Did you ever wonder if a lathe is the same as a milling machine? Well, you’re in the right place to find out! In this article, we’ll explore the similarities and differences between these two powerful tools. So, let’s dive in and uncover the truth about lathes and milling machines!

Now, you may be thinking, “But wait, aren’t lathes and milling machines the same thing?” It’s a common misconception, but the truth is, they are not interchangeable. While both machines can shape and cut metal, they do so in different ways.

Let’s start with lathes. A lathe is a machine that rotates a workpiece on its axis, allowing you to shape it using various cutting tools. On the other hand, milling machines use rotary cutters to remove material from a stationary workpiece, creating complex shapes and designs.

So, if you’re curious to learn more about how these machines work and what sets them apart, keep reading! We’ll delve deeper into the fascinating world of lathes and milling machines. Let’s get started!

Is a Lathe a Milling Machine?

When it comes to machining processes, there are various tools and machines used for different purposes. Two common machines in the machining industry are lathes and milling machines. Although these machines have similar functionalities, they serve distinct purposes. In this article, we will explore the differences between a lathe and a milling machine and understand their unique capabilities.

Understanding a Lathe

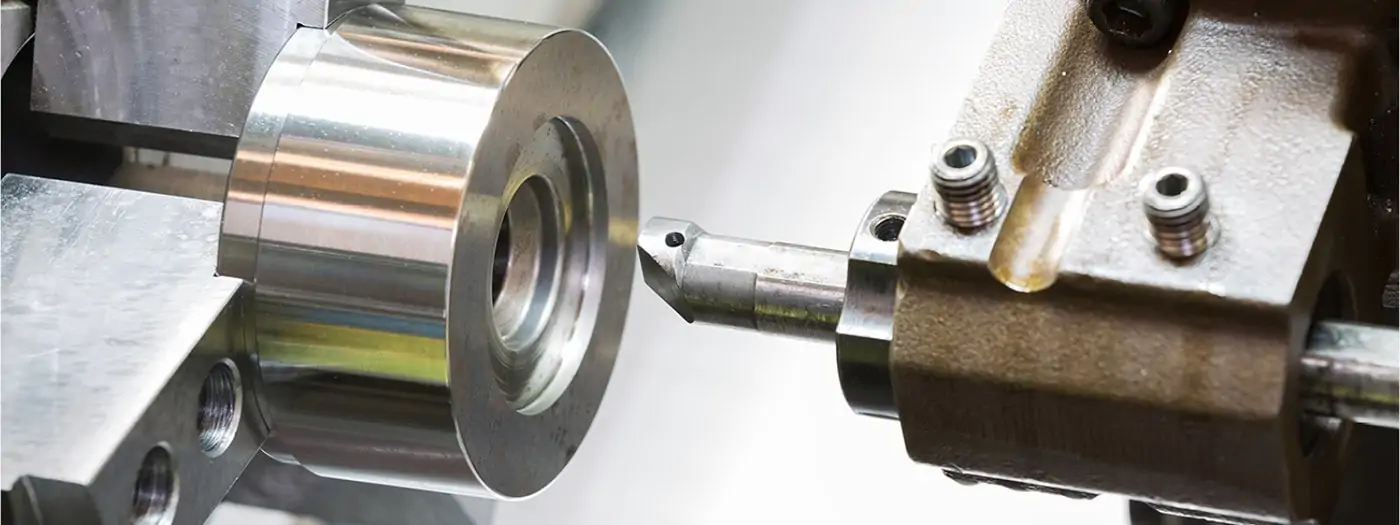

A lathe is a machine tool that rotates a workpiece on its axis and performs various operations such as cutting, sanding, drilling, and turning. It consists of a stationary cutting tool and a rotating workpiece that is clamped in place. The cutting tool moves along the workpiece, shaping it according to the desired specifications. Lathes are commonly used for cylindrical operations like shaping and finishing materials such as wood, metal, and even glass.

Working Principles of a Lathe

Lathes operate on the principle of rotational motion. The workpiece is secured in the lathe chuck or spindle, and the cutting tool is positioned in such a way that it can shape the rotating workpiece. As the lathe spindle rotates, the cutting tool removes material from the workpiece, resulting in the desired shape or design. Lathes can be operated manually or using computer numerical control (CNC) systems, allowing for precise and automated machining processes.

