Have you ever wondered what a turret lathe is? Well, let me tell you all about it!

If you’re curious about the ins and outs of this fascinating machine, you’re in the right place.

In this article, we’ll explore what a turret lathe is, how it works, and why it’s such an important tool in the world of manufacturing. So, let’s dive right in!

What is a Turret Lathe? Exploring the Versatility of this Powerful Machine

A turret lathe is a versatile machine tool that is widely used in the manufacturing industry. With its ability to perform multiple machining operations, it has become an essential part of many production processes. In this article, we will dive deep into the world of turret lathes, exploring their features, benefits, and applications.

The Basics of Turret Lathes: A Comprehensive Overview

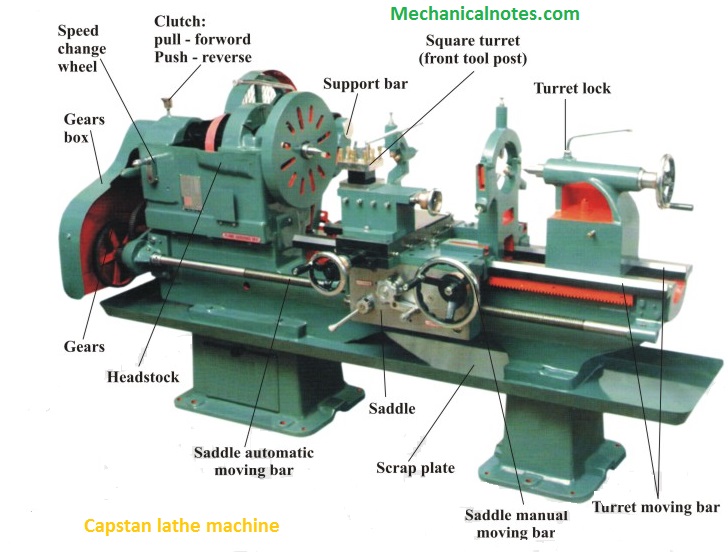

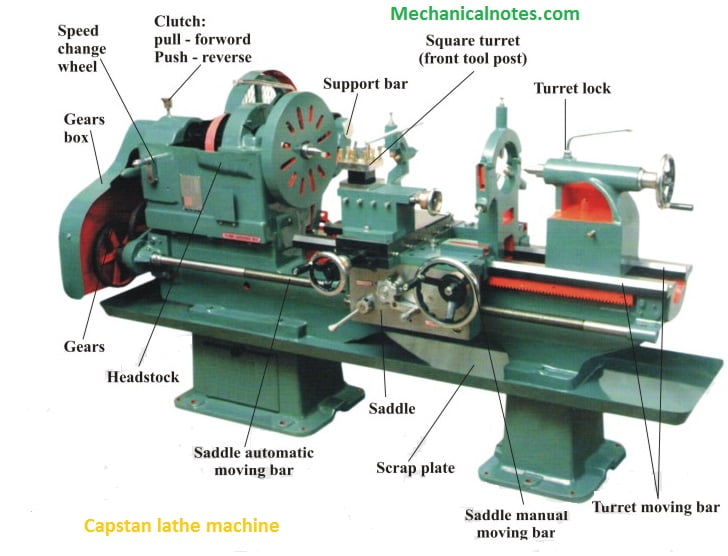

Turret lathes are a type of lathe machine that incorporates a turret tooling system. This system allows for quick and easy tool changes, making the lathe capable of performing a variety of operations without the need for manual intervention. The turret is equipped with multiple tool stations, each holding a specific cutting tool. This enables the machine to execute drilling, turning, milling, and other operations with high precision.

One of the key advantages of turret lathes is their ability to perform multiple operations without the need for retooling. This significantly reduces setup time, increasing productivity and efficiency in the manufacturing process. The machine’s versatility allows it to handle a wide range of materials, from metals to plastics, making it suitable for various industries, including automotive, aerospace, and medical device manufacturing.

