If you’re wondering “how thin can Dewalt planer go?” you’ve come to the right place!

In this article, we’ll explore the capabilities of Dewalt planers and uncover the answer to this question.

Whether you’re a woodworking enthusiast or just curious about planers, let’s dive in and find out!

Dewalt planers are powerful tools that can handle a variety of tasks with ease.

From smoothing rough lumber to creating precise thicknesses, these planers are a valuable addition to any workshop.

But just how thin can they go? That’s what we’re here to discover.

So, get ready to explore the possibilities and unleash your creativity with a Dewalt planer. Let’s get started!

Dewalt planers have impressive capabilities when it comes to thickness. These power tools can plane wood down to incredibly thin dimensions, allowing for precision and fine woodworking projects. With their adjustable depth settings, Dewalt planers can typically go as thin as 1/16 of an inch, depending on the specific model. So, whether you’re working on delicate trim or intricate designs, Dewalt planers can help you achieve the precise thickness you need for your woodworking projects.

How Thin Can Dewalt Planer Go? Exploring the Limits of Dewalt Planers

Dewalt planers are renowned for their precision and versatility in woodworking projects. Whether you’re a professional carpenter or a hobbyist, having the ability to cut thin, precise pieces of wood is essential. But how thin can Dewalt planers go? In this article, we will delve into the world of Dewalt planers and explore their capabilities when it comes to making thin cuts. From the technical specifications to practical tips, we’ll cover everything you need to know about achieving those ultra-thin cuts.

The Technical Capabilities of Dewalt Planers

Dewalt planers, like the popular DW735 and DW734 models, are designed to handle a wide range of woodworking tasks, including cutting thin boards. These planers come equipped with powerful motors and adjustable depth settings, allowing you to customize the thickness of your cuts. The specific capabilities of the planer will depend on the model you choose, but most Dewalt planers can achieve cuts as thin as 1/8 of an inch or even thinner.

When using a Dewalt planer to cut thin pieces of wood, it’s crucial to take certain factors into consideration. Firstly, ensure that the blades of your planer are sharp and properly aligned. Dull or misaligned blades can result in rough cuts and tear-out, which can ruin the appearance of your thin boards. Additionally, adjusting the feed rate and depth settings of the planer can help achieve smoother and more precise cuts. Experimenting with different settings and practicing on scrap pieces of wood can help you find the optimal configuration for cutting thin boards with your Dewalt planer.

Tips for Achieving Thin Cuts with Dewalt Planers

While Dewalt planers are capable of cutting thin boards, there are a few tips and techniques that can help you achieve even better results. Here are some handy tips to keep in mind when working with your Dewalt planer:

1. Use a backing board: When planing thin boards, it’s common for the wood to splinter or tear-out along the edges. To prevent this, place a sacrificial backing board behind the workpiece. This will provide support and minimize the risk of tear-out.

2. Take shallow passes: Instead of trying to remove a large amount of material in one pass, make multiple shallow passes. This will reduce the strain on the planer and result in smoother, more precise cuts.

3. Use a high-quality blade: Investing in a high-quality blade for your Dewalt planer can significantly improve the quality of your cuts. Look for blades with carbide tips, as they are more durable and provide cleaner cuts.

4. Secure the workpiece: Ensure that the workpiece is securely fastened to the planer’s bed to prevent any movement or vibrations during the cutting process. This will help maintain the accuracy and precision of your cuts.

By following these tips and understanding the technical capabilities of your Dewalt planer, you can confidently tackle projects that require thin cuts with ease. However, it’s crucial to always prioritize safety and wear appropriate protective gear when using power tools.

Dewalt Planer vs. Other Planer Brands: A Comparison

When it comes to choosing a planer, Dewalt is not the only player in the market. There are several other reputable brands that offer planers with similar capabilities. Let’s compare Dewalt planers with some of the other popular planer brands to help you make an informed decision.

Dewalt Planer vs. Makita Planer: Which is Better?

Dewalt and Makita are two well-known brands in the power tool industry, each with their own line of planers. Both brands have their strengths and weaknesses, so it’s essential to consider your specific needs and preferences when choosing between them.

Dewalt planers are widely lauded for their robust construction and powerful motors. They are often favored by professionals who prioritize durability and performance. On the other hand, Makita planers are known for their compact design and lightweight nature, making them a popular choice among DIY enthusiasts or those who need a portable planer.

In terms of cutting capacity, both Dewalt and Makita planers are capable of achieving thin cuts. However, Dewalt planers usually offer larger cutting widths, while Makita planers may have more precise depth adjustment mechanisms.

Ultimately, the choice between Dewalt and Makita planers depends on your specific requirements, budget, and personal preference. It’s essential to research and read reviews to make an informed decision.

Dewalt Planer vs. Bosch Planer: Which Should You Choose?

