Are you curious about what High-Speed Steel (HSS) drill bits are used for? Well, you’ve come to the right place! HSS drill bits are an essential tool for any DIY enthusiast or professional. So, let’s dive in and explore the exciting world of HSS drill bits together!

Picture this: you’re working on a woodworking project, and suddenly you realize you need to drill a hole. That’s where HSS drill bits come to the rescue! They’re specifically designed to cut through different materials like wood, metal, plastic, and even concrete.

But what makes HSS drill bits so special? Well, they’re made from a type of steel called High-Speed Steel. This steel is known for its durability, heat resistance, and ability to retain its cutting edge even when exposed to high-speed drilling. So, with HSS drill bits, you get the best of both worlds – strength and efficiency!

So, whether you’re building furniture, installing shelves, or working on a plumbing project, HSS drill bits are your go-to tool. They make drilling holes a breeze and ensure your projects come together smoothly. Ready to learn more about HSS drill bits and their various applications? Let’s jump right in!

The Versatile Uses of HSS Drill Bits: A Comprehensive Guide

When it comes to drilling holes in various materials, High-Speed Steel (HSS) drill bits are a go-to tool for both professionals and DIY enthusiasts. With their exceptional durability and versatility, these drill bits have become an essential part of any toolbox. In this comprehensive guide, we will explore the various uses of HSS drill bits and highlight their benefits, tips, and comparisons to other types of drill bits.

The Basics: Understanding HSS Drill Bits

HSS drill bits, made from high-speed steel, are known for their ability to withstand high temperatures while retaining their hardness. The composition of these drill bits includes a combination of carbon steel and other elements like tungsten, molybdenum, and chromium, which enhances their strength and heat resistance.

Due to their hardness and durability, HSS drill bits are highly versatile and can be used for a wide range of materials, such as wood, metal, plastic, and even composites. Their ability to cut through materials efficiently with less friction makes them a popular choice among professionals and hobbyists alike.

