Are you wondering how tight you should tighten a bandsaw blade? Well, you’ve come to the right place! In this article, we’ll explore the perfect tension for your bandsaw blade and why it’s crucial for optimal performance. So, buckle up and get ready to learn some cool tips about bandsaws!

When it comes to bandsaw blades, finding the right tension is like finding the perfect fit for your favorite pair of shoes. Just like a loose shoe can make walking uncomfortable, a loosely tensioned bandsaw blade can result in poor cutting performance. On the other hand, if you tighten the blade too much, you might end up snapping it like a twig! So, strike a balance and achieve that sweet spot.

But how do you know when your bandsaw blade is tightly tensioned enough? Well, we’ve got you covered! In this article, we’ll delve into the signs that indicate your bandsaw blade is properly tightened, as well as the step-by-step process to achieve that Goldilocks tension. So, let’s dive in and unravel the secrets of bandsaw blade tensioning!

Remember, finding the right tension for your bandsaw blade is essential for precise cuts and a smooth woodworking experience. Stick around as we walk you through the process and equip you with the knowledge to achieve the perfect balance. Get ready to level up your bandsaw skills and make your woodworking projects shine!

- Ensure the bandsaw is turned off and unplugged for safety.

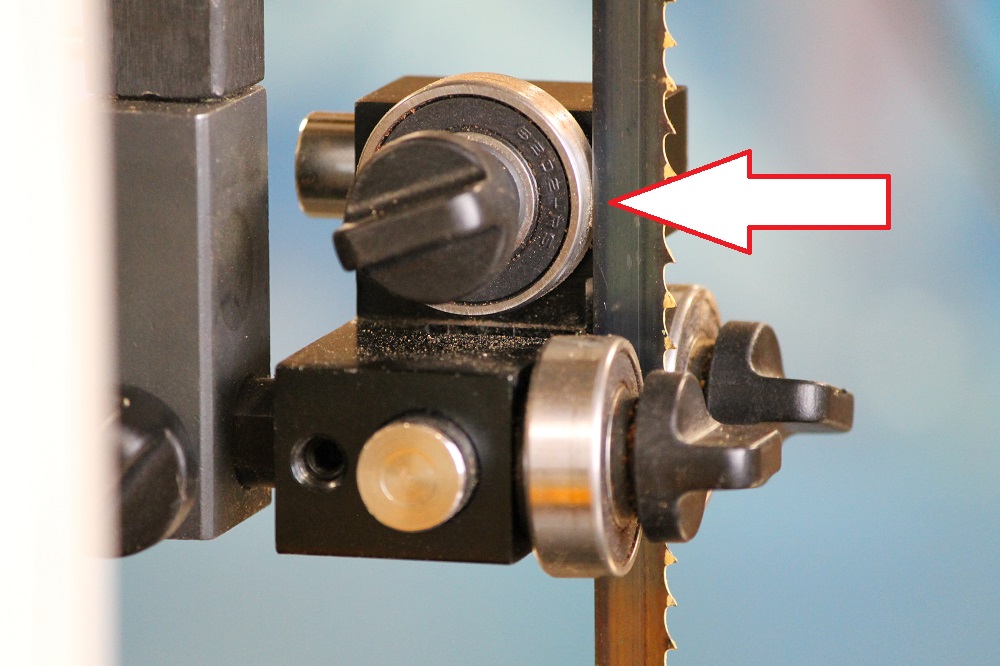

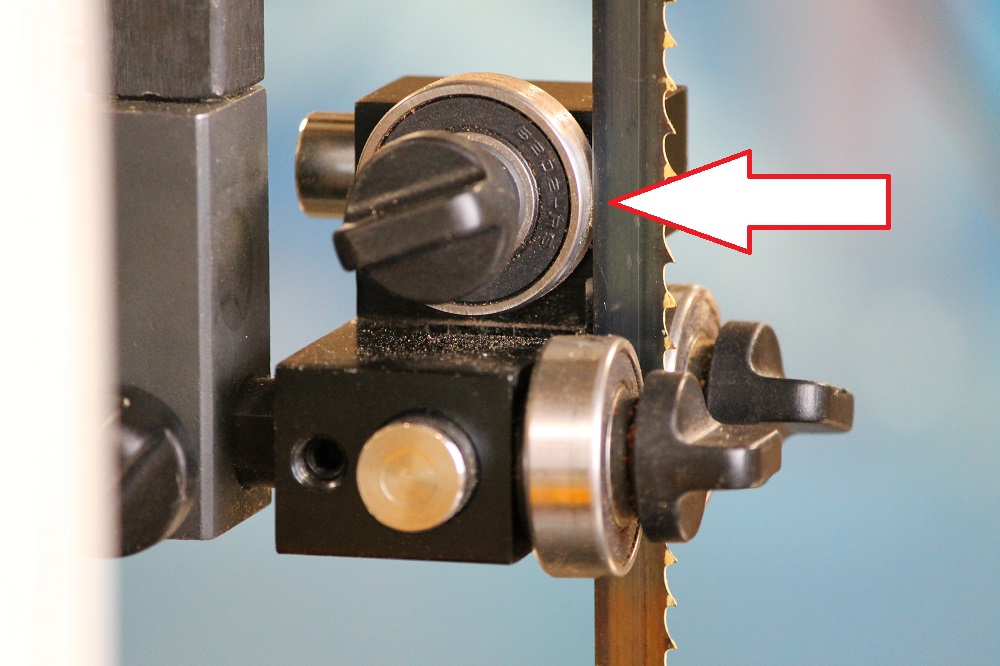

- Loosen the tension on the blade using the tensioning knob or lever.

- Place your fingers on the blade, about 1-2 inches from the edge of the bandsaw wheels, and push it down slightly.

- Tighten the blade by adjusting the tensioning knob or lever until it feels firm, but not overly tight.

- Check the tension by plucking the blade like a guitar string. It should produce a clear, even sound.

Remember to always consult your bandsaw’s manual for specific instructions.

How Tight Do You Tighten a Bandsaw Blade? The Ultimate Guide

