If you’ve ever wondered whether a lathe can also function as a mill, you’re in the right place! Today, we’re going to explore the fascinating world of lathes and mills and find out if these two machines can serve similar purposes. So, grab your curiosity and let’s dive in!

Now, before we jump into the details, let’s make sure we’re on the same page. A lathe is a machine that rotates a workpiece while a cutting tool shapes it. On the other hand, a mill is a machine that uses rotating cutters to remove material from a workpiece. But can a lathe perform milling operations? That’s the question we’re going to answer!

Picture this: you’re working on a project, and you need to cut specific shapes or create precise holes in a piece of metal or wood. You might be wondering if you can achieve this using a lathe. Well, my young engineer, it’s time to find out if a lathe can indeed do the job of a mill. So, let’s explore the possibilities together!

Wondering about the difference between a lathe and a mill? While both machines are used in machining processes, they serve different purposes. A lathe is used to rotate the workpiece while a fixed cutting tool shapes it, while a mill uses a rotating cutting tool to remove material from a stationary workpiece. Each machine has its own unique features and benefits. Let’s explore them further!

Is Lathe a Mill? Understanding the Differences and Similarities

In the world of machining, the terms “lathe” and “mill” are often used interchangeably. However, while both machines are essential tools in any machine shop, they serve different purposes. If you’ve ever wondered about the differences and similarities between a lathe and a mill, you’re not alone. In this article, we’ll delve into the world of machining and explore the distinctive features and functions of lathes and mills.

The Lathe: A Versatile Machining Tool

When it comes to shaping and turning cylindrical workpieces, the lathe is the go-to machine. This powerful tool uses rotational motion to shape materials such as wood, metal, or plastic. The workpiece is clamped securely in the lathe’s chuck, which rotates while cutting tools are applied to shape the material. The lathe offers impressive precision and can create a variety of shapes, including cylinders, tapers, threads, and more.

One of the key advantages of using a lathe is its versatility. The machine can perform a range of operations, including facing, boring, grooving, and even knurling. Additionally, the lathe allows for intricate details and excellent surface finishes, making it ideal for projects that require precision and finesse. Whether you’re working on a small hobby project or a large-scale industrial endeavor, the lathe is an indispensable tool.

In terms of setup and operation, the lathe is relatively straightforward. With the right tools and proper techniques, even beginners can quickly learn to operate a lathe and start creating impressive projects. It’s important to note that lathes are available in different sizes and configurations, catering to various machining needs.

The Mill: Bringing Precision and Power to Machining

If the lathe is the king of cylindrical work, then the mill is the master of flat surfaces. Unlike the lathe, which rotates the workpiece, the mill holds the workpiece stationary while the cutting tool spins. This allows the mill to create precise features, such as slots, pockets, and contours, on flat or irregularly shaped materials. The mill is incredibly versatile and can handle a wide range of materials, including wood, metal, plastics, and composites.

One of the primary advantages of a mill is its ability to perform milling operations in multiple axes. Most mills can move vertically and horizontally, allowing for intricate cuts in all directions. This flexibility opens up a world of possibilities when it comes to complex shapes and designs. Additionally, with the use of computer numerical control (CNC) technology, mills can execute precise and intricate machining processes with little to no manual intervention.

Thanks to its power, precision, and versatility, the mill is an indispensable tool in industries such as aerospace, automotive, and manufacturing. From producing simple flat surfaces to manufacturing intricate parts, the mill is a staple in any machine shop.

The Similarities: Overlapping Features

While the lathe and the mill have distinct functions, they do share some overlapping features. For example, both machines can perform drilling operations, albeit with different techniques. Lathes can be equipped with drilling chucks, allowing for accurate drilling on cylindrical workpieces. Mills, on the other hand, use drill bits mounted on the spindle to create holes in flat or irregular surfaces.

Another shared feature is the ability to execute threading operations. In both lathes and mills, specialized threading tools can be used to create external or internal threads on workpieces. This is a crucial function in applications that require screw connections or precise thread profiles.

