Are you wondering if a drill press is necessary for your workshop? Well, let me tell you, my young friend, that this tool can be a game-changer! 🛠️💪

Imagine having the power to drill precise holes effortlessly and with utmost accuracy. That’s exactly what a drill press brings to the table. With its sturdy base and adjustable depth control, it offers stability and consistency that handheld drills simply can’t match.

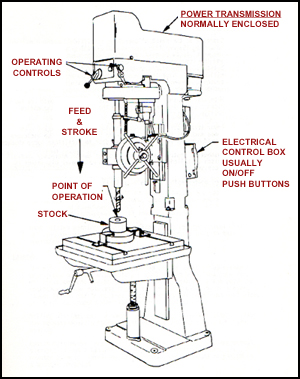

But hold on, before we dive deeper into the topic, let’s take a step back and understand what exactly a drill press is and why it has become a staple in many workshops. 🤔✨

Wondering if a drill press is necessary for your projects? While it’s not essential for every DIY enthusiast, a drill press offers several advantages. It provides precise drilling depth and accuracy, making it ideal for tasks like drilling holes in metal or repetitive drilling. Additionally, a drill press can handle larger drill bits and offer more stability compared to a handheld drill. Consider your specific needs and the type of projects you undertake to determine if investing in a drill press is worth it.

Is a Drill Press Necessary? Exploring the Pros and Cons

When it comes to woodworking or metalworking, having the right tools can make all the difference. One tool that often comes up in discussions is the drill press. But is a drill press necessary? While some might swear by its usefulness, others argue that it’s not essential for every DIYer or professional. In this article, we’ll delve into the pros and cons of owning a drill press, so you can make an informed decision based on your specific needs and projects.

1. Precision and Accuracy

If precision and accuracy are paramount to your projects, then a drill press can be a game-changer. Unlike handheld drills, a drill press offers stability through its fixed platform and vertical movement mechanism. This feature allows you to drill perfect perpendicular holes consistently, making it ideal for repetitive tasks or intricate jobs that require precision.

In addition to accuracy, many drill presses also offer depth-stop features, allowing you to control the depth of your holes with precision. This is particularly useful for projects such as doweling or when working with materials that require specific hole depths.

Moreover, some advanced drill presses come with laser guides or digital readouts, further enhancing your ability to achieve precise results. So, if precision is crucial in your line of work or hobbies, a drill press can be an indispensable tool in your workshop.

2. Power and Versatility

When it comes to power, a drill press generally outperforms handheld drills. Most drill presses are equipped with powerful motors, which allow for consistent and reliable drilling even through tough materials like metal or hardwood.

Besides raw power, drill presses also offer versatility in terms of the range of materials they can handle. With adjustable speed settings, you can drill through various materials with ease, whether it’s wood, plastic, or metal. This makes drill presses suitable for a wide range of projects, from woodworking and metalworking to jewelry making and even electronics.

Additionally, drill presses often have adjustable tables or tilting capabilities, enabling you to work at different angles or positions. This feature comes in handy when dealing with intricate cuts, angled holes, or when you need to accommodate large or irregularly shaped materials.

3. Safety and Stability

One of the significant advantages of using a drill press is the enhanced safety it provides. Unlike handheld drills, drill presses have a fixed platform and a built-in clamp that securely holds your workpiece in place. This eliminates the risk of the material slipping or spinning while drilling, reducing the chances of accidents or injuries.

Moreover, the stable base of a drill press reduces the vibrations and wobbling commonly experienced with handheld drills. This stability not only ensures precise and accurate drilling but also enhances user comfort and reduces fatigue during long hours of work.

Additionally, many modern drill presses come with safety features such as emergency stop buttons, blade guards, and integrated workpiece clamps, further enhancing the overall safety of the tool.

4. Limitations and Space Considerations

While a drill press offers many benefits, it’s important to consider its limitations and space requirements. Drill presses are generally bulkier and heavier than handheld drills, requiring dedicated space in your workshop or garage. If you have limited space or need portability, a drill press may not be the most practical option.

Furthermore, drill presses are primarily designed for vertical drilling. If your projects involve horizontal drilling or require angled holes, you might need additional accessories or tools to achieve the desired results.

Moreover, drill presses are not as versatile as handheld drills when it comes to certain tasks like drilling in tight corners or overhead positions. In such situations, a handheld drill might be a more feasible option.

5. Cost Considerations

Another factor that weighs into the decision of whether a drill press is necessary is the cost. Drill presses, especially those with advanced features, can be pricey compared to handheld drills. If you’re a casual DIYer or occasional user, the investment might not be justified. However, for professionals or avid woodworkers and metalworkers, the cost can be seen as an investment in accuracy, efficiency, and long-term durability.

It’s worth considering your budget and the frequency of your projects before committing to a drill press purchase. Assessing the value it brings to your work and the potential time and effort saved can help you make a well-informed decision.

