If you’re wondering about the safety rules for lathe machines, you’ve come to the right place! Whether you’re a curious kid or someone interested in learning about machinery, this article will provide you with the information you need. We’ll walk through the essential safety guidelines for operating a lathe machine. So, let’s dive in and explore how to stay safe while using this powerful tool!

Operating a lathe machine can be exciting, but it’s important to understand that safety comes first. In this article, we’ll cover the key safety rules that should always be followed when using a lathe machine. So, if you’re ready to become a knowledgeable lathe operator, let’s get started!

As with any piece of machinery, lathe machines require proper safety precautions. Whether you’re a budding woodworker or a curious mind, it’s crucial to understand the essential rules to keep yourself and others safe. So, join us as we explore the safety guidelines for operating a lathe machine!

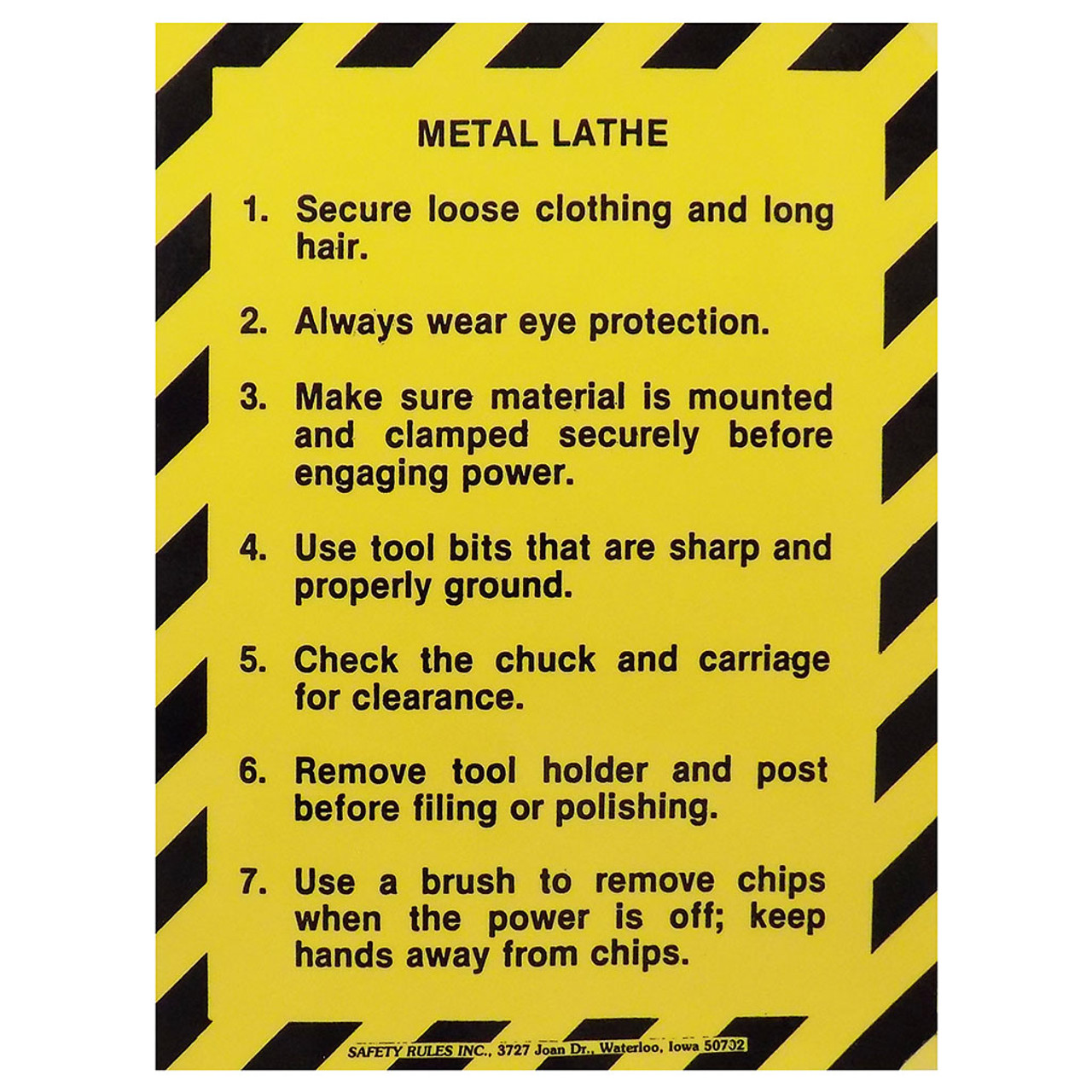

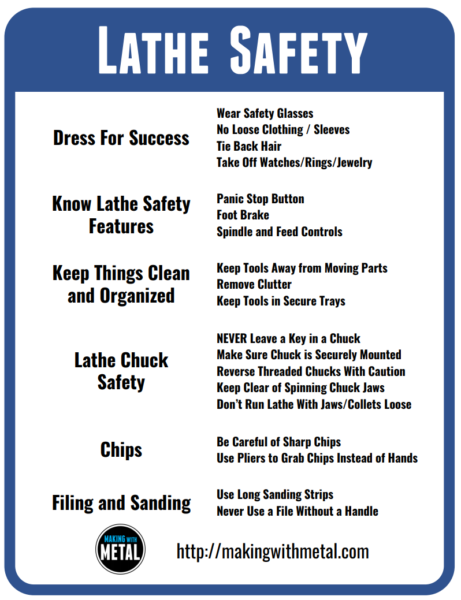

- Always wear proper safety equipment, including safety goggles, gloves, and ear protection.

- Keep the work area clean and organized to prevent accidents.

- Secure the workpiece firmly and use the proper cutting tools.

- Avoid wearing loose clothing or jewelry that could get caught in the machine.

- Regularly inspect the machine for any damages or malfunctions before use.

Following these safety guidelines will help you maintain a safe working environment when using a lathe machine.

Safety Rules for Lathe Machines: Ensuring a Secure Working Environment

Lathe machines are powerful tools used in a variety of industries to shape and cut materials with precision. While these machines offer immense utility, it is crucial to prioritize safety in their operation. This article will provide a comprehensive guide to the safety rules for lathe machines, ensuring a secure working environment for operators and preventing accidents or injuries. By adhering to these rules and following best practices, individuals can minimize the risks associated with lathe machine operation and create a safe and productive workspace.

The Importance of Safety in Lathe Machine Operation

