If you’ve ever wondered whether a claw hammer is a first-class lever, you’re in the right place! In this article, we’ll explore the fascinating world of levers and discover if a claw hammer fits the classification. So, let’s dive in and unravel the mystery together!

Now, you might be wondering, what exactly is a first-class lever? Well, think about a seesaw or a pair of pliers – these are classic examples of first-class levers. But where does the claw hammer fit into the picture? Brace yourself for the explanation in the next paragraph!

Get ready to be blown away because the answer is YES! A claw hammer is indeed a first-class lever. How cool is that? But what makes it so special? We’ll unravel the inner workings of this versatile tool and uncover the secret behind its lever classification. So, hold on tight because we’re about to embark on an exciting journey into the realm of physics and tools!

So, buckle up, grab your hammer, and let’s explore why the claw hammer falls into the fascinating world of first-class levers. Get ready to be amazed by the mechanics behind this everyday tool and gain a deeper understanding of how levers work in our daily lives. Let’s uncover the secrets of the claw hammer’s lever classification and expand our knowledge together!

Is a Claw Hammer a First-Class Lever?

When it comes to tools, understanding how they work and the principles behind their operation can enhance both your efficiency and safety. One tool that has been a staple in most toolboxes is the claw hammer. But have you ever wondered if a claw hammer is a first-class lever?

The Anatomy of a Claw Hammer

Before we dive into the lever classification of a claw hammer, let’s take a moment to understand its anatomy. A typical claw hammer consists of two main parts: the handle and the head. The handle is usually made of wood or fiberglass, providing a comfortable grip for the user. On the other end, we have the head, which consists of two distinct parts: the striking surface and the claw. The striking surface, usually made of metal, is used to drive nails into various materials. The claw, on the other hand, is used to extract nails.

Understanding Levers

To understand whether a claw hammer is a first-class lever, we need to dive into the world of levers. Levers are simple machines that consist of a rigid beam or bar that rotates around a fixed point called the fulcrum. There are three main types of levers: first-class levers, second-class levers, and third-class levers.

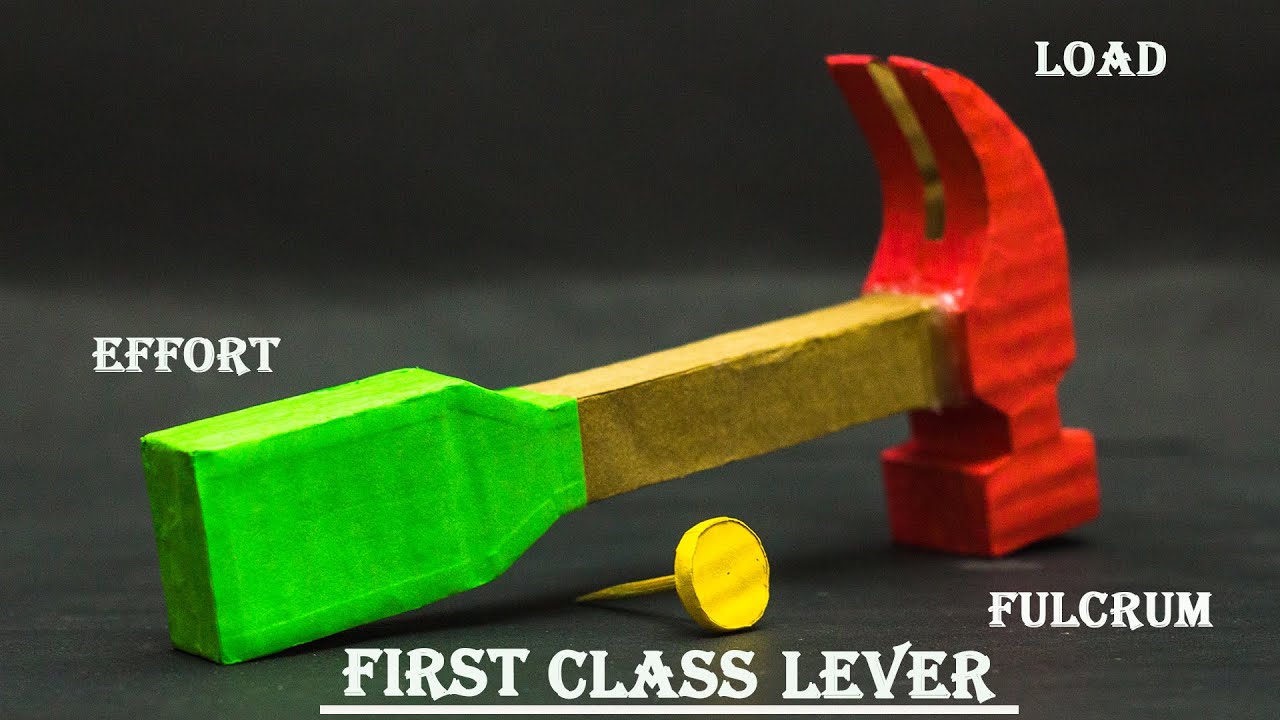

In a first-class lever, like a seesaw or a crowbar, the fulcrum is positioned between the effort and the load. This means that when force is applied to one end of the lever, it can lift or move the load on the other end. In the case of a claw hammer, the fulcrum is the point where the handle and the head meet, and the load is the nail you’re trying to drive or extract.

The Claw Hammer as a First-Class Lever

So, is a claw hammer a first-class lever? The answer is yes! When you swing a claw hammer, the force exerted at the end of the handle creates a rotation around the fulcrum, which is the point where the handle and the head meet. This rotation then allows the striking surface of the hammer to deliver force to the nail or to generate the leverage needed to pull out a nail using the claw. Therefore, the claw hammer fits the definition of a first-class lever.

