What are the risks of using a lathe? Well, let’s dive right in and explore this fascinating topic! Using a lathe can be an exciting and creative experience, but it’s also important to be aware of the potential dangers involved. In this article, we’ll discuss the risks associated with using a lathe and provide you with some useful tips on how to stay safe. So, buckle up and get ready to learn about the risks of using a lathe!

Now, before we get into the specifics, you might be wondering what exactly a lathe is. Well, think of it as a powerful machine that spins a workpiece while a cutting tool shapes it. This versatile tool is commonly used in woodworking, metalworking, and even pottery! But as with any powerful tool, there are risks involved that need to be understood and managed.

So, what are these risks? We’ll cover some common ones, such as flying debris, getting caught in rotating parts, and using the lathe without proper training and supervision. By being aware of these risks and taking necessary precautions, you’ll be able to enjoy the exciting world of lathe work while staying safe! So, let’s dive deeper into each of these risks and learn how to mitigate them effectively.

Risks of Using a Lathe: Stay Safe in the Workshop!

When using a lathe, it’s crucial to be aware of the potential risks involved. Safety should always come first. Some common risks include flying debris, accidental injury from rotating parts, and electrical hazards. Always wear the appropriate protective gear, secure the workpiece properly, and be cautious of your surroundings. Regular maintenance and proper training are essential to mitigate these risks. Stay safe and enjoy your lathe projects!

The Risks of Using a Lathe: Understanding the Potential Dangers

When it comes to woodworking and metalworking tools, a lathe is an essential piece of equipment. It allows craftsmen to shape and create intricate designs with precision. However, it is crucial to be aware of the potential risks involved in using a lathe. From flying debris to entanglement hazards, understanding these risks is vital for ensuring your safety and the safety of those around you.

Flying Debris: Protecting Yourself from Hazards

One of the primary risks of using a lathe is the potential for flying debris. As the lathe spins the workpiece at high speeds, there is a chance for small wood or metal fragments to be thrown from the machine. These projectiles can cause serious injury if they come into contact with your skin or eyes.

To protect yourself from flying debris, always wear appropriate personal protective equipment (PPE). Safety glasses or a face shield should be worn at all times to shield your eyes from potential hazards. In addition, consider wearing a dust mask or respirator to protect your lungs from dust and fine particles that may be released during the turning process.

It is also essential to keep your work area clear of any bystanders. Ensure that no one is standing in the line of fire of any potential flying debris. Additionally, consider installing a barrier or shield around your lathe to contain any flying fragments and prevent them from causing harm outside the immediate work area.

Entanglement Hazards: Safeguarding Against Accidents

Another significant risk associated with using a lathe is the potential for entanglement. Entanglement occurs when loose-fitting clothing, jewelry, or long hair becomes caught in the rotating components of the machine. This can lead to severe injuries, such as fractures, amputations, or even death.

To minimize the risk of entanglement, always wear clothing that fits closely to your body and avoids any loose or dangling items. Long hair should be tied back or tucked under a hat to prevent it from getting caught. In addition, remove any jewelry, including rings, bracelets, or necklaces, before operating the lathe.

Regular maintenance and inspection of the lathe are also essential for reducing the risk of entanglement hazards. Ensure that all components are securely fastened and in good working condition. Regularly check for any loose or damaged parts and address them promptly to avoid accidents.

Electrical Hazards: Staying Safe Around Power

While the primary focus when using a lathe is often on the rotating parts, it is crucial not to overlook the potential electrical hazards associated with the machine. Lathes are powered by electricity, and improper handling or maintenance can lead to shocks, electrocution, or even electrical fires.

Before using a lathe, ensure that the electrical cords, plugs, and outlets are in good condition. Any signs of fraying, exposed wires, or damage should be addressed immediately. It is also crucial to ground the lathe properly to prevent electrical accidents.

When working with a lathe, always use dry hands and stand on a non-conductive surface. Avoid using the lathe in wet or damp conditions, as water can increase the risk of electrical shock. If you notice any unusual odors, sparks, or smoke coming from the machine, stop using it immediately and have it inspected by a qualified professional.

Proper Training: Mitigating Risks Through Knowledge

While understanding the risks associated with using a lathe is crucial, it is equally important to receive proper training before operating the machine. Proper training ensures that you are knowledgeable about the correct operating procedures, safety protocols, and maintenance requirements.

Before using a lathe, consult the manufacturer’s instructions and safety guidelines. These resources will provide you with valuable information on how to operate the machine safely and effectively. If you are unsure about any aspect of lathe operation, seek guidance from a qualified instructor or mentor.

Regularly refresh your knowledge through continued education and stay informed about any updates or changes in safety standards and recommended practices. By maintaining your skills and knowledge, you can mitigate the risks of using a lathe and ensure a safe working environment.

