If you’re curious about woodworking and wondering what c channels are used for, you’ve come to the right place. In this article, we’ll explore the world of c channels and their applications in woodworking projects. So, if you’re ready to dive in, let’s get started!

Woodworking is an exciting craft that allows you to create beautiful and functional pieces using your hands and imagination. One essential element in woodworking is understanding the various tools and materials at your disposal. And that’s where c channels come into play.

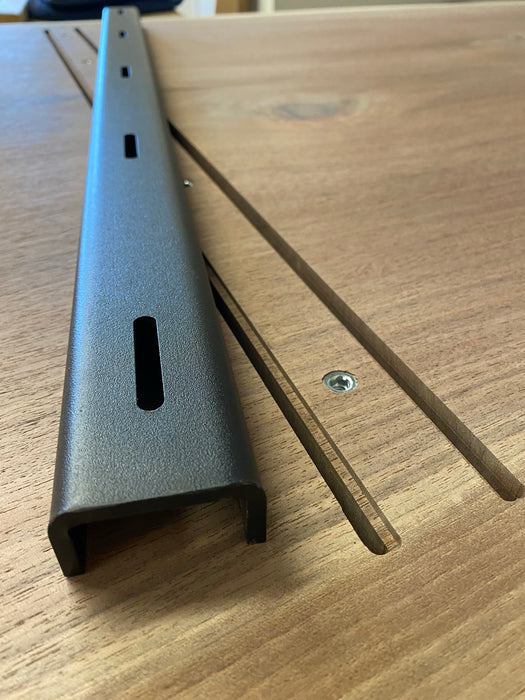

C channels, also known as structural channels or simply “C” shaped profiles, are commonly used in woodworking projects for their versatility and strength. These channels are made of metal and have a unique shape that resembles the letter “C.” But what exactly are they used for? Let’s find out in the next paragraph!

What Are C Channels Used for in Woodworking?

Woodworking is a versatile craft that requires various tools and techniques to create beautiful and functional pieces. One essential component in woodworking is the use of C channels. C channels, also known as metal channels or U channels, are commonly used as reinforcement or structural support in woodworking projects. They offer stability, strength, and versatility, making them indispensable in the woodworking industry. In this article, we will explore in detail the different applications and benefits of using C channels in woodworking.

Applications of C Channels in Woodworking

C Channels have numerous applications in woodworking, ranging from providing structural support to enhancing the aesthetic appeal of furniture and cabinetry. Let’s delve into some of the most common uses of C channels in woodworking:

1. Reinforcing Joints and Corners

One of the primary uses of C channels in woodworking is to reinforce joints and corners. When constructing furniture or cabinets, joints and corners are vulnerable to stress and potential damage due to the weight placed on them. By using C channels, woodworkers can reinforce these weak points, adding strength and durability to their projects. C channels are often affixed to the interior of joints or corners, providing support and preventing them from separating under heavy loads.

Furthermore, C channels can be used as corner protectors, protecting the edges of furniture or cabinetry from chipping or splitting. They act as a barrier between the wood and external impact, enhancing the longevity of the piece.

2. Creating Sliding Doors and Panels

C channels are commonly used in woodworking to create sliding doors and panels. By attaching C channels to the top and bottom edges of a door or panel, woodworkers can easily install them on a track system, allowing for smooth and effortless sliding. This application is particularly useful for wardrobes, cabinets, and room dividers, where space-saving and easy access are essential.

C channels provide stability and support to the sliding mechanism, ensuring that the doors or panels move without any obstructions or jams. Additionally, the use of C channels in sliding systems allows for easy disassembly and replacement of the doors or panels, making maintenance and upgrades a breeze.

3. Installing Shelving Units

Shelving units are a fundamental element in woodworking projects, providing storage and organization solutions. C channels are frequently employed to install shelving in a secure and flexible manner. By mounting C channels to the walls or existing structures, woodworkers can easily slide in and adjust shelves as needed.

The use of C channels in shelving units allows for easy customization and adaptability. Whether you want to add or remove shelves or change their positioning, C channels make the process hassle-free. They provide stability and prevent shelves from sagging under the weight of objects. Additionally, C channels add a sleek and modern aesthetic to the shelving units.

