So, you’re curious about CNC lathes and the mysterious “axis” they possess. Well, my friend, get ready to embark on a journey of discovery! 🚀

Picture this: you’re in a workshop, surrounded by cutting-edge machinery, and you come across a CNC lathe. You wonder, “What are the axis on a CNC lathe? How do they work?” Well, allow me to shed some light on this fascinating topic!

When we talk about CNC lathes, we’re referring to computer-controlled machines used to shape and cut materials with precision. Now, the axis on a CNC lathe are the directions in which the cutting tools can move. Think of them as the superpowers that allow the lathe to create intricate designs and shapes. But how many axes are there? Stay tuned, and all will be revealed! 🕵️♂️

Intrigued? I bet you are! In this article, we’ll explore the different axis on a CNC lathe and unravel their secrets. You’ll discover the role of each axis and how they work in harmony to bring your wildest manufacturing dreams to life. So, strap in, my curious friend, as we journey into the exciting world of CNC lathe axes! Let’s get started! 🎢

What Are the Axis on a CNC Lathe?

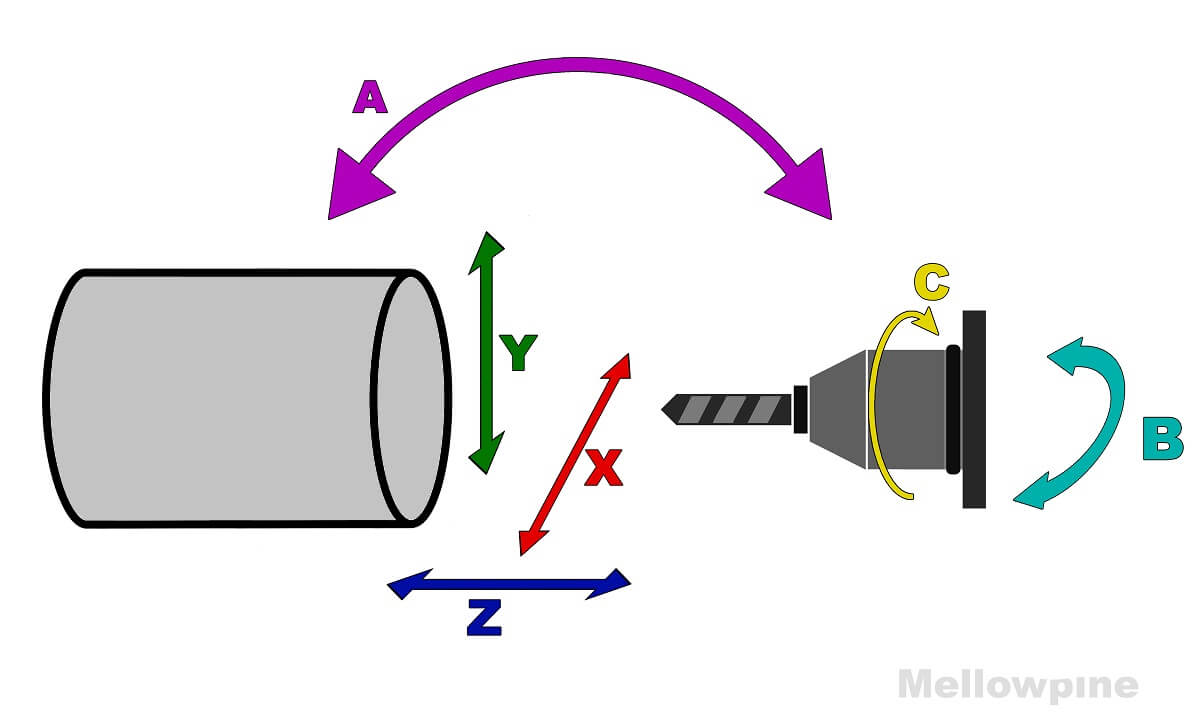

CNC lathes are valuable machines used in the manufacturing industry to shape various materials such as metal, plastic, and wood. Understanding the axis on a CNC lathe is crucial for operating and programming these machines effectively. The axis refers to the direction of movement that the lathe can control, allowing for precise and intricate cutting, shaping, and drilling operations. In this article, we will explore the different axis on a CNC lathe and their significance in the machining process.

