If you’re wondering, “Is semi chisel a ripping chain?” then you’ve come to the right place! Curious minds like yours deserve answers, and we’re here to shed some light on this chainsaw-related topic. Whether you’re a seasoned lumberjack or just getting started with your chainsaw adventures, understanding the differences between chains is essential. So let’s dive in and unravel the mystery together!

Have you ever wondered if semi chisel chains are suitable for ripping wood? Well, we’re about to find out! When it comes to chainsaw chains, there are different types, each with its own unique characteristics. And the term “ripping chain” refers to a specific type of chain used primarily for the task of ripping through wood. But is a semi chisel chain suitable for this purpose? Let’s explore further to get the answers you seek!

Now, before we go any further, let’s make sure we’re on the same page. A semi chisel chain refers to a type of chainsaw chain that strikes a balance between durability and cutting performance. It features semi-rounded teeth with both cutting edges and semi-chisel corners. But can a chain like this handle the demands of ripping wood effectively? We’re going to delve deeper into the topic to help you understand the ins and outs of semi chisel chains and their suitability for ripping. So let’s get started!

When it comes to chainsaw chains, the semi chisel type is not designed specifically for ripping wood. Ripping chains are specially designed for making clean, smooth cuts along the grain of the wood. While semi chisel chains are great for general use and handling more demanding cutting tasks, they are not optimized for ripping. If you’re looking to rip wood, it’s recommended to use a dedicated ripping chain for the best results.

Is Semi Chisel a Ripping Chain?

When it comes to chainsaw chains, there are various types available, each designed for specific purposes. One common question that arises among chainsaw users is whether the semi chisel chain can be used as a ripping chain. In this article, we will dive into the characteristics of the semi chisel chain, explore what sets a ripping chain apart, and provide insights into whether the semi chisel chain is suitable for ripping applications.

Characteristics of a Semi Chisel Chain

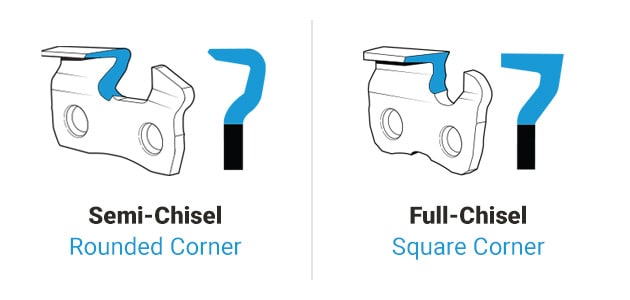

The semi chisel chain is known for its versatility and durability. It features rounded corner cutters, which give it a slightly smoother cutting performance compared to a full chisel chain. This type of chain is less likely to dull quickly, making it a popular choice for general-purpose cutting tasks in various wood types.

Due to its design, the semi chisel chain also has excellent chip control capabilities. The rounded corner cutters produce smaller wood chips, which reduces the likelihood of the chain getting clogged and promotes efficient cutting. This makes the semi chisel chain suitable for cutting dirty or resinous wood.

However, it’s important to note that the semi chisel chain may not be as aggressive as a full chisel chain. It may take slightly longer to cut through harder or denser materials, but it offers better durability and stays sharp longer. Now that we understand the characteristics of a semi chisel chain, let’s explore the concept of a ripping chain.

What Sets a Ripping Chain Apart?

A ripping chain, as the name suggests, is specifically designed for ripping or cutting along the grain of the wood. It features a different cutter shape compared to a standard cutting chain, allowing it to efficiently remove wood fibers as it moves through the material. The ripping chain has a flat-top cutter with a shallow angle, enabling it to slice through the wood fibers cleanly.

One of the key advantages of a ripping chain is its ability to create smoother and more accurate cuts when ripping lumber. This type of chain is commonly used in applications such as milling logs into boards or making precision cuts in woodworking projects.

Compared to a semi chisel chain, a ripping chain tends to be more aggressive and cuts through wood more quickly. Its specialized cutter shape optimizes the cutting process for rip cuts, resulting in smoother surfaces and reduced strain on the chainsaw.

The Compatibility Question: Can a Semi Chisel Chain Be Used as a Ripping Chain?

While the semi chisel chain and a ripping chain have distinct characteristics, it is possible to use a semi chisel chain for ripping applications. However, there are a few considerations to keep in mind.

Firstly, the cutting performance of a semi chisel chain when used for ripping may not be as efficient as that of a dedicated ripping chain. The semi chisel chain’s rounded corner cutters are not specifically designed for the unique requirements of rip cutting. This means it may take longer to rip through the wood and may not produce the same level of accuracy and smoothness as a ripping chain.

Additionally, the semi chisel chain’s design may result in more sawdust production compared to a ripping chain. The rounded corner cutters tend to produce smaller wood chips, which can accumulate and affect the cutting process during ripping. However, this can be mitigated by periodically cleaning the chain and ensuring proper lubrication.

In conclusion, while a semi chisel chain can be used for ripping, it is recommended to use a dedicated ripping chain for optimal results in terms of cutting speed, accuracy, and surface finish.

Tips for Optimal Cutting Performance

When using a chainsaw for ripping or any other cutting task, it’s important to ensure optimal cutting performance and longevity. Here are a few tips to keep in mind:

- Choose the right chain for the job: Consider the type of material and cutting task to select the most suitable chain for the job. In the case of ripping, using a dedicated ripping chain will yield the best results.