Additional Precautions for Lathe Usage

While understanding the risks associated with using a lathe is crucial, there are additional precautions you can take to enhance safety and reduce the likelihood of accidents or injuries.

Proper Tool Selection and Maintenance

Choosing the right tools for your lathe job is essential for ensuring safe and efficient operation. Select tools that are well-suited for the material you are working with and ensure they are in good condition. Dull or damaged tools can increase the risk of accidents and compromise the quality of your work. Regularly inspect your tools and replace any worn or damaged ones promptly.

Additionally, it is essential to use the appropriate cutting speeds and feeds for the material you are working with. Using the wrong settings can cause the tool to become overheated, leading to dulling or breakage.

Workpiece Securement and Support

To prevent the workpiece from becoming dislodged or ejected from the lathe, proper securing and support is crucial. Ensure that the workpiece is firmly held in place by using chucks, faceplates, or other appropriate holding devices. Avoid exerting excessive pressure on the workpiece, as this can lead to instability and increased risk of accidents.

When working with long or thin workpieces, consider using steady rests or tailstock support to prevent bending or whipping. This provides additional stability and reduces the risk of the workpiece breaking or causing injury.

Regular Maintenance and Inspection

Ongoing maintenance and inspection of your lathe are essential for optimal performance and safety. Regularly clean the machine and remove any debris or buildup that may affect its operation. Inspect all moving parts for wear, damage, or misalignment and address any issues promptly.

Additionally, ensure proper lubrication of the lathe components as recommended by the manufacturer. Lubrication reduces friction, keeps the machine running smoothly, and prolongs its lifespan.

Safe Work Environment

Creating a safe work environment is crucial when using a lathe. Keep the work area clean, organized, and free from clutter to minimize the risk of accidents. Ensure proper lighting in the work area to improve visibility and reduce the likelihood of errors or mishaps. Remove any distractions or obstacles that may interfere with your concentration and focus on the task at hand.

Furthermore, it is essential to have a first-aid kit readily available in case of any accidents or injuries. Familiarize yourself with its contents and know how to administer basic first aid. In the event of a severe accident, promptly seek medical attention.

Conclusion

Using a lathe can be a rewarding and satisfying experience, allowing you to create intricate and beautiful pieces. However, it is essential to be aware of the risks involved and take appropriate precautions to ensure your safety.

By understanding the potential dangers associated with using a lathe, such as flying debris, entanglement hazards, and electrical risks, and adhering to safety guidelines, you can mitigate these risks and create a safe working environment.

Remember to seek proper training, use personal protective equipment, and maintain your lathe regularly. By incorporating these safety measures into your woodworking or metalworking routine, you can enjoy the benefits of using a lathe while minimizing the potential for accidents or injuries. Stay safe, stay informed, and happy turning!

Key Takeaways – What are the risks of using a lathe?

- 1. Always wear proper safety gear, such as goggles and gloves, when working with a lathe.

- 2. Avoid loose clothing or jewelry that can get caught in the lathe’s moving parts.

- 3. Take caution to prevent the material from being ejected or breaking off during machining.

- 4. Be aware of rotating parts and keep hands and fingers away from the spinning chuck.

- 5. Make sure the lathe is properly secured and stable to prevent any movement while operating.

Frequently Asked Questions

Here are some commonly asked questions about the risks associated with using a lathe:

1. What are the potential risks of using a lathe?

Using a lathe can pose several risks if proper safety precautions are not followed. One of the main risks is the possibility of getting caught in the rotating parts, leading to severe injuries. This can happen if loose clothing, jewelry, or long hair come into contact with the spinning components of the lathe. Another risk is the potential for flying debris or fragments that may be ejected from the lathe, causing harm to the operator or bystanders.

Moreover, the cutting tools used on a lathe can be extremely sharp, increasing the risk of cuts and abrasions. The heat generated during the machining process can also cause burns if proper protective measures, such as wearing gloves or using appropriate cooling methods, are not implemented.

2. How can I minimize the risks of using a lathe?

Minimizing the risks associated with using a lathe starts with proper training and understanding of the machine’s operation. It is essential to receive adequate training on lathe safety procedures, including wearing the right personal protective equipment (PPE), like safety glasses, face shields, and hearing protection.

