If you’ve ever wondered, “Is capstan a lathe?” then you’ve come to the right place! Let’s explore this interesting question together.

A capstan and a lathe may seem similar at first glance, but they actually serve different purposes.

In this article, we’ll dive into the key differences between a capstan and a lathe, so you can gain a clear understanding of how they work. So, let’s get started!

Is Capstan a Lathe? Understanding the Key Differences

When it comes to machining operations, there are various tools and machines that serve specific purposes. Two commonly used machines in the field of machining are the capstan and the lathe. While both machines are utilized in metalworking processes, they have distinct differences in terms of functionality and design. In this article, we’ll dive deeper into the topic of whether a capstan is a lathe, exploring the characteristics of each machine and shedding light on their individual applications.

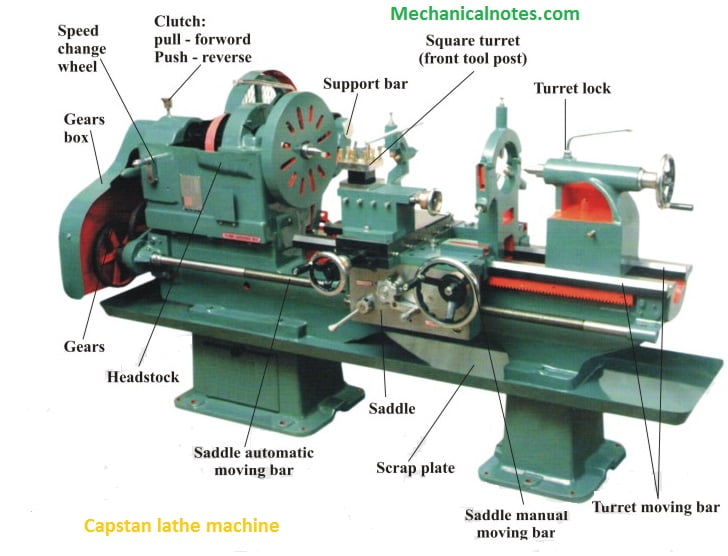

Understanding the Capstan Machine

The capstan machine is a type of turret lathe that is specifically designed for high-speed operations and mass production. It consists of a rotating turret that holds different tools, allowing for quick tool changes and efficient machining of components. The turret, usually mounted on the carriage, can rotate freely and position the tools precisely for the machining process.

One key feature of the capstan machine is the presence of a collet chuck, which securely holds the workpiece and provides enhanced stability during machining. This makes it suitable for producing small components with high accuracy and repeatability. The capstan machine is typically used for operations such as drilling, reaming, facing, and threading, making it a versatile tool in the manufacturing industry.

In addition, the capstan machine is often equipped with automatic bar feeders, which allow for continuous machining of multiple workpieces without manual intervention. This further enhances the productivity and efficiency of the capstan machine, making it an ideal choice for high-volume production.

Exploring the Lathe Machine

On the other hand, the lathe machine is a general-purpose machine tool that is commonly used for turning operations. It operates by rotating the workpiece against a tool, which removes material and shapes the workpiece into the desired form. The lathe machine is known for its versatility and ability to perform various processes such as facing, turning, grooving, and chamfering.

Unlike the capstan machine, the lathe does not have a rotating turret with multiple tools. Instead, it usually has a toolpost that holds a single tool at a time. This means that tool changes are manual and require stopping the machine, replacing the tool, and repositioning it before resuming the machining process. While this may result in slower tool changes compared to the capstan machine, the lathe offers greater flexibility in terms of the size and complexity of the workpiece it can handle.

Lathes can be categorized into various types based on their configurations and purposes. For example, the engine lathe is a commonly used type that is suitable for a wide range of machining operations. Other specialized types include the CNC lathe, which is controlled by computer numerical control, and the vertical lathe, which allows for the machining of large and heavy workpieces. The choice of lathe depends on the specific requirements of the machining task at hand.

Comparing Capstan and Lathe Machines

Now that we have a basic understanding of the capstan and lathe machines, let’s compare the two based on key parameters:

- Tooling: The capstan machine has a rotating turret with multiple tools, while the lathe usually has a toolpost for holding a single tool.

- Speed and Efficiency: The capstan machine is designed for high-speed operations and mass production, offering quick tool changes and automatic bar feeders. The lathe is more versatile but may have slower tool changes and requires manual intervention for workpiece positioning.

- Workpiece Size and Complexity: The capstan machine is generally suitable for small components, while lathes can handle a wider range of workpiece sizes and complexities.

- Application: Capstan machines are often used in industries with high-volume production requirements, such as automotive, electronics, and aerospace. Lathes, on the other hand, find applications in various industries, including metalworking, woodworking, and jewelry making.

