Have you ever wondered about the main parts of a drill press? Well, you’re in the right place! Let’s dive in and explore the fascinating world of drill presses together.

A drill press is a powerful tool that helps us make accurate holes in various materials like wood, metal, or plastic. To understand how a drill press works, it’s essential to know its main components.

So, what are the main parts of a drill press? Let’s uncover the mystery and discover the key elements that bring this incredible machine to life.

Are you ready to embark on a journey of exploration and learn about the intricacies of a drill press? Let’s get started!

The Main Parts of a Drill Press: A Comprehensive Guide

Are you interested in learning about the main parts of a drill press? Look no further! In this article, we will delve into the different components that make up a drill press, their functions, and how they contribute to the overall functionality and performance of this essential tool. From the motor to the chuck, we will explore each part in detail, providing you with the knowledge you need to understand how a drill press works. So, let’s get started and explore the fascinating world of the drill press!

1. The Base

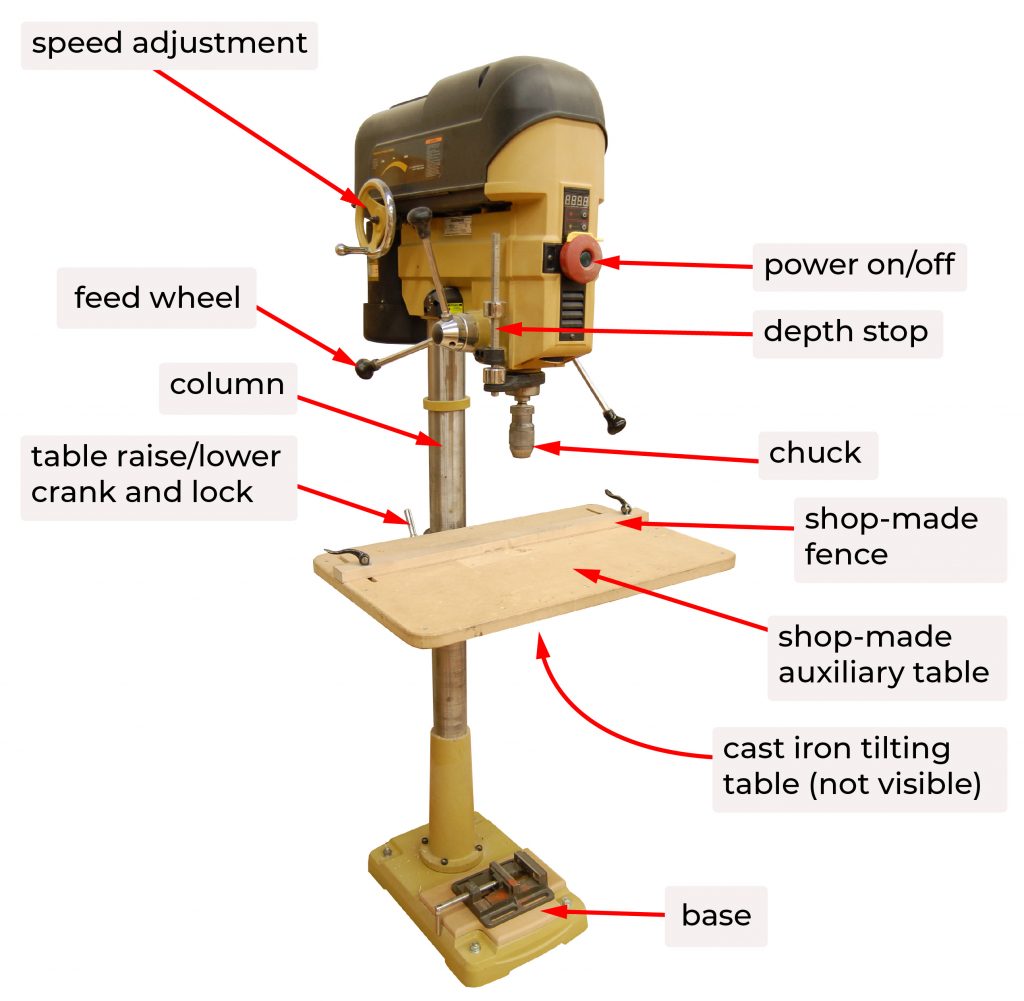

At the foundation of a drill press is its base, which provides stability and support to the entire machine. Typically made of heavy-duty cast iron, the base is designed to minimize vibrations and ensure accurate drilling. The base may have flat or slotted mounting surfaces, enabling users to secure the drill press to a workbench or other surfaces. Additionally, some bases include holes for bolting the drill press to the floor for even greater stability in industrial settings.

