Hey there! So you’re curious about how thick of wood a 9 bandsaw can cut, huh? Well, you’ve come to the right place! In this article, we’re going to dive into the world of bandsaws and explore their cutting capabilities. So let’s get started, shall we?

If you’re into woodworking or just love tinkering with tools, chances are you’ve heard of a bandsaw. It’s a versatile power tool that can make precise and clean cuts through various materials, including wood. But how thick of wood can a 9 bandsaw handle? That’s the question we’re here to answer.

Before we delve into the specifics, let’s first understand what a bandsaw is. Imagine a continuous loop of teethed blade riding on two wheels. This blade is responsible for cutting through materials, with the width of the blade determining the maximum cutting capacity. The 9 bandsaw refers to the blade’s width, which is measured in inches.

Now that we have a basic understanding, we’re ready to explore the thickness of wood a 9 bandsaw can handle. So grab your safety goggles and let’s find out how this tool can help you tackle woodworking projects like a pro!

How Thick of Wood Can a 9 Bandsaw Cut?

Understanding the Types of Bandsaws

Bandsaws are incredibly versatile tools that can make cutting wood a breeze. However, the thickness of wood that a bandsaw can cut depends on several factors, including the size and power of the machine. When it comes to the 9 bandsaw, it falls under the category of benchtop bandsaws, which are compact and ideal for small to medium-sized woodworking projects.

The 9 bandsaw, as the name suggests, has a throat depth of 9 inches, which determines the width of the wood you can cut. This means that the maximum width of wood that a 9 bandsaw can handle is 9 inches. However, when it comes to the thickness of the wood, it depends on the power and tension of the blade, as well as the type of cut you’re making.

The Blade and Cutting Capacity

The thickness of wood that a 9 bandsaw can cut also depends on the blade you’re using. Blades come in various widths and tooth configurations, each designed for different types of cuts. When it comes to thickness, a general rule of thumb is that a bandsaw can typically handle wood that is at least twice the distance between the blade and the upper guide assembly.

For example, if the distance between the blade and the upper guide assembly on your 9 bandsaw is 6 inches, you should be able to cut wood that is up to 12 inches thick. However, it’s important to note that this is a rough estimate, and factors such as the power of the motor, the tension of the blade, and the type of wood can affect the cutting capacity.

Considerations and Tips

While a 9 bandsaw can handle a decent thickness of wood, there are a few considerations you should keep in mind to ensure the best results. Firstly, make sure the blade is properly tensioned and aligned before making any cuts. This will ensure cleaner and more accurate cuts and reduce the risk of the blade wandering or deflecting.

Additionally, consider the hardness and density of the wood you’re working with. Hardwoods like oak or maple may require slower feed rates and sharper blades to cut smoothly. It’s also important to use an appropriate blade with the right tooth configuration for the type of cut you’re making, whether it’s resawing, cross-cutting, or ripping.

In conclusion, a 9 bandsaw can cut wood up to 9 inches in width, but the thickness of the wood will depend on factors such as the power of the machine, the tension of the blade, and the type of cut you’re making. It’s always a good idea to consult the manufacturer’s guidelines and experiment with different blades and techniques to achieve the desired results. Happy woodworking!

Choosing the Right Bandsaw for Your Woodworking Needs

When it comes to woodworking, having the right tools can make all the difference. One essential tool for any woodworker is a bandsaw. Bandsaws come in various sizes and configurations, but choosing the right one for your needs can be a daunting task. In this section, we’ll explore the factors to consider when selecting a bandsaw and provide some tips to help you make an informed decision.

Throat Depth and Cutting Capacity

One of the first considerations when choosing a bandsaw is the throat depth, which determines the width of the wood you can cut. Throat depth is measured from the blade to the vertical frame of the saw. Common throat depths range from 9 inches for benchtop models to 24 inches for larger, floor-standing bandsaws.

In addition to throat depth, you should also consider the cutting capacity of the bandsaw. This refers to the thickness of the wood the machine can handle. The cutting capacity is determined by the power of the motor, the tension of the blade, and other factors. It’s important to choose a bandsaw with a cutting capacity that aligns with your intended woodworking projects.