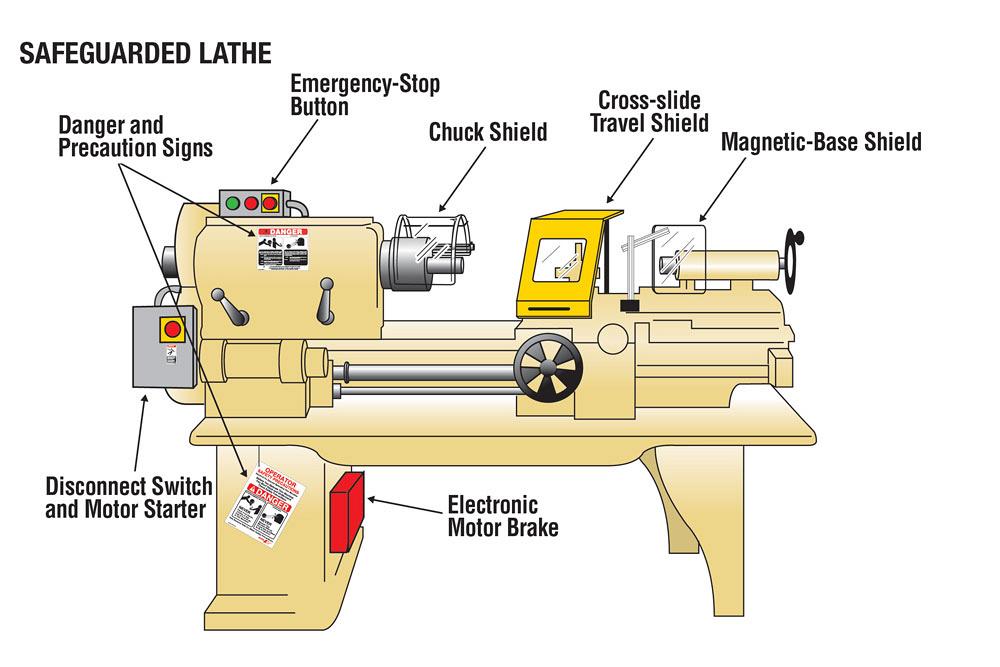

Additionally, keeping the lathe workspace clean and organized can help reduce the risks of accidents. Ensuring that all guards and safety devices are properly installed and functioning correctly is also crucial. Regular maintenance and inspections of the lathe can help identify any potential issues that may pose a risk and should be promptly addressed. Ultimately, following all safety guidelines and using common sense can go a long way in minimizing the risks associated with using a lathe.

3. Can using a lathe lead to respiratory hazards?

Yes, using a lathe can potentially lead to respiratory hazards if proper precautions are not taken. The process of machining on a lathe can generate dust or particles, especially when working with certain materials like wood or metal. Inhaling these airborne particles over time can lead to respiratory issues.

To minimize the risk of respiratory hazards, it is important to use appropriate dust control measures such as local exhaust ventilation or dust collectors. Wearing a respirator when working with materials that produce a significant amount of particles is also recommended. Regularly cleaning the lathe and the surrounding area can help reduce the accumulation of dust and airborne particles, further mitigating the respiratory risks.

4. Are there any electrical risks associated with using a lathe?

Yes, there are electrical risks associated with using a lathe. The lathe is powered by electricity, and if not handled properly, it can lead to electrical shocks or even fires. It is crucial to ensure that the lathe is properly grounded and that all electrical connections are secure and in good condition.

Inspecting the power cords regularly for any signs of damage or wear is important. If any issues are detected, they should be addressed immediately. Additionally, it is recommended to use ground-fault circuit interrupters (GFCIs) to protect against electrical shocks and to follow proper electrical safety practices, such as not using extension cords and avoiding placing cords in high traffic areas where they can be damaged.

5. Is using a lathe safe for beginners?

Using a lathe can be safe for beginners if they receive proper training and follow all safety guidelines. It is essential for beginners to undergo comprehensive training on lathe operation, including safety procedures and best practices. They should also be supervised by experienced individuals who can guide them through the learning process.

Beginners should start with simpler projects and gradually progress to more complex ones as they gain confidence and skills. Following safety precautions, such as wearing appropriate PPE, understanding the lathe’s capabilities and limitations, and maintaining focus during operation, can help beginners safely enjoy the use of a lathe.

Lathe safety

Summary

Using a lathe can be risky, but there are ways to stay safe and prevent accidents. One major risk is getting caught in the rotating parts, so it’s important to always wear protective gear and keep loose clothing and jewelry away. Another risk is flying debris, so wearing safety glasses is a must. It’s also crucial to ensure the lathe is set up properly, with the workpiece secured tightly, to avoid it getting thrown off or causing vibrations. Regular maintenance and proper training can reduce the risks of using a lathe and make it a safer tool to use.

In conclusion, being cautious and taking necessary safety precautions when using a lathe is the best way to avoid accidents. By wearing appropriate protective gear, securing the workpiece properly, and maintaining the lathe regularly, the risks can be significantly minimized. Remember, safety always comes first, so stay alert, stay safe, and enjoy the benefits of using a lathe responsibly.