How wide can a table saw cut? If you’re curious about the cutting capacity of this powerful tool, you’ve come to the right place. Table saws are essential for woodworking projects, allowing you to make precise cuts with ease. Whether you’re a beginner or a seasoned DIY enthusiast, understanding the cutting width of a table saw is crucial for planning and executing your projects effectively. So let’s dive in and explore the fascinating world of table saws!

Picture this: you’ve got a beautiful piece of wood ready to be transformed into a work of art. You need to make a clean, straight cut, but you’re unsure if your table saw can handle the width. Well, fear not! Table saws are designed to cut various widths, depending on their size and specifications. From compact models perfect for small-scale projects to larger, more robust machines for professional use, table saws come in a range of cutting capacities.

Now, you might be wondering, what factors determine the maximum cutting width of a table saw? It’s a great question! The cutting capacity of a table saw is primarily influenced by its blade diameter and the distance between the blade and the right-side rip fence. While blade diameter plays a significant role, the rip fence is equally important as it determines the width of material that can be safely cut. It’s essential to check the manufacturer’s guidelines to ensure you’re aware of the specific cutting dimensions for your table saw.

So, no matter what project you’re tackling, understanding how wide a table saw can cut is crucial for successful woodworking endeavors. From crafting intricate furniture pieces to building sturdy wooden structures, the cutting capacity of a table saw will help you achieve precise, professional-looking results. Now that we’ve covered the basics, let’s delve deeper into the world of table saws and discover their incredible capabilities! Get your safety goggles on, grab your measuring tape, and let’s explore the wide and wonderful world of table saws!

How Wide Can a Table Saw Cut?

A table saw is a powerful tool that allows for precise and accurate cuts in various materials. But have you ever wondered how wide a table saw can actually cut? In this article, we will delve into the capabilities of table saws and explore the factors that determine their maximum cutting width. Whether you are a professional woodworker or an avid DIY enthusiast, understanding the limitations of a table saw will help you make informed decisions and achieve the desired results in your projects.

The Anatomy of a Table Saw

Before we delve into the specifics of how wide a table saw can cut, it’s important to understand its basic anatomy. A typical table saw consists of a flat, horizontal surface called the table or workbench, a circular saw blade that protrudes through the surface, and a motor that drives the blade. The blade height can usually be adjusted to control the depth of the cut, and there is a fence that can be adjusted parallel to the blade to guide the workpiece.

With this basic understanding, let’s explore the determining factors that affect the width of cut a table saw can achieve.

Blade Diameter

The diameter of the saw blade is one of the primary factors that dictate the maximum width of cut. Table saws generally come with blades ranging from 8 to 12 inches in diameter. The larger the blade diameter, the wider the cut it can make. A 10-inch blade, which is commonly found in many table saws, can typically cut through material up to 3 inches thick, depending on the power and design of the saw. However, it’s important to note that the width of the cut may be slightly less than the blade diameter due to the width of the blade itself.

It’s worth mentioning that some table saws have interchangeable blades, allowing you to use different sizes based on your cutting requirements. However, it’s essential to consult the manufacturer’s instructions to determine the maximum cutting width for each blade size and ensure that your table saw can accommodate it.

Rip Fence Capacity

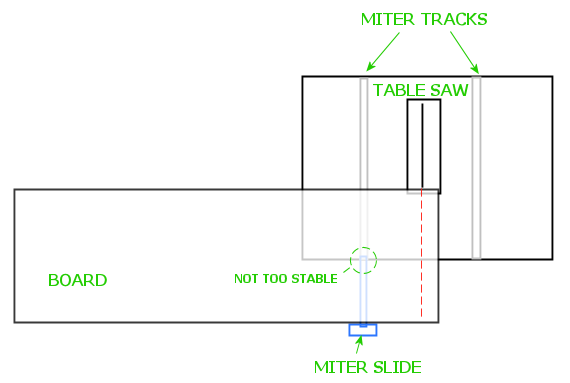

The rip fence is an essential component of a table saw that guides the workpiece during a cut. It helps maintain a consistent width and prevents the material from drifting away from the desired line. The rip fence capacity refers to the maximum distance between the blade and the fence. This capacity determines the maximum width of cut that can be achieved with the table saw.

Table saws typically offer rip fence capacities ranging from 20 to 50 inches. The wider the rip fence capacity, the broader the workpieces you can cut. However, it’s important to keep in mind that as the width of the cut increases, the stability of the workpiece becomes crucial. Proper support and positioning techniques, such as using additional supports or sleds, may be required to prevent the material from sagging or binding during the cut.

Motor Power

The power of the motor driving the saw blade also plays a role in determining the maximum width of cut. The motor’s power is typically measured in horsepower (HP) and can range from 1 to 5 HP or higher for industrial-grade table saws. A more powerful motor can handle larger workpieces and make wider cuts with ease. Additionally, a higher-powered motor is less likely to bog down or stall when cutting through hardwood or thicker materials. However, it’s important to note that the motor’s power alone is not the sole factor affecting the width of cut; the blade diameter and rip fence capacity also come into play.

Choosing the Right Table Saw

When selecting a table saw, it’s essential to consider your specific cutting needs and budget. Determine the maximum width of cut you anticipate needing for your projects. If you primarily work on smaller projects or have limited space, a table saw with a smaller blade diameter and rip fence capacity may be sufficient. However, if you frequently work with larger materials or need the ability to make wider cuts, investing in a table saw with a larger blade diameter and wider rip fence capacity would be more suitable.

Additionally, consider the motor power and ensure it aligns with your cutting requirements. If you foresee working with dense or thick materials, a more powerful motor will provide smoother and more efficient cuts. Remember to always prioritize safety and follow the manufacturer’s guidelines for operating the table saw to avoid accidents and ensure optimal performance.