- Keep the chain sharp: A sharp chain is essential for efficient cutting. Regularly sharpen and maintain the chain to ensure optimal performance.

- Proper tensioning: Maintain proper chain tension to prevent chain slippage and ensure safe operation.

- Use appropriate safety gear: Always wear the necessary protective equipment, including a helmet, protective eyewear, gloves, and chainsaw chaps.

- Follow manufacturer guidelines: Consult the chainsaw manufacturer’s recommendations and guidelines for chain selection, maintenance, and safety precautions.

By following these tips and using the appropriate chain for the task at hand, you can achieve optimal cutting performance and ensure a safe and effective chainsaw operation.

Conclusion

In summary, while a semi chisel chain can be used for ripping applications, it may not offer the same level of cutting speed, accuracy, and surface finish as a dedicated ripping chain. The rounded corner cutters of a semi chisel chain are not specifically designed for rip cuts, and using a ripping chain will yield better results in terms of cutting efficiency. However, if a ripping chain is not available, a semi chisel chain can still be used with proper maintenance and consideration for its limitations. Remember to prioritize safety and follow the manufacturer’s guidelines for optimal chainsaw operation.

Key Takeaways: Is Semi Chisel a Ripping Chain?

- 1. A semi chisel chain is primarily designed for general cutting tasks.

- 2. It is not recommended for ripping or milling activities.

- 3. Ripping chains have a specific design to remove wood quickly and efficiently.

- 4. Ripping chains have a flat-top cutter that bites into the wood for better control.

- 5. If you are planning to do ripping or milling, it is better to use a ripping chain specifically designed for that purpose.

Frequently Asked Questions

In this section, we will address some common questions related to semi chisel chains and their suitability for ripping tasks.

What is a semi chisel chain?

A semi chisel chain is a type of chainsaw chain that features round-cornered cutter teeth with small bumps known as “chisel” or “semi-chisel” teeth. These teeth have rounded edges, making them more durable compared to a full chisel chain. The semi chisel chain strikes a balance between cutting performance and durability, making it versatile and suitable for a range of cutting tasks.

The semi chisel chain is designed to handle various types of wood, including softwoods and hardwoods. Its teeth are less prone to damage from dirt, rocks, or other materials that may be encountered during cutting. This makes it a good choice for general cutting applications in different environments.

Can a semi chisel chain be used for ripping wood?

Yes, a semi chisel chain can be used for ripping wood. While it may not be specifically designed for ripping like a dedicated ripping chain, a semi chisel chain can still handle ripping tasks effectively. The combination of its durability and cutting performance makes it capable of handling the demands of ripping wood.

However, it’s important to note that a dedicated ripping chain, designed specifically for cutting along the grain of the wood, may provide better results and efficiency for ripping tasks. If you frequently engage in ripping wood, it may be worth considering a ripping chain for optimal performance.

What are the advantages of using a semi chisel chain for ripping?

There are a few advantages to using a semi chisel chain for ripping wood. Firstly, the semi chisel chain offers good cutting performance, allowing for efficient wood removal during ripping tasks. Additionally, its durability provides resistance to damage from debris or other materials that may be encountered while ripping.

Furthermore, semi chisel chains are commonly available and more affordable compared to dedicated ripping chains. If you already have a semi chisel chain for general cutting tasks, it can be versatile enough for occasional ripping needs without requiring an additional purchase.

Are there any limitations to using a semi chisel chain for ripping?

While a semi chisel chain can handle ripping tasks, it does have some limitations. As it is not specifically designed for ripping, it may not provide the same level of efficiency or precision as a dedicated ripping chain. The shape of the teeth on a semi chisel chain may not optimize the cutting action for ripping along the grain of the wood.

In addition, the semi chisel chain may create more sawdust during the ripping process compared to a ripping chain. This may affect the overall finish and surface quality of the ripped wood. If you require a smoother and cleaner finish, a dedicated ripping chain is recommended.

What factors should be considered when deciding between a semi chisel chain and a ripping chain for ripping tasks?

When deciding between a semi chisel chain and a ripping chain for ripping tasks, several factors should be considered. Firstly, evaluate the frequency and scale of your ripping needs. If you frequently engage in ripping large volumes of wood, investing in a dedicated ripping chain can provide better efficiency and results.

Consider the desired finish quality as well. If you require a smoother and cleaner finish, a ripping chain with specialized teeth for ripping may be the better choice. Additionally, consider your budget as ripping chains tend to be more expensive compared to semi chisel chains. Balancing your specific requirements, budget, and the available options will help you make an informed decision.

Summary

So, is a semi chisel chain good for ripping wood? Well, not really. While semi chisel chains are great for general cutting, their design makes them less effective for ripping tasks. Ripping chains have a specific shape and tooth angle that allows them to cut through wood fibers smoothly and efficiently. So, if you’re planning on doing a lot of ripping, it’s best to invest in a dedicated ripping chain for optimal results.

In conclusion, if you want to get the most out of your chainsaw when it comes to ripping wood, it’s important to use the right type of chain. While semi chisel chains have their uses, they are not the best choice for ripping tasks. By using a dedicated ripping chain, you can ensure smoother and more efficient cuts, making your woodworking projects a whole lot easier.