Hey there! Are you interested in learning how to machine a square cross-section in a lathe? Well, you’ve come to the right place! In this article, we’ll dive into the process and explore all the steps involved. So let’s get started!

Imagine you have a piece of material that needs to be transformed into a square shape. But how do you accomplish that on a lathe? Don’t worry, it’s not as complicated as it sounds. With the right techniques and tools, you can achieve that perfect square cross-section.

In this guide, we’ll walk you through the process step by step, from setting up the lathe to creating the square shape using various cutting tools. By the end, you’ll have the skills and knowledge to machine a square cross-section like a pro. So let’s roll up our sleeves and dive into the fascinating world of lathe machining!

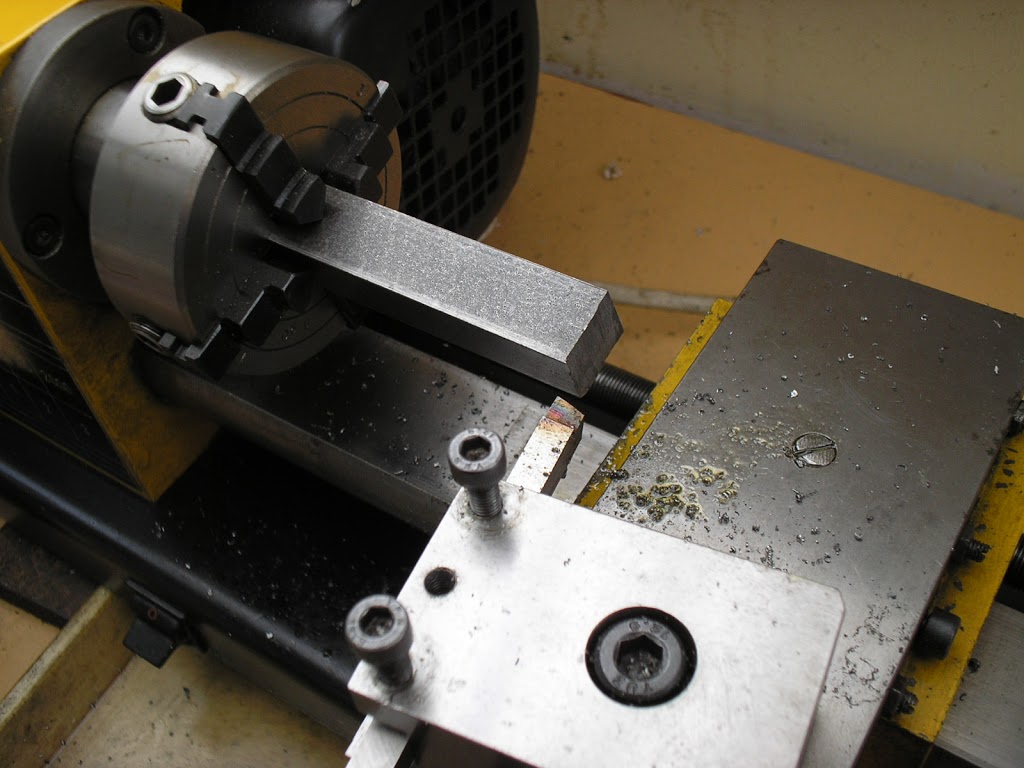

1. Start by securing a square rod in the lathe chuck.

2. Set the lathe to the desired speed and engage the cutting tool.

3. Take light cuts from all four sides of the rod, gradually forming a square cross-section.

4. Use calipers to check the dimensions and make adjustments if needed.

5. Finish with sandpaper or a file to achieve a smooth finish. Practice and patience are key to mastering this technique.

How to Machine a Square Cross-Section in Lathe: A Comprehensive Guide

Are you looking to machine a square cross-section in a lathe? This article will provide you with a step-by-step guide on how to accomplish this task. Whether you are a beginner or an experienced machinist, this guide will equip you with the necessary knowledge and techniques to successfully create a square cross-section using a lathe machine. Read on to discover the methods, tips, and tricks needed to achieve precise and accurate results.

Why Machine a Square Cross-Section in Lathe?

Before diving into the process of machining a square cross-section in a lathe, let’s first understand why you might need or want to perform this operation. Machining a square cross-section allows you to create precise and uniform components for various applications. Square profiles are commonly used in engineering, woodworking, metalworking, and other fields where straight edges and right angles are essential. By mastering this technique, you can expand your capabilities as a machinist and produce high-quality workpieces that meet specific design requirements.

1. Choosing the Right Lathe Machine and Tools

The first step in machining a square cross-section is ensuring you have the right lathe machine and tools. The type and size of the lathe machine will depend on the dimensions of your workpiece. For smaller square cross-sections, a benchtop or small-sized lathe may suffice. However, larger workpieces may require a larger lathe with more power and capacity. Additionally, make sure you have the necessary cutting tools, including a square tool bit and a parting tool.

