Hey there, curious minds! Have you ever wondered what are back gears on a lathe? Well, you’re in the right place! In this article, we’ll embark on a fascinating journey into the world of lathes and uncover the secrets of those mysterious back gears. So, fasten your seatbelts and let’s dive right in!

Picture this: you’re working with a lathe, a powerful machine used for shaping and cutting metal. The lathe has a spindle that rotates at high speeds, allowing you to shape and form your workpiece. But what happens when you need to slow things down a bit? Enter the back gears!

Back gears are like the lathe’s secret speed control system. They work in conjunction with the gears on the headstock, and help you adjust the rotational speed of the spindle to suit the needs of your project. Whether you’re working with a small delicate piece or a large chunk of metal, back gears allow you to choose the right speed for the job.

So, how do back gears actually work? Well, when you engage the back gears, they create a mechanical connection between the spindle and the motor. This connection increases the torque and decreases the speed of the spindle, allowing for more precise and controlled machining. It’s like having a superpower that lets you fine-tune the lathe’s performance!

Now that you know what back gears are and how they work, you’re ready to take your lathe skills to the next level. With the ability to control and adapt the rotational speed of the spindle, you’ll have greater control over your projects and achieve stunning results. So, let’s get spinning and explore the world of lathes together!

What Are Back Gears on a Lathe?

Back gears are an essential component of a lathe machine. They play a crucial role in controlling the speed and power of the lathe’s spindle. By engaging the back gears, operators can achieve lower rotational speeds and higher torque, allowing them to work with larger workpieces or perform heavy-duty cutting operations. In this article, we will explore the function and benefits of back gears, as well as provide tips on how to use them effectively in a lathe machine.

The Function of Back Gears

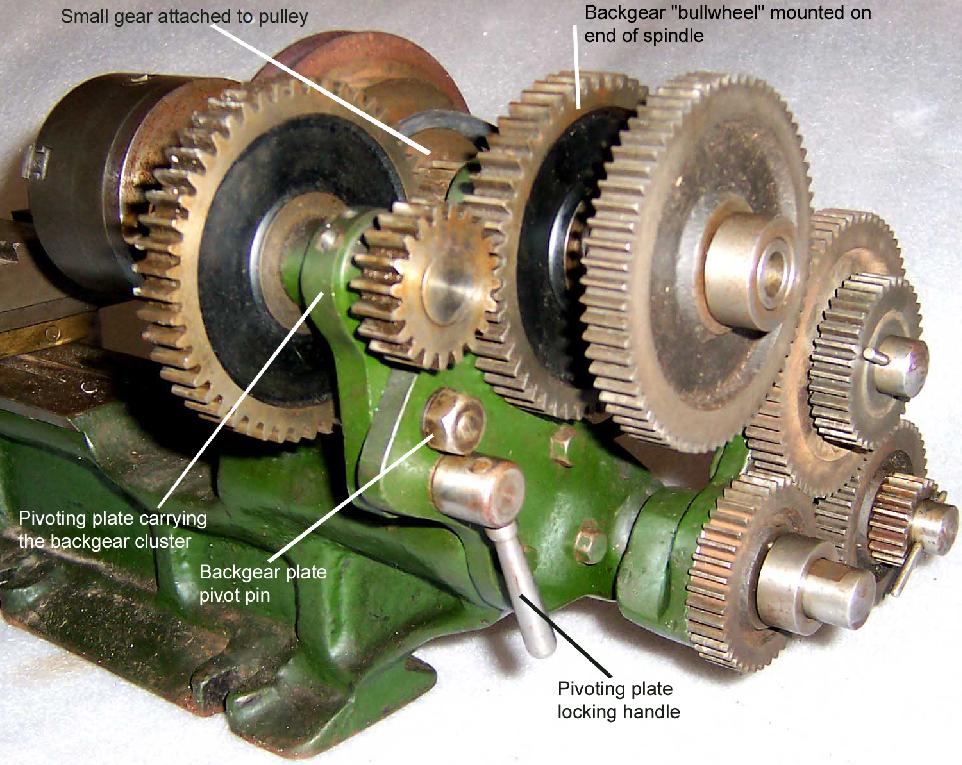

Back gears are a set of gears that create an additional gear reduction between the lathe’s motor and the spindle. They are usually located at the back of the lathe headstock, hence the name. When the back gears are engaged, power is transferred from the motor to the spindle through a series of gears, resulting in a slower rotational speed.

