What are the advantages of a boring machine? Well, let me tell you, my friend! A boring machine is like a superhero for construction projects. It’s fast, efficient, and can handle tasks that would take humans forever. Imagine having a machine that can dig deep, precise holes in the ground with ease. That’s the power of a boring machine!

But wait, there’s more! Boring machines have some amazing advantages that make them indispensable in the construction world. They can create tunnels, install underground utilities, and even help with mining operations. With their precision and power, boring machines save time, money, and manpower.

So, if you’re curious about the advantages of a boring machine, stick around! We’ll dive deep into the world of these incredible machines and explore why they are a game-changer in the construction industry. Get ready to be amazed!

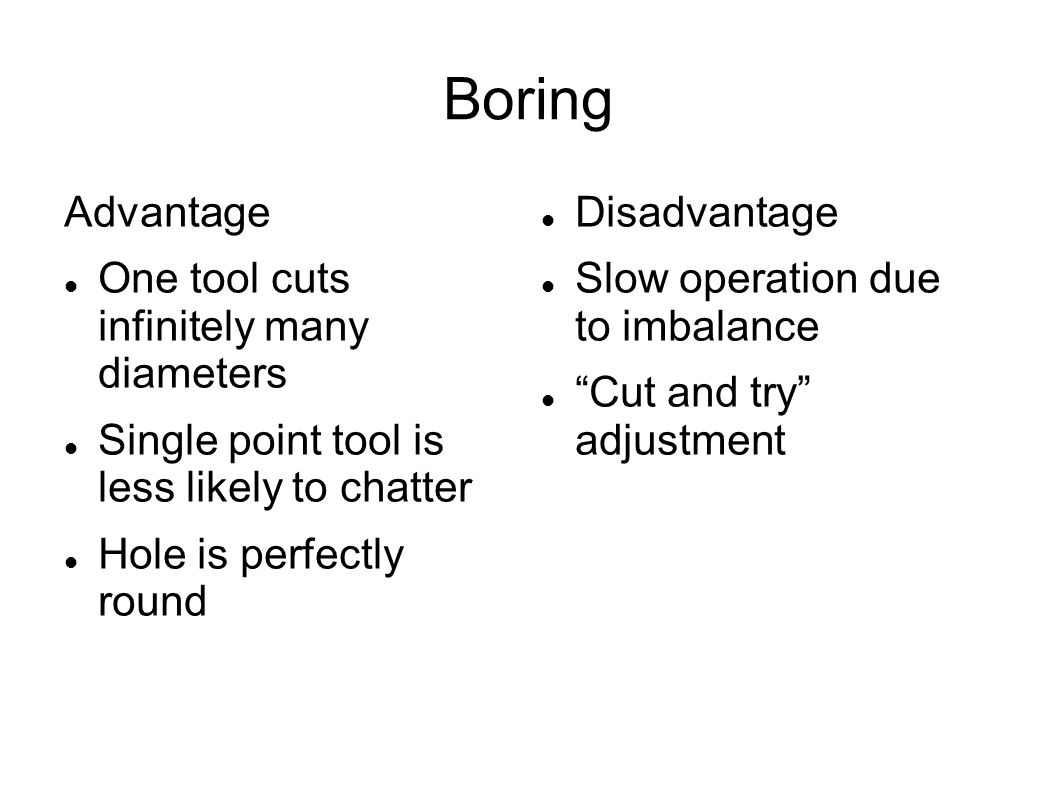

Looking for the advantages of a boring machine? Discover how this powerful tool can benefit you. Increase efficiency with precise and accurate drilling operations. Save time and effort by eliminating the need for manual labor. Enjoy versatility as boring machines can work on various materials. Reduce errors with automated processes and enhanced control. Experience improved productivity and cost-effectiveness. The advantages of a boring machine are numerous, making it a valuable asset in many industries.

The Advantages of Boring Machines: Unlocking Efficiency and Precision

When it comes to excavation and drilling tasks, boring machines have become indispensable in various industries. These powerful and versatile machines have revolutionized the way we approach complex projects, offering a wide range of advantages that traditional drilling methods simply cannot match. From increasing efficiency and precision to reducing labor costs and environmental impact, boring machines have transformed the landscape of construction, infrastructure, and mining. In this article, we will delve into the numerous benefits that these machines bring to the table, exploring their impact on productivity, safety, and overall project success.

