So you’re curious about lathes, huh? Well, you’ve come to the right place! Let’s dive right in and answer the burning question on your mind: how wide is a lathe?

Lathes, my friend, come in various shapes and sizes, but their width is a key factor to consider.

Now, you might be wondering why the width of a lathe is important. Well, the width determines the size of the workpiece you can handle.

How Wide is a Lathe?

When it comes to lathes, width is an important factor to consider. The width of a lathe refers to the amount of space it occupies in a workshop or manufacturing facility. It determines the size of the workpiece that can be accommodated and the range of operations that can be performed. In this article, we will explore the various factors that determine the width of a lathe and how it can impact your machining capabilities.

Factors Affecting the Width of a Lathe

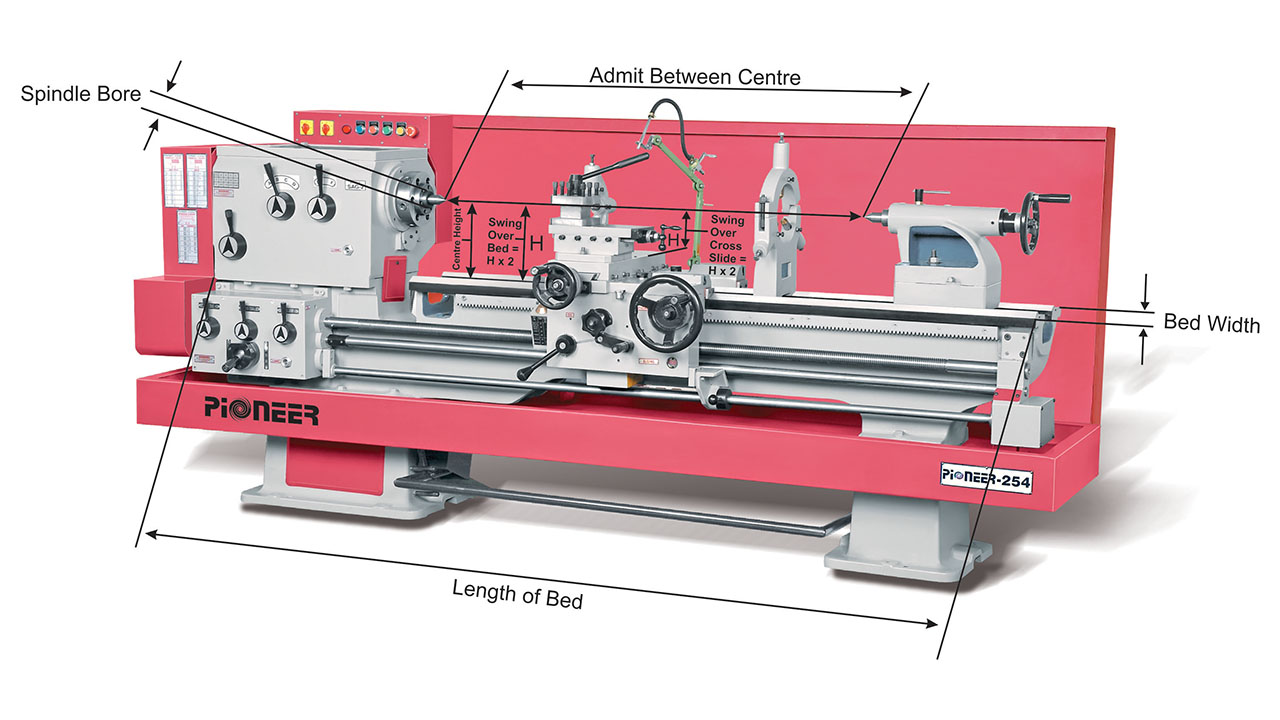

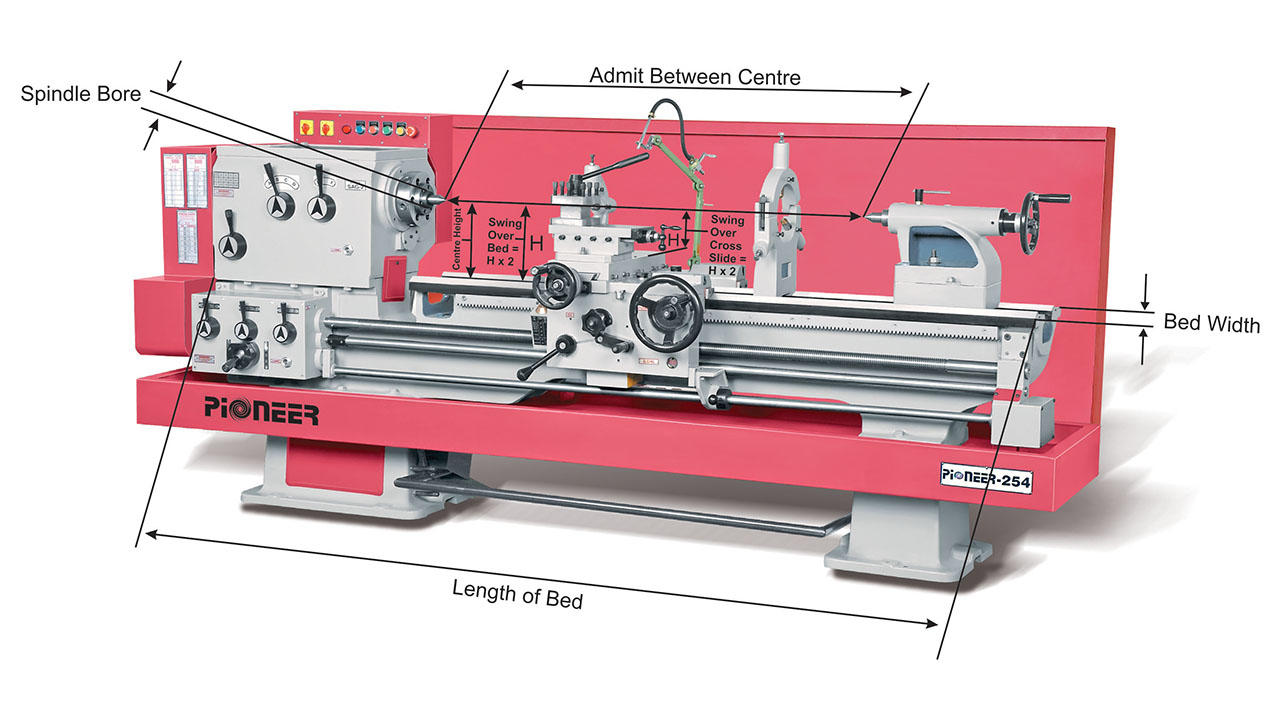

There are several factors that influence the width of a lathe. These factors include the design of the lathe bed, the swing over the bed, the distance between centers, and the specifications of the tailstock. Let’s take a closer look at each of these factors:

The Design of the Lathe Bed

The design of the lathe bed plays a crucial role in determining the width of the lathe. The bed provides a rigid and stable platform for the carriage and headstock. It needs to be wide enough to support the weight of the workpiece and the cutting forces applied during machining. Additionally, the width of the bed determines the maximum distance between centers, which affects the length of the workpiece that can be accommodated.

The swing over the bed refers to the maximum diameter of the workpiece that can be accommodated by the lathe. It is measured from the bed to the highest point of the lathe’s spindle. A larger swing over the bed indicates a wider lathe that can handle larger workpieces.

The distance between centers is the measurement from the headstock to the tailstock of the lathe. It determines the length of the workpiece that can be accommodated. A wider lathe bed usually allows for a longer distance between centers, enabling the machining of larger workpieces.

The Specifications of the Tailstock

The tailstock is an important component of a lathe that provides support to the opposite end of the workpiece. It needs to be wide enough to provide stability and prevent deflection during machining. Additionally, the width of the tailstock can impact the maximum length of the workpiece that can be accommodated by the lathe.