When selecting the lathe machine, consider its spindle speed range, motor horsepower, bed length, swing capacity, and other factors that align with your project requirements. Take into account the materials you will be working with and ensure the machine’s capabilities can handle the workload. It’s also essential to have a reliable chuck or collet system to hold your workpiece securely in place during machining.

Lastly, a square tool bit and a parting tool are essential for creating the square cross-section. The square tool bit features a cutting tip with a 90-degree angle that is perfect for creating straight edges. The parting tool, on the other hand, is used to separate the workpiece from the bar stock once the machining is complete.

2. Preparing the Workpiece and Lathe Machine

Now that you have the right lathe machine and tools, it’s time to prepare your workpiece and the lathe machine itself. Start by selecting a suitable material for your project, such as aluminum, steel, or wood. Ensure that the workpiece is properly squared and free of any defects or warping. This will help you achieve precise and accurate results.

Next, set up your lathe machine by aligning the tailstock and the headstock to create a straight and level machining axis. Ensure that the tool rest is properly adjusted, allowing the cutting tools to engage with the workpiece at the desired height and angle. Securely fasten the workpiece into the chuck or collet, ensuring it is held firmly in place and that it can rotate freely without any wobbling or slippage.

Before proceeding with the machining process, it is essential to wear appropriate safety gear, such as safety glasses and gloves. Remember to adhere to all safety protocols and guidelines to prevent accidents or injuries during the machining process.

3. Machining the Square Cross-Section

Now comes the exciting part – machining the square cross-section. Follow these steps to achieve accurate and precise results:

- Step 1: Roughing Cut

- Step 2: Finishing Cut

- Step 3: Parting Off

Start by aligning the square tool bit with the workpiece’s surface. Begin with a roughing cut, which involves removing excess material to approach the desired square cross-section dimensions. Take slow and steady cuts, gradually shaping the workpiece to near the final dimensions. This stage is crucial for removing most of the material efficiently.

Once the roughing cut is complete, it’s time to perform the finishing cut. This involves making more precise and lighter cuts to achieve the final dimensions of the square cross-section. Take your time and make small adjustments to the tool rest as needed to achieve the desired depth of cut. Remember to measure the workpiece frequently using calipers or a micrometer to ensure accuracy.

After achieving the desired square cross-section dimensions, it’s time to part off the workpiece from the bar stock using the parting tool. Use the tool to make a clean and straight cut through the remaining stock, separating the workpiece from the rest of the material. Take gentle and controlled cuts to prevent any damage to the workpiece or the lathe machine.

4. Tips for Machining a Square Cross-Section in Lathe

To achieve the best results when machining a square cross-section in a lathe, consider the following tips:

- Choose the appropriate cutting speed and feed rate for the material you are working with. Refer to machining guides or consult experienced machinists for recommendations.

- Use cutting fluids or lubricants to reduce friction and heat during the machining process, especially when working with metal materials.

- Securely tighten all the necessary components, including the chuck, collet, tool post, and tool rest, to prevent slippage and ensure stability.

- Regularly inspect and maintain your lathe machine, including lubricating moving parts and checking for any signs of wear or damage.

- Practice proper chip and swarf management by using chip trays or appropriate containers to collect and dispose of the metal or wood shavings.

Common Challenges and Troubleshooting

While machining a square cross-section in a lathe, you may encounter some common challenges. Here are a few troubleshooting tips:

1. Incorrect Dimensions

If your square cross-section does not meet the intended dimensions, ensure that you are using the correct tool bit and that the tool is properly aligned with the workpiece. Review your machining techniques and take accurate measurements to identify any discrepancies.

Preventative Measures:

– Double-check tool alignment and positioning.

– Measure the workpiece frequently to ensure you are achieving the desired dimensions.

– Make gradual adjustments to the tool rest and depth of cut to ensure precision.

2. Chatter or Vibration

Chatter or vibration can occur during machining, resulting in a rough surface finish and potential inaccuracies. To minimize chatter, ensure that the lathe machine is properly set up, and all components are securely fastened. Adjust the cutting speed and feed rate to prevent excessive vibrations.

Preventative Measures:

– Check the alignment of the lathe machine’s tailstock and headstock.

– Tighten all components, such as the chuck, collet, tool post, and tool rest.

– Reduce cutting speed and adjust the feed rate to minimize vibrations.

3. Tool Breakage

Tool breakage can occur due to excessive cutting force or improper tooling. Ensure that you are using the correct tool bit for the material and that it is sharp and free of defects. Reduce the cutting force by taking lighter cuts and adjusting the tool rest and depth of cut as needed.

Preventative Measures:

– Use the appropriate tool bit for the material being machined.

– Ensure the tool bit is sharp and properly secured in the tool post.

– Take lighter cuts and make gradual adjustments to the depth of cut.