Have you ever wondered how tight you should tighten a bandsaw blade? This question is common among both hobbyist woodworkers and professionals alike. The tension in a bandsaw blade plays a crucial role in the overall performance and longevity of the blade. In this comprehensive guide, we will delve into the details of how to properly tighten a bandsaw blade to ensure optimal cutting results and extend the life of your blade.

The Importance of Correct Blade Tension

When it comes to bandsaw blades, proper tension is key. A blade that is too loose will result in poor cutting performance, deflection, and blade fatigue. On the other hand, overtightening the blade can lead to an increased risk of blade breakage, excessive wear on the blade, and unnecessary strain on the bandsaw’s motor and components. Finding the perfect balance is essential to achieving clean, accurate cuts and maximizing the lifespan of your bandsaw blade.

Understanding Blade Tension Indicators

Most modern bandsaws come equipped with a blade tension indicator, typically in the form of a gauge or meter. This indicator provides a visual representation of the blade’s tension, allowing you to adjust it accordingly. It is crucial to note that different bandsaw manufacturers may have slightly different tension recommendations, so consult your bandsaw’s manual for specific guidelines. As a general rule, however, most bandsaws require a tension range of 15,000 to 20,000 psi (pounds per square inch).

When using the tension indicator, it is important to ensure that the blade tension is within the manufacturer’s recommended range. Tightening the blade beyond the recommended limit can lead to premature wear and potential damage to the bandsaw. Conversely, insufficient tension can result in poor cutting performance and an increased risk of blade failure.

Methods for Adjusting Blade Tension

There are several methods for adjusting the tension of a bandsaw blade. The most common method involves using the blade tension knob or wheel located on the bandsaw’s frame. This knob allows you to increase or decrease the tension by turning it clockwise or counterclockwise, respectively. It is crucial to make small adjustments and regularly check the tension with the blade tension indicator to ensure accurate results.

