So, you’re curious about lathes and want to know what their components are. Well, you’ve come to the right place! In this guide, we’ll explore the various parts that make up a lathe and how they work together to bring your woodworking or metalworking projects to life. Ready to dive in? Let’s get started!

A lathe is a versatile machine used for shaping materials like wood or metal. It’s like having your own personal sculpting tool! But before you can begin turning those raw materials into beautiful creations, you need to understand the different components that make up a lathe.

At its core, a lathe consists of three main components: the bed, the headstock, and the tailstock. These parts work in harmony to provide stability, power, and control during the turning process. But wait, there’s more! Lathes also have other essential elements like the tool rest, the spindle, and various controls that make your work easier and more precise.

So, whether you’re a budding woodworker or an aspiring metalworker, understanding the components of a lathe is a crucial first step. Get ready to unleash your creativity and embark on a journey of making stunning objects with this incredible machine!

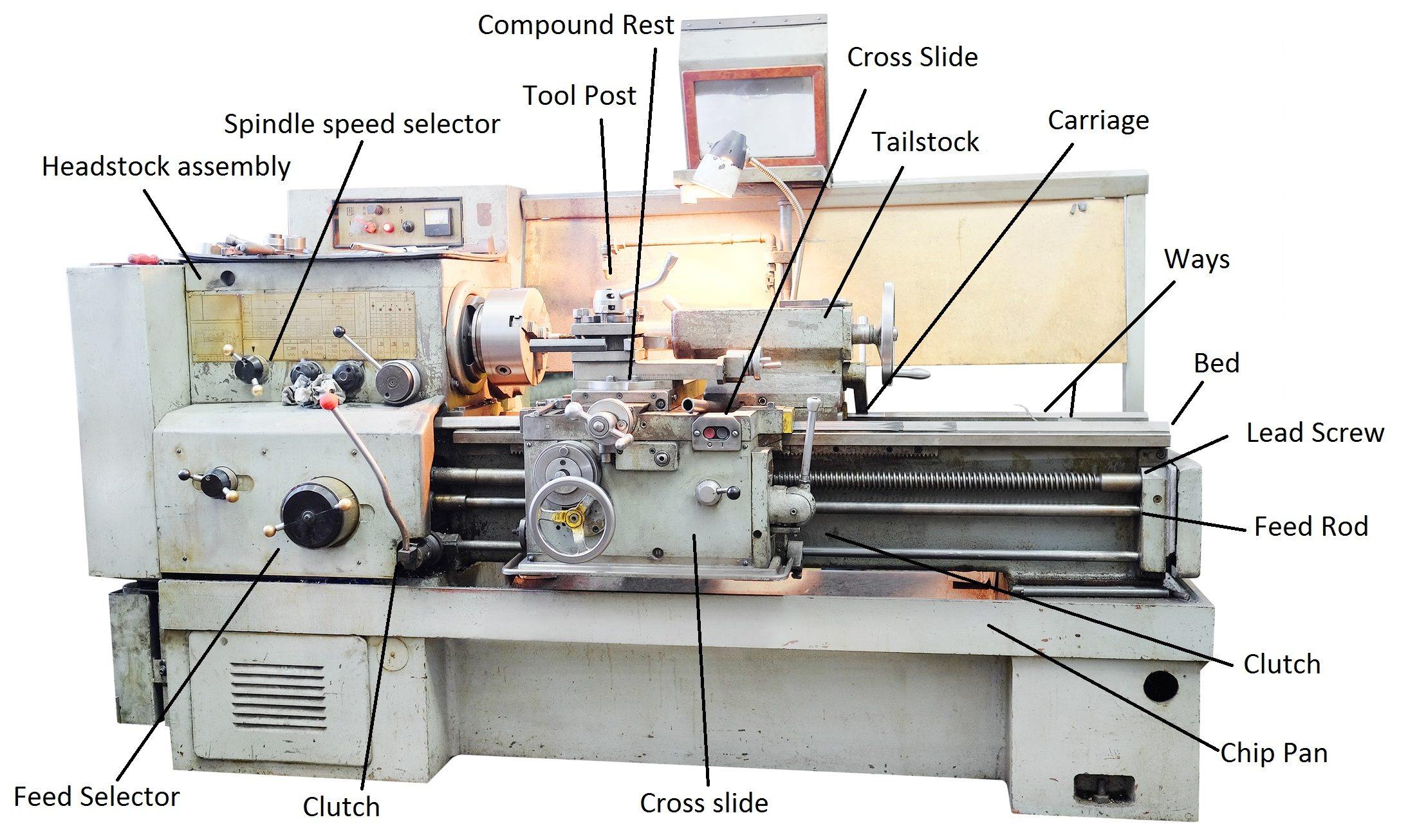

Lathe machines consist of several important components that enable them to perform various machining operations. Some key components of a lathe include the bed, headstock, tailstock, carriage, chuck, and toolpost. The bed provides a sturdy base, while the headstock houses the main spindle. The tailstock supports long workpieces, and the carriage moves the cutting tool. The chuck securely holds the workpiece, and the toolpost holds the cutting tools. These components work together to ensure precise and efficient machining processes.

