If you’ve ever wondered how wide a circular saw cut can be, you’ve come to the right place! Today, we’re diving into the world of circular saws and exploring just how wide their cuts can go. So, if you’re ready to learn something new and exciting, let’s get started!

Now, when it comes to the width of a circular saw cut, there are a few factors to consider. The type of blade, the depth of the cut, and the material being cut all play a role in determining the width of the cut. It’s a fascinating blend of science and craftsmanship that makes each cut unique.

Whether you’re a DIY enthusiast or a budding carpenter, understanding the width of a circular saw cut is essential for your projects. This knowledge will empower you to make precise cuts and create beautiful pieces of work. So, let’s dive deeper into this intriguing topic and uncover the secrets of circular saw cuts!

The Width of a Circular Saw Cut: Exploring the Accuracy for Different Cuts

When it comes to carpentry and woodworking, a circular saw is an essential tool that offers precision and efficiency in making straight cuts. However, one common question that arises is, “How wide is a circular saw cut?” Understanding the width of a circular saw cut is crucial for achieving accurate measurements and ensuring the desired outcome of your project. In this article, we will delve into the factors that affect the width of a circular saw cut and provide you with valuable insights to improve your woodworking skills. Let’s explore!

Factors Influencing the Width of a Circular Saw Cut

Before we dive into the specific measurements of a circular saw cut, it is important to understand the various factors that can affect the width of the cut. By considering these factors, you can ensure accurate results and achieve the desired precision in your woodworking projects. Here are some of the key factors that influence the width of a circular saw cut:

The Blade Thickness

One of the primary factors that determine the width of a circular saw cut is the thickness of the blade. Different circular saw blades come with varying thicknesses, and this can greatly impact the width of the cut. Thicker blades tend to create wider cuts, while thinner blades result in narrower cuts. It is important to choose the appropriate blade thickness based on the desired width of the cut.

When selecting a circular saw blade, consider the material you will be cutting and the type of cut you want to achieve. For example, if you are working with plywood and require a fine and precise cut, a thin blade would be ideal. On the other hand, if you are cutting through thicker materials like hardwood, a thicker blade would be more suitable to ensure stability and prevent bending or wobbling.

It is also worth noting that circular saw blades come in different diameters, and this can affect the total width of the cut. Typically, the larger the diameter of the blade, the wider the cut will be. Therefore, take into account the blade diameter when determining the overall width of your cut.

The Cutting Depth

Another crucial factor that impacts the width of a circular saw cut is the cutting depth. The cutting depth refers to how deep the circular saw blade penetrates into the material being cut. By adjusting the cutting depth, you can control the width of the cut and achieve the desired measurements.

Most circular saws come with adjustable cutting depths, allowing you to set the depth according to your specific needs. By referring to the depth scale on your saw, you can adjust the cutting depth to match the requirements of your project. It is important to be precise with your cutting depth adjustments to ensure accurate and consistent results.

The Material Being Cut

The material you are cutting plays a significant role in determining the width of a circular saw cut. Different materials have varying densities and properties, which can affect how the blade cuts through them. For instance, softwoods like pine tend to be easier to cut and may result in wider cuts compared to hardwoods like oak or maple. Additionally, materials with a higher moisture content or irregular surfaces may also impact the consistency and width of the cut.

When working with different materials, it is important to consider their specific characteristics and adjust your cutting techniques accordingly. Take extra care and make test cuts on scrap pieces of the material before working on your actual project. This will allow you to make necessary adjustments and ensure the desired width of the circular saw cut.

Improving the Accuracy of Circular Saw Cuts

Now that we have discussed the factors that influence the width of a circular saw cut, let’s explore some tips and techniques to improve the accuracy and precision of your cuts:

Use a Guiding System

In order to achieve consistent and accurate cuts, it is recommended to use a guiding system. This can be in the form of a straight edge guide or a table saw fence. These guiding systems help to keep the circular saw on track, ensuring a straight and precise cut. They also provide stability and prevent the saw from deviating, resulting in a more uniform width for the cut.

Make Test Cuts

Before cutting into your actual workpiece, it is always a good idea to make test cuts on scrap materials. This allows you to familiarize yourself with the cutting depth, blade thickness, and any potential variations in the material. By making test cuts, you can adjust the settings and techniques as needed to achieve the desired width.

Maintain a Sharp Blade

A sharp blade is essential for achieving clean and accurate cuts with a circular saw. Dull blades not only result in a wider cut but also increase the risk of kickback and accidents. Regularly inspect and sharpen your circular saw blades to ensure optimal performance and precise cuts. Replace blades that are worn out or damaged, as they can affect the width and quality of your cuts.