Now that we’ve explored the pros and cons of owning a drill press, it’s up to you to decide if it’s a necessary tool for your specific needs. Remember to consider factors such as precision requirements, project versatility, safety considerations, space limitations, and cost. By carefully evaluating these aspects, you can make a decision that aligns with your goals and enhances your woodworking or metalworking endeavors.

Key Features to Consider When Choosing a Drill Press

As you contemplate whether a drill press is necessary for your projects, it’s essential to understand the key features that can make a difference in your drilling experience. Here are three crucial features to consider when choosing a drill press:

1. Motor Power and Speed Settings

The motor power directly impacts the drilling performance of a drill press. Look for a model with sufficient horsepower to tackle your intended applications. For heavy-duty work such as metal drilling, a more powerful motor would be ideal. Additionally, having adjustable speed settings allows you to control the drilling speed based on the material being drilled, ensuring clean and precise results.

2. Size and Table Adjustability

Consider the size of the drill press, both in terms of physical dimensions and the size of the drilling platform. If you often work with large or irregularly shaped materials, a bigger drill press with an adjustable table can provide the necessary stability and maneuverability. Look for models with tilting capabilities if you require angled drilling or tilted cuts.

3. Additional Features and Accessories

Depending on your specific needs, certain additional features and accessories can enhance your drilling experience. Look for drill presses with built-in laser guides or digital readouts for increased precision. Adjustable depth stops can be helpful when you need consistent hole depths, while integrated workpiece clamps improve safety and stability. Consider these extras to further enhance the functionality and usability of your drill press.

By carefully evaluating these key features, you can choose a drill press that aligns with your needs and maximizes your drilling capabilities.

Common Uses for Drill Press: Exploring Its Versatility

The drill press is a versatile tool that finds application in various industries, ranging from woodworking to metalworking, and even electronics. Let’s dive into some of the common uses for a drill press:

1. Woodworking Projects

Woodworkers often rely on drill presses for a multitude of projects. From drilling precise holes for dowels or hardware to creating perfectly aligned shelves or cabinets, a drill press offers consistent accuracy and control. It can be used for tasks like mortising, making stopped holes, or creating intricate designs with hole saws or forstner bits.

Moreover, a drill press can also be used for sanding, buffing, and shaping wood by attaching specialized accessories such as drum sanders or buffing wheels. This further enhances the versatility and utility of the tool in the realm of woodworking.

2. Metalworking and Machining

In the metalworking industry, a drill press is a staple tool used for drilling precise holes in various metals. Whether it’s steel, aluminum, or brass, a drill press provides the necessary stability to ensure accuracy and prevent workpiece movement. It’s often used in applications such as creating holes for screws, bolts, or rivets, or drilling holes for tap and die sets.

Additionally, a drill press can be used for reaming, counterboring, countersinking, or spot facing. These operations are crucial for achieving professional-level results in metalworking or machining applications.

Furthermore, a drill press can also be used for tasks like polishing or buffing metal surfaces using appropriate attachments. This allows for precision finishing and surface treatment in metalworking projects.

3. Electronics and PCB Drilling

Drill presses are not limited to woodworking or metalworking; they also find applications in electronics and PCB (Printed Circuit Board) drilling. The precision, accuracy, and stability of a drill press make it an ideal tool for drilling small holes in circuit boards. This is crucial for creating intricate electronic circuits, whether for hobbyist projects or in professional electronics manufacturing.

Drill presses equipped with high-speed settings and specialized drill bits designed for PCB drilling can ensure clean and precise holes, avoiding damage to the delicate circuitry of the board.

These are just a few of the many applications where a drill press can prove invaluable. Its versatility makes it a favorite tool among DIY enthusiasts, hobbyists, and professionals alike.

Tips for Getting the Most Out of Your Drill Press

To ensure you maximize the benefits of owning a drill press and make the most out of your drilling tasks, here are some useful tips:

1. Select the Right Drill Bits

Using the appropriate drill bits for your intended applications is crucial to achieve optimal results. Different materials require different types of drill bits, whether it’s high-speed steel (HSS) bits for general-purpose drilling, carbide-tipped bits for metalworking, or specialized bits like spade bits or hole saws for specific tasks. Invest in a variety of quality drill bits to have the right tool for every project.

2. Securely Fasten the Material

Prioritize safety and accuracy by securely fastening your workpiece to the drill press table. Make use of clamps or vises to ensure the material doesn’t move during drilling, eliminating any potential accidents or inaccuracies. Take the time to properly secure the workpiece and align it with the desired drilling position.

3. Use a Depth Stop

If you need consistent hole depths for your project, utilizing the depth stop feature on your drill press can save time and effort. Set the desired depth on the depth stop to ensure uniform hole depths throughout your drilling process. This is particularly useful when working on tasks such as doweling or when precision is critical.