Enhancing Productivity through Speed and Precision

One of the most significant advantages of boring machines is the remarkable increase in productivity they deliver. Traditional drilling methods often require time-consuming manual labor, resulting in slower progress and potential delays. In contrast, boring machines are designed to streamline the excavation process, making it faster, more efficient, and highly precise. With their advanced drilling mechanisms, these machines can easily penetrate hard surfaces like rocks and soil, enabling rapid excavation with minimal effort. This translates to reduced project timelines, allowing construction teams to meet deadlines, drive productivity, and ultimately deliver high-quality results.

Accurate Alignment for Seamless Construction

Precision is a key consideration in any construction project, and boring machines excel in this aspect. These machines have built-in alignment systems that ensure accurate and consistent drilling, resulting in perfectly aligned holes or tunnels. This level of precision is crucial when constructing tunnels, foundations, or any structure requiring precise measurements. By eliminating human error and ensuring consistent alignment, boring machines guarantee seamless construction, reducing the need for costly rework and potential setbacks.

Boring machines also offer the flexibility to adjust drilling parameters according to specific project requirements. Operators can customize the speed, torque, and other drilling variables, allowing them to adapt the machine’s performance to different geological conditions. This adaptability further enhances precision and maximizes the machine’s effectiveness in various environments, from rocky terrains to softer soil.

Moreover, boring machines can also be equipped with advanced monitoring systems that provide real-time feedback on drilling parameters. This enables operators to make immediate adjustments as needed, ensuring optimal drilling conditions and further maximizing precision.

Reduced Labor Costs and Enhanced Safety

Boring machines significantly reduce the need for extensive manual labor, leading to substantial cost savings for construction projects. With their advanced automation and high-powered drilling capabilities, these machines can replace large teams of workers, allowing companies to streamline their workforce and allocate resources more efficiently. This not only results in cost reductions but also minimizes reliance on manual labor, reducing the risk of accidents and injuries associated with excavation tasks.

Furthermore, boring machines are equipped with advanced safety features and controls to ensure the well-being of operators and workers on-site. These machines often incorporate safety mechanisms such as emergency stop buttons, automatic shut-off systems, and comprehensive operator training programs. By prioritizing safety, boring machines enhance work environment standards and minimize the likelihood of accidents, making them a safer alternative to traditional drilling methods.

In addition to personnel safety, boring machines also pose minimal environmental impact compared to other excavation techniques. They generate less noise, vibration, and dust pollution, reducing the disturbance to surrounding environments and nearby communities. This makes them an eco-friendly choice for construction and infrastructure projects, aligning with sustainability goals and minimizing harmful effects on the ecosystem.

Advancements in Boring Machine Technology: Paving the Way for Innovation

As technological advancements continue to drive progress in the construction industry, boring machines are also evolving to meet new challenges and demands. Here are three key areas where innovation is shaping the future of boring machine technology:

1. Improved Efficiency and Power

Manufacturers are continuously enhancing boring machines’ drilling power and efficiency by incorporating cutting-edge technologies. This includes the development of more powerful engines, advanced hydraulic systems, and optimized drilling mechanisms. These innovations result in increased drilling speed, higher torque, and improved overall productivity. Additionally, advancements in fuel efficiency and energy conservation contribute to cost savings and reduced environmental impact.

2. Enhanced Automation and Operator Interface

Automation plays a crucial role in the evolution of boring machines, making them more user-friendly and efficient. Manufacturers are integrating intelligent control systems and user interfaces that simplify the operation and monitoring processes. These advancements enhance operator productivity, reduce the learning curve, and enable quick adjustment of drilling parameters. The automation technology also includes features like remote monitoring, diagnostics, and predictive maintenance, ensuring optimal performance and minimizing downtime.

3. Integration of Digitalization and Data Analytics

With the increasing focus on data-driven decision-making, boring machines are incorporating digitalization and data analytics capabilities. Sensors are being integrated into the machines, providing real-time measurements and data on drilling parameters, ground conditions, and performance. This data can be processed and analyzed to optimize drilling strategies, improve safety measures, and enhance productivity. By leveraging data analytics, construction teams can make informed decisions, implement preventive maintenance programs, and drive continuous improvement in boring machine operations.