Motor Power and Speed Options

The power of the bandsaw’s motor is another crucial factor to consider. More powerful motors can handle thicker and harder types of wood, making them suitable for heavy-duty cutting tasks. Motor power is typically measured in horsepower (HP), with higher HP ratings providing greater cutting capacity.

Another aspect related to the motor is the speed options available on the bandsaw. Variable speed control allows you to adjust the blade speed according to the type of wood and cut you’re making. Slower speeds are ideal for harder woods, while faster speeds work well for softer materials. Having this flexibility can greatly enhance the versatility of your bandsaw.

Additional Features and Accessories

When choosing a bandsaw, it’s worth considering the additional features and accessories that come with the machine. Some bandsaws offer tilting tables, which allow for bevel cuts at various angles. This can be particularly useful for creating angled cuts or chamfers. Another feature to look for is a built-in dust collection system, which helps keep your workspace clean and free from sawdust.

Furthermore, consider the availability and cost of replacement blades for the bandsaw you’re considering. Blades wear out over time and will need to be replaced, so it’s important to choose a bandsaw that has readily available and affordable blade options.

In conclusion, when choosing a bandsaw, consider factors such as throat depth, cutting capacity, motor power, speed options, additional features, and available accessories. By taking these factors into account, you can find the right bandsaw for your woodworking needs and enjoy clean and accurate cuts. Happy sawing!

Maintaining and Troubleshooting Your Bandsaw

To get optimal performance and longevity out of your bandsaw, regular maintenance is essential. By taking proper care of your machine and troubleshooting any issues that arise, you can ensure that it continues to perform at its best. In this section, we’ll cover some maintenance tips and common troubleshooting techniques for bandsaws.

Maintenance Tips

Regular cleaning and lubrication are crucial for keeping your bandsaw in good working condition. Remove sawdust and debris from the blade, guides, and other parts of the machine after each use. Use a brush or compressed air to remove dust from hard-to-reach areas. Lubricate the blade and moving parts according to the manufacturer’s recommendations.

Additionally, regularly check the tension and alignment of the blade. Adjust the tension as needed to ensure proper blade performance and reduce the risk of breakage. Align the blade with the guides to ensure accurate and precise cuts. It’s also a good idea to periodically inspect the condition of the blade for any signs of wear or damage and replace it if necessary.

Troubleshooting Common Issues

If you encounter any problems while using your bandsaw, here are some common troubleshooting techniques:

1. Blade Drift: Blade drift occurs when the blade veers off course during a cut. To correct this, adjust the guides to align the blade parallel to the fence or miter gauge. You can also try adjusting the tension and tracking of the blade.

2. Excessive Vibration: If your bandsaw vibrates excessively, check for loose bolts, nuts, or other parts. Tighten as necessary. Uneven or damaged tires may also cause vibration, so inspect them for wear or damage and replace if needed.

3. Uneven Cuts: If your cuts are coming out uneven, make sure the blade is properly tensioned and aligned. Check if the blade is dull or damaged and replace if necessary. It’s also important to feed the wood at a consistent rate to maintain smooth and even cuts.

Remember to consult your bandsaw’s instruction manual for specific troubleshooting steps and maintenance guidelines tailored to your machine.

In conclusion, regular maintenance, including cleaning, lubrication, and blade tensioning, is essential to keep your bandsaw in optimal condition. By troubleshooting common issues and taking appropriate measures, you can ensure that your bandsaw continues to perform well and provide clean and accurate cuts for years to come. Happy sawing!

Key Takeaways: How Thick of Wood Can a 9 Bandsaw Cut?

- A 9 bandsaw is a powerful tool used for cutting wood.

- The thickness of wood that a 9 bandsaw can cut depends on the size and power of the bandsaw.

- Generally, a 9 bandsaw can cut wood up to 8-10 inches thick.

- However, it’s important to consider the type of wood and the blade being used, as different materials may require different settings.

- Always consult the manufacturer’s guidelines and safety instructions to ensure proper usage and to prevent damage or accidents.

Frequently Asked Questions

Welcome to our FAQ section where we answer commonly asked questions about the cutting capacity of a 9 bandsaw. If you’re curious about the maximum thickness of wood this tool can handle, you’ve come to the right place! Read on to get all the details you need.