Another method is to pluck the blade while it is installed on the bandsaw. Plucking the blade produces an audible sound that can indicate whether the tension is too loose or too tight. A properly tensioned blade will produce a clear, crisp sound. If the blade sounds dull or flat, it may be too loose, while a high-pitched or ping-like sound could indicate overtightening.

Some bandsaw manufacturers also provide tensioning recommendations based on the blade’s deflection. By carefully observing the amount of deflection in the blade when applying pressure to the side, you can adjust the tension accordingly. Again, consult your bandsaw’s manual for specific guidelines on deflection-based tensioning.

Factors That Affect Blade Tension

Now that we have covered the basics of blade tension, let’s explore some factors that can affect the ideal tension for your bandsaw blades.

Blade Width

The width of the bandsaw blade can impact the required tension. Narrow blades generally require higher tension to prevent twisting and wandering during cuts, while wider blades can often be tensioned at a lower level without sacrificing stability or cutting performance. Consult your blade manufacturer’s recommendations for the ideal tension range based on blade width.

Blade Material

Different blade materials, such as carbon steel, bi-metal, or carbide-tipped, have varying properties that can affect tension requirements. Carbon steel blades, for example, may require less tension compared to bi-metal blades due to their inherent flexibility. Always refer to the blade manufacturer’s guidelines to determine the optimal tension for your specific blade material.

Cutting Application

The type of material you are cutting also plays a role in determining the ideal blade tension. Harder materials, such as hardwoods or metals, may require higher tension to maintain cutting accuracy and prevent blade deflection. Softer materials, like softwoods or plastics, may require less tension to achieve optimal results.

Bandsaw Size

The size and power of your bandsaw can impact the required tension. Larger bandsaws typically require higher tension due to their longer blade length and higher cutting capacities. Conversely, smaller bandsaws with shorter blades may require less tension. Always adhere to your bandsaw manufacturer’s guidelines for tension recommendations based on the specific model.

Blade Condition

The condition of your bandsaw blade can also affect tension requirements. A new blade may require initial adjustments before settling into its optimal tension range. Similarly, a blade that has been resharpened or repaired may require readjustment. Regularly inspect your blade for signs of wear, damage, or fatigue and adjust the tension as needed.

Environmental Factors

Lastly, environmental factors such as temperature and humidity can influence blade tension. Changes in temperature can cause the blade to expand or contract, affecting its tension. Similarly, fluctuations in humidity can impact the moisture content of the wood being cut, which may require slight adjustments to blade tension. Be mindful of these factors and make necessary adjustments when working in extreme conditions.

Ensuring Safe and Effective Tensioning

Properly tensioning your bandsaw blade not only ensures optimal cutting results but also enhances the safety of your woodworking projects. Follow these tips to ensure safe and effective tensioning:

Regularly Inspect Blade

Inspect your bandsaw blade before each use for signs of wear, damage, or fatigue. Replace any blades that show signs of wear or damage to prevent potential accidents.

Tighten Gradually

When tensioning the blade, make small adjustments and tighten gradually. Check the tension frequently with the blade tension indicator to ensure accurate and safe results.

Consult Manufacturer’s Guidelines

Always refer to your bandsaw and blade manufacturer’s guidelines for proper tensioning recommendations. These guidelines are specific to your equipment and will ensure optimal performance and longevity.

Use Personal Protective Equipment

When working with a bandsaw, always wear appropriate personal protective equipment, including safety glasses, hearing protection, and protective clothing. Safety should always be a top priority in the workshop.

Remember, proper tensioning of your bandsaw blade is essential for achieving clean, accurate cuts and prolonging the life of your blade. By understanding the principles of blade tension, adjusting it based on the factors mentioned above, and following recommended safety practices, you can achieve the best results with your bandsaw. Happy woodworking!

Key Takeaways: How Tight Do You Tighten a Bandsaw Blade?

- Tightening the bandsaw blade to the correct tension is crucial for optimal performance.

- To achieve the right tension, start by loosening the tension knob or adjusting the tension lever.

- Place a small amount of pressure on the blade with your hand and tighten the knob or lever gradually.

- Check the tension by plucking the blade like a guitar string; it should produce a clear, high-pitched sound.