Prioritizing safety in lathe machine operation is of utmost importance for several reasons. Firstly, lathe machines involve rotating parts and sharp tools, which can pose significant hazards if not handled properly. Accidents can result in severe injuries, causing physical harm to operators. Additionally, negligence in adhering to safety rules can lead to damage to the machine, workpiece, or surrounding equipment. These incidents may result in costly repairs, delays in production, and potential liabilities for the organization. By following the recommended safety rules, operators can mitigate these risks and ensure a secure work environment.

1. Understanding the Machine

Before operating a lathe machine, it is crucial to have a thorough understanding of its components and functions. Familiarize yourself with the different parts of the machine, such as the chuck, tailstock, cutting tools, and spindle. Identify the controls that enable you to start, stop, and adjust the machine’s speed. By gaining knowledge about the machine, you will be better equipped to operate it safely and troubleshoot any issues that may arise.

Furthermore, ensure that the machine is in proper working condition. Regular maintenance and inspections are essential to identify any mechanical issues or abnormalities. Check for loose bolts, damaged belts, and worn-out parts. Address these concerns promptly to prevent accidents or malfunctions during operation. Consulting the machine’s manual and seeking guidance from experienced professionals can provide valuable insights into its operation and maintenance.

In addition to understanding the machine, it is essential to be aware of the specific hazards associated with lathe machines. These dangers include ingoing nip points, entanglement hazards, and flying chips or debris. Familiarize yourself with these risks and take appropriate precautions to prevent accidents.

2. Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment (PPE) is crucial to safeguard against potential hazards when operating a lathe machine. The following items should be worn at all times:

- Safety goggles or face shield: Protects the eyes from flying debris or particles.

- Hearing protection: Reduces the risks of hearing damage caused by the machine’s noise.

- Protective gloves: Prevents cuts and injuries from sharp tools or rotating parts.

- Appropriate work clothing: Avoid loose-fitting clothes or jewelry that may get caught in the machine.

