Are you curious about woodworking and the different tools used in this craft? Well, let’s dive into one essential component: C-channels! 🪚🌲

When it comes to woodworking, C-channels are like the unsung heroes. They may not be as flashy as a jigsaw or a chisel, but they play a crucial role in many woodworking projects.

So what are C-channels used for in woodworking? Let’s find out together and discover the amazing versatility of these handy little helpers! 💪🔨🪓

What are C-Channels Used for in Woodworking?

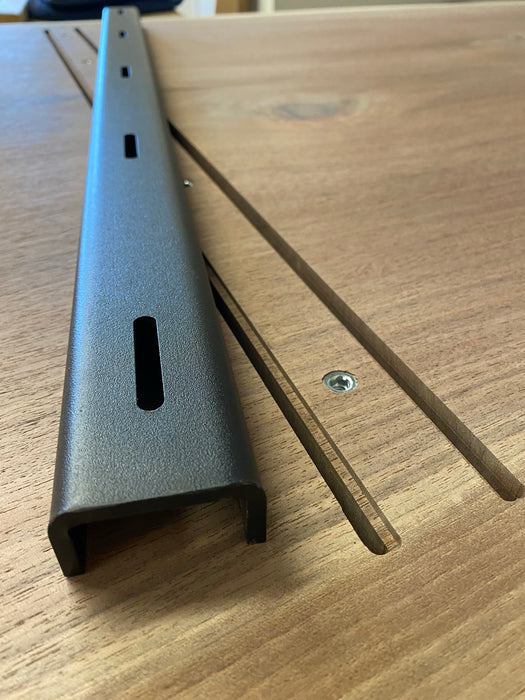

In the world of woodworking, there are various tools and materials that are essential for different projects. One such material that is frequently used is the C-channel. C-channels, also known as U-channels, are versatile metal profiles shaped like a “C” or a “U.” These channels have a wide range of applications in woodworking, making them an indispensable component in many projects. This article explores the various uses of C-channels in woodworking and provides detailed information on how they can enhance the quality and versatility of your woodworking projects.

The Role of C-Channels in Woodworking

When it comes to woodworking, C-channels serve multiple purposes, adding strength, stability, and aesthetic appeal to a variety of projects. Let’s delve into the key roles that C-channels play in woodworking and how they contribute to enhancing the functionality and durability of the finished pieces.

Precision Reinforcement and Support

One of the primary uses of C-channels in woodworking is to reinforce and provide support to structures that require additional strength. The unique shape of the C-channel allows it to fit snugly against surfaces, providing an extra layer of support and stability. Whether used to reinforce joints, brace shelves, or support heavy load-bearing components, C-channels ensure that your woodworking projects are structurally sound and long-lasting.

Additionally, C-channels are often used in cabinetry to strengthen the corners of doors and drawers. By fitting the C-channel on the interior edges of these components, woodworkers can prevent warping, ensure proper alignment, and prolong the lifespan of the furniture. The precision and durability of C-channels make them an invaluable asset in woodworking construction.

Accurate Alignment and Edging

C-channels are also useful in achieving precise alignment and edging in woodworking projects. When working with large panels or tabletops made from multiple boards, it can be challenging to ensure that all the joints are perfectly aligned. Here’s where C-channels come into play. By attaching C-channels to the edges of the panels, woodworkers can create a seamless and uniform surface by eliminating any slight imperfections or gaps between the boards.

In addition to alignment, C-channels also contribute to clean and professional-looking edges. By using C-channels as edging strips, woodworkers can hide the exposed edges of plywood or MDF boards, giving the project a refined and finished appearance. The channels provide a protective barrier against chipping or splintering, safeguarding the wood and enhancing its aesthetic appeal.

How to Incorporate C-Channels in Your Woodworking Projects

Now that we understand the various uses of C-channels in woodworking, let’s explore how you can incorporate them effectively into your projects. Below are some practical tips and techniques to help you make the most out of C-channels in your woodworking endeavors.

Enhancing Stability with C-Channel Joints

One of the most effective ways to utilize C-channels is by incorporating them in joint construction. Whether you’re building a table, cabinet, or frame, using C-channels in joint connections can significantly enhance the stability and durability of the structure. By recessing the C-channels into the adjoining pieces and securely fastening them, you create a more rigid bond that can withstand the test of time. Consider using C-channels in combination with traditional joinery techniques like biscuits or dowels for maximum strength and stability.

Creating Customized Storage Solutions

C-channels offer great flexibility when it comes to creating customized storage solutions. Whether it’s organizing your tool collection or designing storage racks for materials and supplies, incorporating C-channels can help you maximize space and efficiency. By attaching C-channels to walls or workbenches, you can easily create adjustable shelving systems or install hooks and brackets to hang tools and accessories. The versatility of C-channels allows you to adapt and rearrange your storage setups as your needs evolve, making them an excellent choice for creating functional and organized workspaces.