In summary, while the capstan machine can be considered a type of lathe due to its machining capabilities, it has distinct features that set it apart. The capstan machine is specifically designed for high-speed operations and mass production, whereas the lathe is a more general-purpose machine tool suitable for a wide range of turning operations. Understanding the differences between these machines can help manufacturers choose the right tool for their specific needs.

Capstan Applications and Benefits

1. Automotive Industry

The capstan machine finds extensive use in the automotive industry, especially for the production of components like crankshafts, camshafts, and gears. Its high-speed capabilities, combined with automatic bar feeders, allow for efficient mass production of these critical parts. The ability to perform multiple operations, such as drilling, reaming, and threading, makes the capstan machine an integral part of automotive manufacturing processes.

2. Electronics Industry

In the electronics industry, where precision and speed are paramount, the capstan machine plays a crucial role. It is used for producing components like connectors, terminals, and sensor housings. The ability to achieve high accuracy and repeatability makes the capstan machine suitable for the demanding requirements of electronic devices.

3. Aerospace Industry

The aerospace industry relies on the capstan machine for the production of crucial components such as turbine blades, engine parts, and landing gear components. The high-speed capabilities and ability to handle exotic materials make the capstan machine an indispensable tool in the manufacturing of aerospace components. It enables efficient production while maintaining strict quality standards.

Lathe Applications and Benefits

1. Metalworking Industry

Lathes are widely used in the metalworking industry for various operations like turning, facing, chamfering, and grooving. They are essential in the production of components such as shafts, pins, and bushings. The versatility of lathes allows for intricate and precise machining, making them a valuable tool in metalworking processes.

2. Woodworking Industry

In the woodworking industry, lathes are used to shape and carve wooden materials into various decorative and functional pieces. They are commonly used for turning wooden bowls, furniture legs, and tool handles. The precision and control offered by lathes enable woodworkers to create intricate designs and smooth finishes.

3. Jewelry Making

Lathes are also utilized in jewelry making for shaping and polishing metal components like rings, bracelets, and pendants. With the ability to work with different metals and achieve intricate designs, lathes provide jewelers with the necessary tools to create unique and artistic pieces.

Conclusion

In conclusion, the capstan machine is not a lathe in the traditional sense. While it shares some similarities with a lathe in terms of turning operations, the capstan machine is specifically designed for high-speed operations and mass production, offering unique features such as a rotating turret and automatic bar feeders. On the other hand, the lathe is a versatile and general-purpose machine tool that can handle a wide range of turning operations. Both machines have their applications and benefits, and their choice depends on the specific machining requirements of the industry and the components being produced.

Understanding the differences between the capstan machine and the lathe is essential for manufacturers and engineers to make informed decisions when selecting the right machine for their needs. By considering factors such as tooling, speed, workpiece size, and application, the most suitable machine can be chosen to optimize efficiency, productivity, and overall machining quality. Whether it’s automotive, electronics, aerospace, metalworking, woodworking, or jewelry making, the capstan machine and the lathe both have important roles to play in the world of manufacturing and production.

Key Takeaways: Is Capstan a Lathe?

- Capstan is not a type of lathe, but a device used in certain types of lathes.

- A capstan is used to hold cutting tools and rotate them for machining operations in a lathe.

- Capstan lathes are known for their high-speed rotational capabilities.

- Capstan lathes are commonly used in mass production settings for quick and efficient machining.

- Understanding the difference between a capstan and a lathe can help in choosing the right machine for specific manufacturing needs.

Frequently Asked Questions

Welcome to our FAQ section where we’ll address some common questions about capstan lathes!

What is a capstan lathe used for?

A capstan lathe is a type of lathe machine that is specifically designed for high-speed production work. It is commonly used in manufacturing industries for repetitive tasks that require precision, such as turning and facing operations. Capstan lathes are highly efficient and often used in mass production environments.

These machines are ideal for producing small to medium-sized components with high accuracy and consistency. They are widely used in industries such as automotive, aerospace, electronics, and medical device manufacturing.

What are the advantages of using a capstan lathe?

There are several advantages to using a capstan lathe:

1. Speed and efficiency: Capstan lathes are designed for high-speed operations, allowing for quick production cycles and increased productivity.

2. Precision: These machines are known for their accuracy, making them ideal for producing components with tight tolerances.

3. Automation: Capstan lathes are often equipped with automatic tool changers, which reduce manual intervention and increase productivity.

4. Versatility: They can be used for a wide range of turning, drilling, grooving, and threading operations, making them highly versatile machines in a production setting.