The X-Axis: The Horizontal Direction

The X-axis is the most fundamental axis on a CNC lathe and represents the horizontal movement of the cutting tool. It controls the left-right motion of the tool, allowing it to move along the length of the workpiece. By manipulating the X-axis, operators can achieve various cutting operations such as facing, turning, and grooving. This axis plays a crucial role in determining the diameter and length of the final product.

The X-axis movement is precision-controlled through a lead screw mechanism or linear guide system. This allows for accurate and repeatable positioning, ensuring consistent results. By programming the CNC lathe, operators can control the speed, depth, and feed rate of the X-axis movement, resulting in precisely machined parts.

The Z-Axis: The Longitudinal Direction

The Z-axis on a CNC lathe represents the longitudinal or axial movement of the cutting tool. It controls the back and forth motion of the tool, allowing it to move along the axis of the workpiece. This axis is responsible for controlling the depth of the cutting operation, determining the thickness and precision of the machined part.

Similar to the X-axis, the Z-axis movement is controlled through a lead screw mechanism or linear guide system for accuracy and repeatability. By programming the CNC lathe, operators can adjust the speed, depth, and feed rate of the Z-axis movement, ensuring precise and consistent machining operations.

The C-Axis: The Rotational Direction

The C-axis is a rotational axis found in certain advanced CNC lathes. It allows for the rotation of the workpiece, enabling the lathe to perform operations such as milling, drilling, and thread cutting at different angles. This axis is particularly useful for creating complex geometries and contours on cylindrical parts.

The C-axis movement is achieved through a servo motor, which allows for precise and controlled rotational motion. By programming the CNC lathe, operators can specify the degree of rotation and the speed at which it occurs, resulting in intricate and accurate machining operations.

The Y-Axis: The Vertical Direction

In addition to the X, Z, and C axes, some CNC lathes are equipped with a Y-axis. The Y-axis represents the vertical movement of the cutting tool. It allows for additional degrees of freedom and enables machining operations on multiple sides of the workpiece. This axis is particularly valuable for complex and multi-sided components.

By incorporating the Y-axis into the programming of the CNC lathe, operators can control the vertical movement of the tool, achieving precise cuts, chamfers, and other operations that were not possible with traditional lathe setups.

Benefits of Multi-Axis Machining

Multi-axis machining, achieved through the combination of X, Y, Z, and C axes, offers several advantages in CNC lathe operations. These benefits include:

1. Increased Efficiency: Multi-axis machining allows for simultaneous cutting operations, reducing the number of setups required and saving time.

2. Enhanced Precision: With more axes, intricate contours and geometries can be achieved with higher accuracy.

3. Greater Flexibility: Multi-axis machines can handle complex parts with irregular shapes, allowing for more design possibilities.

4. Cost Savings: By minimizing setups and reducing the need for additional machining operations, multi-axis machining can result in cost savings and increased productivity.

5. Improved Surface Finish: The ability to approach the workpiece from multiple angles results in smoother surface finishes, reducing the need for secondary operations.

In summary, understanding the different axis on a CNC lathe is vital for operating these machines effectively. The X-axis controls the horizontal movement, the Z-axis controls the longitudinal movement, and the C-axis allows for rotational motion. The Y-axis, if present, enables vertical movement. Multi-axis machining offers numerous benefits, including increased efficiency, enhanced precision, and greater flexibility. By leveraging the capabilities of the various axes, operators can achieve precise and intricate machining operations on a CNC lathe.

Key Takeaways: What are the Axis on a CNC Lathe?

- The main axes on a CNC lathe are the X, Z, and C axes.

