If you’ve ever wondered about the thickness of half inch plywood, you’re in the right place! Plywood is a versatile material used for various projects, from woodworking to construction. In this article, we’ll explore the dimensions and characteristics of half inch plywood. So, let’s dive in and discover just how thick half inch plywood really is!

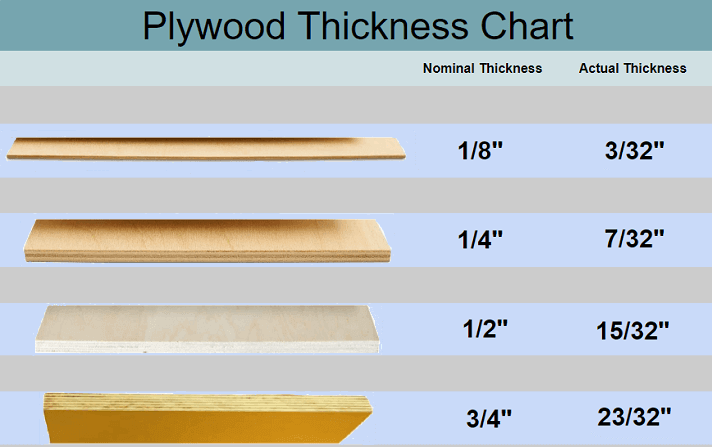

When it comes to determining the thickness of half inch plywood, you might be surprised to learn that its name can be a bit deceiving. Despite its moniker, half inch plywood is not actually half an inch thick. In fact, it measures approximately 0.47 inches in thickness. While it may seem like a small difference, it’s important to consider these precise measurements when planning and executing your projects.

Now that we know the thickness of half inch plywood, you might be wondering why it’s called “half inch” if it’s not exactly half an inch thick. Well, the term “half inch” refers to the nominal thickness of the plywood, which is the dimension used for identification purposes. This nominal thickness is a standard in the industry, allowing builders, carpenters, and DIY enthusiasts to easily select the right plywood for their needs.

So, whether you’re embarking on a woodworking project, building furniture, or carrying out construction work, understanding the true thickness of half inch plywood is crucial. Armed with this knowledge, you can confidently choose the right material for your projects and achieve the desired results. So, let’s get started and explore the world of half inch plywood together!

How Thick is Half Inch Plywood? Exploring the Dimensions and Applications

The Basics of Plywood Thickness

Plywood, a versatile building material, comes in various thicknesses to suit different applications. When it comes to half-inch plywood, its actual thickness may vary slightly depending on the manufacturer and the specific type of plywood. Generally, half-inch plywood refers to panels that are approximately 0.5 inches thick. However, the nominal thickness is often slightly less than the stated measurement due to the sanding and finishing process.

Specifically, standard half-inch plywood has a thickness of around 12.7 millimeters (0.5 inches) whereas metric half-inch plywood measures roughly 13 millimeters. It is essential to understand the nominal thickness of plywood as this impacts its compatibility with standard framing and construction practices.

Half-inch plywood is widely used in various construction projects, including sheathing, subflooring, and cabinet construction. Its versatility, combined with its sturdy nature, makes it a popular choice among builders and DIY enthusiasts alike.

Comparing Half-Inch Plywood to Other Thicknesses

While half-inch plywood is a popular choice, it is essential to understand how it compares to other common thicknesses. By exploring the differences, you can determine the most suitable plywood thickness for your specific project.

Thinner plywood, such as quarter-inch or three-eighths-inch, is often used for projects that require flexibility or reduced weight. These thinner options are commonly employed in crafting, model building, and decorative applications. Conversely, thicker plywood, such as three-quarter-inch or one-inch, offers increased strength and durability, making it suitable for load-bearing structures like floors and walls.

Half-inch plywood strikes a balance between flexibility and strength, making it versatile for a range of applications. It can withstand moderate loads and is often used as underlayment, roof decking, or wall sheathing. Additionally, its thickness allows for easy installation and cutting, making it a favorite among DIY enthusiasts.