By wearing the necessary PPE, operators can minimize the potential risks associated with flying debris, noise exposure, and contact with sharp tools or rotating parts. Regularly inspect and maintain PPE to ensure its effectiveness and replace any worn-out or damaged equipment promptly.

3. Machine Setup and Workpiece Handling

A proper machine setup and careful workpiece handling are essential aspects of ensuring safety in lathe machine operation. Follow these guidelines:

- Secure the workpiece firmly in the chuck, ensuring it is properly aligned. Loose or misaligned workpieces can result in accidents during operation.

- Avoid excessive tool projection beyond the chuck. A longer projection increases the risk of accidents and can cause vibration or chatter, impacting the quality of the finished product.

- Use appropriate cutting tools and ensure they are sharp and in good condition. Dull or damaged tools can lead to poor cutting performance and increase the likelihood of accidents.

- Operate the machine at suitable speed and feed rates, as determined by the material being machined. Excessive speed or feed can cause the workpiece or cutting tool to fail, leading to accidents.

- When adjusting the machine during operation, ensure it is turned off and the rotating parts have come to a complete stop. Attempting adjustments while the machine is running can result in severe injuries.

Following these guidelines during the setup and workpiece handling process will reduce the risks associated with lathe machine operation and enhance the overall efficiency and accuracy of the machining process.

4. Machine Guarding and Safety Devices

Machine guarding and safety devices play a critical role in preventing accidents and protecting operators from potential hazards. Check that the lathe machine is equipped with the necessary guards and safety features, such as:

- Chuck guard: Shields the rotating chuck and prevents contact with moving parts.

- Spindle guard: Covers the spindle area to prevent accidental contact.

- Emergency stop button: Allows for immediate shutdown of the machine in case of an emergency.

- Interlocks: Ensure that the machine cannot be operated until all guards are in place.

Regularly inspect these guards and safety devices to ensure they are in good working condition. Any damaged or malfunctioning components should be promptly repaired or replaced. Additionally, do not attempt to bypass or disable these safety features, as they are designed to protect operators from potential hazards.

5. Training and Supervision

Proper training and supervision are vital to promote safety in lathe machine operation. Operators should receive comprehensive training on the correct procedures, safety rules, and best practices for using the specific lathe machine model they will be operating. This training should cover machine setup, tool selection, workpiece handling, and emergency procedures.

Supervisors should ensure that operators are competent and confident in their abilities to operate the lathe machine safely. Regular refresher training sessions and assessments can help reinforce and update knowledge and skills. Encourage operators to report any safety concerns or incidents promptly, fostering a culture of safety and continuous improvement.

Remember, safety is a collective responsibility. Encourage open communication and collaboration among the entire team to maintain a safe working environment.

Maintaining a Safe Environment: Additional Considerations

In addition to the safety rules outlined above, the following tips can further enhance the safety of the lathe machine operation:

Regular Maintenance and Inspections

Implement a maintenance and inspection schedule for the lathe machine. Regularly inspect and lubricate the machine’s components, checking for any signs of wear or damage. Proper maintenance will minimize the risk of malfunctions or breakdowns during operation and ensure the safety of the operator.

Furthermore, organize periodic inspections by qualified professionals to assess the overall condition of the lathe machine and identify any potential issues. Addressing these concerns promptly will prevent accidents and prolong the lifespan of the machine.

Clear Workspace and Proper Lighting

Maintain a clean and clutter-free workspace around the lathe machine. Remove any unnecessary tools, materials, or debris that may hinder movement or pose a tripping hazard. Clear visibility is essential, so ensure proper lighting is available in the workspace to minimize eye strain and prevent accidents due to poor visibility.

Emergency Preparedness

Establish emergency plans and procedures specific to lathe machine operation. Ensure all operators are familiar with these protocols, including evacuation routes, emergency contact numbers, and the operation of safety devices. Regularly conduct drills to reinforce these procedures and assess their effectiveness.

Moreover, keep appropriate first aid supplies readily available in the vicinity of the lathe machine. Operators should receive training in basic first aid procedures to respond effectively to any accidents or injuries that may occur.

