Welcome to the world of carpentry! If you’re curious about what it takes to stay safe in a carpentry workshop, you’ve come to the right place. In this article, we’ll explore the essential safety precautions that every carpenter should follow to ensure a secure and accident-free working environment. So, grab your tool belt and let’s get started!

Carpentry is an exciting craft that allows you to create amazing things with your hands. But amidst all the sawing, hammering, and drilling, it’s crucial to prioritize safety. From wearing protective gear to properly handling tools, there are various precautions you need to take to prevent any mishaps. By being knowledgeable and vigilant, you can enjoy the art of carpentry and keep yourself and others out of harm’s way.

Whether you’re a beginner or an experienced woodworker, understanding and implementing safety measures is paramount. So, buckle up and join us on this carpentry safety journey. We’ll equip you with the knowledge and skills you need to build a solid foundation of safety practices in your carpentry workshop. Let’s dive in and learn how to make your woodworking experience both fun and safe!

1. Wear appropriate protective gear, such as gloves and safety glasses.

2. Keep the workspace clean and organized to prevent trips and falls.

3. Use tools properly and handle them with care to avoid accidents.

4. Understand and follow proper lifting techniques to prevent strain or injury.

5. Regularly inspect and maintain tools and equipment for safety. Remember, being cautious in a carpentry workshop is essential to prevent accidents and promote a safe working environment.

The Importance of Safety Precautions in a Carpentry Workshop

Carpentry workshops can be a hive of activity, with tools and machinery in constant use. While these spaces are essential for creating beautiful and functional wooden pieces, they can also pose significant risks if proper safety precautions are not taken. In this article, we will discuss the importance of safety in a carpentry workshop and provide detailed information about various precautions that should be implemented to ensure a safe working environment.

1. Personal Protective Equipment (PPE)

Wearing the appropriate personal protective equipment (PPE) is crucial in a carpentry workshop. This includes items such as safety glasses, hearing protection, dust masks, and gloves. Safety glasses protect the eyes from flying debris, while hearing protection guards against the loud noise generated by machinery. Dust masks are vital for safeguarding against the inhalation of hazardous particles, and gloves protect hands from cuts, splinters, and other injuries. Additionally, steel-toed boots should be worn to protect the feet from heavy objects and sharp tools.

Proper training and education about the correct use of PPE should be provided to all workers. Employers should ensure that PPE is available and regularly inspected for any signs of wear or damage. Employees must be encouraged to wear their PPE at all times while in the workshop, as even a momentary lapse in protection can lead to severe injury.

2. Machine and Tool Safety

In a carpentry workshop, machines and tools are the backbone of productivity. However, they also pose significant risks if not used safely. One of the most critical precautions is to ensure that all machines and tools are well-maintained and in good working condition. Regular inspections and maintenance checks should be conducted to identify and address any faults or defects promptly.

Moreover, it is essential to provide training to workers on the proper operation and handling of machinery and tools. They should be aware of safety features and emergency stop buttons. Clear signage and labels should also be displayed to indicate potential hazards and safety instructions. Furthermore, separate areas should be designated for storing and organizing tools to prevent accidents caused by misplaced or improperly stored equipment.

3. Fire Safety

Woodworking involves the use of flammable materials, making fire safety a crucial aspect of workshop precautions. To minimize the risk of fires, all flammable materials should be stored in designated areas away from potential ignition sources. Proper ventilation systems should be in place to decrease the accumulation of flammable vapors or dust particles.

Fire extinguishers should be easily accessible and regularly inspected to ensure they are in proper working condition. Workers should know the location of fire exits and the correct procedure to follow in case of an emergency. Conducting regular fire drills is essential to ensure that employees are well-practiced in responding to an actual fire situation.

Additionally, it is advisable to have a smoke detection system and sprinkler system installed in the workshop. These measures can help detect and contain fires at an early stage, providing valuable time for evacuation and minimizing potential damages.

4. Electrical Safety

In a carpentry workshop, electricity is utilized for various purposes. However, improper electrical installations and practices can lead to electrical shock, fires, and other accidents. Therefore, it is crucial to prioritize electrical safety.

All electrical installations should be performed by licensed professionals and regularly inspected for any faults or potential hazards. Grounding and insulation should be of high quality to prevent electrical shocks. Extension cords and power strips should be used appropriately, ensuring they are not overloaded and are kept away from flammable materials.

Workers should be educated about electrical safety precautions, such as avoiding water contact when using electrical tools and appliances. They should also know how to identify and report any electrical faults or anomalies promptly.

5. Safe Handling of Materials

Carpentry workshops deal with a wide range of materials, including wood, adhesives, paints, and finishes. Proper handling and storage of these materials are essential to minimize the risk of accidents and health hazards.

Wood should be stacked and stored securely to prevent it from falling or causing injury. Adhesives, paints, and finishes should be stored in well-ventilated areas according to the manufacturer’s instructions to prevent chemical reactions or inhalation hazards.

Furthermore, it is crucial to train workers in proper material handling techniques to prevent strains or injuries. Lifting heavy objects should always be done with the assistance of others and using appropriate lifting techniques. Ergonomic workstations and tools should be provided to minimize repetitive strain injuries.

6. Housekeeping and Organization

Maintaining a clean and organized workshop is essential for safety. Cluttered work areas can increase the risk of tripping and falling, while improper storage of tools and materials can lead to accidents caused by misplaced or unstable items.