4. Reinforcing Tabletops and Countertops

C channels are also instrumental in reinforcing tabletops and countertops, ensuring their structural integrity and preventing warping or cracking. By attaching C channels underneath the surfaces, woodworkers can distribute the weight evenly and minimize the effects of expansion and contraction due to changes in temperature and humidity.

This application is particularly crucial for large, heavy tabletops or countertops that need to withstand regular use and weight-bearing. C channels offer additional support, preventing the wood from flexing or sagging over time, and providing a solid and stable surface.

5. Enhancing Aesthetic Appeal

In addition to their functional uses, C channels can also enhance the aesthetic appeal of woodworking projects. They can be used as decorative accents, adding a touch of elegance and sophistication to furniture and cabinetry. By incorporating C channels into the design, woodworkers can create beautiful lines, highlight edges, or add contrast to the overall piece.

C channels come in various finishes and materials, including brass, stainless steel, and aluminum, allowing woodworkers to choose the option that best complements their design concept. Whether it’s a modern, minimalist look or a vintage-inspired piece, C channels can elevate the visual appeal and make a statement.

6. Supplementary Support for Workbenches

C channels can also be used to provide supplementary support for workbenches – a staple in any woodworking workshop. By adding C channel braces to the legs or underside of the workbench, woodworkers can enhance its stability and load-bearing capacity. This is particularly beneficial when working with heavy machinery or applying significant force during the woodworking process.

Incorporating C channels into workbenches ensures that they can withstand the rigors of woodworking, preventing wobbling, and maintaining a safe and secure workspace. This application is especially important for professionals and enthusiasts who undertake larger projects or work with heavy materials.

7. Edge Banding and Trimming

Another common use of C channels in woodworking is edge banding and trimming. When applying veneer or laminate to the edges of furniture or cabinetry, C channels can be used to create a clean and finished appearance. The C channel is affixed to the edge, covering and protecting the exposed material, resulting in a sleek and professional look.

C channels also act as a barrier, preventing the edges from chipping or becoming damaged over time. This application not only enhances the durability of the piece but also adds a polished and refined touch to the overall design.

Benefits of Using C Channels in Woodworking

1. Increased Stability and Durability

C channels provide essential stability and durability to woodworking projects. By reinforcing joints, corners, and other weak points, C channels prevent sagging, splitting, or separating of components. This ensures that the piece remains sturdy and can withstand regular use and weight-bearing. Increased stability also contributes to the longevity of the furniture or cabinetry.

2. Versatility and Flexibility

C channels offer versatility and flexibility in woodworking projects. They can be easily incorporated into various designs and adapted for different purposes. Whether it’s reinforcing joints, creating sliding doors, or installing shelving units, C channels provide a flexible solution that can be customized to meet specific requirements.

3. Easy Installation and Maintenance

One of the key advantages of using C channels is their easy installation and maintenance. They can be quickly affixed to the desired areas using screws, nails, or adhesive, making the woodworking process efficient and time-saving. Additionally, if any adjustments, replacements, or repairs are needed, C channels can be readily removed and replaced without significant effort.

4. Enhanced Aesthetic Appeal

C channels not only provide functional benefits but also enhance the visual appeal of woodworking projects. They can be used to add decorative accents, create clean lines, or highlight edges, elevating the overall design. With a range of finishes and materials available, C channels offer opportunities for personalization and customization.

5. Improved Workbench Stability

For woodworkers who rely on workbenches, the use of C channels can significantly improve stability and safety. By adding supplementary support with C channel braces, workbenches can withstand heavy loads and vibrations, ensuring a stable and secure workspace.

6. Protection of Edges and Corners

C channels act as protective barriers, preventing the edges and corners of furniture or cabinetry from chipping, splitting, or becoming damaged. This extends the lifespan of the piece and maintains its aesthetic appeal over time. C channels also provide added safety, reducing the risk of accidents or injuries caused by sharp edges.

