Is lathe milling machine? If you’ve ever wondered about this, you’re in the right place! Let’s dive into the fascinating world of machining and explore what makes a lathe different from a milling machine. Grab your curiosity goggles, and let’s get started!

In the world of machining, lathe and milling machines are like the dynamic duo of precision engineering. It’s like having Batman and Robin in a workshop! They may look similar, but they each have their own unique superpowers.

A lathe is a machine that spins a workpiece while a tool shaves away material to shape it, almost like a master sculptor crafting a masterpiece. On the other hand, a milling machine is like a mechanical wizard. It moves a cutting tool in different directions to carve out complex shapes from a stationary workpiece. So, while both machines are essential for crafting all kinds of objects, they have distinct ways of making magic happen.

Now that we’ve set the stage, let’s uncover the secrets of lathe and milling machines and how they work their magic in the world of machining. Get ready for an adventure filled with chips flying, tools spinning, and incredible creations coming to life! Are you excited? Let’s explore!

Is Lathe Milling Machine? Exploring the Capabilities of Lathe in Milling

Lathe machines and milling machines are two popular tools used in the metalworking industry. While they may share some similarities, there are distinct differences that set them apart. In this article, we will delve into the topic of whether a lathe can be used as a milling machine. We will explore the capabilities of a lathe when it comes to milling operations and discuss the pros and cons of using a lathe for milling. So, let’s dive in and shed light on this intriguing question.

Understanding the Basics: Lathe and Milling Machine

Before we delve into whether a lathe can be used as a milling machine, let’s first understand the basic functionalities of both machines.

- Lathe Machine: A lathe machine is a versatile tool used for shaping and cutting different materials such as wood, metal, and plastics. It operates by rotating the workpiece on its axis, while various tools are used to shape the material. Lathes are commonly used for tasks such as turning, facing, drilling, and threading.

- Milling Machine: On the other hand, a milling machine is primarily used for cutting, shaping, and drilling solid materials. It utilizes a rotating cutting tool called a milling cutter to remove material from the workpiece. Milling machines are capable of performing a wide range of operations including face milling, end milling, slotting, and drilling.

With a basic understanding of these two machines, let’s now explore whether a lathe machine can be used for milling operations.

Can a Lathe Machine Perform Milling Operations?

A lathe machine is primarily designed for rotational operations, such as turning and facing, where the workpiece rotates while the cutting tool remains stationary. However, with the right attachments and modifications, a lathe machine can be used to perform basic milling operations.

One common attachment used to convert a lathe into a milling machine is the milling attachment. This attachment is mounted on the lathe’s cross-slide and allows for vertical and horizontal movement of the cutting tool. While a lathe with a milling attachment can perform basic milling operations, it is important to note that it is not as efficient or precise as a dedicated milling machine. The limitations of a lathe when it comes to milling include slower cutting speeds, less rigidity, and limited tooling options.

Another approach to milling on a lathe is using a lathe milling slide. This slide is a separate accessory that can be mounted on the lathe’s bed and provides precise movement in multiple directions. With a lathe milling slide, more complex milling operations can be performed, but again, it is crucial to acknowledge the limitations compared to a dedicated milling machine.

Pros and Cons of Using a Lathe for Milling

Now let’s weigh the pros and cons of using a lathe for milling operations.

Benefits of Using a Lathe for Milling:

- Cost-effectiveness: A lathe with milling capabilities can be a more cost-effective option for small-scale milling operations, especially when compared to purchasing a dedicated milling machine.

- Space-saving: For workshops with limited space, using a lathe with milling capabilities can save valuable floor space since it eliminates the need for an additional milling machine.

- Versatility: With the right attachments and accessories, a lathe can perform both turning and milling operations, providing greater versatility in a single machine.

Drawbacks of Using a Lathe for Milling:

- Reduced Precision: Due to the design limitations of a lathe, the milling operations performed on a lathe may not be as precise as those performed on a dedicated milling machine. This can be a significant drawback for projects that require high accuracy.

- Limited Tooling Options: A lathe has limited tooling options compared to a dedicated milling machine, which can restrict the types of milling operations that can be performed.

- Slower Cutting Speeds: A lathe is generally designed for rotational operations and may have slower cutting speeds compared to a milling machine. This can result in increased machining time for milling tasks.

In conclusion, while a lathe machine can be modified and equipped with attachments to perform basic milling operations, it is not a substitute for a dedicated milling machine. The limitations in precision, tooling options, and cutting speeds make a dedicated milling machine a more suitable choice for precise and complex milling tasks. However, for small-scale or occasional milling operations, a lathe with milling capabilities can be a viable option.