Benefits of Using Half-Inch Plywood

Choosing half-inch plywood for your projects offers several advantages:

- Strength and Durability: Half-inch plywood provides a sturdy and durable surface for various applications, making it suitable for construction projects that require stability and structural integrity.

- Ease of Use: With its standardized thickness, half-inch plywood is easy to handle and cut to size, allowing for precise installation even for DIYers with minimal experience.

- Cost-Effective: Half-inch plywood strikes a balance between affordability and quality, providing a cost-effective solution for many construction and renovation projects.

- Versatility: From sheathing to subfloors and cabinets to structural components, half-inch plywood can be used in a wide range of applications.

- Availability: Half-inch plywood is readily available at most hardware stores, making it convenient to source for your projects.

Overall, the combination of strength, versatility, and ease of use makes half-inch plywood a go-to option for many builders and DIY enthusiasts.

Tips for Working with Half-Inch Plywood

Working with half-inch plywood requires attention to detail and proper technique to ensure successful results. Here are a few tips to keep in mind:

- Measurement Accuracy: Accurately measure and mark the plywood before cutting to avoid errors and ensure precise fit and alignment.

- Proper Support: When installing half-inch plywood as subflooring or sheathing, ensure proper support beneath to prevent sagging or flexing over time.

- Sealing Edges: To protect the plywood from moisture damage, seal the edges using an appropriate sealant or wood preservative.

- Secure Fastening: Use the appropriate fasteners, such as screws or nails, to securely attach the plywood to the supporting structure.

- Finishing: Depending on the application, consider finishing the plywood surface with paint, stain, or a protective coating to enhance its appearance and durability.

By following these tips, you can ensure that your half-inch plywood projects are completed with precision and longevity.

Understanding the Applications of Half-Inch Plywood

Half-inch plywood finds extensive use in various construction and woodworking projects. Its thickness and strength make it suitable for both structural and decorative applications. Let’s explore some common uses of half-inch plywood:

Subflooring and Flooring

When constructing or renovating a building, half-inch plywood is often employed as a subflooring material. Its strength and stability provide a solid foundation for the finished floor, ensuring long-lasting durability and support. Additionally, half-inch plywood’s resistance to warping and its ability to span joists make it well-suited for flooring applications.

Before installing the finished floor covering, half-inch plywood is installed perpendicular to the floor joists, creating a smooth and level surface. This provides stability and helps to prevent squeaking and unevenness in the floor.

In addition to subflooring, half-inch plywood can be used as the finished flooring material in certain situations. It can be painted, stained, or sealed to achieve the desired aesthetic appeal. However, it is important to note that additional preparation and finishing steps may be required for the plywood to serve as the final flooring material.

Sheathing and Wall Construction

Half-inch plywood is commonly utilized as sheathing material in both exterior and interior wall construction. Sheathing provides structural support and serves as a base for the application of exterior finishes, insulation, and interior wall coverings.

In exterior wall construction, half-inch plywood acts as a barrier against wind, moisture, and temperature fluctuations. It ensures the stability and integrity of the wall while providing a sturdy surface for the application of siding materials, such as brick or vinyl.

In interior wall construction, half-inch plywood can be used as a base for drywall or other wall coverings. It creates a solid and level surface that helps to minimize cracking, sagging, or warping of the finished wall.

Cabinet and Furniture Construction

Half-inch plywood is often favored for cabinet and furniture construction due to its strength, stability, and ease of use. It can be cut and shaped into various sizes and configurations to create cabinet boxes, shelves, and other furniture components.

The smooth and uniform surface of half-inch plywood makes it ideal for painting, staining, or veneering. It can be finished to match any desired aesthetic, whether it be a clean and modern look or a rustic and natural appearance.

When using half-inch plywood for cabinets or furniture, it is important to consider the weight of the items to be stored or supported. Thicker plywood or additional reinforcement may be necessary for heavier loads.