Maintenance and Safety Tips

Proper maintenance and safety precautions are paramount when using a table saw. Here are some essential tips to keep in mind:

1. Keep the Blade Clean and Sharp:

A clean and sharp blade ensures precise cuts and reduces the risk of kickback. Regularly clean the blade and check for any damage or dullness. Replace or sharpen the blade as needed.

2. Use a Blade Guard and Anti-Kickback Device:

Always utilize a blade guard and anti-kickback device to prevent accidents. These safety features help protect your hands and minimize the chance of material being forcefully thrown back at you during the cut.

3. Wear Appropriate Safety Gear:

Wear safety glasses, ear protection, and a dust mask to protect yourself from flying debris and noise. Avoid loose-fitting clothing or jewelry that can get caught in the saw.

4. Maintain a Clean and Organized Workspace:

Clear the table and surrounding area of any clutter or obstructions. This ensures a safe and efficient work environment, reducing the risk of accidents caused by tripping or stumbling.

5. Follow Proper Cutting Techniques:

Learn and practice proper cutting techniques, such as using the rip fence and miter gauge correctly. Ensure the workpiece is securely positioned and make slow, controlled movements while cutting.

6. Disconnect Power when Making Adjustments:

Before making any adjustments or changing blades, ensure the table saw is unplugged or the power source is turned off. This prevents accidental activation of the saw during the adjustment process.

Remember, safety should always be the top priority when operating any power tool, including a table saw. By following these maintenance and safety tips, you can create a safe, enjoyable, and productive woodworking experience.

Conclusion

Understanding the limitations and capabilities of a table saw is crucial for any woodworker or DIY enthusiast. By considering factors such as blade diameter, rip fence capacity, and motor power, you can determine the maximum width of cut achievable with your table saw. Remember to choose a table saw that aligns with your specific cutting needs and always prioritize safety by following proper maintenance and safety precautions. With the right tools and knowledge, you can confidently embark on woodworking projects and achieve precise and accurate cuts.

Key Takeaways: How Wide Can a Table Saw Cut?

When using a table saw, it is important to know the maximum width it can cut.

- Table saws can typically cut boards up to 24 inches wide.

- Some larger table saw models can handle wider cuts, up to 36 inches or more.

- It is crucial to check your specific table saw’s user manual for its maximum cutting capacity.

- Keep in mind that the width of the blade and the type of materials being cut can also affect the maximum width.

- Always ensure that the width of your material does not exceed the table saw’s cutting capacity to maintain safety and accuracy.

Frequently Asked Questions

Looking to learn more about the cutting capacity of a table saw? Check out these commonly asked questions to gain a better understanding.

What is the cutting capacity of a table saw?

The cutting capacity of a table saw refers to the maximum width a saw blade can cut through a material. This capacity is determined by the size of the table and the length of the blade. While the specific width can vary depending on the model and make of the table saw, most table saws can typically cut materials up to 25 inches wide.

However, it’s important to note that the cutting capacity may vary for different types of cuts, such as crosscuts or rip cuts. Additionally, it’s essential to consider the blade’s height adjustment capability, as it can affect the depth of the cut.

Can a table saw cut wider materials by using specialty blades?

Yes, it’s possible to cut wider materials on a table saw by utilizing specialty blades. For instance, a dado blade, which consists of two outer blades with multiple chippers in between, can create wider grooves and dado cuts by removing more material with each pass.

Another option is a thin-kerf blade, which has a narrower width, allowing it to remove less material during each cut, effectively increasing the cutting capacity. It’s important to ensure that the specialty blade is compatible with your table saw model and that you follow the manufacturer’s guidelines for safe usage.

What are the safety precautions to consider while cutting wider materials on a table saw?

When cutting wider materials on a table saw, it’s crucial to prioritize safety. First and foremost, make sure the material is properly positioned and secured on the table saw. Use clamps or other appropriate methods to prevent it from moving during the cutting process.

Additionally, check that the blade is properly aligned, sharp, and in good condition. Wearing protective gear, such as safety goggles and gloves, is essential to minimize the risk of injury from flying debris. Finally, it’s important to use a push stick or push block to keep your hands a safe distance from the blade while feeding the material through.

Are there any limitations to the cutting capacity of a table saw?

While table saws have impressive cutting capacities, there are a few limitations to keep in mind. One limitation is the depth of cut. Depending on the model, a table saw may have a maximum depth of cut, which determines how thick of a material it can effectively cut through.

Another limitation is the table size itself. Larger materials may become challenging to handle and manipulate on a smaller table. In such cases, it may be more practical to use alternative tools or consider using additional support, such as outfeed tables or roller stands, to manage larger materials.

Can I customize the cutting capacity of a table saw?

While the cutting capacity of a table saw is primarily determined by the saw’s design and specifications, certain modifications can be made to enhance its capabilities. For instance, attaching table extensions or a larger table surface can provide additional support and allow for cutting larger materials more easily.

It’s important to note that any modifications should be done carefully and in accordance with the manufacturer’s recommendations to ensure both safety and optimal performance. Consulting the owner’s manual or seeking professional assistance can help guide you in making appropriate modifications to suit your specific needs.

Summary

So, how wide can a table saw cut? Well, it depends on a few factors. Firstly, the size of the blade matters. A larger blade can cut wider, but it needs more power to do so.

Secondly, the size of the table saw itself plays a role. A bigger table saw can accommodate wider cuts, while a smaller one has its limitations.

Lastly, it’s important to consider the type of material being cut. Hardwoods may require slower, narrower cuts, while softwoods may allow for wider cuts.

To sum it up, the width of a table saw cut depends on the blade size, the table saw itself, and the type of material being cut. It’s always important to follow safety guidelines and use caution when operating a table saw.