- The X axis controls the horizontal movement of the tool along the lathe’s bed.

- The Z axis controls the longitudinal movement of the tool towards or away from the workpiece.

- The C axis is used for rotating the workpiece, allowing for angled cuts and cylindrical features.

- Understanding the different axes is crucial for programming and operating a CNC lathe.

Frequently Asked Questions

In this section, we will answer some common questions regarding the axis on a CNC lathe.

What are the different axis on a CNC lathe?

A CNC lathe typically has two main axes – the X-axis and the Z-axis. The X-axis controls the horizontal movement of the cutting tool, while the Z-axis controls the longitudinal movement of the tool. These two axes work together to accurately position the tool for machining operations. Some advanced CNC lathes may also have a C-axis, which allows for rotation of the workpiece.

The X-axis and Z-axis on a CNC lathe are crucial for achieving precise machining results. The X-axis controls the depth and width of the cut, while the Z-axis controls the length of the cut. By properly programming and controlling these axes, manufacturers can create intricate shapes and achieve high levels of precision in their machining operations.

What is the purpose of the X-axis on a CNC lathe?

The X-axis on a CNC lathe controls the horizontal movement of the cutting tool. It enables the tool to move left and right relative to the workpiece. This axis is crucial for operations that require shaping or cutting the workpiece’s diameter. By controlling the X-axis, manufacturers can achieve precise cuts, create complex shapes, and achieve the desired dimensions on the workpiece.

For example, when turning a cylindrical workpiece, the X-axis movement allows the tool to cut the desired diameter along the workpiece’s length. By programming the X-axis movements correctly, manufacturers can create threads, grooves, and other intricate features on the workpiece’s surface.

How does the Z-axis work on a CNC lathe?

The Z-axis on a CNC lathe controls the longitudinal movement of the cutting tool. It allows the tool to move towards or away from the workpiece. This axis is essential for operations that require cutting the workpiece’s length, such as facing or turning operations. By controlling the Z-axis, manufacturers can achieve the desired length and finish on the workpiece.

For example, when facing a workpiece, the Z-axis movement controls the depth of the cut, determining how much material is removed from the workpiece’s end. By programming the Z-axis movements accurately, manufacturers can achieve smooth surfaces and precise dimensions along the length of the workpiece.

What is the role of the C-axis on a CNC lathe?

The C-axis, when present on a CNC lathe, allows for the rotation of the workpiece. This additional axis is beneficial for operations that require complex machining, such as multi-sided machining, contouring, or thread milling. By controlling the C-axis, manufacturers can achieve precise positioning and rotation of the workpiece, enabling them to create intricate features and achieve high levels of accuracy.

For example, with the C-axis, a CNC lathe can easily produce angled features or complex contours on the workpiece. It is particularly useful for machining cylindrical workpieces with features that require rotation, such as cams or splines.

Can a CNC lathe have more than three axes?

Yes, some advanced CNC lathes can have additional axes beyond the X, Z, and C axes. These additional axes, such as the Y-axis or the B-axis, provide enhanced machining capabilities. For example, the Y-axis allows for off-center machining, while the B-axis enables angled or tilted cuts. These additional axes enable manufacturers to create even more complex and precise parts, expanding the capabilities of the CNC lathe.

It’s important to note that not all CNC lathes have these additional axes. The number and types of axes on a CNC lathe depend on the specific model and the machining requirements of the manufacturer.

Summary

So, what are the axes on a CNC lathe? Well, the X-axis moves the tool horizontally, while the Z-axis moves it vertically. These axes work together to shape and create intricate designs on the material being machined. It’s important to understand these axes to operate a CNC lathe effectively.

Additionally, the Y-axis may be present on some CNC lathes, allowing for more complex machining operations. By controlling these axes, operators can precisely shape and cut materials, creating a wide range of products from metal parts to artistic pieces. Understanding the different axes is key to mastering the capabilities of a CNC lathe.