Ah, the majestic lathe machine! Have you ever wondered about the advantages and disadvantages of this powerful tool? Well, you’re in luck because today we’re going to dive into this topic and explore what makes the lathe machine tick.

Now, let’s start by understanding the advantages of using a lathe machine. Firstly, it’s incredibly versatile, allowing you to shape and craft various materials with precision. Whether you’re turning wood, metal, or even plastic, the lathe machine can handle it all. Secondly, it’s a time-saver! With its automated features, you can easily replicate designs, saving you hours of tedious manual work. Finally, let’s not forget about the satisfaction it brings. Creating beautiful, custom-made pieces using a lathe machine is an absolute joy!

Of course, like any tool, the lathe machine has its fair share of disadvantages too. One major drawback is the initial cost. Quality lathes can be quite expensive, making it a significant investment for many individuals. Additionally, there’s a learning curve involved. Operating a lathe machine requires skill and practice, so it might take some time before you can master its intricacies. Finally, maintenance can be a bit tricky. Keeping the lathe machine in top condition requires regular cleaning, oiling, and adjustments.

But don’t let these downsides stop you from exploring the world of lathe machines. Despite the challenges, the advantages far outweigh the disadvantages. So grab your safety goggles, roll up your sleeves, and let’s embark on a thrilling journey into the world of lathe machines!

Discover the benefits and drawbacks of utilizing a lathe machine. This powerful tool offers several advantages in the manufacturing process, including precise shaping, versatility, and efficiency. However, there are also a few disadvantages to consider, such as the upfront investment required and the need for skilled operators. By understanding both the advantages and disadvantages, you can make an informed decision about incorporating a lathe machine into your production workflow.

The Advantages and Disadvantages of Lathe Machines:

Welcome to our comprehensive guide on the advantages and disadvantages of lathe machines. Lathe machines are powerful tools used in various industries for shaping and cutting materials such as metal, wood, and plastic. In this article, we will explore the benefits and drawbacks of using a lathe machine, helping you make an informed decision.

Advantages of Lathe Machines:

1. Versatility: One of the key advantages of a lathe machine is its versatility. These machines can be used for a wide range of applications, including turning, facing, chamfering, threading, and grooving. With different attachments, a lathe machine can also be used for tasks like drilling, milling, and grinding.

Lathe machines allow for the creation of complex shapes and precise cuts, making them invaluable in industries such as aerospace, automotive, and manufacturing. Whether you need to create intricate designs or large-scale components, a lathe machine can handle the job with ease.

2. Efficiency: Another advantage of lathe machines is their efficiency. These machines are designed to perform repetitive tasks accurately and quickly. They can handle large volumes of material, making them ideal for mass production. With the ability to automate certain processes and utilize computer numerical control (CNC), lathe machines can further enhance productivity.

By reducing manual errors and minimizing wastage, lathe machines help businesses save time and costs. They enable manufacturers to meet deadlines and increase overall production output, leading to improved profitability.

3. Precision: Precision is a crucial factor when it comes to working with materials. Lathe machines excel in providing high levels of accuracy and precision. They can achieve tight tolerances and smooth surface finishes, resulting in superior product quality.

Whether you are creating intricate metal components or delicate wooden designs, a lathe machine allows for precise measurements and cuts. This level of precision is especially important in industries like medical device manufacturing and jewelry making, where even the slightest deviation can significantly impact the final product.

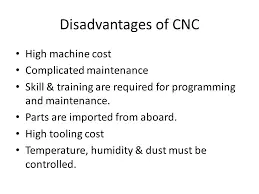

Disadvantages of Lathe Machines:

1. Initial Investment: One of the main disadvantages of lathe machines is the initial investment required. Buying and setting up a lathe machine can be expensive, especially for small businesses or individuals. Additionally, specialized equipment and tools may be needed for specific applications, further adding to the cost.

However, it is important to consider the long-term benefits and potential cost savings that a lathe machine can bring. If used frequently and efficiently, the return on investment can be significant.