7. Cost-Effective Solution

Using C channels in woodworking can be a cost-effective solution compared to other methods of reinforcement or support. C channels are readily available at affordable prices and can be easily installed without the need for specialized tools or techniques. This makes them an accessible option for woodworkers of all skill levels.

Choosing the Right C Channel for Your Woodworking Project

When selecting C channels for your woodworking project, it’s important to consider factors such as material, size, and finish. The right C channel will depend on the specific application and design concept you have in mind. Here are some tips to help you make an informed decision:

1. Material

Choose a material that matches the aesthetic and functional requirements of your project. Brass C channels offer a classic and luxurious look, while stainless steel provides durability and resistance to corrosion. Aluminum C channels are lightweight and suitable for applications that require ease of installation and versatility.

2. Size

Consider the size of the C channel based on the dimensions and weight-bearing capacity required for your project. Ensure that the C channel is wide and deep enough to provide adequate support without being bulky or obtrusive. Consult woodworking experts or refer to load capacity charts for guidance.

3. Finish

The finish of the C channel can significantly impact the overall design aesthetic. Choose a finish that complements the style and tone of your woodworking project. Options range from polished or brushed finishes to powder coating or anodized finishes.

4. Installation Method

Consider the installation method required for the C channel you choose. Some C channels can be affixed with nails, screws, or adhesive, while others may require specialized brackets or clips. Ensure that the installation method aligns with your woodworking skills and the tools available to you.

5. Supplier Reputation

Choose a reputable supplier or manufacturer for your C channels to ensure quality and consistency. Research customer reviews, certifications, and warranties to make an informed decision. Consult with fellow woodworkers or industry professionals for recommendations.

C Channels vs. Other Reinforcement Methods

While C channels offer numerous advantages in woodworking, it’s essential to understand how they compare to other reinforcement methods. Here are some comparisons between C channels and alternative solutions:

C Channels vs. Dowels

Dowels are commonly used for joint reinforcement in woodworking. While dowels provide strength and stability, C channels offer greater flexibility in terms of customization and disassembly. C channels can be easily adjusted or replaced, while dowels require more extensive woodworking skills to remove and replace.

C Channels vs. Brackets

Brackets are another popular choice for reinforcement in woodworking. While brackets offer excellent support, C channels provide a sleeker and more streamlined appearance. C channels can be hidden within the wood or showcased as decorative accents, whereas brackets may be more visible and affect the overall aesthetics of the project.

C Channels vs. Metal Plates

Metal plates are often used to reinforce corners and joints. While metal plates offer robust reinforcement, they can be challenging to install, especially in tight or hard-to-reach areas. C channels, on the other hand, can be easily attached using screws or adhesive, providing a simpler and more accessible solution.

Tips for Using C Channels in Woodworking

To ensure successful and effective use of C channels in your woodworking projects, consider the following tips:

1. Accurate Measurements

Take precise measurements before installing C channels to ensure a proper fit. Accuracy is crucial to provide optimal support and prevent any misalignments or gaps.

2. Pre-Drilling

If using screws to attach C channels, pre-drill the holes to prevent the wood from splitting. Select drill bit sizes that match the diameter of the screws for a secure and reliable installation.

3. Flush Mounting

For a seamless look, consider flush mounting the C channels by embedding them within the wood. This technique creates a clean and professional appearance.

4. Sanding and Finishing

Ensure that the edges and surfaces of the wood are sanded and finished properly before attaching C channels. This will result in a smooth and polished finish.

5. Regular Maintenance

Inspect the C channels periodically for any signs of wear or damage. Replace them if necessary to maintain the integrity and functionality of your woodworking projects.

Conclusion

C channels play a vital role in the world of woodworking, providing stability, support, and aesthetic appeal to a wide range of projects. From reinforcing joints to creating sliding doors, shelving units, and workbenches, C channels offer versatility and durability that is essential for woodworking success. By understanding the applications, benefits, and tips for using C channels effectively, woodworkers can elevate their craftsmanship and create stunning pieces that will stand the test of time.

Key Takeaways: What Are C Channels Used for in Woodworking?

- C channels are metal materials shaped like the letter “C” often used in woodworking projects.