Exploring Alternatives: Options for Milling without a Dedicated Machine

Now that we have established that a lathe with milling capabilities is not a perfect substitute for a dedicated milling machine, let’s explore some alternative options for milling tasks without the need for a dedicated milling machine.

CNC Lathe:

A CNC lathe, or Computer Numerical Control lathe, is a modern variant of a lathe machine that utilizes computer programming to control the machining process. With a CNC lathe, it is possible to perform precise milling operations by using specialized tooling and controlling the movement of the cutting tool with high accuracy. This eliminates the need for a separate milling machine and provides greater flexibility in performing milling operations.

Manual Milling Attachments:

Another option for milling without a dedicated machine is to use manual milling attachments that can be mounted on a workbench or a drill press. These attachments typically provide limited movement capabilities, but they can be useful for simple milling tasks. However, it is important to note that manual milling attachments have their own limitations in terms of precision and versatility.

Outsourcing Milling Tasks:

If milling tasks are infrequent or highly complex, it may be more practical to outsource them to a professional machine shop equipped with dedicated milling machines. This ensures high-quality results and allows for the utilization of advanced milling techniques and equipment.

Ultimately, the choice between using a lathe with milling capabilities, alternative options, or outsourcing milling tasks depends on the specific requirements of the project, the available resources, and the desired level of precision. It is important to carefully evaluate the pros and cons of each option to make an informed decision.

Explore, experiment, and weigh your options to find the best solution for your milling needs. Whether it’s a lathe machine with milling capabilities, a CNC lathe, or outsourcing to a machine shop, there are various avenues to explore when it comes to milling operations. Happy milling!

Key Takeaways: What is a Lathe Milling Machine?

- A lathe milling machine is a powerful tool used for cutting and shaping metal or wood.