DIY and Craft Projects

Due to its versatility and ease of use, half-inch plywood is a popular choice for DIY and craft projects. It can be used in a multitude of creative applications, including:

- Shelving and storage units

- Wooden signs and plaques

- Craft and model building

- Decorative panels and partitions

Half-inch plywood’s affordability and wide availability also make it an economical choice for hobbyists and DIY enthusiasts.

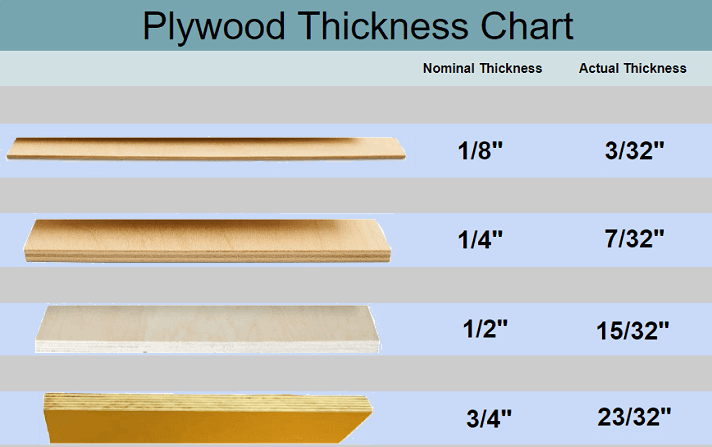

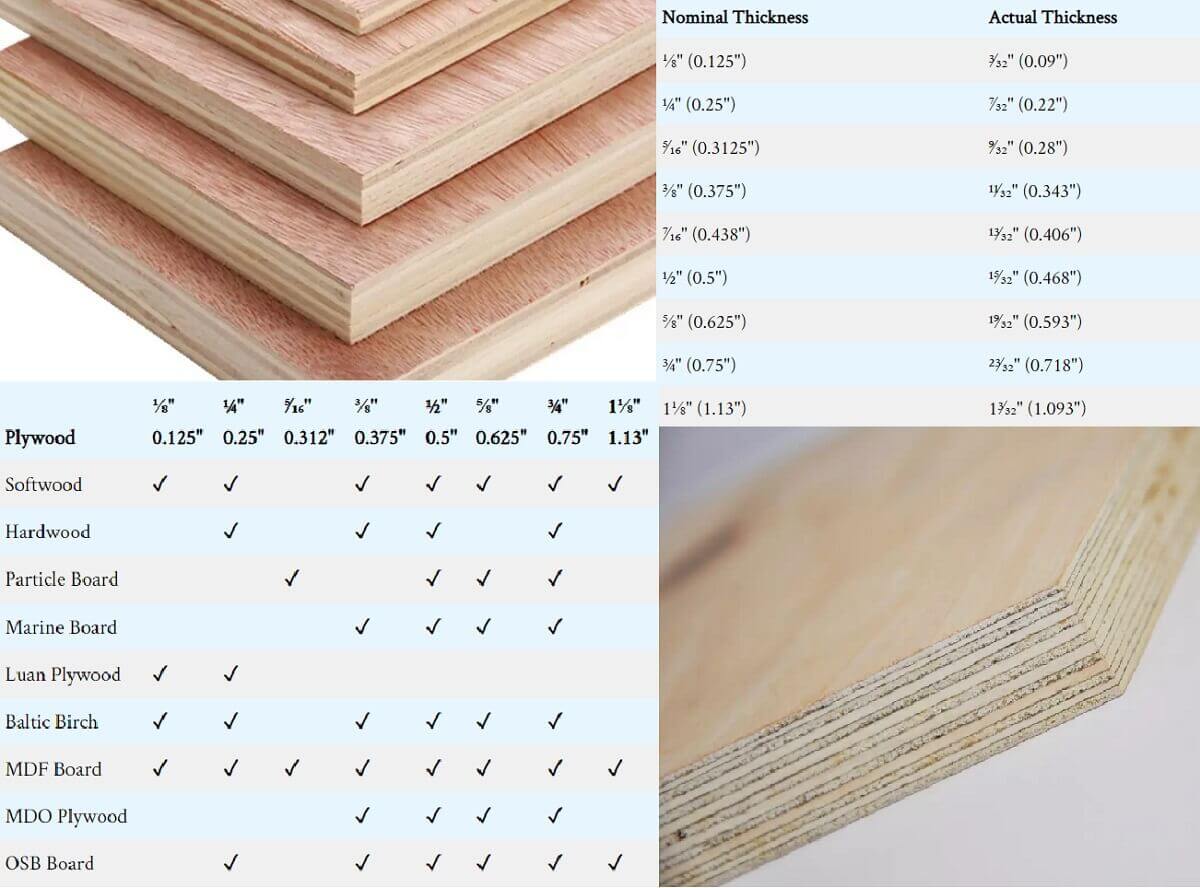

Understanding Plywood Thickness Distinctions

Aside from half-inch plywood, there are several other common thicknesses available. Each thickness serves specific purposes in construction and woodworking projects. Here’s an overview of some widely used plywood thickness options:

Quarter-Inch Plywood (6mm)

Quarter-inch plywood, also known as 6mm plywood, is the thinnest commonly available plywood. It is lightweight and flexible, making it suitable for decorative and crafting purposes. However, it is not as structurally strong as thicker plywood options and may require additional support for load-bearing applications.

Quarter-inch plywood is commonly used in model making, creating backings for picture frames, or lining cabinets and drawers.

Three-Eighths-Inch Plywood (9mm)

Three-eighths-inch plywood, measuring approximately 9mm, strikes a balance between flexibility and strength. It is commonly used for projects that require a sturdier material than quarter-inch plywood but do not necessitate the thickness of half-inch plywood.

Three-eighths-inch plywood can be used for wall sheathing, cabinet backs, and smaller furniture pieces.

Three-Quarter-Inch Plywood (18mm)

Three-quarter-inch plywood, also known as 18mm plywood, is a commonly used thickness for load-bearing applications. Its increased thickness provides enhanced strength and durability, making it suitable for structural components like floors, walls, and roofs.

Three-quarter-inch plywood is often used as subflooring, exterior sheathing, and heavy-duty furniture construction.

One-Inch Plywood (25mm)