The size and shape of the base vary depending on the model and brand of the drill press. It is usually rectangular or circular in shape, with a larger surface area for heavy-duty drilling tasks. Additionally, some drill presses have adjustable bases that can be tilted or rotated to accommodate drilling at different angles, making them versatile tools for various applications.

The base often features laser-etched markings or scales that aid in accurate positioning of the workpiece during drilling. By aligning the markings, users can ensure precise drilling depths and hole locations, enhancing the overall efficiency and accuracy of the drilling process.

2. The Column

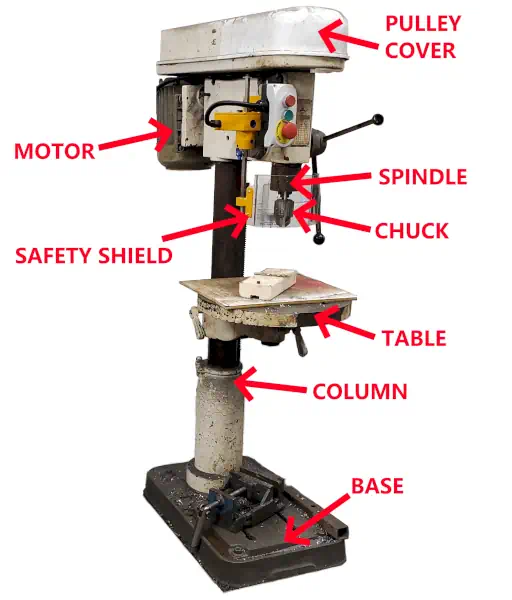

The column of a drill press, also known as the pillar or post, is a vertical component that attaches the base to the head. Like the base, the column is typically made of sturdy cast iron to provide stability and support during drilling. It acts as a guide, allowing the head and other parts of the drill press to move up and down smoothly.

The height and diameter of the column vary depending on the size and capacity of the drill press. Generally, larger drill presses have thicker, taller columns to accommodate heavy-duty drilling tasks and minimize vibrations. Smaller drill presses, on the other hand, have slimmer columns suitable for light-duty applications.

To enable smooth vertical movement, the column often has precision-ground surfaces or linear bearings. These features reduce friction and ensure precise alignment of the head and other moving parts, allowing for accurate drilling. Some drill presses also have rack and pinion mechanisms or hydraulic systems integrated into the column, facilitating height adjustments and making it easier to position the workpiece.

3. The Head

The head of a drill press is a crucial part that houses the motor, spindle, and other components responsible for the drilling operation. It is typically connected to the top of the column and can be adjusted vertically along the column to accommodate different workpiece heights.

The motor, which is housed within the head, is the heart of the drill press. It provides the power needed to rotate the spindle and drive the drilling tool. The motor can be either belt-driven or direct-driven, depending on the design of the drill press. Belt-driven motors often allow for greater speed control and can handle heavier drilling tasks, while direct-driven motors tend to be more compact and efficient.

In addition to the motor, the head contains various controls, such as speed adjustments, on/off switches, depth stop mechanisms, and belts or pulleys for changing speeds. These controls enable users to customize the drilling operation according to their specific needs, providing versatility and convenience.

4. The Spindle

The spindle is the part of the drill press that holds the drilling tool, such as a drill bit or a cutting tool. It is connected to the motor and rotates at high speeds, allowing for precise drilling in materials such as wood, metal, or plastic. The spindle is typically made of hardened steel to withstand the stress and heat generated during the drilling process.

