Are you wondering if a lathe is dangerous? Well, let’s find out! Lathes are incredible machines that can shape and cut various materials, but safety should always be the top priority. In this article, we’ll explore whether a lathe can pose any risks and how you can stay safe while using one.

Now, you might be thinking, “What’s so dangerous about a lathe?” Well, my friend, as with any powerful tool, it’s crucial to understand the potential hazards involved. We’ll delve into the specific dangers associated with lathes and the safety measures you can take to mitigate those risks.

So, whether you’re a curious teenager interested in woodworking or someone who wants to learn more about the topic, this article has got you covered. Let’s dive in and explore the fascinating world of lathes while keeping safety at the forefront of our minds!

While lathes are incredibly useful machines for woodworking and metalworking, they can pose risks if not used properly. Safety precautions, such as wearing appropriate personal protective equipment, securing the workpiece, and using proper cutting tools, are essential to prevent accidents. It’s important to receive training on lathe operation and follow all safety guidelines. By being aware of the potential dangers and taking the necessary precautions, you can safely enjoy the benefits of using a lathe.

Is a Lathe Dangerous? Understanding the Risks and Safety Measures

When it comes to operating a lathe, safety should always be the top priority. Lathe machines can be incredibly useful in shaping and transforming raw materials, but they can also pose serious risks if not handled with care. In this article, we will delve into the topic of lathe safety, exploring the potential dangers associated with operating a lathe and discussing the safety measures that can be taken to mitigate these risks. Whether you are a seasoned lathe operator or someone new to the craft, understanding the potential dangers and how to protect yourself is crucial.

The Importance of Proper Training and Equipment

Before diving into the specifics of lathe dangers, it is vital to emphasize the importance of proper training and equipment. Operating a lathe without adequate knowledge or training can lead to accidents and injuries. It is crucial to undergo comprehensive training in lathe operation, including understanding the different components of the machine, proper tool handling techniques, and safety protocols. Additionally, wearing appropriate personal protective equipment (PPE), such as safety goggles, gloves, and ear protection, is essential in minimizing the risk of injury.

Moreover, regular maintenance and inspection of the lathe machine is vital to ensure its safe operation. Worn-out parts or malfunctioning components can increase the likelihood of accidents. It is important to adhere to manufacturer recommendations regarding maintenance and seek professional assistance when necessary.

Identifying the Potential Hazards

Before delving into the potential hazards associated with lathe operation, it is essential to have a clear understanding of the machine’s components. A lathe consists of a rotating spindle, tool post, carriage, and tailstock. The material being shaped is held in place by a chuck or collet. Now, let’s explore the potential hazards:

Hazard 1: Contact with Rotating Parts

One of the primary dangers of a lathe lies in the contact with rotating parts. The high-speed rotation of the spindle and chuck can result in severe injuries if a hand, clothing, or an accessory comes into contact with the moving parts. Even a brief moment of inattentiveness or a loose article of clothing can lead to a catastrophic accident. It is crucial to maintain a safe distance from the rotating parts and always wear fitted clothing without any dangling accessories.