Bosch is another prominent brand in the power tool industry, offering a range of planers for various woodworking applications. Let’s compare Dewalt and Bosch planers to help you decide which one is right for you.

Dewalt planers are known for their robustness and durability, making them an excellent choice for heavy-duty projects. They are equipped with powerful motors and have larger cutting capacities, allowing you to tackle larger boards with ease. On the other hand, Bosch planers are often praised for their precision and user-friendly features. They may have more advanced depth control mechanisms and additional features like chip ejection systems for smoother operations.

When it comes to cutting thin boards, both Dewalt and Bosch planers are capable of achieving precise results. However, Dewalt planers may offer a wider range of depth settings, which can be beneficial for tasks that require extremely thin cuts.

Consider your specific needs, the type of projects you’ll be working on, and your budget when choosing between Dewalt and Bosch planers. Reading customer reviews and comparing technical specifications can also provide valuable insights.

Additional Tips for Optimal Performance with Dewalt Planers

In addition to understanding the capabilities of Dewalt planers and comparing them with other brands, here are a few more tips to ensure optimal performance when working with your planer:

Regular Maintenance and Blade Sharpening

To maintain the accuracy and efficiency of your Dewalt planer, it’s crucial to perform regular maintenance and blade sharpening. Clean the planer after each use, removing any residue or debris that may hinder its performance. Additionally, inspect the blades regularly and sharpen or replace them as necessary. Dull blades can lead to poor quality cuts and strain on the motor.

Proper Safety Measures

When using a Dewalt planer or any power tool, prioritize safety. Wear appropriate protective gear, such as safety glasses, ear protection, and dust masks. Familiarize yourself with the user manual and follow all safety guidelines provided by Dewalt. It’s important to work in a well-ventilated area and secure the workpiece properly to prevent any accidents or mishaps.

Experimentation and Practice

To master the art of cutting thin boards with your Dewalt planer, practice on spare pieces of wood before attempting the final project. Experiment with different feed rates, depth settings, and techniques to find the optimal configuration for achieving the desired results. With time and experience, you’ll become more proficient in making precise, thin cuts with your Dewalt planer.

In conclusion, Dewalt planers are capable of achieving thin cuts, with some models being able to cut as thin as 1/8 of an inch or even thinner. By understanding the technical capabilities of your Dewalt planer, following helpful tips, and practicing safe usage, you can confidently tackle projects that require precision and thin cuts. Remember to compare Dewalt planers with other brands to choose the one that best suits your needs. With proper maintenance and regular blade sharpening, your Dewalt planer will continue to deliver exceptional results for your woodworking projects. Happy planing!

Key Takeaways: How Thin Can DeWalt Planers Go?

- DeWalt planers can go as thin as 1/8 of an inch.

- These planers are designed to handle thin stock, making them suitable for fine woodworking projects.

- By adjusting the depth of cut, you can control how thin the planer can go.

- It’s important to ensure the stock is securely held to avoid any accidents while planing thin pieces.

- DeWalt planers offer precision and versatility, allowing you to achieve the desired thickness for your projects.

Frequently Asked Questions

If you’re wondering about the minimum thickness a Dewalt planer can handle, you’ve come to the right place. Check out the following questions and answers to learn more about the thinness capabilities of a Dewalt planer.

1. How thin can a Dewalt planer go?

A Dewalt planer can typically handle boards as thin as 1/8 inch. However, it’s important to note that the thickness capacity may vary depending on the specific model and adjustments made to the machine. It’s always a good idea to consult the user manual or contact Dewalt directly for exact specifications on your particular planer model. Remember to take caution when planing thin boards to ensure safety and accuracy.

In certain cases, some woodworkers have reported successful planing of boards as thin as 1/16 inch with a Dewalt planer. However, it’s worth noting that planing such thin boards requires careful setup and technique to minimize any potential risks.

2. Are there any special considerations when planing thin boards?

When planing thin boards, it’s essential to make some adjustments and take extra precautions. First, ensure that the machine is properly calibrated and the blades are sharp. This will help prevent any tear-out or uneven thickness on the board. It’s also recommended to make multiple light passes instead of a single heavy pass to minimize the stress on the board and maintain control.