Furthermore, the tailstock may feature additional functionalities such as a live center or a drill chuck. These additions can affect the width of the tailstock and consequently, the overall width of the lathe.

The Overall Dimensions of the Lathe

Finally, the overall dimensions of the lathe, including the width, are determined by the manufacturer based on the intended use and the target market. Different types of lathes, such as benchtop lathes or industrial lathes, will have varying widths to meet different requirements and constraints. It is important to consider the available space in your workshop or manufacturing facility when choosing a lathe, as the width can impact its installation and accessibility.

Importance of Considering Lathe Width

The width of a lathe is an essential consideration when selecting a machine for your workshop or manufacturing facility. Here are a few reasons why it is important to consider the width of a lathe:

- Workpiece Size and Machining Capabilities: The width of a lathe determines the maximum size of the workpiece that can be accommodated. If you work with large or long workpieces, you will need a wider lathe to ensure proper machining and support.

- Space Limitations: The available space in your workshop or manufacturing facility can dictate the maximum width of the lathe you can accommodate. It is crucial to measure your space accurately and consider any constraints, such as doors or other machinery, to ensure a proper fit.

- Accessibility: A wider lathe may require more space for proper access, especially when operating or performing maintenance tasks. It is important to consider the ease of access to the lathe when determining its width.

- Future Expansion: If you anticipate future growth or an expansion of your operations, it may be wise to choose a lathe with a wider bed to accommodate larger workpieces that you may work on in the future.

Benefits of a Wider Lathe

Opting for a wider lathe can provide several benefits:

- Increased Flexibility: A wider lathe allows for a greater range of workpiece sizes, opening up opportunities for a broader range of machining operations.

- Enhanced Stability: A wider lathe bed and tailstock offer increased stability during machining, resulting in higher precision and better surface finishes.

- Improved Accessibility: A wider lathe provides more room for operators to access the workpiece and easily perform various tasks, such as tool changes and part inspection.