Adding Decorative Accents and Trims

Aside from their functional purposes, C-channels can also be used as decorative accents and trims in woodworking projects. Whether it’s to highlight edges, emphasize corners, or add a contemporary touch to furniture, incorporating C-channels as decorative elements can elevate the overall aesthetics of your pieces. With various finishes available, such as brushed nickel, black, or brass, you can choose the C-channel that complements the design and style of your project. From modern and minimalistic designs to rustic and industrial motifs, C-channels offer endless possibilities for creative customization.

Key Takeaways: What are C-Channels Used for in Woodworking?

- C-Channels are metal strips shaped like the letter “C” and are commonly used in woodworking projects.

- They provide structural support and reinforcement, helping to prevent warping or bending of wooden pieces.

- C-Channels are often used to build frames for cabinets, doors, and shelves.

- They can also be used to reinforce joints and corners, adding strength and stability to the overall structure.

- In addition, C-Channels can be used as guides for sliding doors or drawers, ensuring smooth and precise movement.

Frequently Asked Questions

When working with wood, c-channels can serve a variety of purposes. These U-shaped metal channels are commonly used in woodworking projects to enhance stability, reinforce structures, and provide additional support. Here are some commonly asked questions about the use of c-channels in woodworking:

1. How can c-channels enhance stability in woodworking projects?

C-channels are often used to add stability to different woodworking structures. By attaching c-channels to the edges or joints of certain wooden pieces, you can prevent warping or twisting. This makes your projects more durable and long-lasting, ensuring they can withstand regular use over time. With c-channels, you can reinforce weak points and create sturdier structures.

Additionally, c-channels can be utilized as bracing elements in both vertical and horizontal applications. By adding c-channels to the back or edges of shelves, cabinets, or other wooden structures, you can provide extra support and prevent sagging or bending over time. This helps maintain the overall stability and structural integrity of your woodworking projects.

2. How do c-channels reinforce wooden structures?

C-channels can be used to reinforce wooden structures by distributing the weight and stress across a larger area. When attached to the edges or joints of wooden pieces, c-channels help to strengthen these weak points. This is particularly useful in projects such as table legs or workbenches, where a significant amount of weight is placed on the joints.

Furthermore, c-channels can help absorb shocks and vibrations that may occur in certain woodworking applications. For example, when constructing a speaker cabinet, adding c-channels along the panels can effectively dampen vibrations, resulting in better sound quality. By reinforcing wooden structures with c-channels, you can enhance their load-bearing capacity and overall durability.

3. Can c-channels be used for decorative purposes in woodworking?

Yes, c-channels can indeed be used for decorative purposes in woodworking. In addition to providing structural support, c-channels can add a unique visual element to your projects. They can be used as trim pieces to highlight the edges of tables, cabinets, or panels. This can create a more polished and finished look for your woodworking projects.

C-channels can also be customized and painted to match the aesthetic of your overall design. Whether you prefer a sleek modern style or a rustic look, c-channels can be incorporated in various ways to complement your woodworking project.

4. Are c-channels suitable for outdoor woodworking projects?

Yes, c-channels can be suitable for outdoor woodworking projects, provided they are made of materials that can withstand outdoor conditions. Look for c-channels made of weather-resistant metals such as stainless steel or aluminum. These materials are less likely to corrode or rust when exposed to moisture or other outdoor elements.

However, it’s important to note that if the c-channels are constantly exposed to harsh weather conditions, regular maintenance may be required to prevent deterioration. This may involve applying protective coatings or sealants to ensure the longevity of your outdoor woodworking projects.

5. Can c-channels be used in other types of DIY projects, beyond woodworking?

Absolutely! C-channels have versatile applications beyond woodworking. They can be utilized in various DIY projects, such as metalwork, construction, or even automotive fabrication. C-channels can assist in enhancing stability, reinforcing structures, and providing additional support in a wide range of applications.

For example, in metalworking, c-channels are commonly used as guides or tracks for sliding doors, panels, or gates. In construction, c-channels can be used as support beams or junctions in larger structures. Moreover, c-channels are often employed in automotive fabrication to reinforce chassis or add structural strength to certain vehicle components. The possibilities of incorporating c-channels into DIY projects are vast and depend on the specific requirements of each project.

Summary

C-Channels are a type of metal accessory commonly used in woodworking projects. They come in different sizes and are usually made of steel. C-Channels are mainly used to support and strengthen structures, like shelves, cabinets, and frames. They provide stability and prevent bending or sagging. Another use of C-Channels is as a track for sliding doors or gates, making them versatile in various woodworking applications. Their simple design and easy installation make them a popular choice for woodworking projects.

C-Channels can be found in most hardware stores and are often affordable. They are a practical addition to any woodworking project that requires extra support or stability. Whether you’re building a bookshelf, a storage rack, or a sliding door, C-Channels are a useful tool to enhance the durability and functionality of your woodworking creations. So, next time you’re working on a woodworking project, consider incorporating C-Channels for added strength and reliability.