glide effortlessly through a thick piece of wood!

But hold your horses! Before we jump into the specifics of how thick a circular saw can cut, let’s take a step back and explore how these mighty tools work their magic. Understanding the inner workings of a circular saw will help us appreciate their cutting prowess even more. Shall we proceed? Let’s do it!

How Thick Can a Circular Saw Cut? Exploring the Limits

When it comes to woodworking and construction projects, a circular saw is a versatile tool that can make precise and clean cuts. But have you ever wondered how thick of a material a circular saw can actually handle? In this article, we’ll take a closer look at the capabilities of a circular saw and explore its limitations in terms of cutting thickness. Whether you’re a seasoned DIY enthusiast or a professional carpenter, understanding the limitations of this tool is crucial for choosing the appropriate saw for your projects and ensuring safety.

The Cutting Edge: How Circular Saws Work

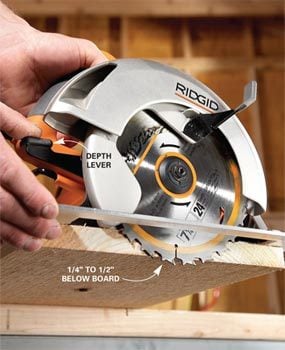

Before diving into the thickness capabilities of a circular saw, it’s important to understand how this power tool actually works. A circular saw consists of a round blade with sharp teeth that spins rapidly to cut through various materials. The blade is mounted to a motor, and when powered on, it rotates to create a cutting action that slices through wood, metal, and other types of materials. The depth of cut is determined by the height of the blade, which can be adjusted on most circular saws.

Now that we have a basic understanding of how circular saws operate, let’s explore the different factors that influence their cutting capabilities:

1. Blade Diameter

The diameter of the circular saw blade plays a significant role in determining its cutting depth. Most circular saws come with blades ranging from 6 inches to 12 inches in diameter. Typically, the larger the blade diameter, the deeper the cut the saw can achieve. However, it’s important to note that the maximum cutting depth may vary depending on the specific model and manufacturer.

For example, a 6-inch circular saw blade might have a maximum cutting depth of around 2 inches, while a 12-inch blade could have a cutting capacity of up to 4 inches. It’s crucial to refer to the manufacturer’s guidelines and specifications to determine the maximum cutting depth of a specific circular saw model.

Additionally, larger blades with bigger diameters tend to result in more powerful cutting, making them suitable for heavy-duty applications such as cutting through thick lumber or concrete.

2. Saw Type

There are various types of circular saws available on the market, each designed for different cutting purposes. The two most common types are sidewinder saws and worm drive saws. While the basic function of these saws is the same, there are differences that affect their cutting capabilities.

Sidewinder saws, also known as direct-drive circular saws, have the motor positioned on the side of the blade. These saws are lightweight and easy to handle, making them ideal for jobs that require agility and maneuverability. Sidewinders typically have smaller diameter blades, making them better suited for cutting thinner materials.

On the other hand, worm drive saws have the motor positioned at the back of the blade. These saws are heavier and offer more power and torque, making them great for cutting through thicker and tougher materials. Worm drive saws often come with larger diameter blades, enabling them to achieve deeper cuts.

3. Material Type

The type of material being cut also plays a significant role in determining the maximum cutting depth of a circular saw. While circular saws are adept at cutting through a wide range of materials, such as wood, metal, plastic, and even tile, different materials have different hardness levels and densities.

For instance, when cutting through softwood like pine or cedar, a circular saw will be able to achieve its maximum cutting depth more easily compared to cutting through hardwoods like oak or teak. The denser the material, the slower the cutting process, and the shallower the maximum cut depth may be due to the blade being under greater strain and resistance.

4. Blade Quality and Sharpness

The quality and sharpness of the circular saw blade also have a direct impact on its cutting capabilities. A dull or low-quality blade will struggle to cut through materials efficiently, reducing the maximum achievable cutting depth. It’s essential to ensure that you have a sharp and high-quality blade suitable for the material you’re working with.

Regular maintenance, such as sharpening the blade or replacing it when necessary, will ensure optimal performance and extend the lifespan of your circular saw.

Choosing the Right Circular Saw for Your Needs

Now that we’ve explored the factors affecting the cutting thickness of a circular saw, it’s time to consider how to choose the right tool for your specific needs.

1. Determine Your Project Requirements

Start by evaluating the types of projects you plan to undertake. If you primarily work with thinner materials or require agility and ease of use, a sidewinder saw with a smaller blade diameter might be sufficient. However, if you frequently work with thick or dense materials or need more power and torque, a worm drive saw with a larger blade diameter would be a better option.

2. Consider Blade Adjustments

Look for a circular saw that offers easy and precise blade depth adjustments. This feature will allow you to customize the cutting depth based on the requirements of your project. Being able to adjust the blade height gives you versatility and enables you to achieve accurate and clean cuts.

