What are table saw trunnions? If you’re into woodworking or simply curious about tools, you’ve come to the right place! Table saw trunnions are an essential component of a table saw, but what exactly do they do? Allow me to break it down for you in the simplest terms possible.

Imagine a table saw as a superhero fighting crime in the woodworking world. The trunnions would be its trusty sidekick. These small but mighty mechanisms are the hidden heroes responsible for the smooth operation and precision of a table saw. They’re like the hinges that allow the blade to tilt and pivot, enabling you to make accurate angled cuts.

Think of a trunnion as the joint that connects the saw’s table to the arbor, where the blade is attached. It acts as a pivot point, allowing you to adjust the angle of the blade and lock it in place. Thanks to the trunnions, you can effortlessly switch between straight cuts and bevel cuts, unleashing your creativity in your woodworking projects.

Now that you know what table saw trunnions are, let’s dive deeper into their role and how they work. Get ready to unlock the secrets behind the scenes of your favorite woodworking tool!

Exploring the Function and Importance of Table Saw Trunnions

Table saw trunnions are an essential component of any table saw. They play a crucial role in ensuring the accuracy, stability, and safety of the saw. In this article, we will dive into the details of what table saw trunnions are, how they work, and why they are important for woodworkers and DIY enthusiasts alike. Whether you are a beginner or an experienced woodworker, understanding table saw trunnions will enhance your knowledge and improve your woodworking projects.

How Table Saw Trunnions Work

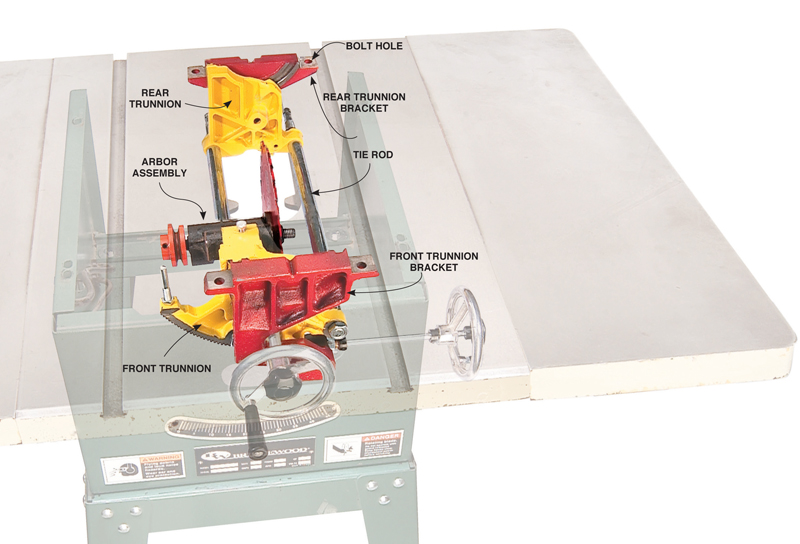

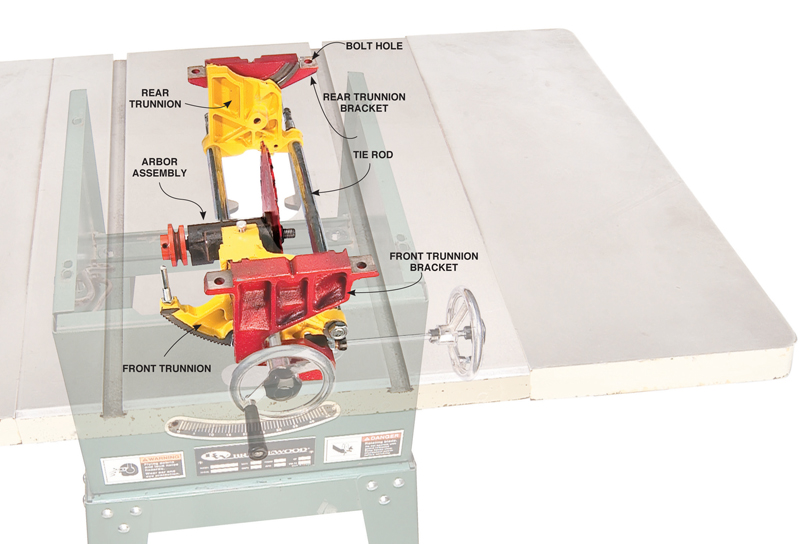

Table saw trunnions are mechanical devices that connect the arbor assembly (which holds the saw blade) to the table. They provide support and stability to the blade, allowing it to tilt and adjust vertically with precision. Trunnions consist of a set of brackets or arms that are securely attached to the underside of the table. The saw’s motor and arbor assembly are then mounted on the trunnion brackets, allowing them to pivot and move according to the user’s adjustments.