Final Thoughts

Machining a square cross-section in a lathe requires precise techniques, the right tools, and careful attention to detail. By following the steps outlined in this guide and considering the provided tips and troubleshooting advice, you can achieve exceptional results. Remember to always prioritize safety and regularly practice your machining skills to improve and refine your craftsmanship. Now, armed with this knowledge, go forth and create beautiful square cross-sections with confidence!

Key Takeaways: How to Machine a Square Cross-Section in a Lathe

- To machine a square cross-section in a lathe, you need to start with a round workpiece.

- Use a four-jaw chuck to hold the workpiece securely in the lathe.

- Set the lathe to the desired spindle speed and engage the cutting tool with the workpiece.

- Make a series of cuts at different depths and angles to create the square shape.

- Check the dimensions of the square cross-section using measuring tools for accuracy.

Frequently Asked Questions

When it comes to machining a square cross-section in a lathe, there may be several questions that come to mind. Here are some frequently asked questions and their answers to help you understand the process better.

1. How can I create a square cross-section in a lathe?

To machine a square cross-section in a lathe, you can use a technique called “turning.” Start by mounting the workpiece on the lathe’s chuck. Then, measure the desired dimensions and mark the four corners of the square on the workpiece. Use a turning tool to gradually remove material from the round workpiece, shaping it into a square. Regularly check the dimensions to ensure accuracy. It may take several passes and adjustments to achieve the desired square cross-section.

Another method is to use a lathe with a four-jaw chuck. Mount the workpiece securely in the chuck and align it properly. Adjust the jaws of the chuck to hold the workpiece at equal distances on all sides. This method allows for more precise machining of the square cross-section.

2. What factors should I consider when machining a square cross-section in a lathe?

When machining a square cross-section in a lathe, there are a few key factors to consider. First, ensure that the lathe is properly set up and calibrated. Check the alignment, tool clearance, and make sure all components are in good working condition. Additionally, choose the appropriate turning tool for the job. Consider the material of the workpiece to determine the proper tool geometry and cutting parameters. Proper tool selection plays a significant role in achieving the desired square cross-section.

Another factor to consider is the material’s hardness and stability. If the material is too soft or prone to vibrations, it may pose challenges in achieving a precise square cross-section. In such cases, using appropriate cutting fluids, reducing cutting speeds, or making multiple passes can help mitigate these issues. It’s important to monitor the machining process closely and make adjustments as necessary to achieve the desired outcome.

3. Are there any safety precautions I should take when machining a square cross-section in a lathe?

Yes, safety should always be a top priority when using a lathe or any other machining equipment. Firstly, wear appropriate personal protective equipment (PPE), such as safety glasses or goggles to protect your eyes from flying debris. Make sure to secure the workpiece properly and use clamps if necessary to prevent any movement during machining. Remove any loose clothing, jewelry, or accessories that could get caught in the lathe’s rotating parts.

When operating the lathe, always follow the manufacturer’s guidelines and instructions. Pay close attention to the cutting tool’s position and adjust the tool rest and cutting speed accordingly. Regularly inspect the lathe for any signs of wear or damage and address them promptly. And lastly, if you’re unsure about any aspect of machining a square cross-section in a lathe, it’s always recommended to seek guidance from experienced professionals.

4. Can I machine a square cross-section on any type of lathe?

Yes, you can machine a square cross-section on various types of lathes. However, the ease and precision of the process may vary depending on the lathe’s design and capabilities. Engine lathes, which are commonly used, can be suitable for machining square cross-sections, but they may require additional setup and adjustments. CNC lathes, on the other hand, offer greater precision and control, making them well-suited for machining square cross-sections.

It’s important to understand the capabilities and limitations of your specific lathe and adjust your machining techniques accordingly. Additionally, consider the size and stability of the workpiece when selecting the appropriate lathe for machining square cross-sections.

5. Can I achieve a square cross-section with other machining methods besides a lathe?

Yes, it is possible to achieve a square cross-section using other machining methods besides a lathe. Milling machines, for example, are commonly used to create square or rectangular shapes. By using a square end mill or a slitting saw, you can remove material systematically to achieve the desired square cross-section.

Wire EDM (Electrical Discharge Machining) is another method that can be used to produce precise square cross-sections. It uses an electrically conductive wire to erode the workpiece material and shape it into a square. This process is suitable for materials that are difficult to machine using traditional methods.

Summary

So, you want to machine a square cross-section on a lathe? Here’s what you need to know:

A square cross-section on a lathe can be achieved by using the method of “turning” and “facing.” First, you will need a four-jaw chuck to hold your workpiece securely. Then, using a tool called a lathe cutting tool, you will turn the workpiece to create the desired shape. After turning, you will face the ends of the workpiece to make them flat and square. Taking proper measurements and using precise techniques will help you achieve a perfect square cross-section.

Remember, practice makes perfect, so don’t get discouraged if it takes a few tries to get it right. Keep learning, experimenting, and refining your skills, and you’ll be machining square cross-sections like a pro in no time!