Lathes offer versatility in terms of the shapes they can create. With the right tooling, lathes can produce complex geometries such as threads, tapers, and contours. Their rotary motion enables them to perform concentric machining and achieve high precision. Lathes are widely used in industries like automotive, aerospace, and woodworking, where cylindrical components are prevalent.

One of the primary advantages of a lathe is that it can handle long workpieces with ease. The rotational motion allows for continuous machining along the length of the workpiece, making it suitable for creating shafts, rods, and tubes. Lathes can also be used for facing operations, where the cutting tool moves perpendicularly to the rotational axis, resulting in a flat surface.

The Benefits of Using a Lathe

Using a lathe offers several benefits, including:

- Versatility: Lathes can produce a wide range of shapes and contours, making them suitable for various applications.

- Precision: The rotary motion of lathes allows for high precision machining, crucial for creating intricate designs and achieving tight tolerances.

- Efficiency: Lathes can efficiently handle long workpieces, reducing the need for multiple machining operations.

- Cost-effectiveness: Lathes are relatively cost-effective compared to other machining tools, making them accessible to a wider range of industries and businesses.

Understanding a Milling Machine

Unlike lathes, milling machines operate on a different principle of machining known as milling. A milling machine utilizes rotary cutters to remove material from a workpiece, creating complex shapes, slots, and surfaces. Milling machines are commonly used in industries such as manufacturing, automotive, aerospace, and prototyping.

Working Principles of a Milling Machine

A milling machine operates by holding the workpiece in place while the milling cutter removes material. Milling cutters consist of multiple teeth that rotate at high speeds, allowing for precise cutting. The workpiece is held on a milling table or bed, and the cutters move vertically, horizontally, or both to shape the material. Milling machines can be manually operated or controlled by CNC systems, offering enhanced precision and automation.

One of the key advantages of milling machines is their ability to shape complex geometries. They can create slots, gears, pockets, and contours that may not be achievable with other machines. This versatility makes milling machines a preferred choice for producing custom-designed components and prototypes.

Another notable feature of milling machines is the ability to perform both peripheral and face milling operations. Peripheral milling involves cutting the material around its periphery, while face milling focuses on creating flat surfaces perpendicular to the rotational axis of the cutter. This dual capability makes milling machines suitable for a wide range of applications.

The Benefits of Using a Milling Machine

Using a milling machine offers several benefits, including:

- Versatility: Milling machines can shape complex geometries, allowing for the production of intricate components and custom designs.

- Efficiency: With the ability to remove material at high speeds, milling machines can quickly produce components, improving productivity.

- Precision: Milling machines offer high precision machining, ensuring tight tolerances and accurate results.

- Flexibility: Milling machines can be used for both peripheral and face milling operations, providing flexibility in machining processes.

Is a Lathe a Milling Machine?

Now that we have explored the working principles and benefits of both lathes and milling machines, it is clear that they serve distinct purposes in the machining industry. While lathes focus on rotational motion and the shaping of cylindrical workpieces, milling machines excel in complex shaping, slotting, and surface machining tasks. Therefore, a lathe is not the same as a milling machine, but rather complementary tools with diverse capabilities.

Benefits of Using Both Lathe and Milling Machine

Although lathes and milling machines are different, using both machines in combination can provide numerous advantages. By owning both a lathe and a milling machine, manufacturers can leverage the strengths of each machine and achieve enhanced productivity and versatility.

Considerations When Choosing Between a Lathe and a Milling Machine

When deciding whether to invest in a lathe or a milling machine, it is essential to consider various factors. Some factors to consider include:

- Application: Determine the specific machining tasks required and choose the machine that aligns with those needs.

- Workpiece Size: Consider the size and length of the workpieces you typically work with to ensure that the chosen machine can accommodate them.

- Budget: Evaluate your budget and decide which machine offers the best value for your investment.

- Training: Assess the availability of skilled operators and their familiarity with either lathes or milling machines.

- Future Expansion: Consider future business needs and the possibility of expanding your machining capabilities.

By carefully evaluating these factors, you can make an informed decision and choose the machine that best suits your machining requirements.