By following the safety rules and incorporating these additional considerations, individuals can create a secure working environment when operating a lathe machine. Prioritizing safety at all times not only protects the well-being of operators but also enhances productivity and fosters a positive work culture. With proper training, adherence to guidelines, and vigilance, the potential hazards associated with lathe machine operation can be effectively minimized.

Key Takeaways: What are the Safety Rules for Lathe Machine?

- Wear proper safety gear, including goggles and gloves.

- Keep long hair and loose clothing secured to prevent accidents.

- Be cautious of sharp edges and moving parts.

- Always use the machine’s guards and shields.

- Never leave the lathe unattended while it’s running.

Frequently Asked Questions

Welcome to our comprehensive guide on the safety rules for lathe machines! Below, we have provided answers to some common questions regarding the safety measures associated with operating a lathe machine. Read on to ensure a safe and secure working environment.

1. What precautions should be taken before starting a lathe machine?

Prior to starting a lathe machine, it is important to take several precautions to ensure your safety. Firstly, make sure you are wearing appropriate personal protective equipment (PPE) such as safety glasses and a face shield to protect your eyes and face from flying debris. Additionally, ensure that the lathe machine is in proper working condition with all safety guards in place. Check that the tool rest is correctly positioned and adjusted, and that the lathe chuck is securely mounted. Finally, make sure you have received proper training on operating the lathe machine and are familiar with its specific safety features.

Taking these precautions before starting a lathe machine will greatly minimize the risk of accidents or injuries and create a safe working environment for yourself and others.

2. What are some safety guidelines for handling lathe machine tools?

When it comes to handling lathe machine tools, following safety guidelines is essential. Firstly, always use the correct tool for the job and ensure that it is sharp and in good condition. Dull or damaged tools can lead to accidents. It is also important to hold the tool firmly, but not too tightly, to maintain control while cutting. Avoid running your hands over the cutting tool and keep your fingers away from the rotating workpiece. Always use a brush or hook to remove chips or debris, rather than your hands.

By adhering to these safety guidelines, you can prevent accidents and maintain a safe working environment while operating a lathe machine.

3. Why is it important to secure the workpiece properly before using a lathe machine?

Securing the workpiece properly before using a lathe machine is crucial for maintaining safety. Improperly secured workpieces can come loose and cause serious injuries. To prevent this, make sure the workpiece is securely fastened to the lathe machine’s chuck or spindle. Check that any additional clamps or fixtures are properly tightened and that the workpiece does not wobble or move while being worked on.

Properly securing the workpiece ensures stability, reduces the risk of accidents, and allows for accurate and controlled machining on the lathe machine.

4. What should be done in case of an emergency while operating a lathe machine?

In the event of an emergency while operating a lathe machine, it is important to know the correct procedures to follow. First and foremost, familiarize yourself with the location of the emergency stop button or switch and make sure it is easily accessible. If an emergency occurs, immediately press the emergency stop button to shut down the machine and cut off power. Afterward, report the incident to your supervisor or relevant authority and seek any necessary medical attention. It is crucial to act quickly and calmly in emergency situations to minimize the risk of further harm.

Having knowledge of emergency procedures and the location of safety equipment can save valuable time and prevent potential injuries while operating a lathe machine.

5. How can operators avoid common lathe machine hazards?

To avoid common lathe machine hazards, operators should be well-informed and cautious. Proper training in lathe machine operation is essential to understand the potential hazards and the necessary safety measures. Additionally, operators should always follow the manufacturer’s guidelines and recommended safety procedures. Regular maintenance and inspections of the lathe machine should be conducted to identify any potential issues that may compromise safety. It is also important to maintain a clean and organized work area to prevent tripping hazards and reduce the risk of accidents.

By staying informed, practicing caution, and following safety procedures, operators can significantly reduce the occurrence of common hazards associated with lathe machines.

Summary

So, what are the safety rules for using a lathe machine? Here’s a quick rundown to keep in mind:

First, always wear appropriate safety gear like goggles, gloves, and closed-toe shoes. Second, make sure the lathe machine is properly secured and stable before using it. Third, be cautious when operating the machine, especially when changing speeds or adjusting the tool. Fourth, never wear loose clothing or jewelry that could get caught in the machine. And finally, always keep your hands away from the moving parts and never leave the lathe unattended when it’s still running. Remember, safety first!