Additionally, both machines can be automated and controlled with CNC technology, enabling highly accurate and repeatable machining processes. With computer control and programming, lathes and mills can execute complex operations with minimal human intervention.

Choosing the Right Tool for Your Project

Now that we’ve explored the differences and similarities between lathes and mills, it’s essential to consider which machine is the best fit for your project. If you’re working on cylindrical workpieces and require precision and versatility, a lathe is the way to go. On the other hand, if your project involves flat surfaces, complex shapes, or requires milling in multiple axes, a mill is the machine for you.

Ultimately, the choice will depend on the specific requirements of your project and the materials you’re working with. Consider factors such as the size of the workpiece, the complexity of the design, and the level of precision needed. Consulting with machining experts or attending machining workshops can also provide valuable insights and guidance.

Whichever tool you choose, a lathe or a mill, both machines are essential for any machining enthusiast or professional. With their unique capabilities, they open up a world of possibilities in creating intricate and precise projects.

Key Takeaways: Is Lathe a Mill?

- A lathe and a mill are two different machines used in metalworking.

- A lathe is used to rotate a workpiece while a cutting tool shapes it.

- A mill, on the other hand, uses rotating cutters to remove material from a workpiece.

- Both machines have their own distinct functions and applications.

- While some tasks can be performed on both a lathe and a mill, they are not interchangeable.

Frequently Asked Questions

Are you curious about lathes and mills? Here are some commonly asked questions about the topic.

1. What is the difference between a lathe and a mill?

A lathe and a mill are two different types of machines used in machining processes. A lathe is a machine tool used for rotating a workpiece while a cutting tool is applied to shape or cut the material. It is primarily used for cylindrical parts. On the other hand, a mill is a machine that uses rotary cutters to remove material from a workpiece by advancing or feeding the cutter into the workpiece. Milling machines are commonly used for flat or irregularly shaped parts.

So, the main difference between a lathe and a mill lies in their primary functions and the type of workpieces they are best suited for. While a lathe is used for rotational shaping, a mill is used for removing material from a workpiece using rotary cutters.

2. Can a lathe be used as a mill?

Yes, a lathe can be used as a mill, but it requires additional attachments and modifications. With the appropriate attachments, a lathe can perform some milling operations such as drilling, boring, and slot cutting. However, it is important to note that a lathe’s primary function is not milling, and it may not provide the same precision and versatility as a dedicated milling machine.

Using a lathe as a mill can be useful for small-scale or simple milling operations, but for more complex or heavy-duty milling tasks, a dedicated milling machine is recommended.