One-inch plywood, measuring approximately 25mm, is the thickest plywood typically available. It offers exceptional strength and load-bearing capabilities, making it suitable for heavy-duty applications.

One-inch plywood excels in applications such as structural beams, support posts, and other load-bearing elements.

Custom Thicknesses

In addition to the standardized thicknesses mentioned above, plywood can also be custom manufactured to specific thickness requirements. Custom thicknesses are often used in specialty applications where standard options may not meet the project’s unique needs.

It is worth noting that plywood thicknesses may vary slightly due to factors such as sanding, moisture content, and the specific grading standards of different plywood types and manufacturers.

Caring for Half-Inch Plywood

To ensure the longevity and continued performance of your half-inch plywood projects, proper care and maintenance are essential. Follow these tips to keep your plywood in top condition:

Moisture Protection

Protect your plywood from excessive moisture, as prolonged exposure can cause warping, swelling, and delamination. Seal the edges of the plywood using an appropriate sealant to prevent moisture penetration, and use a waterproofing coating or paint if the plywood will be exposed to high humidity or wet conditions.

When storing plywood, keep it off the ground and in a dry, well-ventilated area to prevent moisture damage.

Regular Cleaning

Regularly clean the surface of your plywood to remove dirt, dust, and other debris. For painted or stained plywood, follow the manufacturer’s recommendations for cleaning and maintenance to preserve the finish.

Avoid using harsh chemicals or abrasive cleaners, as they can damage the plywood surface. Instead, use mild soap and water or a specially formulated wood cleaner.

Inspection and Repair

Periodically inspect your half-inch plywood for signs of damage or wear. Look for any warping, delamination, or loose fasteners. If you identify any issues, take prompt action to address them to prevent further damage.

Minor scratches or dents can often be repaired using wood fillers or touch-up paint. For more extensive damage, consider consulting a professional or replacing the affected plywood.