The Components of a Lathe: Exploring the Inner Workings of a Versatile Machine

Welcome to our comprehensive guide on the components of a lathe. In this article, we will take an in-depth look at the various parts that make up this versatile machine. Whether you’re a machinist, enthusiast, or simply curious about how a lathe operates, this guide will provide you with the knowledge you need to understand the inner workings of this essential tool.

The Bed

The bed is the foundation of a lathe and is typically made of durable cast iron. Its job is to provide a rigid and stable platform on which all other components are mounted. The bed is designed to withstand the vibrations and forces generated during machining operations. It is generally shaped like a prism to increase stability and reduce flexing. Depending on the size and design of the lathe, the bed may be flat or V-shaped.

Located on the top of the bed is the carriage, which moves along the length of the bed and supports several other crucial components. The carriage houses the tool post, which holds cutting tools and controls their movement. It also contains the apron, which houses the gears and mechanisms responsible for controlling the feed and cutting operations. Additionally, the carriage typically includes a saddle that holds the workpiece securely in place.

Another important feature of the bed is the tailstock, often located at one end. The tailstock can be moved along the bed and is used to support longer workpieces. It contains a spindle and a mechanism for gripping and releasing the workpiece. The tailstock is essential for ensuring the accuracy and stability of the machining process.

The Headstock

The headstock is the central component of a lathe and is responsible for driving the workpiece’s rotation. It houses the main spindle, which holds the workpiece securely in place. The spindle is driven by a motor and is capable of rotating at various speeds. The headstock also contains a gear train that allows for speed changes and ensures the smooth transfer of power from the motor to the spindle.

The headstock may feature a chuck, which is used to hold and rotate the workpiece. Chucks come in various sizes and designs to accommodate different types of workpieces. They provide a secure grip on the workpiece and allow for precise machining operations. Some lathes may also have a faceplate, which is used for irregularly shaped or oversized workpieces that cannot be held by a chuck.

In addition to the spindle and chuck, the headstock often includes various controls and indicators. These may include a speed control lever, which allows for easy adjustment of the rotation speed, as well as indicators for measuring the current speed and monitoring the operation of the lathe.

The Tailstock

The tailstock, also known as the looseheadstock or the tail center, is an important component of a lathe. It is located on the opposite end of the headstock and serves several essential functions. The main function of the tailstock is to support long workpieces that extend beyond the headstock. It provides stability and prevents the workpiece from sagging or vibrating during machining operations.

The tailstock consists of a base, a spindle, and a mechanism for gripping and releasing the workpiece. It can be moved along the bed to accommodate workpieces of different lengths. The spindle of the tailstock is typically aligned with the axis of the lathe to ensure precise and accurate machining. It may also feature a center, which serves as a support for the workpiece and minimizes deflection during cutting.

Some tailstocks may include additional features such as a drill chuck or a live center. A drill chuck allows for drilling operations to be carried out directly on the lathe, while a live center has a rotating tip that helps support the workpiece during machining. These features enhance the versatility and functionality of the lathe.

The Carriage

The carriage is a crucial component of a lathe and is responsible for supporting the cutting tool and controlling its movement. It is mounted on the bed and moves along the length of the lathe to perform various machining operations. The carriage consists of several sub-components, including the saddle, cross-slide, compound rest, and tool post.

The saddle is the part of the carriage that holds the tool post and the compound rest. It provides support and stability to these components, allowing for precise and controlled movement. The saddle can be locked in place or moved along the bed using handwheels or power mechanisms.

The cross-slide is mounted on the saddle and allows for horizontal movement perpendicular to the axis of the lathe. It is used to position the cutting tool accurately and control its depth of cut. The cross-slide typically features a handwheel for manual adjustments and may have automatic feed mechanisms for more precise and automated machining.

The compound rest is located on top of the cross-slide and allows for angular adjustment of the cutting tool. It can be tilted to control the angle of the tool and enable the machining of tapered surfaces and angled cuts. The compound rest may have micrometer dials or other precise measuring devices for accurate adjustments.

The tool post is attached to the compound rest and holds the cutting tool securely in place. It allows for quick and easy tool changes and adjustments. The tool post may have multiple tool holders to accommodate different types of cutting tools. Some lathes also have tool turrets, which can hold multiple tools simultaneously and enable faster tool changes during machining operations.