To change the drilling tool, the spindle often features a chuck, which is a clamping device that securely holds the tool in place. Chucks can be keyless or keyed, with keyless chucks allowing for quick and easy tool changes without the need for additional tools. Keyed chucks, on the other hand, require a specialized key to tighten or loosen the chuck, ensuring a secure grip on the drilling tool.

The spindle may also have a quill, which is a cylindrical component that moves up and down within the head. The quill enables users to control the drilling depth by adjusting its position. By locking the quill at a specific height, users can achieve consistent drilling depths, resulting in precise and uniform holes.

Key Takeaways: What are the main parts of a drill press?

- A drill press consists of a base, column, and head.

- The base provides stability and support to the drill press.

- The column is the vertical support structure that connects the base to the head.

- The head contains the motor and spindle, which rotate the drill bit.

- Other important parts include the table, chuck, and depth stop.

Frequently Asked Questions

Welcome to our FAQ section, where we’ll answer your questions about the essential parts of a drill press. Whether you’re a beginner or an experienced user, understanding the main components of a drill press is crucial for safe and effective operation. Read on to learn more!

1. What is the purpose of the chuck in a drill press?

The chuck is a key component of a drill press as it holds and secures the drill bit in place. It allows you to easily change the drill bits depending on your task or the material you’re working with. Common chuck sizes include 1/4 inch and 1/2 inch, and they can hold various types of drill bits, from twist drills to spade bits.

By tightening or loosening the chuck, you can secure or release the drill bit. This feature provides stability and precision during drilling operations, ensuring accuracy while minimizing the risk of the bit slipping or coming loose.

2. What role does the spindle play in a drill press?

The spindle is the part of the drill press that rotates the drill bit. It is connected to the chuck and is responsible for transferring power from the motor to the bit. The spindle is designed to rotate at different speeds, allowing you to adjust the drilling speed based on the material being drilled.

Most drill presses have a lever or a speed setting that controls the rotation speed of the spindle. You can choose from a range of speeds, which are typically measured in revolutions per minute (RPM). This versatility allows you to optimize the drilling process, ensuring clean and accurate holes in various materials.

3. What is the table used for in a drill press?

The table is a flat, sturdy surface attached to the base of the drill press. It serves as a support for the workpiece and provides stability during drilling operations. The table can be adjusted in different directions, allowing you to position the workpiece at the desired angle and height.

Many drill press tables also come with adjustable fences or clamps to help secure the workpiece in place. This feature promotes accuracy and prevents the workpiece from moving or vibrating while drilling. Some tables even have built-in measurement scales or laser guides to assist in precise positioning and drilling.

4. What is the purpose of the depth stop in a drill press?

The depth stop is a feature that allows you to control the depth of the hole being drilled. It helps ensure that you drill to a specific depth without going too far. By setting the desired depth on the depth stop, you can limit the travel of the drill press, preventing the drill bit from penetrating beyond the desired depth.

This is particularly useful when you need to drill holes to a consistent depth, such as when creating dowel joints or countersinking screws. The depth stop adds precision to your drilling operations and helps you achieve consistent and professional results.

5. What safety features should I look for in a drill press?

When operating a drill press, safety should always be a top priority. Look for a drill press that has safety features such as a transparent chuck guard or a safety switch. The transparent chuck guard provides protection by enclosing the rotating chuck, preventing accidental contact with moving parts.

A safety switch, on the other hand, is designed to prevent the drill press from turning on unintentionally. This feature ensures that the drill press remains off until the switch is consciously activated, reducing the risk of accidental startup and potential injuries. Additionally, always wear appropriate personal protective equipment (PPE) such as safety glasses and ear protection when using a drill press.

Summary

So, there you have it: the main parts of a drill press! Remember, the head holds the motor and spindle, the column provides support and can be adjusted for height, and the base keeps everything stable. The chuck holds the drill bit and allows it to rotate, while the table provides a flat surface for your work. With these parts, you can tackle all sorts of drilling projects with ease.

Now that you know the key components of a drill press, you’ll be able to understand how it works and use it effectively. Just remember to always follow safety guidelines and wear protective gear when operating any power tool. Happy drilling!