If you’ve ever wondered about the hazards of drill presses, you’re in the right place! 🙌 In this article, we’ll explore the potential risks associated with using these powerful tools. But don’t worry, we’ll also share tips on how to stay safe while working with a drill press. Now, let’s dive in and uncover the important information you need to know! 💡

Drill presses are amazing tools that can make your DIY projects a breeze. But like any powerful tool, they come with their fair share of hazards. 😯 It’s crucial to understand these risks so that you can take the necessary precautions and protect yourself while working with a drill press. Don’t worry, we’ll make sure you have all the knowledge you need to stay safe and sound. Let’s get started!

When it comes to drill presses, safety should be your number one priority. That’s why it’s essential to be aware of the potential hazards that could arise while using these tools. In this article, we’ll discuss the common risks associated with drill presses and provide you with practical advice on how to mitigate these dangers. So, let’s explore the hazards together and ensure your safety in the workshop! 🔧🔒

When working with a drill press, it’s important to be aware of the potential hazards involved. Safety should always be a top priority. Some common hazards associated with drill presses include:

- Entanglement of loose clothing or jewelry

- Flying debris from drilling operations

- Electrical hazards from faulty wiring

- Hand and finger injuries from rotating parts

- Slips, trips, and falls due to cluttered work areas

By understanding these hazards and taking proper safety precautions, you can ensure a safer work environment when using a drill press.

What Are the Hazards of Drill Press?

Drill presses are powerful and versatile tools that are commonly used in woodworking, metalworking, and construction projects. While they offer many benefits, it’s important to be aware of the potential hazards they pose. In this article, we will explore the hazards associated with drill presses and provide you with valuable information to ensure your safety and the safety of those around you.

Understanding the Hazards

When operating a drill press, there are several hazards that can arise if proper precautions are not taken. It’s crucial to understand these hazards to prevent accidents and injuries.

1. Mechanical Hazards

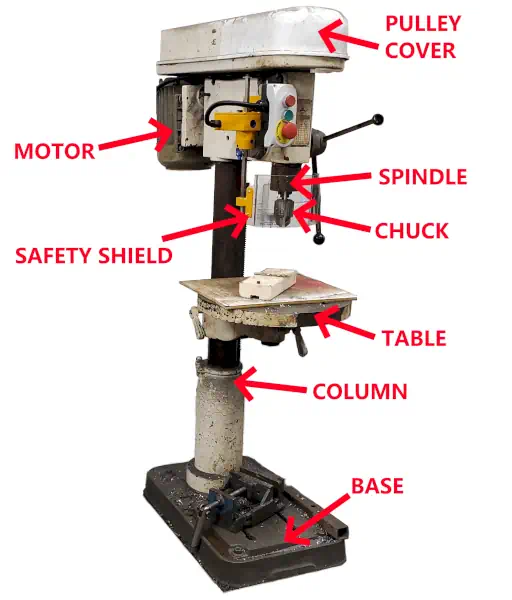

One of the primary hazards associated with drill presses is the risk of mechanical accidents. This includes getting hands or clothing caught in rotating parts, such as the drill bit or the chuck. The powerful rotational force of the drill press can cause severe injuries, including amputations or fractures. It is essential to keep loose clothing, jewelry, and long hair secured to prevent entanglement. Additionally, using appropriate safety guards and accessories, such as a drill press vise or a workpiece clamp, can help mitigate the risk of mechanical accidents.

Another mechanical hazard is the risk of flying debris. When drilling, fragments of material, such as wood or metal, can be ejected from the workpiece at high speeds. These flying projectiles can cause serious eye injuries or lacerations. Wearing safety goggles or a face shield is imperative to protect your eyes and face from potential harm.

Finally, the weight and stability of the drill press itself pose a hazard. If the machine is not securely anchored or if it is unbalanced, it can tip over during operation, potentially causing crushing injuries. Ensuring that the drill press is properly mounted on a stable surface or using additional support, such as clamps or a workbench, can minimize the risk of toppling.

2. Electrical Hazards

As with any power tool, there are electrical hazards associated with drill presses. Faulty wiring, damaged cords, or improper grounding can lead to electrocution or electrical fires. It is essential to regularly inspect the power cord and plug for any signs of wear or damage. If any defects are identified, the drill press should be taken out of service until the necessary repairs are made. Furthermore, always ensure that the drill press is plugged into a grounded outlet to reduce the risk of electrical shocks.

Another electrical hazard specific to drill presses is starting the machine unexpectedly. Accidental starting can occur if the power switch is left in the “on” position or if the drill press is inadvertently triggered. It is crucial to always turn off the power switch and unplug the machine before making any adjustments or changing the drill bit.

Tip: Consider using a lockout/tagout system to control the electrical energy to the drill press during maintenance or servicing to prevent accidental start-ups.

3. Ergonomic Hazards

Improper ergonomics while operating a drill press can lead to muscular strains, back injuries, or repetitive motion disorders. It’s important to maintain a proper working posture by standing with your feet shoulder-width apart and ensuring that the workpiece is at a comfortable height. Additionally, using ergonomic accessories, such as a height-adjustable worktable or a footrest, can help reduce the risk of strain and fatigue.

Repetitive drilling motions can also contribute to musculoskeletal disorders, such as tendinitis or carpal tunnel syndrome. Taking regular breaks, using good drilling techniques, and using appropriate drill bits can help minimize the strain on your hands, wrists, and arms.

Tip: Consider using a drill press with a built-in laser guide or depth stop feature to enhance precision and reduce the need for awkward postures or repetitive motions.