3. What are the advantages of using a lathe as a mill?

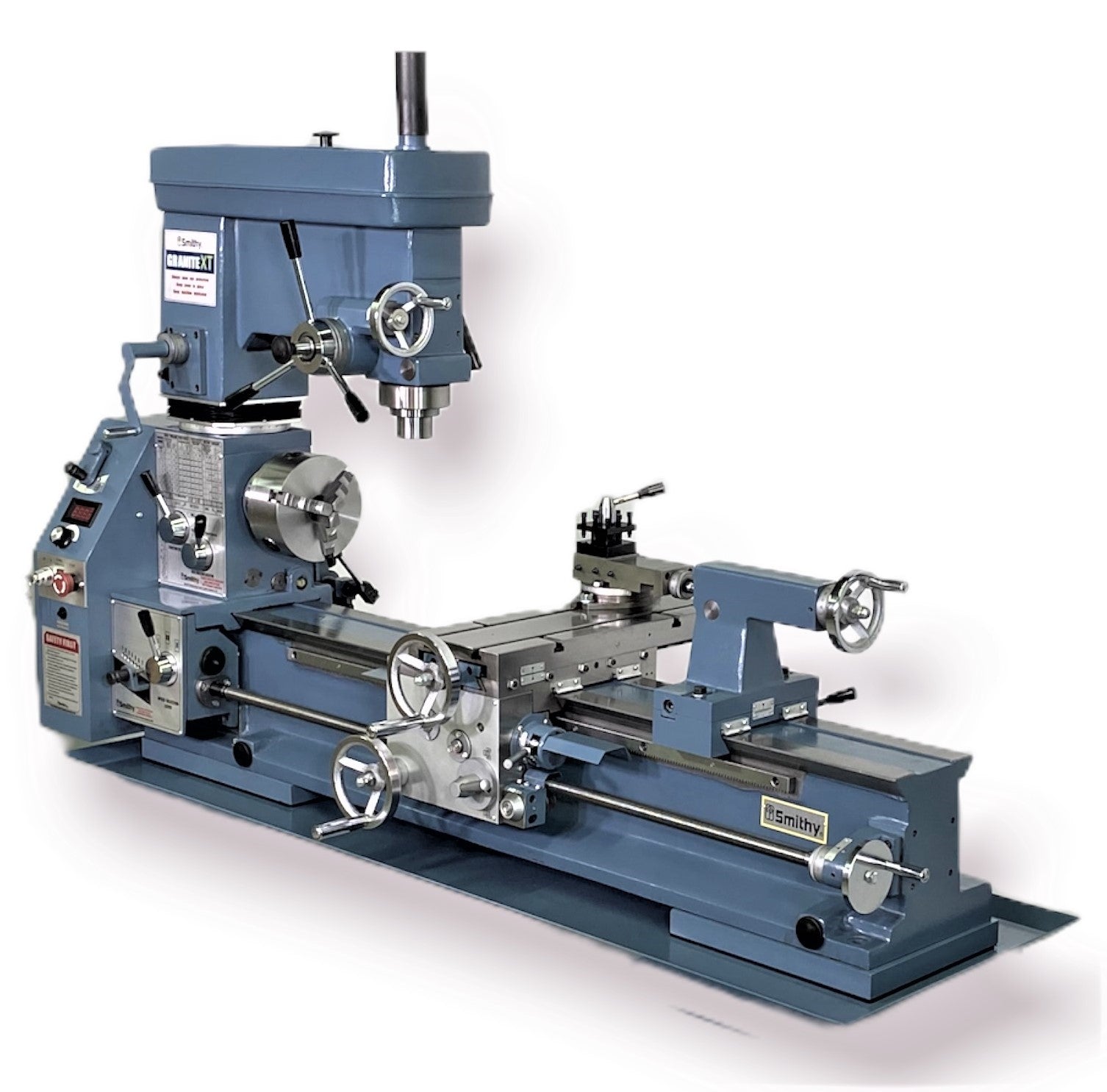

Using a lathe as a mill can have a few advantages in certain situations. One advantage is that it allows you to save space and cost by combining two functions in one machine. Additionally, if you already have a lathe in your workshop, using it as a mill can be a convenient option for occasional milling tasks.

However, it is important to note that a lathe’s milling capabilities are limited compared to a dedicated milling machine. The precision, power, and versatility of a lathe as a mill may not match that of a standalone milling machine.

4. Can a mill be used as a lathe?

No, a mill cannot be used as a lathe. The design and functionality of a milling machine are different from that of a lathe. A milling machine uses rotary cutters to remove material from a workpiece, while a lathe rotates the workpiece and uses cutting tools to shape or cut the material.

While a milling machine can perform some operations similar to a lathe, such as slotting and drilling, it cannot replicate the rotational shaping capabilities of a lathe. Therefore, if you need lathe-specific operations, a lathe machine is necessary.

5. Which machine is better for precision work: a lathe or a mill?

Both lathes and mills have their strengths and limitations when it comes to precision work. However, in general, a milling machine is better suited for precision work due to its ability to remove material precisely and accurately using rotary cutters.

A lathe, while capable of producing precise results, is primarily used for rotational shaping and may not have the same level of precision as a milling machine. If precision is your main concern, using a dedicated milling machine would be the recommended option.

Summary

A lathe and a mill are different machines used for cutting and shaping materials.

A lathe rotates the material while cutting, while a mill moves the material and cutting tool. It’s important to choose the right machine for the desired task to achieve the best results.