2. Space Requirements: Lathe machines are typically large and require a dedicated space for setup and operation. This can be challenging for businesses with limited space or home workshops. Adequate ventilation and safety measures must also be taken into consideration, adding to the spatial requirements.

Before investing in a lathe machine, it is essential to ensure that you have enough space to accommodate the machine and its accessories comfortably. Careful planning and organization can help optimize the available space and maximize productivity.

3. Learning Curve: Operating a lathe machine requires skill and knowledge. The learning curve can be steep, especially for individuals new to machining. Understanding the machine’s controls, techniques for different operations, and safety protocols is essential to achieve optimal results.

Training and practice are crucial when it comes to using a lathe machine effectively. Investing time in learning and gaining hands-on experience will ultimately improve productivity and prevent accidents or mistakes.

Different Types of Lathe Machines and Their Applications:

Now that we have explored the advantages and disadvantages of lathe machines, let’s delve into the different types of lathe machines and their specific applications. Understanding the various types will help you choose the right machine for your needs and optimize your machining operations.

Bench Lathe Machines:

Introduction: Bench lathe machines are compact and versatile, designed to be placed on a workbench or table. They are commonly used for small-scale projects and hobbyist applications.

Applications: Bench lathe machines are ideal for tasks like creating jewelry, model making, and small woodworking projects. They are suitable for turning small metal or wooden components and are often used by hobbyists, artists, and crafters.

Engine Lathe Machines:

Introduction: Engine lathe machines, also known as center lathe machines, are one of the most common types of lathe machines used in workshops and manufacturing facilities.

Applications: Engine lathe machines are suitable for a wide range of applications, including turning, facing, threading, and tapering. They are used for machining cylindrical components, shafts, and other metal parts. Engine lathes are versatile and can be found in industries such as automotive, aerospace, and general engineering.

Turret Lathe Machines:

Introduction: Turret lathe machines are known for their ability to perform multiple operations without requiring manual intervention.

Applications: Turret lathe machines are widely used for mass production, especially in industries like automotive and firearms manufacturing. With the ability to mount multiple tools in a turret, these machines can efficiently complete complex tasks, such as drilling, milling, and threading.

Maintenance and Safety Tips for Lathe Machines:

Now that we have covered the advantages, disadvantages, and different types of lathe machines, it is essential to address maintenance and safety tips. Proper maintenance ensures the longevity and optimal performance of your lathe machine, while safety precautions minimize the risk of accidents or injuries.

Maintenance Tips:

1. Regular Cleaning and Lubrication: Clean the lathe machine regularly to remove dust, debris, and metal shavings. Apply lubricants to ensure smooth operation and prevent wear and tear.

2. Inspection and Replacement of Parts: Check for any damaged or worn-out parts. Replace them promptly to avoid further damage and potential accidents.

3. Calibration: Regularly calibrate the machine to maintain accuracy and precision. Check for alignment and adjust if necessary.

Safety Tips:

1. Wear Personal Protective Equipment (PPE): Always wear appropriate protective gear, including safety glasses, gloves, and ear protection. Avoid loose clothing or jewelry that can get caught in the machine.

2. Familiarize Yourself with Emergency Procedures: Understand the emergency shutdown procedures and location of safety switches. Ensure that fire extinguishers and first aid kits are easily accessible.

3. Follow Operating Instructions: Adhere to the manufacturer’s guidelines and operating instructions. Never exceed the machine’s recommended capacity or attempt unfamiliar operations without proper training.

Conclusion:

Lathe machines offer numerous advantages, including versatility, efficiency, and precision. However, they also come with a few disadvantages, such as the initial investment and space requirements. By considering these factors and understanding the different types of lathe machines, you can make an informed decision based on your specific needs.

Remember to prioritize maintenance and safety when operating a lathe machine. Regular maintenance and following safety protocols will help ensure the longevity of the machine and the well-being of the operator.

Key Takeaways: What are the Advantages and Disadvantages of Lathe Machines?

- Advantage: Lathe machines are versatile and can produce various shapes and sizes of objects.