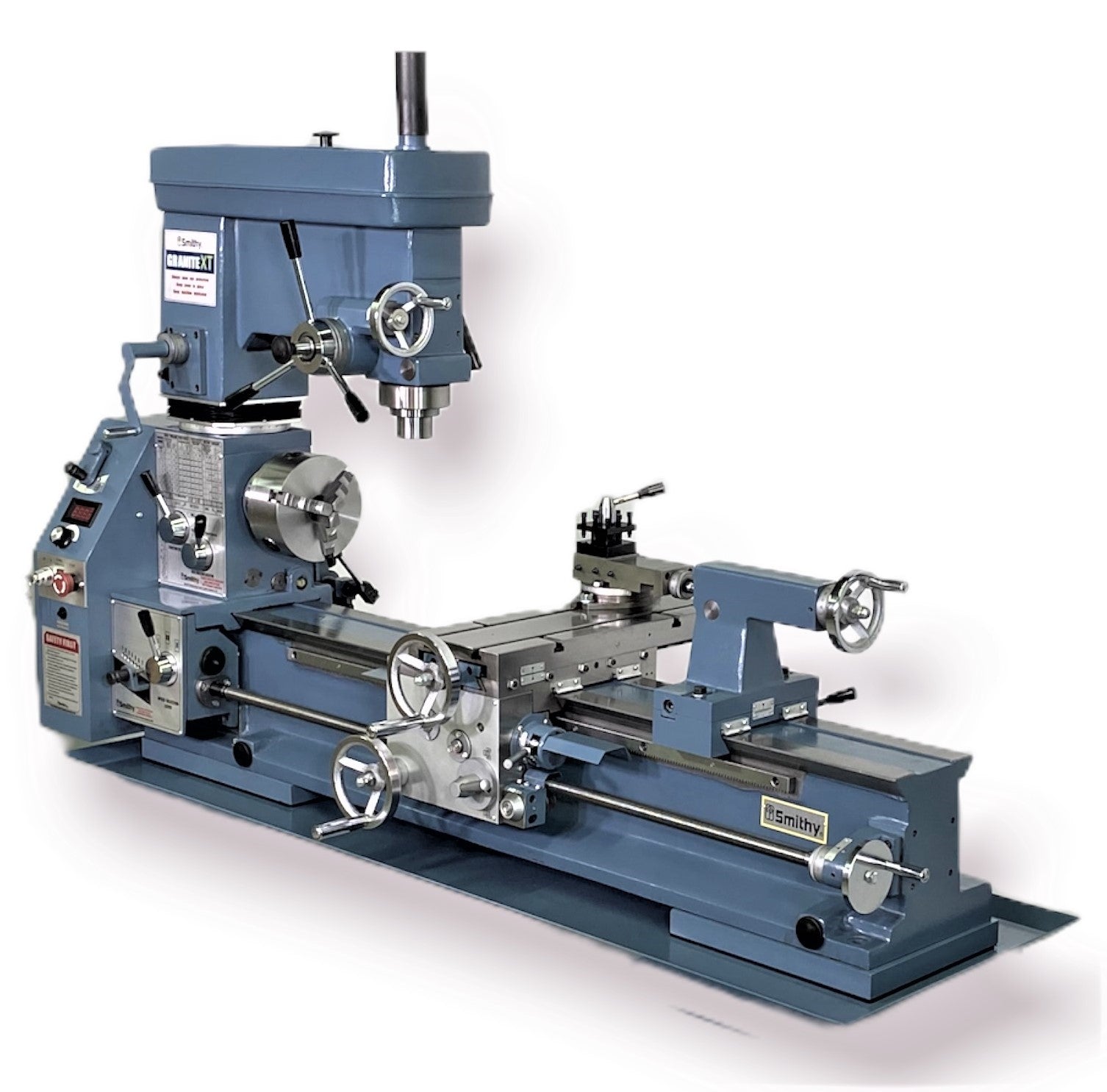

- It combines the functions of both a lathe and a milling machine, making it versatile for various applications.

- The lathe component allows for cylindrical shaping, while the milling component enables horizontal and vertical cutting.

- This machine is commonly used in industries such as manufacturing, construction, and woodworking.

- By using different cutting tools and techniques, a lathe milling machine can create precise and intricate designs.

Frequently Asked Questions

Below are some commonly asked questions related to lathe milling machines.

1. How does a lathe milling machine work?

A lathe milling machine is a versatile tool that combines the capabilities of a lathe and a milling machine. It uses a rotating cutting tool to remove material from a workpiece, in both rotational and linear motions. The workpiece is held securely in place and the cutting tool is guided by a spindle, allowing for precise shaping and machining.

By using different types of cutting tools, such as end mills and drills, a lathe milling machine can perform various operations, including facing, drilling, cutting threads, and more. This makes it an essential tool for metalworking and woodworking industries.

2. What are the advantages of using a lathe milling machine?

One of the main advantages of using a lathe milling machine is its versatility. It allows for a wide range of operations to be performed, eliminating the need for multiple machines. This saves both time and space in the workshop or manufacturing facility.

In addition, a lathe milling machine offers high accuracy and precision in machining. It allows for intricate designs and complex shapes to be achieved with ease. The ability to control the speed and feed of the cutting tool also ensures optimal results and reduces the risk of errors.

3. Can a beginner use a lathe milling machine?

Yes, a beginner can learn to use a lathe milling machine with proper guidance and practice. While it may seem daunting at first, there are many resources available, including tutorials and training courses, that can help beginners get started.

It is important for beginners to learn about the different tools and their uses, as well as the proper safety precautions to follow. Starting with simple projects and gradually working towards more complex ones allows beginners to gain confidence and master the techniques required to operate a lathe milling machine effectively.

4. What are some common applications of lathe milling machines?

Lathe milling machines are widely used in various industries, including automotive, aerospace, and manufacturing. They are commonly used for tasks such as turning, boring, drilling, and threading of metal and wood materials.

Some specific applications include creating cylindrical or conical shapes, cutting keyways or splines, and making precision holes or slots. Lathe milling machines are also used for producing prototypes, repairing parts, and modifying existing components in a variety of industries.

5. How does a lathe milling machine differ from a regular lathe or milling machine?

A lathe milling machine combines the functionalities of both a lathe and a milling machine. While a regular lathe is used primarily for turning and shaping cylindrical objects, and a milling machine is used for cutting and shaping flat surfaces, a lathe milling machine can perform both tasks.

This versatility allows for more complex machining operations to be carried out using a single machine, reducing the need for multiple tools. Additionally, lathe milling machines often have additional features, such as multiple axes and computer numerical control (CNC) capabilities, which further enhance their capabilities and precision.

Summary

A lathe milling machine combines the features of both a lathe and a milling machine. It can shape and cut materials in different ways, making it versatile for various projects. By rotating the workpiece and using cutting tools, it can create flat surfaces, grooves, and complex shapes with precision.

This machine is helpful in woodworking, metalworking, and even making prototypes. It saves time and effort by eliminating the need for multiple machines. Whether you’re a hobbyist or a professional, a lathe milling machine can be a valuable tool to have in your workshop for a wide range of tasks.