One primary function of back gears is to provide the necessary torque for heavy-duty operations. When working with larger workpieces or materials that require a significant amount of force to cut, the back gears allow the lathe machine to generate higher torque at lower speeds. This ensures that the cutting tool can effectively remove material without damaging the workpiece or the tool itself.

Additionally, back gears allow operators to work with materials that require lower rotational speeds. Some materials, such as certain alloys or heat-treated metals, can be extremely hard and difficult to machine at high speeds. By engaging the back gears, users can decrease the rotational speed of the spindle, enabling them to accurately shape and cut these challenging materials without compromising the quality of the finished product.

Benefits of Using Back Gears on a Lathe

Using back gears on a lathe offers several benefits, particularly when it comes to working with large or heavy workpieces. Here are some advantages of utilizing back gears:

- Increased Torque: Engaging the back gears allows for higher torque generation, enabling efficient cutting of tough materials and heavier workpieces.

- Accurate Machining: Lower rotational speeds provided by back gears enable precise machining, resulting in better surface finishes and dimensional accuracy.

- Versatility: With back gears, a lathe machine can handle a wider range of materials and workpiece sizes, expanding its capabilities.

- Reduced Wear and Tear: By slowing down the rotational speed, back gears reduce friction and wear on the cutting tool and the lathe itself, prolonging their lifespan.

Tips for Using Back Gears Effectively

While back gears offer various advantages, using them effectively requires proper understanding and attention to detail. Here are some tips to maximize the benefits of back gears on a lathe:

- Check the manual: Consult your lathe’s user manual or manufacturer’s guidelines to understand the specific steps for engaging and disengaging the back gears on your machine.

- Start with a lower speed: When using back gears, begin with a lower rotational speed and gradually increase it based on the material being machined and the cutting operation.

- Select the right gear ratio: Choose the appropriate gear ratio for the specific task at hand. Higher gear ratios provide more torque, while lower ratios offer higher speeds.

- Monitor the cutting operation: Pay close attention to the performance of the lathe, ensuring that the back gears are effectively supporting the cutting process. Adjust the speed and gear ratio as needed.

- Maintain proper lubrication: Regularly lubricate the gears and other moving parts of the lathe to ensure smooth operation and prevent premature wear.

Exploring Different Types of Back Gears

In addition to the traditional back gears, there are several variations and advancements in lathe technology that offer enhanced capabilities. Here are three common types:

1. Electronic Variable Speed Lathes:

Electronic Variable Speed (EVS) lathes use advanced technology to provide variable speed control without the need for traditional back gears. These lathes allow operators to easily adjust the speed through a control panel, offering precise speed control and convenience.

2. Step Pulley Lathes:

Step Pulley lathes rely on a series of different-sized pulleys to change the rotational speed. By manually adjusting the belt position, operators can engage different pulleys to achieve the desired speed. Although not as versatile as back gears, step pulley lathes can still handle a range of materials and workpieces effectively.

3. Geared Headstock Lathes:

Geared Headstock lathes feature an integrated gear mechanism that allows for easy speed changes. By manipulating the gears within the headstock, operators can quickly and effortlessly adjust the rotational speed to match the requirements of different applications.

Each type of back gear system offers unique advantages and may be more suitable for specific machining needs. Understanding the different options available can help users choose the right lathe for their requirements.

Conclusion

Back gears are a crucial component of a lathe machine, enabling operators to control rotational speed and torque according to the task at hand. By engaging the back gears, users can work with larger workpieces, tough materials, and achieve accurate machining results. Understanding how to use back gears effectively, along with exploring different types of back gear systems, can help operators make the most of their lathe machine’s capabilities. Whether it’s a traditional lathe with back gears or an advanced electronic or geared headstock lathe, leveraging this technology can enhance productivity and the quality of machined parts.