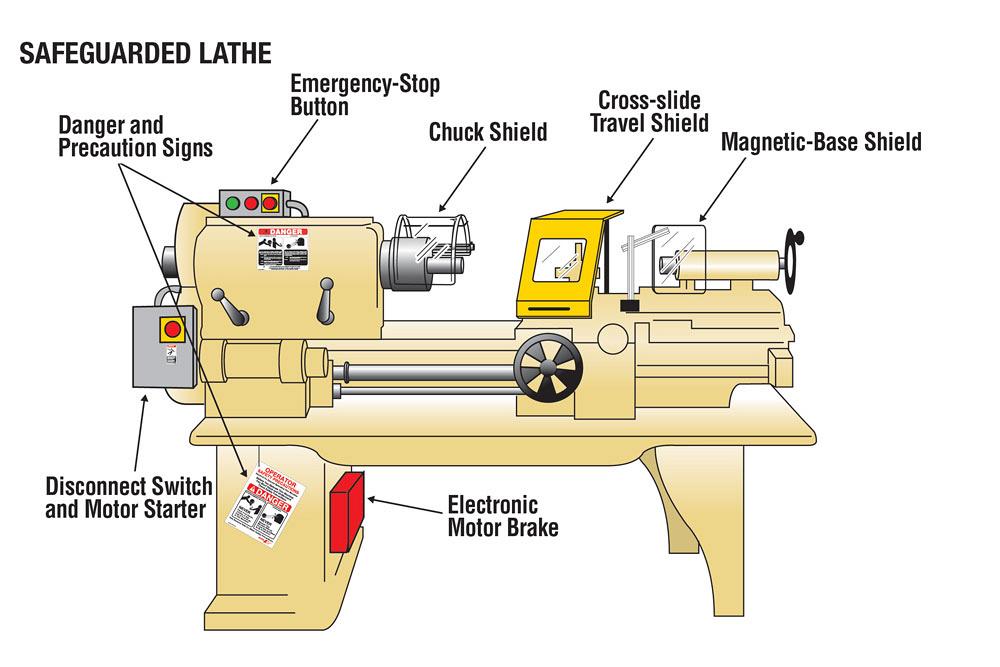

To reduce the risk of contact with rotating parts, lathe machines are equipped with safety features such as chuck guards and emergency stop buttons. These safety components should never be bypassed or disabled.

Hazard 2: Flying Debris

Lathe operations involve cutting, drilling, and shaping materials, which can generate flying debris and chips. These projectiles can cause severe eye injuries if they come into contact with unprotected eyes. Wearing safety goggles or a face shield that provides adequate coverage is absolutely crucial to protect against these potential hazards.

Additionally, keeping the work area clean and free of clutter can minimize the chances of flying debris getting caught in moving parts or obstructing the operator’s view. Using proper cutting tools and techniques can also help reduce the generation of flying debris.

Hazard 3: Entanglement and Catching Hazards

Lathe machines have numerous moving parts, including belts, pulleys, and gears. These can create entanglement and catching hazards if loose clothing, hair, or jewelry gets caught in them. It is crucial for operators to secure their hair and avoid wearing loose clothing or jewelry that can be snagged by the moving parts. Taking safety precautions such as tying back long hair and removing jewelry before operating the lathe can help prevent these accidents.

Moreover, it is important to ensure that the lathe is securely anchored to a stable surface to prevent it from tipping or moving during operation. This stability can prevent accidents caused by the lathe suddenly shifting or falling off the worktable.

Protective Measures for Safe Lathe Operation

Now that we have examined the potential dangers associated with lathe operation, let’s discuss the safety measures that can be taken to ensure safe practices:

Safety Measure 1: Training and Supervision

Proper training and supervision are paramount when it comes to safe lathe operation. Operators should receive comprehensive training on lathe operation, safety protocols, and emergency procedures. Supervision by experienced operators or mentors is crucial, especially for those who are new to lathe work.

Safety Measure 2: Personal Protective Equipment (PPE)

Wearing the appropriate personal protective equipment (PPE) is vital in protecting against potential hazards. Safety goggles or a face shield, safety gloves, and ear protection should be worn at all times during lathe operation. Operators should ensure that their PPE fits properly and is in good condition.

Safety Measure 3: Machine Inspection and Maintenance

Regular inspection and maintenance of the lathe machine are essential for safe operation. It is important to check for any signs of wear and tear, damage, or malfunctioning parts. Any issues should be addressed promptly, and professional assistance should be sought when needed.

Safety Measure 4: Safety Features and Emergency Procedures

Operators must familiarize themselves with the safety features of the lathe machine, such as chuck guards and emergency stop buttons. These safety components should never be bypassed or disabled. In case of an emergency, operators should know the proper emergency procedures and be able to quickly shut off the machine.

Lastly, maintaining a clean and organized work area can greatly contribute to safe lathe operation. Clearing away clutter, debris, and unnecessary items reduces the risk of accidents and promotes a more focused working environment.