The Advantages of a First-Class Lever Design

The first-class lever design of the claw hammer offers several advantages. Firstly, the lever design allows you to exert a significant amount of force with relatively little effort. By placing the fulcrum at an optimal distance from the handle and the head, you can generate a mechanical advantage, making it easier to drive nails or extract them. Secondly, the length of the handle allows for increased leverage, giving you better control and precision.

In conclusion, a claw hammer is indeed a first-class lever. Understanding this principle can help you make the most of your tools, perform tasks more efficiently, and ensure both your safety and the longevity of the tool. So, the next time you pick up a claw hammer, remember the lever design that makes it such a versatile and indispensable tool.

Frequently Asked Questions About Claw Hammers

1. How do I choose the right size claw hammer?

When choosing a claw hammer, consider the size and weight that feels comfortable for you. Smaller hammers are generally better for lighter tasks, while larger hammers provide more power for heavier-duty jobs. It’s also important to choose a hammer with a handle length that allows for a comfortable grip.

2. Can a claw hammer be used for tasks other than driving nails?

Yes, a claw hammer can be used for various tasks. In addition to driving and extracting nails, it can also be used for prying, shaping metal, and even breaking small objects. However, it’s important to use the hammer for its intended purpose to avoid damaging the tool or causing accidents.

3. Are there any safety precautions to consider when using a claw hammer?

Yes, when using a claw hammer, always wear appropriate eye protection to shield against flying debris. Make sure you have a secure footing and a stable work surface. When using the claw, keep your other hand away from the striking surface to prevent accidental injuries. Always use the hammer with controlled force and accuracy to avoid damaging your work or experiencing hand fatigue.

Key Takeaways: Is the Claw Hammer a First Class Lever?

- Yes, the claw hammer is a first class lever.

- A first class lever has the fulcrum positioned between the effort and the load.

- In the case of a claw hammer, the fulcrum is located where the handle meets the head.

- When you strike a nail with a claw hammer, the force is exerted at the head, while the load is the resistance of the nail.

- The long handle of the claw hammer acts as the lever arm, amplifying the force exerted on the nail.

Frequently Asked Questions

Welcome to our FAQ section, where we’ll answer some common questions about claw hammers and whether they are considered first-class levers. If you’re curious about the mechanics behind these tools, you’ve come to the right place!

1. How does a lever work?

A lever is a simple machine that rotates around a fixed point, called a fulcrum. It consists of three main parts: the fulcrum, the load or weight being moved, and the force applied to move the load. When force is applied to one end of the lever, it generates a torque that causes the load to move at the other end. This is done by leveraging the mechanical advantage gained through the lever’s design.

Levers can be classified into three types: first-class levers, second-class levers, and third-class levers. The classification is determined by the relative position of the fulcrum, load, and force. In a first-class lever, the fulcrum is located between the load and the applied force.

2. Is a claw hammer a first-class lever?

Yes, a claw hammer is indeed a first-class lever. The fulcrum, or pivot point, of a claw hammer is where the handle and the metal head meet. When you swing the hammer, the force is applied at one end of the lever, which generates torque at the other end to drive the nail into the surface. The claw on the opposite end allows you to extract nails by using the same principle.

To further confirm its classification as a first-class lever, think about how the load (the nail or the resistance) is placed between the applied force and the fulcrum. The distance from the fulcrum to the applied force determines the mechanical advantage and the ease with which the hammer can drive or extract nails.

3. What advantages does a first-class lever offer for a claw hammer?

The use of a first-class lever in a claw hammer provides several advantages. Firstly, having the fulcrum in the middle allows the user to apply a force with greater precision. This enables more control over the striking force, reducing the risk of striking too hard and damaging the work surface.

Additionally, a first-class lever provides leverage, meaning you can apply a smaller force to generate a greater amount of torque. This allows you to exert more power when driving or extracting nails, reducing the amount of effort required on your part. The mechanical advantage makes the task easier and more efficient.

4. Are all hammers considered first-class levers?

No, not all hammers are classified as first-class levers. While a claw hammer, with its fulcrum positioned between the load and applied force, is a good example of a first-class lever, there are other types of hammers that fall into different classifications.

For example, a ball-peen hammer is typically classified as a third-class lever, as the force is applied between the fulcrum and the load. Similarly, a sledgehammer can be classified as a second-class lever, with the load being located between the force and the fulcrum. The classification of a hammer depends on the position of the fulcrum, load, and applied force.

5. Can you give other examples of first-class levers outside of hammers?

Absolutely! There are many other examples of first-class levers beyond the realm of hammers. Some common examples include scissors, seesaws, crowbars, and even human limbs such as the forearm when bending the elbow.

Scissors, for instance, have a fulcrum at the joint where the two blades meet. The force is applied on one blade, causing the other blade to move, allowing for cutting action. Seesaws and crowbars also demonstrate the functioning of first-class levers, with the fulcrum placed between the applied force and the load.

First Class Lever | Hammer

Summary

So, to sum it all up, a claw hammer is indeed a first-class lever. It works by using the force you apply on the handle to lift or pry objects using the claw at the other end. By positioning the fulcrum in the middle, it magnifies your strength and makes your job easier.

But remember, not all hammers are first-class levers. It depends on where the fulcrum is placed. So the next time you pick up a hammer to do some DIY, you’ll know exactly how it uses leverage to get the job done!