- Advantage: They can handle both manual and automated operations, offering flexibility in manufacturing processes.

- Advantage: Lathe machines can achieve high precision and accuracy in machining operations.

- Disadvantage: They require skilled operators, as improper use can lead to damage and accidents.

- Disadvantage: Lathe machines can be expensive to purchase and maintain.

Frequently Asked Questions

Looking to learn more about the advantages and disadvantages of a lathe machine? You’re in the right place. Below are some commonly asked questions about lathe machines and their pros and cons.

1. How can a lathe machine be beneficial?

A lathe machine offers several advantages. Firstly, it enables precision machining, allowing you to create intricate and accurate parts. Additionally, a lathe machine can be used for a wide range of applications, from metalworking to woodworking. It offers versatility in shaping, cutting, and drilling materials. Moreover, a lathe machine can be operated manually or with computer numerical control (CNC), providing flexibility and automation.

Furthermore, using a lathe machine can save time and effort. It allows for efficient material removal, reducing the need for extensive manual labor. Additionally, lathe machines often come with various attachments and accessories that further enhance their functionality.

2. Are there any disadvantages to using a lathe machine?

While lathe machines have numerous advantages, they do come with a few drawbacks. One limitation is the size constraint. Depending on the machine’s capacity, there may be restrictions on the size of the material that can be worked on. This can be a disadvantage when working on larger projects or oversized components.

Another drawback is the learning curve associated with operating a lathe machine. It requires skill and expertise to use the machine effectively. Novice users may find it challenging to master all the features and techniques. Additionally, lathe machines can be costly, particularly models with advanced features or CNC capabilities. The initial investment may be a barrier for some individuals or businesses.

3. Can a lathe machine be used for both woodworking and metalworking?

Yes, a lathe machine can be used for both woodworking and metalworking. By utilizing different cutting tools and techniques, a lathe machine can shape various materials, including wood and metal. When working with wood, the lathe machine enables the creation of intricate designs, spindle work, and even bowl turning. When it comes to metalworking, a lathe machine allows for precise cutting, turning, and threading of metal parts.

It’s important to note that different tools and attachments may be required depending on the material being worked on. For example, woodturning tools are designed specifically for woodworking applications, while carbide cutting tools are commonly used for metalworking on a lathe machine.

4. Is it necessary to have prior experience to operate a lathe machine?

While prior experience can be beneficial, it is not always necessary to operate a lathe machine. Many machines come with user-friendly features and controls, making them accessible to beginners. It’s advisable to start with basic projects and gradually increase the complexity of the tasks as you gain more experience and confidence.

Additionally, there are ample resources available, including tutorials, online courses, and manuals, that can help individuals learn the fundamentals of operating a lathe machine. With practice and patience, newcomers to lathe machining can acquire the necessary skills to utilize the machine effectively.

5. Are there any safety precautions to consider when using a lathe machine?

Yes, safety precautions are essential when operating a lathe machine. First and foremost, it is crucial to wear appropriate protective equipment, such as safety goggles, gloves, and hearing protection. Be cautious of loose clothing or jewelry that may get entangled with the machine.

Additionally, ensure that the machine is properly secured and stable, with all safety guards in place. Familiarize yourself with the emergency shut-off procedures and keep a fire extinguisher nearby. It’s also important to maintain a tidy work area, free from clutter or obstacles that may pose a safety risk. Lastly, proper training and understanding of the machine’s operation manual are vital to ensure safe usage of the lathe machine.

lathe machine and their types ,applications and advantage and disadvantage

Summary

So, let’s sum it all up. The lathe machine has some advantages and disadvantages.

On the bright side, the lathe machine is versatile and can be used for different tasks. It allows you to shape materials like wood and metal with precision. Plus, it helps save time and effort.

However, there are also some downsides to consider. Lathe machines can be expensive and take up a lot of space. They require skilled operators and regular maintenance. And, of course, safety precautions must be taken to avoid accidents.

In the end, it’s all about weighing the pros and cons to decide if a lathe machine is right for you.