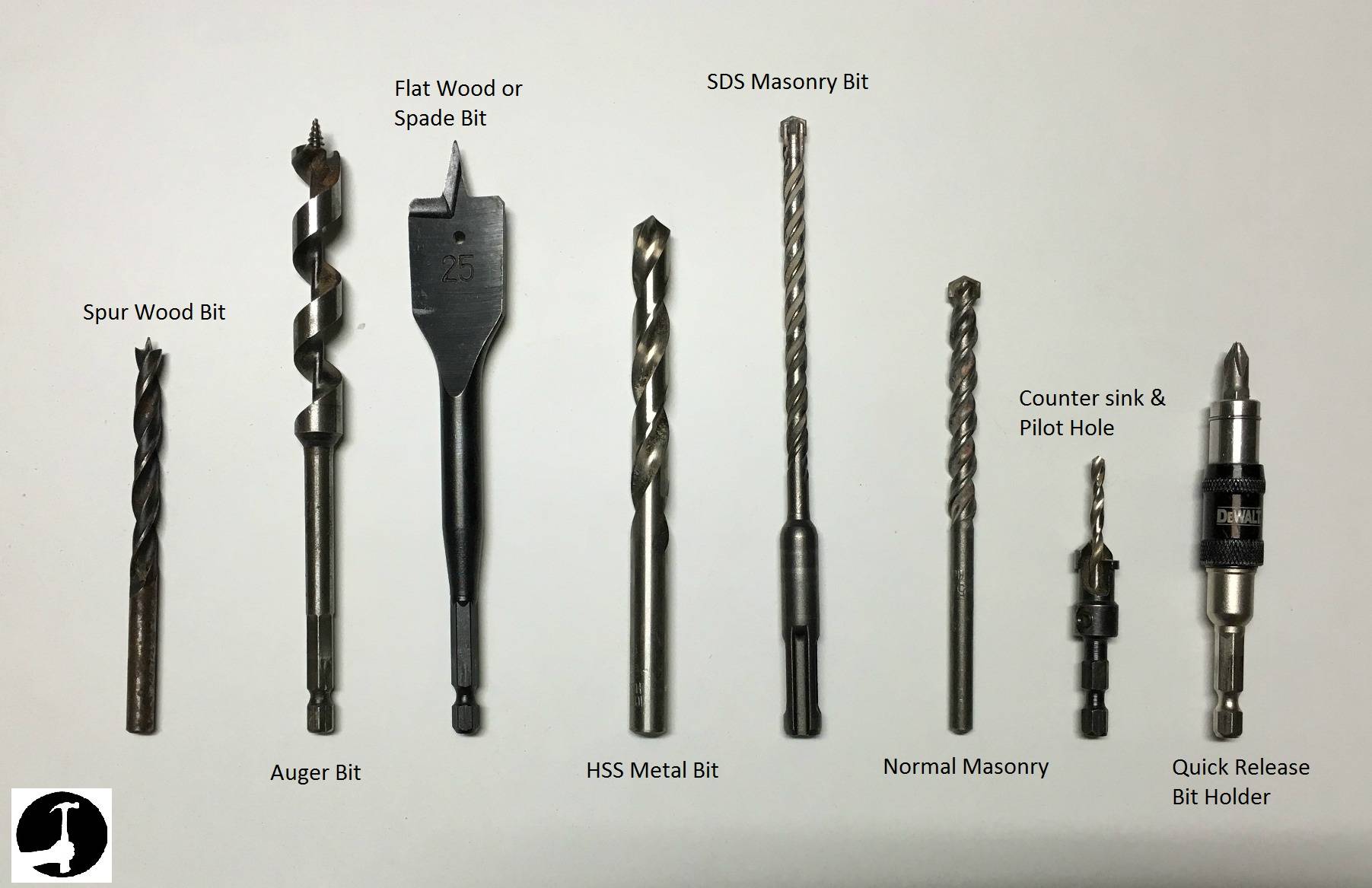

When it comes to the different types of HSS drill bits, you will find a variety of options, including twist bits, step bits, and countersink bits, each designed for specific applications. Now, let’s dive into the diverse uses of HSS drill bits.

Woodworking Applications

One of the primary uses of HSS drill bits is in woodworking projects. Whether you’re creating furniture, installing shelves, or building a wooden structure, HSS drill bits are an indispensable tool. Their sharp edges and efficient chip removal allow for precise and clean holes in wood.

When drilling holes in wood, it is essential to determine the correct diameter of the drill bit based on the size of the screws or dowels you will be using. HSS drill bits come in various sizes, allowing you to choose the appropriate one for your specific woodworking needs.

Additionally, HSS drill bits are also compatible with various woodworking machines like drill presses, which further enhances their accuracy and stability during drilling operations. Whether you’re a professional woodworker or a DIY enthusiast, having a set of HSS drill bits in your toolbox is essential for any woodworking project.

Metalworking Applications

HSS drill bits are equally adept at handling metalworking tasks, making them a reliable tool for professionals in the construction, plumbing, and automotive industries. Whether you need to drill through aluminum, steel, or stainless steel, HSS drill bits are up to the challenge.

Compared to other types of drill bits, HSS bits are specifically designed to withstand the higher temperatures generated when drilling into metal. Their ability to dissipate heat efficiently reduces the risk of overheating, which can lead to premature wear and damage to the drill bit.

A common application for HSS drill bits in metalworking is creating pilot holes for screws or bolts. These pilot holes help guide the screws in place, preventing them from slipping or damaging the material. Additionally, HSS drill bits can be used for enlarging or widening existing holes in metal.

Plastic and Composite Applications

In addition to wood and metal, HSS drill bits can also be utilized for drilling holes in plastic materials. Whether you’re working on a DIY project involving PVC pipes, acrylic sheets, or fiberglass, HSS drill bits offer precise and clean holes without causing damage or melting the material.

When working with composites like fiberglass or carbon fiber, HSS drill bits with special coatings, such as titanium nitride (TiN), offer superior performance by reducing friction and preventing the material from sticking to the drill bit. The use of HSS drill bits ensures that the integrity of the composite material remains intact and prevents delamination or splintering.

Tile and Masonry Applications

HSS drill bits, though primarily designed for drilling through wood, metal, and plastic, can also be used for certain tile and masonry applications. While specialized drill bits like carbide-tipped bits or diamond-coated bits are more suitable for drilling through hard materials like ceramic tiles or concrete, HSS drill bits can still be used for softer tiles or bricks.

When using HSS drill bits for tile or masonry, it’s essential to proceed with caution and use a slower drilling speed. Applying too much force or excessive speed can cause the drill bit to overheat or become dull quickly. Water or a lubricant can be used to cool the drill bit during the drilling process and prevent damage.

Other Applications

HSS drill bits are not limited to the aforementioned applications. They are also used in various industries and DIY projects where precision drilling and durability are required. Here are some additional applications of HSS drill bits:

- Electronics and circuitry: HSS drill bits are used to create pilot holes for mounting electronic components on circuit boards.

- Model-making: HSS drill bits are utilized for drilling precise holes in scale models or miniatures.

- Jewelry making: HSS drill bits enable jewelers to create holes for pendant bails or drill pearl beads for stringing.

- Arts and crafts: HSS drill bits find applications in various crafting projects, such as creating holes in glass bottles for making them into decorative lamps.

- DIY repairs: Whether it’s fixing a broken hinge or replacing a doorknob, HSS drill bits come in handy for various household repairs.

Factors to Consider When Using HSS Drill Bits

Now that we have explored the diverse applications of HSS drill bits, let’s discuss some important factors to consider when using them:

Material Compatibility

Before drilling any material, it’s vital to ensure that the specific HSS drill bit you are using is suitable for the material. Different drill bit coatings and compositions are better suited for various materials. For example, a drill bit designed for metal may not yield optimal results when used for drilling wood. Always consult the manufacturer’s guidelines or do some research to ensure the compatibility of the drill bit with the material you’re working on.