4. Chemical Hazards

While not directly related to the drill press itself, it’s important to consider the potential chemical hazards associated with the materials being drilled. For example, when drilling into certain types of wood or metals, harmful dust, fumes, or particulates can be generated. These can cause respiratory issues or skin irritations if proper precautions are not taken. It is advisable to wear a dust mask or respirator when drilling materials that may produce hazardous airborne contaminants. Additionally, working in a well-ventilated area or using local exhaust ventilation systems can help minimize exposure to harmful substances.

Tip: Familiarize yourself with the material safety data sheets (MSDS) for the materials you are drilling to identify any potential hazards and to understand the necessary safety precautions.

#Drill Press Safety Precautions

Now that we have explored the hazards associated with drill presses, here are some important safety precautions to keep in mind when operating a drill press:

Safe Operation Tips

1. Always read and understand the manufacturer’s instructions and follow them explicitly.

2. Wear appropriate personal protective equipment, including safety goggles, a face shield, hearing protection, and any required respirators or dust masks.

3. Secure your workpiece with a vise, clamp, or workpiece support to prevent movement or spinning.

4. Check that the drill bit is securely tightened and properly aligned with the workpiece before drilling.

5. Avoid wearing loose clothing, jewelry, or accessories that can get caught in the rotating parts.

6. Ensure a clear and well-lit working area, removing any potential obstructions or trip hazards.

7. Keep your hands away from moving parts and never attempt to adjust the drill press while it is running.

8. Use the appropriate drill bit for the material you are drilling, and avoid excessive drilling speeds or feed rates.

9. Regularly inspect the drill press for any signs of damage or malfunction, and address them promptly.

10. Clean the drill press regularly, removing dust, debris, or any built-up materials that can affect its performance.

By following these safety precautions and being aware of the potential hazards, you can ensure a safe and productive experience when operating a drill press.

Key Takeaways: What are the Hazards of Drill Press?

- Always wear safety goggles to protect your eyes from flying debris.

- Avoid loose clothing or jewelry that can get caught in the machine’s moving parts.

- Never touch the drill bit while it is in motion to prevent injuries.

- Keep the work area clean and free from clutter to minimize the risk of accidents.

- Make sure to secure the workpiece properly to prevent it from spinning or moving unpredictably.

Frequently Asked Questions

Welcome to our FAQ section where we address common questions about the hazards of using a drill press. Keep reading to find out about the potential dangers and how to mitigate risks when operating this powerful tool.

Q1: What are the risks associated with using a drill press?

Using a drill press can pose several hazards if not handled properly. First and foremost, there is a risk of injury from contact with rotating machinery, such as the drill bit or spindle. Accidental contact can result in severe cuts, bruises, or even amputation. Additionally, the high rotational speed of the drill bit can cause it to become a projectile if it becomes dislodged or breaks. This can lead to serious injuries if the operator or others are in close proximity to the machine.

Furthermore, the drill press can create a significant amount of dust or debris, which may be hazardous if inhaled or comes into contact with the eyes. This can cause respiratory issues or eye injuries. Lastly, improper use of the drill press, such as using incorrect drilling techniques or using inappropriate drill bits, can result in workpiece damage, tool breakage, or even fires.

Q2: How can I mitigate the risks associated with a drill press?

To reduce the potential hazards of using a drill press, it is important to follow some safety guidelines. Firstly, always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection. This will help protect you from flying debris, as well as noise-related issues.

Secondly, ensure that the drill press is properly maintained and in good working order. Regularly inspect and clean the machine, lubricate moving parts, and replace any worn-out components. Additionally, follow the manufacturer’s instructions for safe operation and ensure that your work area is clear of any hazards or distractions.

Q3: Can electrical hazards be associated with using a drill press?

Yes, there are electrical hazards to be aware of when using a drill press. Improper grounding or faulty electrical connections can lead to electrical shocks or other electrical accidents. It is crucial to ensure that the drill press is plugged into a grounded electrical outlet and that the power cord is in good condition. Avoid using extension cords as they may not provide sufficient electrical capacity, leading to overheating and potential fire hazards.

Always inspect the power cord for any damage before use, and if any defects are found, have it repaired or replaced by a qualified professional. It is also important to never touch the power switch or any electrical components with wet hands, as this increases the risk of electrical shock.

Q4: Are there any ergonomic risks associated with using a drill press?

Yes, there can be ergonomic risks when using a drill press. Awkward body positions, repetitive movements, or prolonged use can lead to musculoskeletal disorders or injuries. It is essential to maintain proper posture and use ergonomic principles while operating the drill press.

Adjust the work surface and the drill press height to a comfortable level, ensuring that your wrists, shoulders, and back are properly supported. Take regular breaks and stretch to relieve muscular tension. If possible, use additional aids, such as clamps or supports, to minimize the need for excessive force or awkward positioning.

Q5: What precautions should be taken when drilling certain materials?

When drilling certain materials with a drill press, special precautions should be taken. For example, drilling metal may produce sharp chips or metal shavings that can cause injury if not properly controlled. Always use appropriate cutting fluids or lubricants to reduce friction and heat buildup.

When drilling into wood or other materials, be cautious of splinters or flying debris. Clamp the material securely and consider using a backing board to prevent tear-out or splitting. Also, be aware that certain materials may release toxic fumes when drilled, so it is important to work in a well-ventilated area or use respiratory protection if necessary.

Summary

Using a drill press can be dangerous, so it’s important to know the hazards. The main risks include getting fingers or clothing caught in the moving parts, inhaling harmful dust or fumes, or being exposed to loud noises. To stay safe, always wear protective gear, keep long hair tied back, and avoid wearing loose clothing. Using the drill press in a well-ventilated area and wearing a mask can help prevent inhalation of dust or fumes. Lastly, using ear protection can prevent damage to your hearing from the loud noises the drill press makes.

Remember, safety should always come first when using a drill press. By following these guidelines and being aware of the hazards, you can reduce the risks and enjoy using the drill press safely.