- Remember not to overtighten the blade, as excessive tension can lead to blade breakage and equipment damage.

Frequently Asked Questions

Welcome to our FAQ section, where we answer some common questions about tightening a bandsaw blade. Whether you’re a beginner or an experienced user, these Q&As will help you keep your bandsaw blade in optimal condition for precise and efficient cutting.

1. What is the recommended tension for a bandsaw blade?

While the ideal tension may vary depending on the specific bandsaw and blade you are using, a general guideline is to tighten the blade until it produces a clear, audible hum when plucked. This sound indicates that the blade has reached sufficient tension. It is important not to over-tighten the blade, as this can lead to premature wear or even breakage.

Additionally, some bandsaw manufacturers provide recommended tension range charts based on blade width. These charts can serve as a useful reference point when determining the appropriate tension for your blade.

2. How do I know if my bandsaw blade is too loose?

If your bandsaw blade is too loose, you may encounter several issues. One common problem is poor cutting performance. The blade may drift or wander while cutting, resulting in inaccurate and uneven cuts. Another sign of a loose blade is excessive vibration, which can lead to a decrease in cutting efficiency and overall saw performance.

To check if your bandsaw blade is too loose, gently push on the side of the blade midway between the wheels. If the blade deflects more than 1/4 inch, it likely needs to be tightened. Remember, proper tension is crucial for achieving precise and clean cuts.

3. Can overtightening a bandsaw blade cause damage?

Yes, over-tightening a bandsaw blade can indeed cause damage. When a blade is excessively tightened, it becomes excessively strained, which can lead to premature wear and even breakage. Additionally, overly tight blades can cause excessive stress on the bearings, wheels, and other components of the bandsaw, potentially leading to costly repairs.

To avoid over-tightening, follow the manufacturer’s recommendations for tension or refer to tension range charts if available. Remember, finding the right balance between proper tension and avoiding excessive strain is essential for maximizing the performance and lifespan of your bandsaw blade.

4. How often should I check and adjust the tension of my bandsaw blade?

It is recommended to check and adjust the tension of your bandsaw blade before each use or at least once a day if you use the bandsaw regularly. Keeping the blade properly tensioned ensures consistent cutting results and prolongs the lifespan of the blade.

However, it’s important to note that temperature changes and different blade types may require more frequent tension adjustments. For example, during colder weather, the blade may shrink, causing a decrease in tension, while in hotter conditions, it may expand, leading to increased tension. Monitoring the tension regularly and making adjustments as needed will help maintain optimal performance.

5. Are there any additional tips for properly tightening a bandsaw blade?

Absolutely! Here are a few tips to help you properly tighten your bandsaw blade:

– Before tightening, make sure the bandsaw is turned off and unplugged for safety.

– Use a blade tension gauge to achieve accurate and consistent tension.

– Check the blade for any signs of damage, such as cracks or missing teeth, before tightening.

– Make sure the blade is correctly seated in the blade guides and properly aligned on the wheels.

– Gradually increase the tension while listening for the audible hum, ensuring the blade is evenly tensioned along its length.

Following these tips and guidelines will help you maintain optimal blade tension for smooth, precise, and efficient cuts with your bandsaw.

How To Tension Your Bandsaw Blade Correctly – WOOD magazine

Summary

So, to sum it up, when it comes to tightening a bandsaw blade, there are a few key things to keep in mind. First, you want the blade to be tight enough to avoid any wobbling or slipping, but not so tight that it damages the saw or the blade itself. A general rule of thumb is to have about 1/8 to 1/4 inch of deflection when pressing on the blade with your finger. Remember to check the tension regularly and adjust as needed. Also, make sure to follow the manufacturer’s guidelines for your specific bandsaw model.

Another important point is to ensure that the blade is properly centered on the wheels. This helps to prevent unnecessary wear and tear and promotes smooth, accurate cuts. You can do this by adjusting the tracking knob or using a tracking gauge if your bandsaw has one. Lastly, take your time and be patient when tightening the blade. It may require a bit of trial and error to find the perfect tension, but with practice, you’ll get the hang of it.