Turret lathes come in different configurations, including horizontal and vertical models. Horizontal turret lathes have the spindle positioned horizontally, while vertical turret lathes have a vertically oriented spindle. Each configuration has its own advantages, depending on the specific machining requirements.

The Benefits of Using a Turret Lathe in Manufacturing

There are several significant benefits to using a turret lathe in the manufacturing industry. One of the primary advantages is the machine’s ability to reduce setup time. With multiple tool stations in the turret, the lathe can quickly switch between different tools, eliminating the need for manual changes and reducing downtime.

Another advantage is the high level of precision that turret lathes offer. The combination of a rigid structure and advanced control systems ensures precise machining, resulting in high-quality finished products. This precision is especially critical in industries where tight tolerances are required, such as aerospace and medical device manufacturing.

Turret lathes also enhance productivity by allowing for simultaneous machining operations. While one tool is actively machining the workpiece, other tools can be simultaneously prepared for the next operation. This reduces cycle times and increases overall production efficiency.

Turret Lathes vs. Other Machining Tools: A Comparative Analysis

When it comes to selecting the right machine tool for a particular application, it is essential to consider the options available. Turret lathes are just one of many machining tools on the market, each with its own strengths and weaknesses. Let’s take a closer look at how turret lathes compare to other machining tools.

Turret Lathes vs. Engine Lathes

Engine lathes are one of the most common types of lathes and are widely used for general-purpose turning operations. While turret lathes and engine lathes share some similarities, such as their ability to turn cylindrical workpieces, there are crucial differences between the two.

One key difference is the ability of turret lathes to perform multiple operations without manual intervention. Engine lathes typically require manual tool changes, which can be time-consuming. Turret lathes, on the other hand, have a turret tooling system that allows for automatic tool changes, greatly enhancing efficiency and reducing setup time.

Turret lathes also offer greater versatility compared to engine lathes. With multiple tool stations in the turret, turret lathes can perform operations such as drilling, milling, and threading in addition to turning. This makes them ideal for applications that require a variety of machining operations on a single workpiece.

Turret Lathes vs. CNC Lathes

CNC (Computer Numerical Control) lathes are another common type of lathe that is widely used in the manufacturing industry. Like turret lathes, CNC lathes offer a high level of precision and versatility in machining operations. However, there are some key differences between the two.

One primary difference is the control system. CNC lathes are controlled by computer programs that dictate the movements of the cutting tools, while turret lathes typically use manual controls or pre-programmed operations. This makes CNC lathes more suitable for complex and intricate machining processes that require precise control over tool movement.

Another difference is the automation level. CNC lathes are fully automated machines that require minimal manual intervention. They can be programmed to perform complex operations with minimal operator input. Turret lathes, on the other hand, still require some manual controls and tool changes, although the turret system streamlines the process.

Turret Lathes vs. Swiss Lathes

Swiss lathes, also known as Swiss-type lathes, are specialized machines that are commonly used for precision machining of small, intricate parts. These lathes are particularly suitable for long, slender workpieces that require high precision and accuracy.

While both turret lathes and Swiss lathes offer precision machining capabilities, they differ in their design and application. Swiss lathes are specifically designed for machining small parts with high aspect ratios (length-to-diameter ratio) and complex geometries. They are equipped with sliding headstocks and guide bushings, which allow for tight control over the workpiece and tool movement.

Turret lathes, on the other hand, are more versatile and can handle a wider range of workpiece sizes and shapes. Their turret tooling system allows for the execution of various machining operations, making them suitable for a broader range of applications.

Applications of Turret Lathes in Various Industries

Now that we have explored the features and benefits of turret lathes, let’s take a closer look at their applications in different industries.

Turret Lathes in the Automotive Industry: Streamlining Production Processes

The automotive industry relies heavily on precision machining for the production of engine components, suspension parts, and transmission components. Turret lathes play a vital role in this industry by ensuring the accurate and efficient manufacturing of these critical components.