Key Takeaways – What are Back Gears on a Lathe?

- Back gears are an important part of a lathe machine.

- They provide additional power and control for different machining operations.

- Back gears have different gear ratios that can be adjusted to suit specific needs.

- Engaging back gears allows for slower speeds and increased torque.

- Using back gears can help with heavy-duty cutting and threading tasks.

Frequently Asked Questions

In this section, we will answer some common questions about back gears on a lathe.

How do back gears work on a lathe?

Back gears on a lathe are a set of gears that control the spindle’s speed. They work by providing a lower speed for heavy cutting operations or when working with larger workpieces. When the back gears are engaged, power is transmitted from the motor to the spindle through a series of gears that reduce the rotational speed of the spindle. This allows for better control and precision during certain machining operations.

On most lathes, the back gears are located at the back of the headstock and can be engaged or disengaged using a lever or a control knob. By adjusting the speed of the back gears, machinists can select the most suitable speed for the specific task at hand, ensuring optimal performance and accuracy.

What are the advantages of using back gears on a lathe?

Using back gears on a lathe offers several advantages. Firstly, it provides increased torque, which is essential for heavy-duty operations such as turning large workpieces or removing materials at a faster rate. The gears reduce the rotational speed of the spindle, allowing the lathe to handle more challenging tasks effortlessly.

Additionally, back gears offer greater control and precision during machining operations. The lower speed provided by the gears enables the operator to make precise cuts while maintaining accuracy and preventing any unwanted vibrations or chatter. This is particularly important when working on intricate projects or when high-quality finishes are required.

When should I use the back gears on a lathe?

The back gears on a lathe should be used when you need to perform heavy cutting operations or when working with larger workpieces. These situations often require more torque and power, which can be achieved by engaging the back gears. When you encounter materials that are difficult to cut, or when you need to remove a substantial amount of material, using the back gears will ensure a smoother and more controlled cutting process.

It’s important to note that not all machining operations require the use of back gears. For lighter cuts or when working with smaller workpieces, the regular spindle speed provided by the lathe’s direct drive may be sufficient. It is recommended to consult the lathe’s user manual or seek guidance from an experienced operator to determine when to use the back gears for optimal results.

Can I change the speed of the back gears on a lathe?

Yes, the speed of the back gears on a lathe can usually be changed. Most lathes will have a set of different gears that can be swapped in order to achieve different speeds. By changing the gears, you can customize the rotational speed of the spindle according to your specific machining needs.

It’s important to refer to the lathe’s instruction manual to understand the process of changing gears and to ensure you select the appropriate gears for the desired speed. In some cases, you may need to disengage the back gears before changing the gears. This process may vary depending on the specific lathe model, so always consult the manufacturer’s guidelines for accurate instructions.

Are back gears found on all lathes?

No, not all lathes have back gears. The presence of back gears depends on the specific design and purpose of the lathe. Back gears are typically found on larger, more heavy-duty lathes that are designed to handle larger workpieces and perform more demanding machining tasks.

Smaller, lighter lathes may not have back gears as they are usually designed for lighter cuts and more precise work. These lathes often rely on direct drive systems or other mechanisms to adjust spindle speed. It is important to consider your specific machining needs and the type of lathe you are using to determine if back gears are present and required for your work.

What are Back Gears and How to Use them

Summary

Back gears on a lathe are important for controlling the speed of the spindle. They help to slow down the rotation so that you can work with larger, tougher materials. By engaging the back gears, you can increase torque and make your lathe more powerful. However, it’s important to use them properly and follow safety precautions.

In conclusion, back gears on a lathe are a useful feature that allow you to work with larger materials and provide more power. Understanding how to engage and use them will help you achieve better results and stay safe. So, next time you’re using a lathe, don’t forget to check out the back gears!