The trunnions are typically controlled by a handle or knob that allows the operator to set the desired angle for bevel cuts or adjust the blade height. When the handle is turned, it engages with the trunnions, causing them to move, thus changing the angle or height of the blade. The accuracy and smoothness of the trunnion movement are imperative for achieving precise cuts.

In addition to their pivotal function, trunnions also provide stability to the entire table saw. They are designed to evenly distribute the weight of the motor and blade assembly, preventing vibrations and minimizing the risk of the saw tipping or wobbling during operation. This stability is crucial for both safety and the quality of the cuts.

The Components of Table Saw Trunnions

Table saw trunnions consist of several key components that work together to facilitate smooth and accurate adjustments. These components include:

- Brackets or arms: These are the main structural pieces of the trunnions and are securely attached to the table.

- Mounting studs: These are the bolts or screws that connect the motor and arbor assembly to the trunnions.

- Handle or knob: This component allows the user to adjust the angle or height by engaging with the trunnions.

- Locking mechanism: A locking mechanism ensures the trunnions remain securely in place once the desired angle or height is set.

- Bearings: High-quality trunnions often incorporate bearings to provide smooth and consistent movement.

By combining these components, table saw trunnions enable woodworkers to make precise and accurate cuts with ease, enhancing their productivity and the quality of their work.

The Importance of Table Saw Trunnions

Table saw trunnions are essential for several reasons:

- Precision: Accurate cuts are crucial in woodworking projects, and trunnions play a significant role in ensuring precise bevel cuts and blade height adjustments.

- Stability: The stability provided by trunnions prevents the saw from tipping or wobbling during operation. This enhances both safety and the quality of the cuts.

- Efficiency: Smooth and precise trunnion movement allows woodworkers to work more efficiently, saving time and effort in their projects.

- Safety: Trunnions contribute to the overall safety of the table saw by maintaining stability, reducing the risk of accidents or kickbacks caused by unstable table saws.

Investing in a table saw with high-quality trunnions ensures a better woodworking experience and improved results. Woodworkers should prioritize robust trunnions when purchasing a table saw, as they are a critical component that significantly impacts performance and output.

Comparing Various Types of Trunnions

When it comes to table saw trunnions, there are different types available in the market. Each type has its own design and mechanism of operation. Let’s take a closer look at some of the common types of table saw trunnions and their characteristics.

Standard Trunnions

Standard trunnions are the most common type found in table saws. They are typically made of cast iron or steel and offer reliable performance. Standard trunnions usually have a limited range of blade height and angle adjustments but are suitable for most woodworking tasks. They are prevalent in contractor saws and some hybrid saws.

One potential drawback of standard trunnions is that they can be challenging to adjust accurately and smoothly. However, with proper maintenance and adjustments, they will serve most woodworkers well.

Cabinet Trunnions

Cabinet trunnions are often found in high-end cabinet table saws. They offer more advanced features and flexibility compared to standard trunnions. Cabinet trunnions are known for their ability to provide precise and smooth adjustments, making them ideal for professional woodworkers and for projects that require intricate cuts.

Unlike standard trunnions, cabinet trunnions usually have a greater range of blade height and angle adjustments, allowing woodworkers to work with more challenging materials and designs.

Hybrid Trunnions

Hybrid trunnions, as the name suggests, combine features of both standard and cabinet trunnions. They are commonly found in hybrid table saws, which are a mid-range option between contractor saws and cabinet saws. Hybrid trunnions provide better adjustability and precision compared to standard trunnions, but not as extensive as cabinet trunnions.

Hybrid trunnions are a suitable choice for woodworkers who require more advanced features than what standard trunnions provide but do not want to invest in a high-end cabinet saw.

Tips for Maintaining and Optimizing Performance

To ensure the longevity and optimal performance of your table saw trunnions, it is essential to follow some maintenance practices and tips. Here are a few recommendations to keep in mind:

Regular Cleaning and Lubrication

Table saw trunnions should be kept clean and well-lubricated to prevent friction and ensure smooth movement. Regularly clean off dust, debris, and buildup from the trunnions using a brush or a clean cloth. Lubricate the moving parts with a suitable lubricant to reduce wear and tear.

Adjustment and Alignment

Periodically check the alignment and adjustment of your trunnions. Over time, they may shift or become misaligned, affecting the accuracy of the cuts. Consult the manufacturer’s instructions or a professional if adjustments are necessary.