- Future-Proofing: By investing in a wider lathe, you are prepared for larger projects and potential future expansion, saving the need for a costly upgrade down the line.

Tips for Choosing the Right Lathe Width

Choosing the right width for your lathe can be a crucial decision. Here are a few tips to help you make an informed choice:

- Assess Your Needs: Evaluate the types of workpieces you will be machining and determine the maximum size and length requirements. This will help you determine the necessary width for your lathe.

- Consider Your Workspace: Measure the available space in your workshop or manufacturing facility and consider any constraints or obstructions that may limit the width of the lathe you can accommodate.

- Go for Versatility: If possible, choose a lathe with a wider bed and greater swing over the bed to provide flexibility and handle a broader range of workpieces.

- Keep Future Growth in Mind: If you anticipate future expansion or larger projects, opt for a wider lathe that can handle the anticipated workpiece sizes.

- Seek Expert Advice: Consult with experts or professionals in the machining industry who can provide guidance based on your specific needs and requirements.

Conclusion

When it comes to lathes, the width is a critical factor to consider. It determines the maximum size of the workpiece that can be accommodated, the range of machining operations that can be performed, and the overall accessibility and stability of the machine. By assessing your needs, considering your workspace constraints, and keeping future growth in mind, you can choose the right lathe width for your workshop or manufacturing facility. A wider lathe offers increased flexibility, stability, and accessibility, providing you with the capabilities to tackle a wider range of projects and achieve better machining results.

Key Takeaways: How Wide is a Lathe?

2. Mini-lathes, commonly used for hobbyists, can have a width of around 6 to 8 inches.

3. Industrial-sized lathes, used in large-scale manufacturing, can be as wide as several feet.

4. Benchtop lathes typically have a width ranging from 10 to 18 inches.

5. It’s important to consider the available space in your workshop when choosing a lathe.

Frequently Asked Questions

Here are some commonly asked questions about lathe width:

1. What factors determine the width of a lathe?

The width of a lathe can be determined by various factors, including the size and type of workpiece it is designed to handle. Larger lathes are generally wider and can accommodate longer and wider workpieces. Additionally, the type of lathe bed, which provides support and stability, can also affect the width of a lathe. Bed designs such as gap beds offer increased width by allowing the removal of a section in the middle.

It’s essential to consider the specific requirements of the projects you’ll be working on to determine the appropriate width of a lathe that will suit your needs. Consulting with an expert or researching the width requirements for your intended applications can help you make an informed decision.

2. Why is the width of a lathe important?

The width of a lathe is important because it determines the maximum size of workpieces that can be accommodated on the machine. If a lathe is too narrow, it may not be able to handle larger and wider workpieces, limiting your ability to work on certain projects. On the other hand, if a lathe is too wide for your needs, you may be spending unnecessary money on a larger machine with excess capacity.

Choosing a lathe with an appropriate width ensures that you can comfortably and efficiently work on a range of projects, maximizing the machine’s utility and your productivity.

3. Can the width of a lathe be adjusted?

The width of a lathe is generally fixed and cannot be easily adjusted. However, some lathes have features that allow for increased width when needed. For example, gap beds can be utilized to remove a section in the middle of the bed, effectively increasing the width for accommodating larger workpieces. This feature provides flexibility and versatility in handling workpieces of varying sizes.

It’s important to note that these adjustments may have limitations, and lathes with adjustable widths are not as common as fixed-width lathes. Therefore, it’s crucial to assess your specific requirements and choose a lathe with an appropriate width from the outset.

4. How do I measure the width of a lathe?

The width of a lathe is typically measured from the inner edge of the lathe bed to the inner edge of the opposite side. Use a measuring tape or ruler to measure this distance accurately. Make sure to align your measurement with the width of the lathe bed itself and not include any additional parts or features that might extend beyond the bed’s edges. If you are unsure, consult the lathe’s manual or contact the manufacturer for guidance on the appropriate measurement method.

By measuring the width of a lathe, you can determine its capacity and compare it to your project requirements to ensure a suitable fit.

5. What are the standard widths of lathes?

The standard widths of lathes can vary depending on the specific type and model. However, most common lathes for general-purpose machining have bed widths ranging from around 8 inches to 24 inches. Industrial lathes used for heavy-duty work may have wider beds, often exceeding 24 inches.

It’s important to note that there isn’t a one-size-fits-all width for lathes, as different applications require different capacities. Assessing your specific needs and considering the size and type of workpieces you’ll be working with will help you determine the appropriate width when choosing a lathe.

Summary

So, how wide is a lathe? Well, the width of a lathe can vary depending on its size. Larger lathes can have widths ranging from a few feet to over 10 feet. Smaller lathes, on the other hand, can be as narrow as a few inches wide. The width of a lathe is an important factor to consider when choosing the right machine for your needs.

In conclusion, the width of a lathe can vary greatly, with larger lathes being wider than smaller ones. It is crucial to take into account the width of a lathe when selecting the appropriate machine for your specific requirements.