In conclusion, while a lathe and a milling machine have similarities in terms of their machining techniques, they serve different purposes. Lathes are ideal for shaping cylindrical workpieces, while milling machines are suitable for complex shaping, slotting, and surface machining. By owning both machines or selecting the appropriate one based on specific needs, manufacturers can maximize their machining capabilities and produce high-quality components efficiently and effectively.

Key Takeaways: Is a Lathe a Milling Machine?

- A lathe and a milling machine are two different tools used in machining.

- A lathe is used for spinning a workpiece while a milling machine is used for cutting and shaping the workpiece.

- A lathe primarily creates cylindrical shapes, while a milling machine can create a variety of shapes and contours.

- You can perform some milling operations on a lathe by using a milling attachment, but it has limitations compared to a dedicated milling machine.

- If you need to perform milling operations frequently, it’s recommended to invest in a dedicated milling machine.

Frequently Asked Questions

A lathe and a milling machine are two different tools used for different purposes in machining. However, they do share some similarities in terms of their functions and capabilities. Here are some commonly asked questions about the relationship between a lathe and a milling machine:

Q: What is a lathe used for?

A lathe is a machine tool used to shape and cut cylindrical workpieces. It rotates the workpiece while a cutting tool is held against it, resulting in a symmetrical shape along its axis. Lathes are commonly used for turning, facing, boring, and threading operations. They are ideal for creating cylindrical or conical shapes.

Lathes are often used in woodworking, metalworking, and even in the production of musical instruments. They can be manually operated or computer-controlled, depending on the complexity of the work.

Q: What is a milling machine used for?

A milling machine is a machine tool used for cutting and shaping solid materials, typically metal. It utilizes a rotating cutter that removes material from the workpiece by advancing it into the cutter. Milling machines can perform a wide range of operations, such as face milling, end milling, drilling, and tapping.

Milling machines are commonly used in industries such as automotive, aerospace, and manufacturing. They can create complex shapes, contours, and patterns with high precision. Milling machines can be manually operated or computer-controlled, offering versatility and efficiency in machining processes.

Q: Can a lathe be used as a milling machine?

While a lathe and a milling machine are different tools, it is possible to perform limited milling operations on a lathe with the help of additional attachments. These attachments, known as milling attachments, enable a lathe to perform drilling, slotting, and other milling operations to some extent. However, the capabilities of a lathe for milling are limited compared to a dedicated milling machine.

It’s important to note that using a lathe for milling operations requires careful setup and the right attachments. It may not be suitable for complex milling tasks, but it can be a cost-effective solution for simple operations on certain workpieces.

Q: What are the advantages of using a milling machine over a lathe for milling operations?

A milling machine offers several advantages over a lathe for milling operations. Firstly, milling machines are specifically designed for milling tasks, allowing for more precise and efficient cutting and shaping of materials. They have a wider range of cutting tools and can handle more complex milling operations than a lathe.

Additionally, milling machines can handle larger workpieces and perform multiple operations in a single setup, reducing production time and increasing productivity. They also offer greater flexibility, as they can create various types of cuts, contours, and patterns with high accuracy. Overall, a milling machine is better suited for milling tasks compared to a lathe.

Q: Do I need both a lathe and a milling machine?

Whether you need both a lathe and a milling machine depends on your specific machining needs and the complexity of the projects you work on. If you primarily work with cylindrical or conical shapes and simple milling operations, a lathe with milling attachments may be sufficient.

However, if you frequently work on more complex shapes and intricate milling operations, it would be beneficial to have a dedicated milling machine. A milling machine offers greater precision, versatility, and efficiency for milling tasks. Assess your requirements and consider the scope of your projects to determine whether both tools are necessary for your machining operations.

Summary

A lathe and a milling machine are not the same thing. They have different functions and uses. A lathe is used to shape and cut objects by rotating them, while a milling machine is used to remove material from a workpiece using rotary cutters. Although both machines involve rotational movement, they have distinct purposes and capabilities. It’s important to understand the differences between a lathe and a milling machine to choose the right tool for the job.

Both a lathe and a milling machine are important tools in machining processes. A lathe is great for cylindrical objects and producing symmetrical shapes, while a milling machine is ideal for creating flat surfaces and intricate designs. Depending on the project at hand, one machine may be more suitable than the other. So, when it comes to a lathe or a milling machine, it’s all about choosing the tool that best fits the task you need to accomplish.