As we explored in this article, boring machines offer a myriad of advantages that positively impact construction projects’ efficiency, productivity, and safety. Their ability to enhance precision, reduce labor costs, and minimize environmental impact makes them indispensable in various industries. As technology continues to evolve, advancements in boring machine capabilities will further revolutionize the construction landscape, paving the way for greater innovation and success in excavation and drilling projects.

Key Takeaways: What are the Advantages of Boring Machines?

- Boring machines can create precise and accurate holes in various materials.

- They are efficient and save time compared to manual drilling processes.

- Boring machines are versatile and can be used for drilling horizontal, vertical, or angular holes.

- They can handle heavy-duty drilling tasks and are commonly used in industries like construction and manufacturing.

- Boring machines offer improved safety as they minimize the risk of drifting or wandering while drilling.

Frequently Asked Questions

Welcome to our FAQ section on the advantages of boring machines. Here, we’ll address common queries about the benefits these machines bring to various industries. Read below to learn more!

1. How can a boring machine improve productivity in manufacturing?

Boring machines play a vital role in increasing productivity in manufacturing processes. By automating repetitive tasks, they reduce human error and enhance efficiency. These machines can accurately and precisely drill holes, enlarge existing holes, or create new cavities, saving valuable time and effort. Additionally, boring machines can perform multiple tasks in one setup, eliminating the need for separate machines and optimizing production schedules, ultimately leading to increased output and profitability.

Furthermore, boring machines equipped with advanced technology and computer numerical control (CNC) systems offer the advantage of improved precision and repeatability. This ensures consistent quality and reduces the likelihood of errors, minimizing waste and further boosting productivity.

2. What are the benefits of using a boring machine in construction projects?

When it comes to construction projects, boring machines offer several advantages. First and foremost, they enable the creation of underground utility tunnels, allowing utility lines and pipes to be installed without causing damage to existing structures or disrupting traffic flow above. This reduces the inconvenience caused by traditional excavation methods.

Boring machines also excel at working in confined spaces or areas with limited access. This versatility enables construction projects to proceed smoothly, even in challenging environments. Additionally, these machines are highly efficient, reducing project completion times and minimizing costs. By minimizing disruption to surrounding areas and reducing the need for manual labor, boring machines prove to be a valuable asset for construction projects.

3. How does a boring machine benefit the woodworking industry?

In the woodworking industry, boring machines offer numerous advantages. They can create precise and accurate holes needed for joinery, such as dowel holes, shelf holes, or holes for hinges. This leads to improved craftsmanship and ensures that components fit together seamlessly.

Boring machines also provide increased efficiency and consistency during mass production. They allow woodworkers to accurately replicate holes in multiple pieces, ensuring uniformity in products like cabinets, furniture, or wooden decorative items. This saves time and effort compared to manual drilling, increasing overall productivity in woodworking operations.

4. What advantages do horizontal boring machines offer to the mining industry?

Horizontal boring machines bring several advantages to the mining industry. One notable benefit is their ability to bore large-diameter holes for mining exploration and extraction. These machines are capable of reaching depths and diameters that may be impractical or challenging with traditional drilling methods.

Furthermore, horizontal boring machines can be equipped with advanced drilling techniques and tools, such as rotary cutting heads or diamond drilling bits, which can enhance the efficiency of mining operations. These machines also provide a safer working environment, as operators can work remotely while the machine performs the drilling, reducing human exposure to potentially hazardous conditions.

5. How can a portable boring machine be advantageous for repair and maintenance work?

A portable boring machine offers significant advantages for repair and maintenance work. Its portability allows it to be easily taken to the location where the repair is needed, eliminating the need to disassemble large components or transport them to a workshop.

Portable boring machines are incredibly versatile and can be used for on-site repairs of various types of equipment and machinery. They can bore and reface damaged holes, repair worn-out surfaces, or create new openings as required. This flexibility saves time and money by reducing downtime and eliminating the need for expensive equipment transportation or component replacements. Moreover, portable boring machines can be operated by a single person, further streamlining the repair process.

Drilling, Boring And Reaming difference || Difference Between Drilling, Boring And Reaming

Summary

So, to sum it up, boring machines have some cool advantages. First, they can make holes in the ground quickly and accurately. Second, they can dig tunnels underground without causing much disruption on the surface. Third, they can be used for various projects like mining, construction, and even exploring outer space. Overall, boring machines are pretty awesome tools that help us build and explore in a more efficient way. So, next time you see a big, boring machine in action, remember all the amazing things it can do!