Proper Handling and Care

Handle your table saw with care to avoid any unnecessary stress or damage to the trunnions. Avoid overtightening or forcing adjustments, as this can put strain on the components. Additionally, store your table saw in a clean and dry environment to prevent rust or corrosion.

Enhance Your Woodworking with Reliable Trunnions

Table saw trunnions are a vital part of any table saw, ensuring accurate cuts, stability, and safety. By understanding how trunnions work and selecting the right type for your needs, you can enhance your woodworking projects and achieve exceptional results. Remember to maintain and care for your trunnions regularly to optimize their performance, ensuring longevity and consistency in your woodworking journey.

Key Takeaways: What are Table Saw Trunnions?

1. Table saw trunnions are an important component of a table saw.

2. They are metal brackets that hold the saw’s arbor assembly.

3. Trunnions allow for the saw blade to be adjusted for different cutting angles.

4. Proper alignment and adjustment of trunnions are crucial for accurate cuts.

5. Understanding how trunnions work can help improve your woodworking skills.

Frequently Asked Questions

Welcome to our FAQ section, where we answer common questions about table saw trunnions. If you’re unfamiliar with trunnions, they are an essential component of a table saw that help support and control the movement of the saw blade. Read on to find answers to some intriguing questions about table saw trunnions!

1. How do table saw trunnions work?

Table saw trunnions are typically mounted on the underside of the table and act as a pivot point for the blade assembly. They allow for the smooth and precise tilting, raising, and lowering of the blade. The trunnions consist of two parts: the bracket mounted to the table and the arbor bracket that holds the saw blade. By adjusting the trunnions, you can change the angle and height of the cut.

When you turn the adjustment wheel or handle, the gears connected to the trunnions move, causing the blade assembly to tilt or adjust in height. The trunnions are designed to offer stability and accuracy during cutting, enabling you to make precise cuts at various angles and depths.

2. Why are table saw trunnions important?

Table saw trunnions play a crucial role in the overall performance and accuracy of a table saw. They provide the means for adjusting the cutting depth and angle, allowing you to make precise and consistent cuts. Without properly functioning trunnions, the blade may not stay in alignment, leading to inaccurate cuts and potentially unsafe conditions.

By having reliable trunnions, you can trust that the blade will maintain its position while cutting, resulting in cleaner cuts and reducing the risk of kickback. The trunnions also support the weight of the blade assembly, ensuring stability and preventing vibrations that could adversely affect the cutting quality. A well-maintained and calibrated trunnion system is vital for achieving optimal performance from your table saw.

3. Can table saw trunnions be adjusted or replaced?

Yes, table saw trunnions can oftentimes be adjusted to correct misalignments or ensure accurate cutting. Many table saws come with adjustment mechanisms that allow you to fine-tune the trunnions’ position. By following the manufacturer’s instructions, you can recalibrate the trunnions to maintain their accuracy and performance.

If the trunnions are damaged or worn beyond repair, they can be replaced. However, it’s important to note that trunnion replacement may require some technical expertise and should be carried out by a professional or experienced individual. Always refer to the table saw’s user manual or consult a professional if you’re unsure about trunnion adjustment or replacement.

4. Are all table saw trunnions the same?

No, table saw trunnions can vary in design and quality across different brands and models. The quality of the trunnions can affect the overall performance and accuracy of a table saw. Higher-quality trunnions are typically made from durable materials and offer smoother adjustments, resulting in more precise cuts.

If you’re in the market for a table saw, it’s worth researching the trunnion system of the models you’re considering. Look for table saws with robust, well-engineered trunnions that receive positive reviews from users. This will ensure that you’re investing in a table saw with reliable trunnions that will enhance your woodworking experience.

5. How can I maintain table saw trunnions?

To keep your table saw trunnions in good condition, regular maintenance is essential. Here are a few steps you can follow:

First, ensure that you keep the trunnions clean and free from sawdust and debris. Periodically check for any signs of wear or damage, such as loose bolts or cracks in the brackets. Lubricate the trunnion gears and moving parts as recommended by the manufacturer. Regularly check the alignment of the trunnions using a reliable measuring tool to ensure they are properly adjusted.

By taking these preventive measures and addressing any issues promptly, you can extend the lifespan of your table saw trunnions and ensure optimal performance for years to come.

Summary

Table saw trunnions are important parts that help the blade move up, down, and tilt. They’re like the joints of the saw, allowing it to make different cuts. Trunnions also keep the blade aligned for accurate and safe cutting. Without them, the saw wouldn’t work properly.

If the trunnions get loose or damaged, it can affect the saw’s performance and make it unsafe to use. It’s important to regularly check and maintain the trunnions to ensure they’re functioning correctly. Remember to always follow safety guidelines when using a table saw!