Regular housekeeping practices should be implemented, including sweeping floors, removing debris, and organizing tools and materials. Spills should be cleaned up immediately to prevent slips and falls. Aisles and walkways should be clear, with no obstructions hindering movement or emergency evacuation.

7. Training and Communication

One of the most critical safety precautions is adequate training and communication. All workers should receive comprehensive safety training before starting their duties in the carpentry workshop. This training should cover all aspects of workshop safety, including the proper use of machinery, the importance of PPE, and emergency procedures.

Regular safety meetings and toolbox talks should be conducted to communicate updates, reinforce safe practices, and address any concerns or questions raised by the workers. Employees should be encouraged to report any safety hazards or near-miss incidents promptly.

By prioritizing training and open communication, carpentry workshops can foster a safety-conscious culture where all workers actively contribute to maintaining a safe working environment.

Key Takeaways: Safety Precautions in a Carpentry Workshop

1. Always wear appropriate protective gear, including safety glasses, gloves, and a dust mask, to protect yourself from potential hazards.

2. Keep the work area clean and organized to avoid tripping hazards and ensure easy access to tools and equipment.

3. Use tools properly and follow the manufacturer’s instructions to prevent accidents and injuries.

4. Never rush or work under the influence of drugs or alcohol, as it impairs judgment and increases the risk of accidents.

5. Regularly inspect and maintain tools and equipment to ensure they are in good working condition, and avoid using damaged or faulty tools.

Frequently Asked Questions

When it comes to working in a carpentry workshop, safety is of utmost importance. To ensure a safe work environment, it’s essential to follow certain precautions. Here are some frequently asked questions about safety precautions in a carpentry workshop:

1. How can I protect myself from flying debris in a carpentry workshop?

Protecting yourself from flying debris is crucial in a carpentry workshop. Always wear safety goggles or a full-face shield to guard your eyes against wood chips, sawdust, and other flying particles. In addition, keep the area well-ventilated to reduce dust levels. It’s also advisable to wear a dust mask or respirator to prevent inhaling harmful dust.

Furthermore, make sure to secure your workpieces properly. Use clamps or other appropriate techniques to hold the material in place while you work, minimizing the risk of sudden shifts that could cause debris to fly towards you.

2. What measures should I take to prevent injuries from sharp tools?

Working with sharp tools poses a potential risk for injuries. To prevent accidents, always maintain sharp and well-maintained tools. Dull tools can slip or require greater force, increasing the likelihood of accidents. Additionally, use appropriate handling techniques by holding the tools securely and avoiding awkward positions that could lead to loss of control.

When not in use, store the tools in a designated area, such as a tool rack or cabinet, to minimize the risk of accidental contact. It’s also crucial to wear appropriate protective gear, such as cut-resistant gloves, to safeguard your hands while handling sharp tools.

3. How can I ensure electrical safety in a carpentry workshop?

Electrical safety is paramount in a carpentry workshop. To ensure safety, regularly inspect all electrical equipment for any signs of damage, such as frayed cords or loose connections. Make sure all electrical components are properly grounded to prevent electric shocks. Avoid overloading outlets with too many appliances and use surge protectors to safeguard against power surges.

When working with power tools, avoid using them in wet or damp areas to minimize the risk of electric shock. It’s also important to handle the equipment by their insulated grips and keep cords away from sharp tools or potential hazards to prevent accidental cuts or damage.

4. How can I minimize the risk of fire in a carpentry workshop?

Fire safety is crucial in a carpentry workshop. Keep a well-maintained and easily accessible fire extinguisher in the workshop, ensuring everyone knows its location and how to use it. Regularly inspect and clean all electrical equipment to prevent any potential electrical fires.

In addition, maintain a clear and uncluttered workspace, with proper ventilation and ample space between materials, to reduce the risk of fire spreading. Store flammable materials, such as solvents and paints, in a designated area away from ignition sources, and ensure proper disposal of sawdust and other wood debris to prevent spontaneous combustion.

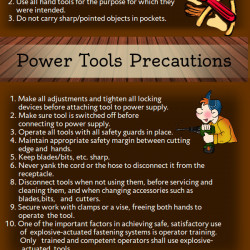

5. What precautions should I take when working with power tools in a carpentry workshop?

Working with power tools requires extra caution. Always read and follow the manufacturer’s instructions for each tool. Wear appropriate personal protective equipment, including safety glasses, ear protection, and a dust mask, when working with power tools.

Before operating any power tool, inspect it for any signs of damage or wear. Ensure that all guards and safety features are in place, and that the power source is grounded and protected with a circuit breaker or fuse. Additionally, avoid wearing loose clothing or jewelry that could get caught in the tool, and maintain a firm grip on the tool throughout its operation.

Summary

Safety precautions are essential in a carpentry workshop to protect yourself and others. Firstly, always wear the proper safety gear like goggles, gloves, and a hard hat. Secondly, keep the workspace organized and clean to avoid accidents. Thirdly, use tools correctly and make sure they are in good condition. Fourthly, never rush and take your time to work safely. Lastly, ask for help if you’re unsure or need guidance.

In summary, to stay safe in a carpentry workshop, remember to wear protective gear, maintain a clean work area, use tools correctly, work patiently, and seek assistance when needed. Following these precautions will help ensure a safe and enjoyable woodworking experience.