The Benefits of Lathe Operation and How to Minimize the Risks

While lathe machines do possess certain risks, they also offer numerous benefits. With proper training, equipment, and safety measures in place, these risks can be effectively minimized, allowing you to enjoy the advantages of lathe operation.

By understanding the potential dangers and implementing the necessary safety measures, you can confidently operate a lathe while protecting yourself against accidents and injuries. Remember, safety should always be the top priority in any woodworking or machining endeavor, and it is up to each individual to prioritize their own well-being.

Key Takeaways – Is a Lathe Dangerous?

1. Yes, a lathe can be dangerous if not used properly.

2. Always wear appropriate safety gear, such as goggles and gloves, while operating a lathe.

3. Make sure the lathe is properly secured to a stable surface before use.

4. Keep hands and loose clothing away from moving parts of the lathe.

5. Never leave the lathe unattended while it is running.

Frequently Asked Questions

Curious to know more about working with a lathe and the potential dangers involved? We’ve got you covered. Check out these frequently asked questions:

How can using a lathe be dangerous?

Working with a lathe can be dangerous due to the nature of the machine and the tools involved. The spinning motion of the lathe can cause objects to be thrown off or become entangled. The cutting tools used can also pose a risk if not handled properly. Additionally, the high-speed rotations and vibrations of the lathe can lead to accidents if caution is not exercised.

It is crucial for operators to be aware of the potential risks, use safety equipment such as goggles and gloves, and follow proper training and guidelines to minimize the chances of accidents or injuries while using a lathe.

What safety precautions should I take when working with a lathe?

When working with a lathe, there are several safety precautions you should take to protect yourself and others. Firstly, always wear appropriate personal protective equipment (PPE) such as safety goggles, gloves, and a dust mask. These will shield you from flying debris and potential respiratory hazards.

Next, ensure the lathe is properly secured to a stable surface and that all guards are in place. Make sure to keep your work area clean and free from clutter to avoid accidents. Additionally, avoid loose clothing or accessories that could get caught in the moving parts of the lathe. Lastly, familiarize yourself with emergency shut-off procedures and keep them easily accessible in case of any mishaps.

Is proper training required to operate a lathe safely?

Yes, proper training is essential to operate a lathe safely. A lathe is a complex machine with various components and potential hazards. Understanding how to set up the lathe, select the correct tools, and use them safely requires training and experience.

Seek out training programs or courses that are specifically designed to teach lathe operation. These programs will cover important topics such as lathe safety, tool handling, maintenance, and troubleshooting. By investing in proper training, you will gain the knowledge and skills necessary to use a lathe safely and effectively.

What are common accidents or injuries associated with lathes?

Accidents involving lathes can range from minor cuts and bruises to more severe injuries. Some common accidents include getting fingers caught between rotating parts, being struck by flying debris, or suffering from a tool-related injury.

It’s important to note that many accidents can be prevented by following proper safety procedures and using the correct techniques. By wearing appropriate safety gear, understanding the machine’s limitations, and exercising caution, the risk of accidents or injuries can be significantly reduced.

What steps can I take to ensure my lathe is in safe working condition?

To ensure your lathe is in a safe working condition, regular maintenance and inspections are key. Begin by checking for any loose or damaged parts such as belts, pulleys, or bolts. Replace or repair any faulty components immediately.

Lubrication is also important to keep the lathe running smoothly. Consult the manufacturer’s guidelines to determine the appropriate lubricants and intervals for lubrication. Additionally, always keep the lathe clean and free from dust and debris. Regularly inspect the electrical components and power supply to ensure they are in good condition and functioning properly.

Lathe incident

Summary

So, is a lathe dangerous? While a lathe can be potentially dangerous, proper safety precautions can minimize the risks. Always wear safety goggles, avoid loose clothing and jewelry, and keep your hands away from the spinning parts. Remember to turn off the machine and unplug it when not in use.

Furthermore, receiving proper training and guidance from an experienced person can help you operate a lathe safely. Lastly, always follow the manufacturer’s instructions and guidelines to ensure your safety while using a lathe.