1. Can a 9 bandsaw cut through thick hardwood?

Absolutely! A 9 bandsaw is designed to handle thick hardwood with ease. With a powerful motor and a sturdy frame, it can effortlessly slice through dense woods like oak, maple, and walnut. Whether you’re working on furniture projects or crafting intricate wooden designs, a 9 bandsaw will be up to the task.

It’s important to note that the specific cutting capacity may vary slightly depending on the brand and model of the bandsaw you’re using. Be sure to check the manufacturer’s guidelines for the maximum thickness of wood recommended for your particular machine.

2. What is the typical maximum cutting thickness of a 9 bandsaw?

The typical maximum cutting thickness of a 9 bandsaw is around 8 to 10 inches. This means it can easily handle boards or logs that are up to 8 to 10 inches thick. However, it’s always a good idea to leave some extra room for safety and smooth operation.

If you need to cut thicker pieces of wood, you may need to consider a larger bandsaw with a higher cutting capacity. But for most woodworking projects, a 9 bandsaw will provide more than enough cutting power.

3. Can a 9 bandsaw cut through plywood and other sheet materials?

Yes, a 9 bandsaw is capable of cutting through plywood and other sheet materials effectively. Thanks to its versatility, this tool allows you to effortlessly cut straight lines, curves, and intricate shapes in thin materials like plywood, MDF, and particleboard. Just make sure to use the appropriate blade for clean and accurate cuts.

However, it’s important to note that a bandsaw is primarily designed for cutting solid wood, so if you primarily work with sheet materials and need precise cuts, you may want to consider a different type of saw, such as a table saw or a circular saw.

4. Can a 9 bandsaw cut other materials apart from wood?

While a 9 bandsaw is primarily designed for cutting wood, it can also handle certain non-ferrous metals, plastics, and other materials. However, it’s essential to use the appropriate blade for each specific material you’re working with. For non-wood materials, a metal-cutting blade or a specialized blade designed for plastics would be required.

Keep in mind that cutting materials other than wood may require slower feed rates, different blade settings, and additional precautions. Always consult the manufacturer’s recommendations and guidelines before attempting to cut non-wood materials with your bandsaw.

5. What are the safety considerations when using a 9 bandsaw?

When using a 9 bandsaw, it’s crucial to prioritize safety. Here are a few key safety considerations to keep in mind:

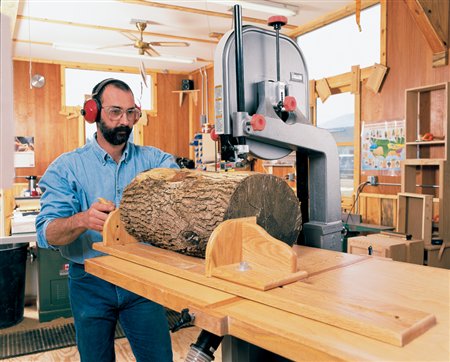

First, always wear appropriate personal protective equipment, including safety glasses or goggles and ear protection. This will protect you from potential flying debris and excessive noise.

Second, ensure that the blade is properly tensioned and aligned, and the blade guards are in place. Regularly inspect the bandsaw for any signs of damage or wear, and never operate the machine if it’s not in optimal condition.

Lastly, when cutting, maintain a steady feed rate and avoid forcing the wood through the blade. Let the bandsaw do the work, and always keep your hands a safe distance away from the blade. Remember, safety should be your number one priority when working with any power tool.

Summary

So, to sum it all up, a 9 bandsaw can cut wood that is around 9 inches thick. But it’s important to remember that the actual cutting capacity may vary based on the specific bandsaw model and the type of wood being cut. It’s always a good idea to refer to the manufacturer’s guidelines for the maximum cutting capacity.

When it comes to choosing the right bandsaw for your woodworking projects, consider the size and thickness of the wood you’ll be working with. A bandsaw with a larger cutting capacity is better for thick pieces of wood, while a smaller bandsaw may be suitable for thinner materials. Always prioritize safety and follow proper procedures when using any power tool, including a bandsaw.