Secure Your Workpiece

Another crucial aspect of achieving accurate cuts is to securely fasten your workpiece. This prevents the material from shifting or vibrating during the cutting process, which can affect the width and consistency of the cut. Use clamps or other suitable methods to hold the workpiece firmly in place, ensuring that it remains stable throughout the cut.

Conclusion

The width of a circular saw cut is influenced by various factors, including blade thickness, cutting depth, and the material being cut. By understanding these factors and incorporating the recommended techniques, you can enhance the accuracy and precision of your circular saw cuts. Remember to choose the appropriate blade thickness, adjust the cutting depth accordingly, and consider the characteristics of the material you are working with. Utilize guiding systems, make test cuts, maintain a sharp blade, and secure your workpiece for optimal results. With these considerations in mind, you will be able to achieve the desired width and create impressive woodworking projects.

Key Takeaways: How Wide is a Circular Saw Cut?

- A circular saw cut width is determined by the size of the saw blade.

- Most circular saw blades are 7 ¼ inches in diameter, resulting in a cut width of approximately 2 ½ inches.

- Smaller circular saw blades, like those used in trim saws, may have a cut width of around 1 ½ inches.

- The cut width can be adjusted by changing the position of the saw blade or using different blades with varying tooth configurations.

- It is important to always measure and mark the desired width before making cuts with a circular saw to ensure accuracy.

Frequently Asked Questions

Welcome to our Frequently Asked Questions page on circular saw cuts! Here you’ll find answers to commonly asked questions about the width of a circular saw cut. Take a look below to learn more.