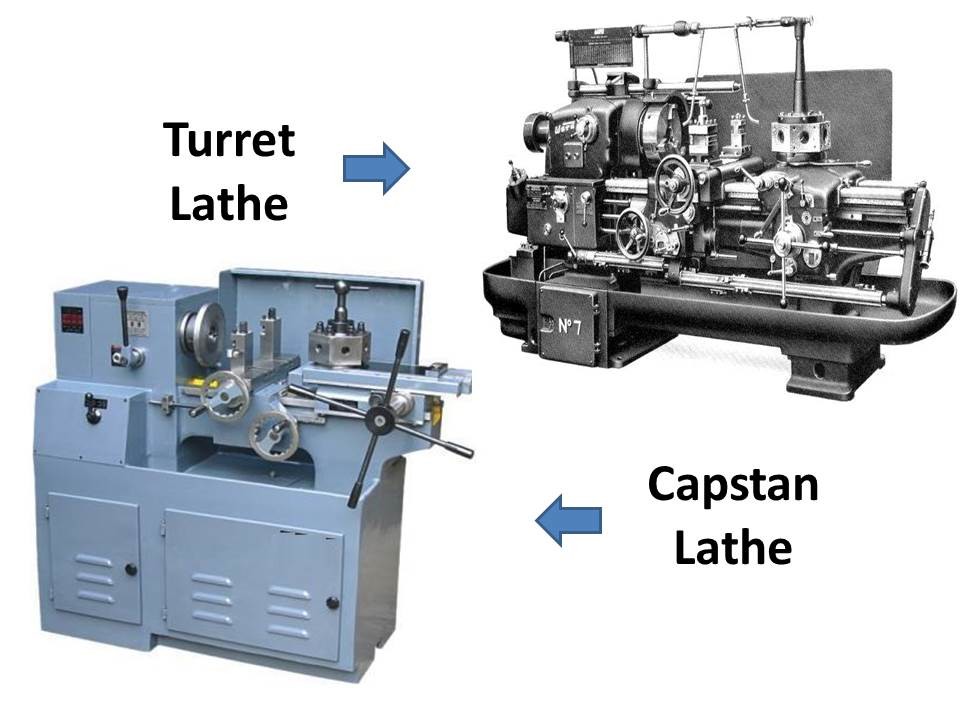

How does a capstan lathe differ from a turret lathe?

A capstan lathe and a turret lathe are both types of machine tools used for repetitive machining operations, but they differ in their design and usage. While both lathes are designed to increase productivity and reduce manual intervention, there are a few key differences:

1. Configuration: Capstan lathes typically have a hexagonal turret on top, which holds the tools and indexes them for operations. Turret lathes, on the other hand, have a cylindrical turret that rotates and has more tool positions.

2. Usage: Capstan lathes are more suited for small to medium-sized components and high-speed production, while turret lathes are commonly used for larger components and heavy-duty machining.

3. Automation: Capstan lathes often have automatic tool changers and are more automated compared to turret lathes, making them highly efficient for repetitive work.

What are the different types of capstan lathes?

There are two main types of capstan lathes:

1. Single Spindle Capstan Lathe: This type of capstan lathe has a single spindle and is designed for quick production work. It is commonly used for light to medium machining operations and is known for its high speed and accuracy.

2. Multiple Spindle Capstan Lathe: As the name suggests, this type of capstan lathe has multiple spindles and is designed for even higher productivity. It allows for parallel machining of multiple components, significantly reducing cycle times and increasing output.

Both types of capstan lathes offer advantages in terms of speed, efficiency, and precision, but the choice depends on the specific requirements of the manufacturing process.

What are some safety precautions to take when using a capstan lathe?

When operating a capstan lathe, it is important to follow safety guidelines to avoid accidents or injuries:

1. Proper training: Ensure that operators are trained in the safe operation of capstan lathes, including proper use of tools, machine controls, and safety features.

2. Personal protective equipment (PPE): Operators should wear appropriate PPE, such as safety glasses, gloves, and protective clothing, to minimize the risk of injury from flying chips or coolant.

3. Machine inspection: Regularly inspect the machine for any worn-out or damaged parts that could compromise safety. Keep the machine clean and free of debris to prevent accidents.

4. Emergency stop: Familiarize yourself with the location and operation of the emergency stop button, in case of any unforeseen circumstances or emergencies.

Following these safety precautions can help ensure a safe working environment when using a capstan lathe.

Various operations on Capstan and Turret lathe

Summary

So, is a capstan a lathe? The answer is no. While they may have some similarities, a capstan and a lathe are two different types of machines.

A capstan is used for producing small and precise components, such as screws, while a lathe is used for larger and more versatile machining operations. Both machines have their own unique features and uses, so it’s important to understand the differences between them.