Turret lathes are used in the production of engine valves, camshafts, and crankshafts, to name a few. The ability of turret lathes to perform multiple operations, such as turning, drilling, and milling, makes them ideal for machining these complex components. The high level of precision offered by turret lathes ensures that the finished parts meet the strict quality standards of the automotive industry.

In addition to engine components, turret lathes are also used in the production of suspension parts, such as control arms and tie rods, as well as transmission components like gears and shafts. The versatility and efficiency of turret lathes help streamline production processes in the automotive industry, contributing to the overall quality and reliability of vehicles.

Turret Lathes in the Aerospace Industry: Ensuring Precision and Safety

The aerospace industry demands the highest level of precision and quality in the manufacturing of aircraft components. Turret lathes play a critical role in this industry, providing the accuracy and efficiency required for the production of aerospace parts.

One of the key applications of turret lathes in the aerospace industry is in the production of turbine components. Turret lathes are used to machine turbine blades, shafts, and casings with utmost precision. These components are subject to extreme operating conditions and require tight tolerances to ensure optimal performance and safety.

Turret lathes are also used in the production of aerospace fasteners, such as bolts and screws, which play a crucial role in holding aircraft structures together. The ability of turret lathes to perform threading operations with high accuracy ensures that the fasteners meet the stringent requirements of the aerospace industry.

Turret Lathes in the Medical Device Industry: Meeting Strict Quality Standards

The medical device industry demands the highest level of precision and accuracy to ensure the safety and functionality of medical devices. Turret lathes offer the capabilities required to manufacture medical device components with the necessary precision and quality.

Turret lathes are used in the production of medical device components such as orthopedic implants, surgical instruments, and dental prosthetics. These components require complex machining operations and tight tolerances to ensure proper fit and functionality.

In addition to precision machining, turret lathes also play a vital role in the production of custom medical devices. With its ability to perform multiple operations, a turret lathe can efficiently machine intricate designs and complex geometries required for tailor-made medical devices.

Elevating Efficiency and Precision with Turret Lathes: Tips for Optimal Performance

While turret lathes offer numerous benefits in terms of efficiency and precision, there are certain strategies that can further enhance their performance. Here are a few tips to optimize the use of turret lathes:

1. Proper Selection of Cutting Tools

The selection of cutting tools plays a crucial role in the performance of a turret lathe. It is important to choose tools that are suitable for the specific material being machined and the desired operation. High-quality cutting tools and proper tool management can significantly improve cutting performance and extend tool life.

2. Regular Maintenance and Lubrication

To ensure consistent performance and longevity of a turret lathe, regular maintenance is essential. This includes proper lubrication of moving parts, cleaning and inspection of components, and monitoring of machine accuracy. Routine maintenance not only prolongs the life of the machine but also helps avoid unexpected breakdowns.

3. Operator Training and Skill Development

The skills and knowledge of the machine operator can greatly impact the performance of a turret lathe. Proper operator training is essential to maximize the capabilities of the machine and ensure safe and efficient operations. Ongoing skill development and staying up-to-date with the latest advancements in machining technology can further enhance performance.

By following these tips and implementing best practices, manufacturers can unlock the full potential of turret lathes, achieving higher levels of efficiency, precision, and productivity.

In conclusion, a turret lathe is a versatile machine tool that offers numerous benefits in terms of efficiency, precision, and versatility. With the ability to perform multiple machining operations and quick tool changes, turret lathes are an essential asset in various industries such as automotive, aerospace, and medical device manufacturing. By understanding the features, benefits, and applications of turret lathes, manufacturers can make informed decisions and optimize their production processes.

Key Takeaways: What is a Turret Lathe?

- A turret lathe is a type of lathe machine used for complex and repetitive turning operations.

- It features a turret that holds multiple tooling options, allowing for quick tool changes.

- With its ability to perform multiple operations in one setup, it increases productivity and reduces setup time.

- Turret lathes are commonly used in industries like automotive, aerospace, and manufacturing.