Appropriate Drill Speed and Technique

The speed at which you operate the drill plays a crucial role in achieving better results while also preserving the lifespan of the HSS drill bit. Higher speeds are generally used for drilling through softer materials like wood or plastic, while slower speeds are recommended for drilling into harder materials like metal or masonry.

Additionally, using the correct drilling technique, such as applying moderate pressure and maintaining a steady hand, will ensure precise holes without causing unnecessary damage or wear to the drill bit.

Proper Maintenance and Care

To prolong the lifespan and performance of your HSS drill bits, it’s important to maintain and care for them properly. After each use, clean the drill bits thoroughly to remove any debris or material residue. You can use a brush or compressed air to clean the flutes and ensure they are free from any obstructions.

When storing your HSS drill bits, consider using a designated case or organizer to prevent them from banging against each other, which can cause damage to the cutting edges. Regularly inspect the drill bits for any signs of wear, such as dull or chipped edges, and replace them when necessary.

Using the Right Accessories and Safety Equipment

While using HSS drill bits, always use the appropriate accessories and safety equipment to ensure your safety and the best results. Wear safety goggles or glasses to protect your eyes from flying debris, and consider using hearing protection when drilling in louder environments.

Depending on the application and material, you may need additional accessories like drilling jigs, clamps, or guides to secure the workpiece and ensure precise drilling. These accessories can improve accuracy and minimize the risk of accidents or mistakes.

In conclusion, HSS drill bits are an essential tool in a wide range of applications, from woodworking and metalworking to arts and crafts. Their durability, versatility, and ability to cut through various materials make them a valuable asset for both professionals and DIY enthusiasts. By considering factors like material compatibility, drill speed, maintenance, and safety, you can make the most out of your HSS drill bits and achieve excellent results in your drilling projects.

Key Takeaways: What Are HSS Drill Bits Used For?

- HSS drill bits are used for drilling holes in various materials like metal, wood, and plastic.

- They are known for their high speed and durability, making them suitable for heavy-duty applications.

- These drill bits are essential for DIY projects, construction, and manufacturing industries.

- HSS drill bits can withstand high temperatures, ensuring efficient cutting and drilling.

- They come in different sizes and shapes to accommodate different drilling needs.

Frequently Asked Questions

Are you wondering what high-speed steel (HSS) drill bits are used for? Look no further! Below are some common questions and answers to help you understand the purpose and applications of HSS drill bits.

1. How are HSS drill bits different from other drill bits?

HSS drill bits are made of high-speed steel, a material that can withstand high temperatures without losing its hardness. This makes them ideal for drilling through tough materials like metal, wood, and plastic. Unlike other drill bits, HSS bits can retain their sharpness for longer periods, providing durability and efficiency.

Whether you’re a professional or a DIY enthusiast, HSS drill bits offer versatility and reliability for a wide range of drilling applications.

2. What types of projects are HSS drill bits commonly used for?

HSS drill bits are commonly used for a variety of projects, such as drilling holes in metal or woodworking tasks. They are perfect for creating clean and precise holes in materials, making them indispensable in construction, automotive, and DIY projects.

From installing shelves to building furniture or even working on jewelry, HSS drill bits are versatile tools that can handle different materials and projects with ease.

3. Can HSS drill bits be used with a regular drill?

Yes, HSS drill bits can be used with a regular drill. They are compatible with both handheld drills and drill presses, enabling you to tackle various drilling tasks. However, it’s important to choose the right type and size of HSS drill bit for your specific project to achieve the best results.

Remember to use appropriate speed settings and apply consistent pressure when drilling to prevent damage to the drill bit or the material you’re working with.

4. Are HSS drill bits suitable for drilling through hardened steel?

Yes, HSS drill bits are well-suited for drilling through hardened steel. Their high-speed steel composition allows them to withstand the heat generated by drilling into hard materials without losing their sharpness or durability. However, for extremely hard metals, such as stainless steel or hardened tool steel, you may need to use specialized HSS drill bits or consider using cobalt drill bits for better performance.

Always ensure you match the drill bit’s size and type to the material you’re drilling to achieve the best results.

5. How can I extend the lifespan of my HSS drill bits?

To extend the lifespan of your HSS drill bits, it’s essential to use proper drilling techniques and take care of the bits. Start by choosing the right drill speed for the material you’re working with, as excessive heat can shorten the lifespan of the bits. Lubricating the drilling area helps to reduce heat buildup and prolong the life of the drill bits.

Additionally, remember to clean your HSS drill bits after each use and store them in a dry place to prevent rust or corrosion. Regularly sharpening your drill bits or investing in a drill bit sharpener can also help maintain their sharpness and performance over time.

Summary

HSS drill bits are special tools used to make holes in different materials. They are made from a strong material called high-speed steel. HSS drill bits can be used for wood, metal, and plastic, making them very versatile.

These drill bits are known for their durability and ability to cut through materials quickly. They come in different sizes, including small ones for delicate jobs and larger ones for bigger holes. With the right technique and care, HSS drill bits can last a long time and help you get your drilling tasks done easily.