Conclusion

Understanding the thickness and applications of half-inch plywood is crucial for successful construction and woodworking projects. Half-inch plywood provides a versatile solution, offering a balance between strength and ease of use. It finds extensive use in subflooring, sheathing, cabinet construction, and DIY projects.

By following proper care and maintenance practices, such as protecting against moisture and regular cleaning, you can ensure the longevity and performance of your half-inch plywood projects. Whether you’re a professional builder or a DIY enthusiast, half-inch plywood is a reliable and functional material that can bring your projects to life.

Key Takeaways: How Thick is Half Inch Plywood?

- Half inch plywood is actually 0.5 inches thick.

- It is a commonly used plywood thickness for various projects.

- It offers a good balance between strength and weight.

- Half inch plywood is suitable for furniture, cabinets, and shelving.

- It is important to choose the right thickness for your specific project to ensure durability and stability.

Frequently Asked Questions

Discover everything you need to know about the thickness of half-inch plywood.

1. What is the average thickness of half-inch plywood?

Although it may sound counterintuitive, half-inch plywood is actually not exactly half an inch thick. The term “half-inch” refers to the nominal thickness of the plywood, but the actual thickness can vary. However, the most commonly available half-inch plywood has an actual thickness of around 15/32 of an inch, which is slightly less than half an inch.

It is important to note that plywood thicknesses can slightly differ between manufacturers and regions, so it’s always a good idea to check the actual thickness when purchasing half-inch plywood for a specific project.

2. Can I use half-inch plywood for flooring?

Yes, half-inch plywood can be used for flooring, but it may not be suitable for all situations. When choosing plywood for flooring, it’s important to consider the load-bearing requirements and the specific conditions of the space. Half-inch plywood is commonly used as a subfloor for hardwood, carpet, vinyl, or laminate flooring.

However, for higher traffic areas or heavy loads, a thicker plywood, such as 5/8 or 3/4 inch, may be more appropriate to provide better structural support and durability.

3. Is half-inch plywood suitable for building furniture?

Half-inch plywood can be used for building furniture, especially for pieces that don’t require heavy structural support. It is commonly used for shelves, cabinets, and other light-duty furniture applications. However, for furniture that will bear significant weight or require extra sturdiness, thicker plywood, such as 3/4 inch, may be a better choice.

Keep in mind that the type of wood veneer used for the surface of the plywood can also impact the appearance and suitability for furniture making. High-quality hardwood veneers can provide a more desirable finish and durability.

4. Can I use half-inch plywood for exterior applications?

Half-inch plywood is generally not recommended for exterior applications that will be directly exposed to the elements. It is not designed to withstand moisture and can warp or deteriorate over time when exposed to rain, sun, or humidity. For outdoor projects, it is best to use exterior-grade plywood that is specifically designed to withstand weather conditions.

If you still need to use half-inch plywood for an exterior project, make sure to adequately seal and protect it from moisture using suitable weather-resistant coatings, such as paint or varnish, to prolong its lifespan.

5. What are the alternatives to half-inch plywood?

If you’re looking for alternatives to half-inch plywood, there are a few options depending on your specific needs. One common alternative is oriented strand board (OSB), which is a wood composite made of interlocking strands of wood and adhesive. OSB is often used in construction and can be a cost-effective substitute for plywood.

Other alternatives include medium-density fiberboard (MDF), which is a dense engineered wood product made from wood fibers, and particleboard, which is made of wood particles bonded with adhesive. Each alternative has its own strengths and weaknesses, so it’s important to consider the specific requirements of your project before choosing the most suitable material.

Summary

So, how thick is half inch plywood? Well, despite the name, half inch plywood is actually about 0.44 inches thick. This is because of the production process and the way plywood is measured.

Plywood is made by gluing together multiple layers of thin wood veneers, and during the manufacturing process, the wood undergoes some shrinkage. As a result, the actual thickness of half inch plywood ends up being slightly less than half an inch. So, if you’re working on a project that requires precise measurements, keep this in mind when using half inch plywood.