- They are suitable for producing cylindrical and symmetrical components with high precision.

Frequently Asked Questions

Are you curious about what a turret lathe is? Look no further! Below, we’ve provided answers to some commonly asked questions about this fascinating machine.

1. How does a turret lathe work?

A turret lathe is a type of machine tool used for shaping and cutting metal. It consists of a horizontal bed and a rotating turret that holds various cutting tools. The workpiece is clamped onto the bed, and as the turret rotates, different tools can be brought into contact with the workpiece to perform tasks like drilling, turning, and threading. This enables efficient and precise machining operations without the need for manual tool changes.

The machine’s versatility lies in the turret, which can hold multiple tools simultaneously. By indexing the turret, different tools can be selected and used in a programmed sequence, reducing the time it takes to complete a job. With its ability to perform various operations in one setup, turret lathes are widely used in manufacturing and production industries.

2. What are the advantages of using a turret lathe?

One of the main advantages of using a turret lathe is its efficiency. With multiple tools available on the turret, there is no need to manually change tools during the machining process. This saves a significant amount of time and increases productivity. Additionally, turret lathes are known for their accuracy and precision. The machine’s rigidity and stability ensure consistent results, making it suitable for intricate and complex machining operations.

Turret lathes are also versatile machines. They can handle various sizes and shapes of workpieces, making them suitable for a wide range of applications. Whether it’s drilling, boring, or turning, a turret lathe can handle the task efficiently. Moreover, the ability to automate the tool selection and sequence allows for easy programming and reduces the chances of error.

3. What industries use turret lathes?

Turret lathes are used in several industries, including automotive, aerospace, and medical manufacturing. In the automotive industry, turret lathes are utilized for producing intricate parts like engine components and transmission shafts. In aerospace, they are employed in the fabrication of aircraft parts, such as landing gear components and hydraulic fittings. The medical manufacturing industry also benefits from turret lathes, as they can be used to create precision medical devices and implants.

Overall, any industry that requires precise metal shaping and cutting can benefit from using a turret lathe. Its versatility and ability to handle a wide range of operations make it an invaluable tool for manufacturing companies.

4. Are there different types of turret lathes?

Yes, there are different types of turret lathes to suit various machining needs. Some common types include single-spindle turret lathes, multi-spindle turret lathes, and vertical turret lathes. Single-spindle turret lathes have a single turret head that can hold multiple tools, while multi-spindle turret lathes have multiple turrets, each with its own set of tools. Vertical turret lathes differ in their vertical orientation, allowing for efficient machining of larger workpieces.

Additionally, turret lathes can be manual or CNC (Computer Numerical Control) operated. Manual turret lathes require manual operation and tool changes, while CNC turret lathes are automated and can be programmed to perform precise machining operations. The choice of turret lathe depends on the specific requirements of the machining task at hand.

5. Is operating a turret lathe difficult?

Operating a turret lathe requires some training and understanding of machining principles, but it is not excessively difficult. With proper guidance and practice, individuals can learn to operate the machine effectively. Many vocational schools and technical institutes offer courses and programs specifically designed to train individuals in operating turret lathes. Additionally, manufacturers often provide training and support to their employees to ensure safe and efficient machine operation.

It’s important to note that operating any machine tool requires attention to safety guidelines and precautions. By following proper procedures and taking necessary safety measures, individuals can operate turret lathes with confidence and skill.

Why a Manual Machine Shop Needs a Turret Lathe

Summary

So, what is a turret lathe? A turret lathe is a type of machine that is used to shape and form metal. It has a rotating turret that holds different cutting tools, allowing for efficient and precise machining. By selecting the appropriate tool from the turret, the lathe can perform various operations like drilling, cutting, and threading. Turret lathes are commonly used in industries such as automotive, aerospace, and manufacturing.

In conclusion, a turret lathe is a powerful and versatile machine that helps create and shape metal parts. Its rotating turret with different cutting tools allows for efficient machining, making it a crucial tool in various industries.