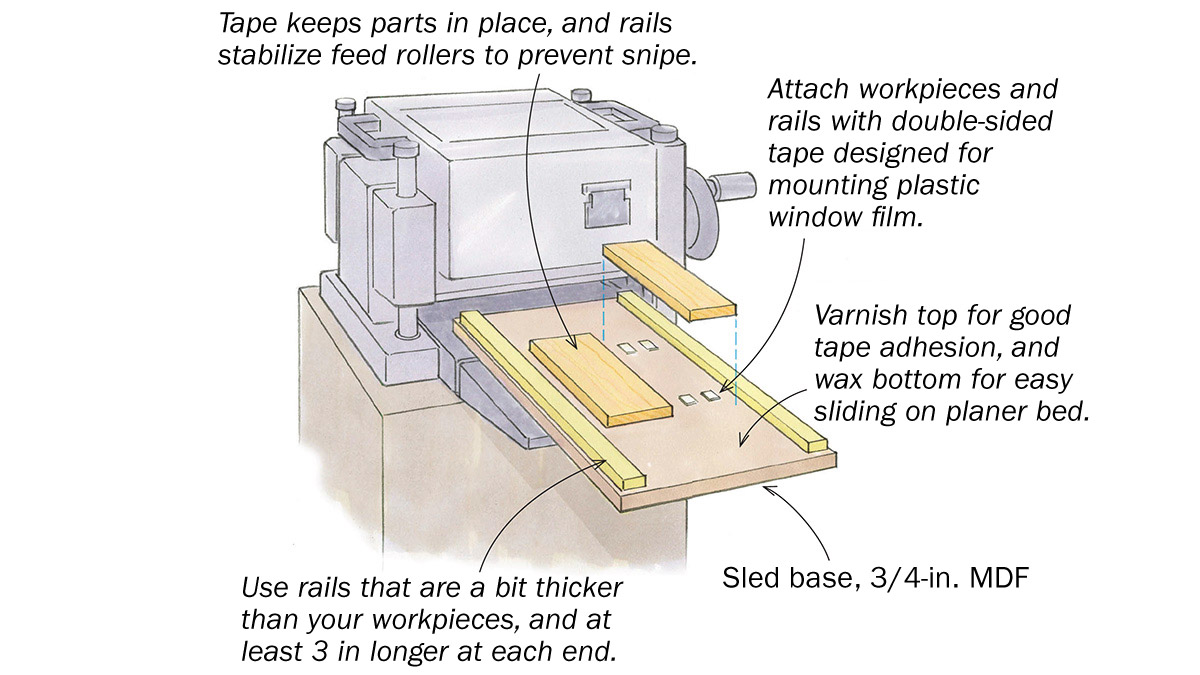

Additionally, using a planer sled or auxiliary bed can provide additional support and stability when planing thin boards. These accessories help distribute the pressure evenly across the board and reduce the risk of snipe. Always test on a scrap piece before planing your actual workpiece to ensure you achieve the desired results without damaging the material.

3. Can a Dewalt thickness planer be used for veneers?

Yes, a Dewalt thickness planer can be used for veneers, but there are a few important considerations to keep in mind. Veneers are typically very thin, and planing them can be challenging. To ensure successful planing, it’s crucial to use a sled or auxiliary bed to provide additional support and prevent any tear-out or damage to the fragile veneer.

It’s also recommended to take lighter passes and make multiple runs through the planer to gradually achieve the desired thickness. This approach helps minimize the risk of chipping or splintering, ensuring a smooth and clean finish on the veneer. As always, it’s best to practice on scrap pieces and develop the right technique before working on your actual veneer projects.

4. How does planing affect the thickness of a board?

Planing typically reduces the thickness of a board by removing material from the surface. The amount of material removed depends on the depth of cut and the number of passes made through the planer. Each pass shaves off a small amount of material until the desired thickness is achieved. It’s important to measure the board’s thickness before and after planing to ensure the desired dimensions are achieved.

It’s worth noting that planing may also result in some slight variations in thickness across the board, known as “snipe.” Snipe is more likely to occur at the beginning and end of the board. To minimize snipe, using a planer sled or making multiple passes with lighter cuts can help produce a more uniform thickness across the entire board.

5. Can a Dewalt planer be used on other materials besides wood?

While Dewalt planers are primarily designed for woodworking purposes, some models may have the capability to handle materials like plastic or certain soft metals. However, it’s crucial to refer to the manufacturer’s specifications and guidelines for your specific planer model.

Using a planer on materials other than wood may require specialized blades or accessories. It’s important to exercise caution and consider the properties of the material you’re working with to avoid damage to the planer or the material itself. Whenever in doubt, consult the user manual or contact Dewalt directly for guidance on using your planer on different materials.

Summary

The Dewalt planer is a handy tool that helps to make wood surfaces smooth. It has different thickness settings, which allow you to choose how thin you want the wood to be. The lower the number on the planer, the thinner the wood will be. However, there is a limit to how thin the Dewalt planer can go. It is important to follow the instructions and not force the planer to go below its recommended thickness setting. Doing so could cause damage to the tool and result in an unsafe working environment. Remember to always prioritize safety when using any power tool, including the Dewalt planer.

In conclusion, the Dewalt planer can make wood surfaces smooth and has adjustable thickness settings. However, it is important to use it within its recommended limits to avoid damage or accidents. Be safe and happy planing!