The Chuck

The chuck is a vital component of a lathe and is used to hold and rotate the workpiece during machining operations. It provides a secure grip on the workpiece and allows for precise and accurate machining. There are several types of chucks commonly used in lathes, including three-jaw and four-jaw chucks.

A three-jaw chuck is the most commonly used chuck in lathe operations. It consists of three jaws arranged in a triangular pattern, which can be adjusted simultaneously to grip the workpiece. Three-jaw chucks are ideal for holding cylindrical workpieces and offer quick and easy setup.

A four-jaw chuck, as the name suggests, has four independently adjustable jaws. This allows for the secure gripping of irregularly shaped or non-symmetrical workpieces. Four-jaw chucks provide greater flexibility but require more time for setup and adjustment compared to three-jaw chucks. They are often used for specialized machining operations.

In addition to three-jaw and four-jaw chucks, there are other types of chucks that serve specific purposes. These include collet chucks, which are used for holding small-diameter workpieces, and magnetic chucks, which use magnets to hold ferrous workpieces. The choice of chuck depends on the type and requirements of the machining operation.

The Lead Screw and Feed Rod

# Key Takeaways

The Components of a Lathe

– A lathe consists of a bed, which is the base of the machine and provides stability.

– The headstock is located at one end of the bed and holds the main spindle.

– The tailstock is located at the other end and is used to support the other end of the workpiece.

– The carriage is the part that holds the cutting tools and moves along the bed.

– The chuck is a device that holds the workpiece and allows it to rotate while being shaped by the cutting tools.

Frequently Asked Questions

Curious about the components of a lathe? Look no further! We’ve got answers to all your questions.

1. What is the main component of a lathe?

The main component of a lathe is the bed. It is the foundation that supports all the other components of the machine. The bed is typically made of cast iron, and its design determines the overall rigidity and stability of the lathe. It provides a stable platform for the movement of the tool and workpiece.

The bed of a lathe usually has precision guides or ways, which ensure smooth and accurate movement of the carriage and tailstock. It also houses the spindle and headstock assembly, making it the central component of the lathe.

2. What is the purpose of the headstock?

The headstock is an essential component of a lathe located at one end of the bed. Its primary purpose is to hold and rotate the workpiece. The headstock contains the spindle, which is responsible for the rotational motion of the workpiece.

Typically, the spindle in the headstock is driven by an electric motor. It also houses the bearings that support the rotation of the spindle. Some lathes have a hollow spindle, allowing long workpieces to pass through, while others have a solid spindle for shorter workpieces.

3. What is the tool post used for in a lathe?

The tool post is a crucial component located on the carriage of a lathe. Its purpose is to hold the cutting tool securely in place while it performs various operations on the workpiece. The tool post allows for quick and easy tool changes, ensuring efficient and versatile machining.

There are different types of tool posts, such as quick-change tool posts, which provide even more convenience by allowing swift tool swaps. The tool post also enables precise adjustment of the tool position, which is crucial for achieving the desired machining results.

4. What role does the tailstock play in a lathe?

The tailstock is another essential component of a lathe, situated at the opposite end of the headstock. Its main function is to support the other end of the workpiece, adding stability and preventing deflection during machining operations.

The tailstock typically consists of a spindle, which can be extended or retracted to accommodate different workpiece lengths. It often includes a center, which assists in aligning and gripping the workpiece. Some tailstocks may also have additional features like a live center or a drill chuck for specific machining operations.

5. What are the functions of the carriage in a lathe?

The carriage is a critical component that moves along the bed of a lathe. It carries the cutting tool and controls its position and movement during machining operations. The carriage consists of several parts, including the apron, cross-slide, and compound rest.

The apron houses the gears and mechanisms for engaging different feeds and thread cutting. The cross-slide allows lateral movement of the cutting tool, allowing for the creation of different shapes and contours. The compound rest enables the tool to pivot, facilitating angled cuts and tapers. Together, these components ensure precise and controlled tool movement for accurate and high-quality machining.

Summary

So, now you know all about the different parts of a lathe. We’ve learned that a lathe is a machine used to shape wood or metal. It has important components like the bed, headstock, tailstock, and tool rest. The bed is the base of the lathe, while the headstock holds the spindle. The tailstock helps support long pieces of material, and the tool rest holds the cutting tools. By understanding these components, you’re on your way to becoming a lathe expert! Keep on learning and exploring new things.

Remember, practice makes perfect, and learning about tools like lathes can be lots of fun. There’s so much you can create by using a lathe, from wooden bowls to metal parts for machines. These machines have been around for a long time and are still used today. Who knows? Maybe one day you’ll be the one designing and creating amazing things with a lathe. So keep exploring, keep learning, and keep having fun!