4. Wear Personal Protective Equipment

Always prioritize safety by wearing appropriate personal protective equipment (PPE). Safety goggles or glasses protect your eyes from debris or flying particles, while ear protection helps reduce the noise generated by the drill press. Additionally, consider using a dust collection system or wearing a dust mask to minimize exposure to harmful particles or fumes, particularly when working with materials like wood or metal.

5. Keep the Drill Press Clean and Well-Maintained

Regularly clean your drill press to ensure optimal performance and longevity. Remove any debris, dust, or shavings that may accumulate on the drill press table, motor, or other components. Lubricate moving parts according to the manufacturer’s recommendations to minimize friction and ensure smooth operation. A well-maintained drill press will provide years of reliable service.

Remember, practice makes perfect. Take the time to familiarize yourself with the features and capabilities of your drill press, and don’t hesitate to experiment or seek guidance from experienced users or professionals. With proper understanding and utilization, a drill press can become an essential tool in your workshop.

Key Takeaways: Is a Drill Press Necessary?

- A drill press is a powerful tool for precision drilling.

- It offers stability and accuracy that handheld drills cannot provide.

- Using a drill press ensures consistent drilling depth and perpendicular holes.

- If you frequently work with wood, metal, or plastic, a drill press is highly recommended.

- For projects that require repetitive drilling, a drill press saves time and effort.

Frequently Asked Questions

Below are some commonly asked questions about the necessity of a drill press.

Can I use a regular drill instead of a drill press?

While a regular handheld drill can be used for various tasks, a drill press offers distinct advantages. A drill press provides greater accuracy, stability, and control, allowing you to make precise and consistent holes. Additionally, a drill press often has adjustable speed settings, which can be beneficial for different types of materials or hole sizes.

Moreover, a drill press usually has a larger working surface, including a table and adjustable height settings, making it easier to secure your workpiece and reduce the risk of accidents. So, while a regular drill can certainly get the job done, a drill press can greatly enhance the quality and precision of your work.

Is a drill press necessary for woodworking?

A drill press can be extremely useful in woodworking projects. Woodworking often involves various types of joinery, such as dowels or mortise and tenon joints. Using a drill press ensures accurate hole placement, alignment, and consistent depth, leading to cleaner and more professional-looking joints.

Additionally, a drill press can be equipped with different bits designed specifically for woodworking, such as spade bits, forstner bits, and brad point bits. These bits help prevent tear-out and splintering, resulting in cleaner holes and a smoother finish. So, while it is possible to complete woodworking projects without a drill press, having one can greatly improve the quality and precision of your work.

Can a drill press be used for metalworking?

Yes, a drill press can certainly be used for metalworking tasks. Metalworking often requires precise drilling, threading, and reaming, which can be challenging to achieve with a handheld drill. A drill press provides the necessary stability and control to tackle these tasks more effectively.

In addition, drill presses designed for metalworking are typically equipped with specialized features, such as adjustable speed settings, depth stops, and sturdy vises, specifically designed for working with metal. These features ensure accurate drilling, prevent overheating, and increase efficiency. So, if you frequently work with metal, having a drill press can greatly enhance your productivity and the quality of your metalworking projects.

Are there any alternatives to a drill press?

While a drill press offers unique advantages, there are alternative methods you can use depending on your needs and the type of work you are doing. One option is to use a portable drilling guide, which can be attached to a handheld drill to provide more stability and precision.

Another alternative is to use a bench vise and a handheld drill. By securely clamping your workpiece to the bench vise, you can achieve a level of stability similar to that of a drill press. However, it’s important to note that these alternatives may not offer the same level of accuracy and control as a drill press, so it ultimately depends on the specific requirements of your project.

When is a drill press necessary?

A drill press is highly recommended when you need high precision and accuracy in your drilling tasks. If you frequently work with small or delicate materials, or if you need to create consistent and precise holes, a drill press is a valuable tool.

Furthermore, a drill press is often necessary for repetitive drilling tasks, allowing you to save time and effort by quickly and efficiently drilling multiple holes with consistent results. It is also essential for certain specialized applications, such as drilling into hard materials like metal or thick wood, where the power and stability of a drill press are crucial. So, if you’re looking to achieve professional-grade results in your drilling tasks, a drill press is definitely worth considering.

What’s a drill press? Do you need one? | Mere Mini

Summary

So, is a drill press necessary for you? It depends on your needs and preferences.

If you do a lot of woodworking or metalworking, a drill press can be a valuable tool. It provides precision and stability that handheld drills don’t offer. However, if you only occasionally need to drill holes and don’t require precise results, a handheld drill might be sufficient.

Consider factors like the type of projects you do, your budget, and the amount of space you have. Ultimately, the decision is up to you.

Remember, safety should always come first when working with power tools. Whether you choose a drill press or a handheld drill, make sure to follow proper safety precautions to prevent accidents and injuries.