1. What determines the width of a circular saw cut?

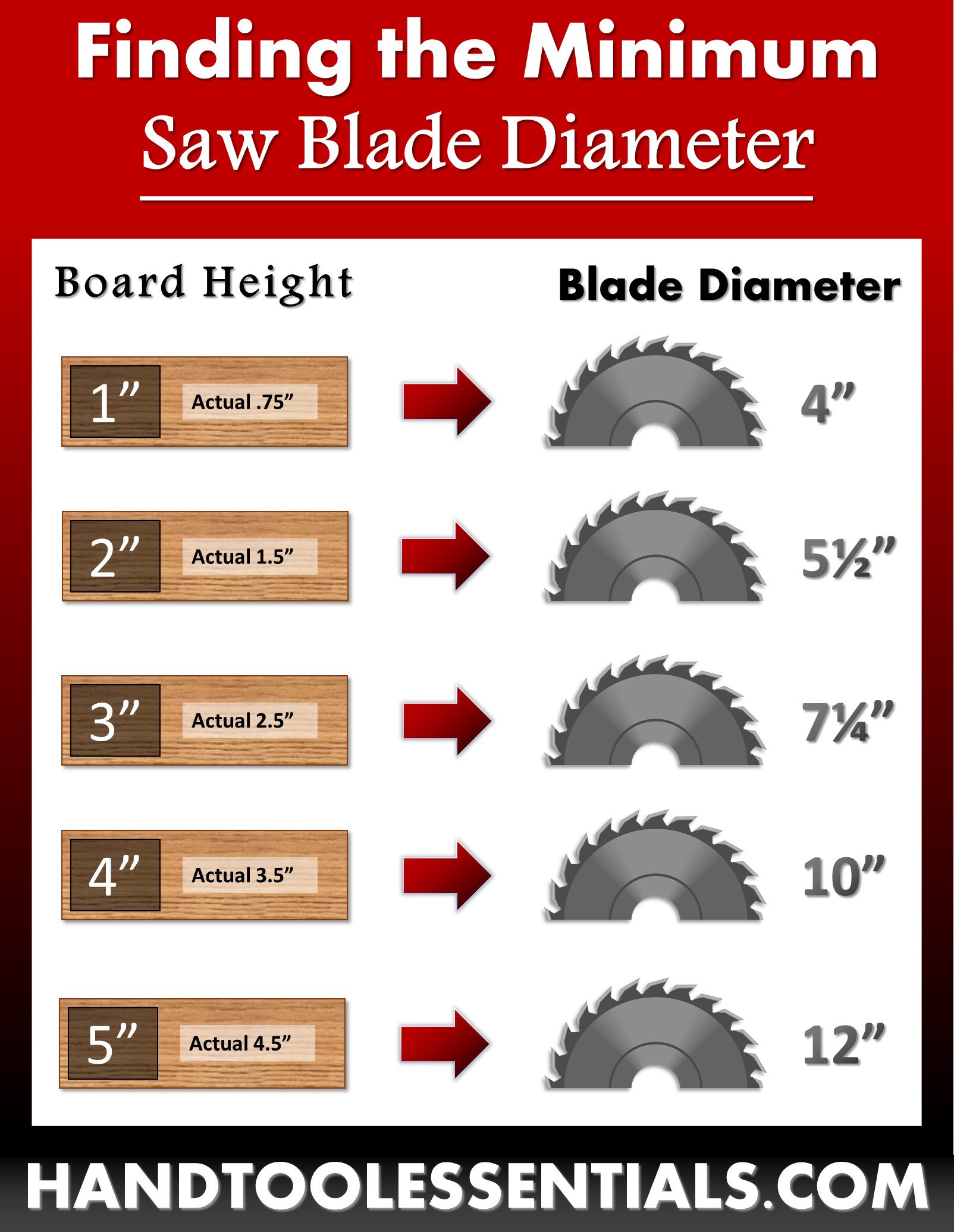

The width of a circular saw cut is primarily determined by the size of the saw blade. Circular saw blades come in different diameters, typically ranging from 4 inches to 12 inches. The larger the diameter of the blade, the wider the cut it can make. However, it’s important to note that the width of the cut can also be influenced by other factors such as the depth setting of the saw and the angle at which it is used.

Furthermore, it’s important to consider the type of material being cut. Different materials have different hardness levels, and this can impact the width of the cut. So, while the size of the blade is a significant factor, it’s not the sole determining factor for the width of the cut.

2. Can I adjust the width of a circular saw cut?

Yes, you can adjust the width of a circular saw cut to some extent. One way to modify the width is by changing the angle at which the saw is tilted. By adjusting the bevel angle, you can make angled cuts that are wider or narrower than a straight cut. Additionally, altering the depth setting of the saw can also affect the width of the cut.

However, it’s important to note that there are limits to how much you can adjust the width of a circular saw cut. The capabilities of the saw itself, including the size of the blade, will have an impact on the maximum width that can be achieved. It’s also important to follow safety guidelines and manufacturer recommendations when adjusting the settings of a circular saw to ensure proper functionality and prevent accidents.

3. What is the average width of a circular saw cut?

The average width of a circular saw cut will depend on several factors, such as the size of the blade and the material being cut. As mentioned earlier, circular saw blades come in various sizes, with common diameters ranging from 6 inches to 8 inches for standard circular saws used in woodworking and construction projects.

For these common sizes, the average width of a circular saw cut can range between approximately 1/16 inch to 1/8 inch, although this can vary depending on factors like blade sharpness, feed rate, and the hardness of the material being cut. It’s always a good idea to consult the manufacturer’s guidelines and experiment on scrap materials before making precise cuts on your project.

4. Can I make wider cuts by using multiple passes with a circular saw?

Yes, it is possible to make wider cuts by using multiple passes with a circular saw. This technique is often referred to as “plunge cutting” or “step cutting.” Instead of trying to make a single wide cut, you can make a series of narrower cuts, gradually increasing the width of the cut with each pass.

However, it is important to exercise caution when using this technique. Ensure that the saw is properly aligned and stable with each pass, and be mindful of any potential kickback or loss of control. This method may also require more time and precision, so it’s recommended for experienced users or in situations where a wider cut is necessary but alternative tools may not be available.

5. Are there specialized blades available for wider circular saw cuts?

Yes, there are specialized blades available for making wider circular saw cuts. These blades are often referred to as “dado blades” or “stacked dado sets.” Unlike standard circular saw blades, dado blades consist of multiple individual blades, shims, and chippers that can be stacked together to achieve a wider cut.

Dado blades are commonly used for making dado joints, rabbets, and other wide grooves in woodworking projects. They allow for precise and efficient cuts with widths that can be adjusted according to specific requirements. However, it’s important to note that the usage of dado blades may require additional safety precautions and a different setup procedure compared to standard circular saw blades. Always refer to the manufacturer’s guidelines when using specialized blades like dado blades.

Summary:

Circular saws can make different sized cuts depending on the blade’s diameter and the saw’s depth-of-cut adjustment. The size of the cut can range from around 2 inches to over 6 inches, so it’s important to adjust the saw for the desired cut.

A smaller blade will make a smaller cut, while a larger blade will make a wider cut. To know how wide a specific circular saw will cut, you can measure the diameter of the blade and subtract the thickness of the blade. Remember to always follow safety precautions when using power tools like circular saws.