- They are commonly used as support and reinforcement for structures, such as cabinets, shelves, or frames.

- These channels can provide added rigidity and stability to the wooden structure.

- They are also useful for attaching and securing different components together.

- C channels offer versatility as they can be cut and customized to fit specific woodworking needs.

Frequently Asked Questions

Welcome to our Q&A section on the topic of “What are C channels used for in woodworking?” Below, we have answered some common questions related to this topic in a simple and concise manner. Whether you’re a beginner or an experienced woodworker, we hope you find this information helpful!

1. Why are C channels commonly used in woodworking?

C channels, also known as structural channels, are a popular choice in woodworking due to their versatility and strength. These channels have a unique shape, resembling the letter “C,” with two flat, parallel flanges forming the sides and a vertical web connecting them. The design of C channels allows them to add structural support and rigidity to various woodworking projects.

Whether you’re constructing furniture, building shelves, or creating a framework for cabinets, C channels can help you create sturdy and stable structures. Their shape makes them ideal for handling heavy loads, distributing weight evenly, and preventing sagging or bending over time. They are often used to reinforce joints, braces, and frames in woodworking projects.

2. Can C channels be used to hang or mount objects in woodworking?

Absolutely! C channels are often used for hanging or mounting objects in woodworking projects. Due to their strong and durable nature, they provide reliable support for various applications. For example, you can use C channels to hang heavy tools, such as clamps or saws, on the wall of your woodworking workshop.

Additionally, C channels can be used to mount shelves, cabinets, or even workbenches securely to the wall. The flat flanges on the sides of the C channel allow for easy attachment of these objects using screws or other fasteners. By using C channels for hanging or mounting, you can ensure that your woodworking space remains organized and your tools are easily accessible.

3. Are C channels suitable for creating hidden joints in woodworking?

C channels are not typically used for creating hidden joints in woodworking projects. While they offer excellent structural support, their shape and design make them more suitable for visible applications or for reinforcing visible joints. Hidden joints, on the other hand, require specialized joinery techniques or concealed fasteners.

If you’re looking to create hidden joints in woodworking, there are alternative methods such as dovetail joints, mortise and tenon joints, or pocket hole joinery that are better suited for achieving seamless and concealed connections. These techniques provide a clean and aesthetically pleasing finish without the need for visible brackets or reinforcements.

4. Can C channels be used for decorative purposes in woodworking?

While C channels are primarily used for their structural support and functional aspects in woodworking, they can also serve decorative purposes in certain projects. For example, you can incorporate C channels into furniture designs to enhance the aesthetic appeal or create unique visual elements.

By strategically placing C channels on the edges or corners of wooden furniture, you can add an industrial or modern touch to the overall design. The sleek lines and clean look of C channels can complement various styles, from minimalist to contemporary. Just make sure to consider the harmony and balance of the overall design when incorporating C channels for decorative purposes.

5. Can C channels be used for framing in woodworking projects?

Yes, C channels are commonly used for framing in woodworking projects. Whether you’re constructing a wooden structure, like a shed or a small cabin, or building partition walls within a workspace, C channels can provide the necessary structural support.

By using C channels as the framework, you can easily create a sturdy and durable structure that can withstand the test of time. The vertical web of the C channel acts as a beam, supporting the weight and evenly distributing it across the structure. Additionally, the flat flanges on the sides allow for easy attachment of other components, such as panels or siding, making the framing process more efficient.

Summary:

C channels in woodworking are metal strips shaped like the letter “C”. They are used to support and strengthen wooden structures, like shelves and cabinets. These channels, also known as U-channels, are screwed into the sides or undersides of wood to provide extra stability. C channels make the wood less likely to warp or bend, and they can also be used to hide screws and other hardware. Overall, C channels help make woodworking projects more durable and sturdy.

In addition to their support function, C channels also add a decorative touch to woodworking. They come in different sizes and finishes, allowing woodworkers to choose the one that best matches their project’s style. By using C channels, woodworkers can achieve a professional, polished look for their furniture and other wooden creations. So next time you’re working with wood, consider using C channels to make your projects stronger and more visually appealing.