3. Don’t Forget Safety

When operating a circular saw, safety should always be a top priority. Consider models with built-in safety features such as blade guards, electric brakes, and anti-kickback mechanisms. Additionally, always wear appropriate safety gear, including safety glasses and hearing protection, to minimize the risk of accidents or injuries.

Conclusion

Knowing how thick a circular saw can cut is essential for both the efficiency and safety of your woodworking or construction projects. Factors such as blade diameter, saw type, material type, and blade quality all play a role in determining the maximum cutting depth. By considering these factors and choosing the right circular saw for your needs, you can achieve precise and clean cuts with ease. Remember to prioritize safety and practice proper maintenance to ensure the longevity and optimal performance of your circular saw.

Key Takeaways: How Thick Can a Circular Saw Cut?

- A circular saw can typically cut through materials with a thickness of up to 2.5 inches.

- However, the maximum cutting depth may vary depending on the specific circular saw model.

- It is important to check the manufacturer’s guidelines and specifications to determine the maximum cutting capacity of your circular saw.

- When using a circular saw, always follow proper safety precautions, wear protective gear, and ensure the workpiece is securely clamped or supported.

- If cutting thicker materials, an alternative tool, such as a jigsaw or reciprocating saw, may be more suitable.

Frequently Asked Questions

Are you curious about the cutting capabilities of circular saws? Look no further! Here are some commonly asked questions about how thick a circular saw can cut, answered just for you.

1. How thick can a circular saw cut?

A circular saw can typically cut through materials up to 2 inches thick, depending on the type and power of the saw. This includes materials like wood, plastic, metal, and even some masonry materials. However, it’s important to note that different blades are designed for specific materials, so it’s crucial to choose the appropriate blade for your cutting needs.

For thicker materials, alternate tools such as a table saw or band saw might be more suitable, as they offer more power and stability for cutting through thicker stock. When in doubt, consult the manufacturer’s recommendations and guidelines for your specific circular saw model.

2. Can a circular saw cut through plywood?

Yes, a circular saw is an excellent tool for cutting through plywood. Since plywood is a common material in woodworking and construction, circular saws are designed to handle it easily. Plywood can range in thickness from 1/8 inch to 3/4 inch or more. Most circular saws can effortlessly cut through plywood up to 1 inch thick, but with the right blade and adjustment, thicker plywood can also be cut.

When cutting plywood, it’s important to use a fine-toothed blade with a high tooth count to minimize tear-out. Additionally, ensure that the blade depth is set appropriately to avoid cutting too deep and creating kickback or damaging the material. Always wear appropriate safety gear, such as eye protection and gloves, when using a circular saw.

3. Is it safe to cut metal with a circular saw?

Yes, it is safe to cut metal with a circular saw, as long as you use the appropriate blade designed specifically for cutting metal. Metal-cutting circular saw blades have more teeth and are made of harder materials like carbide or cermet to withstand the demands of cutting metal. These blades make clean and precise cuts through materials like steel and aluminum.

When cutting metal, it’s essential to secure the workpiece properly to prevent it from moving or vibrating during the cutting process. This ensures a safer and more accurate cut. It’s also important to wear safety gear, such as safety glasses, ear protection, and gloves, to protect yourself from metal shards and sparks.

4. Can a circular saw cut through concrete?

No, a standard circular saw is not designed to cut through concrete. Concrete is a dense material that requires specialized tools, such as a concrete saw or a rotary hammer with a masonry blade, for cutting. These tools are equipped with powerful motors and diamond-tipped blades that can easily cut through concrete and other masonry materials.

Attempting to cut concrete with a circular saw not only risks damaging the saw, but it is also ineffective and can be dangerous. If you need to cut through concrete, it’s best to use the appropriate tools designed for that purpose to ensure efficient and safe results.

5. How do I choose the right blade for my circular saw?

Choosing the right blade for your circular saw is crucial for achieving clean and precise cuts. There are various factors to consider when selecting a blade, including the type of material you will be cutting, the desired finish, and the thickness of the material. Different blades are designed for cutting wood, metal, plastic, and other specific materials.

When selecting a blade, look for the appropriate tooth count and design that matches your cutting needs. A higher tooth count is generally better for fine cuts and a smoother finish, while a lower tooth count is more suitable for rough cuts and faster material removal. Always consult the manufacturer’s guidelines and recommendations to ensure you choose the right blade for your specific circular saw model and cutting requirements.

How to Cut Thick Wood with Circular Saw

Summary

Circular saws are powerful tools that can cut through various materials like wood, plastic, and metal. The thickness of the material that a circular saw can cut depends on the size of the blade and the power of the saw.

It is important to choose the right blade and adjust the cutting depth to avoid damaging the saw or getting an inaccurate cut. Safety precautions such as wearing protective gear and securing the material to be cut are also crucial. Remember to always follow the manufacturer’s guidelines for the specific saw you are using.