Are you curious about what trunnions are on a table saw? Well, let me break it down for you in a way that’s both informative and fun! Trunnions may sound like a funny word, but they play a crucial role in how a table saw operates. So, let’s dive right in and explore what these trunnions are all about.

Picture this: you’re in a woodworking shop, and you see a sleek table saw in the corner. You know it’s a powerful tool, but what makes it tick? That’s where the trunnions come into play. Trunnions are the mechanical components that hold the arbor and the blade in place on a table saw. Think of them as the superheroes that keep everything stable and ensure those precise cuts you’re looking for!

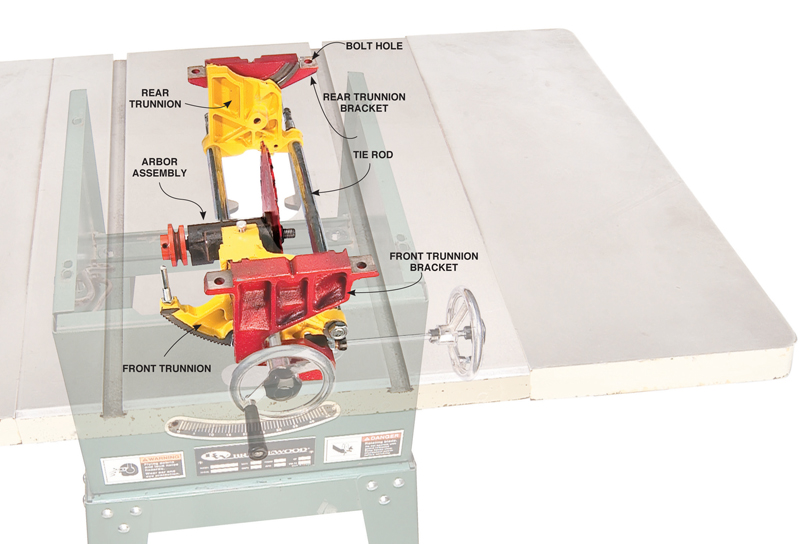

But how do these trunnions work their magic? Well, imagine a pair of sturdy brackets attached to the saw’s underside. These brackets are the trunnions. They provide support and allow the arbor to tilt and raise or lower the blade, giving you the ability to make angled cuts and adjust the cutting depth. So, whether you’re creating a bevel or a crosscut, trunnions are the unsung heroes that make it all possible.

Now that you know what trunnions are, you’ll have a better understanding of how a table saw operates. So, the next time you’re in a woodworking shop or tackling a DIY project, you can impress your friends with your knowledge about these essential components. Stay tuned for more exciting woodworking tips and tricks!

What Are Trunnions on a Table Saw?

A table saw is a versatile tool used in woodworking to make straight cuts on various materials. One crucial component of a table saw is the trunnions. Trunnions play a vital role in the stability, precision, and overall functionality of the table saw. In this article, we will explore what trunnions are and how they contribute to the performance of a table saw.

Understanding Trunnions and their Functionality

Trunnions are mechanical components found on the underside of a table saw’s tabletop, connecting it to the base and allowing it to tilt at various angles. They are essentially pivoting points that provide support and control the movement of the blade. Trunnions consist of a pair of metal brackets or arms that hold the tabletop in place and enable it to be adjusted to different angles. These arms are attached to the base of the table saw and have gears or mechanisms to adjust the angle of the tabletop effortlessly.

Trunnions ensure the stability and accuracy of the blade during cutting operations. By allowing the tabletop to tilt, they enable users to make bevel cuts or angled cuts with precision. They also provide a secure connection between the blade and the motor, ensuring that the blade remains aligned and parallel to the miter slots. Without trunnions, the blade would not be able to tilt, limiting the variety of cuts that can be made on a table saw.

In addition to their primary function of adjusting the tabletop angle, trunnions also contribute to the overall structural integrity of the table saw. They provide support and balance to the entire unit, preventing any unwanted vibrations or movements that could affect the quality of the cuts. Trunnions are typically made of durable materials, such as cast iron or steel, to withstand the heavy-duty nature of table saw operations.

The Benefits of Trunnions on a Table Saw

Trunnions offer several benefits that enhance the performance and versatility of a table saw:

- Angle Adjustments: Trunnions allow for precise and quick angle adjustments on the tabletop, enabling the user to make bevel cuts or angled cuts with ease.

- Stability: Trunnions ensure the stability of the blade during cutting operations, reducing vibrations and ensuring accurate cuts.

- Flexibility: With trunnions, table saws can handle a wide range of cutting tasks, from straight cuts to complex angles, expanding their functionality and versatility.

- Durability: Trunnions are typically made of strong, durable materials that can withstand the demands of heavy-duty woodworking.

- Alignment: Trunnions help maintain the alignment of the blade and the miter slots, ensuring consistent and precise cuts.

Trunnions vs. Other Blade Adjustment Mechanisms

While trunnions are widely used in table saws, there are alternative blade adjustment mechanisms available in some models. Let’s compare trunnions with some of these mechanisms:

Rack and Pinion System

The rack and pinion system uses a gear (pinion) that meshes with a rack (toothed bar) to control the table saw’s angle adjustments. This system is known for its smooth and precise operation, offering fine-tuned control over the tabletop’s tilt angle. However, the rack and pinion system can be more expensive than trunnions and may require additional maintenance over time.

Direct Drive System

In a direct drive system, the motor is directly connected to the blade, eliminating the need for trunnions or other adjustment mechanisms. This design offers simplicity and a compact footprint. However, it limits the range of angle adjustments and may not provide the same level of stability and precision as trunnions.

Hybrid Systems

Some table saws feature hybrid systems that combine trunnions with additional adjustment mechanisms, providing users with a greater range of options and flexibility. These hybrid systems incorporate the best features of both trunnions and other mechanisms, offering enhanced precision, stability, and ease of use.

Tips for Maintaining Trunnions on a Table Saw

To ensure the optimal performance and longevity of trunnions on a table saw, consider the following maintenance tips:

- Clean Regularly: Remove sawdust, debris, and other particles that can accumulate on and around the trunnions to maintain smooth operation.

- Lubricate Gears: Apply lubricant to the gears or mechanisms associated with the trunnions to reduce friction and ensure easy adjustments.

- Check Alignment: Regularly check the alignment of the blade and the miter slots to ensure that the trunnions are properly adjusted.

- Tighten Connections: Inspect and tighten any loose connections or bolts associated with the trunnions to prevent instability during cutting operations.

- Follow Manufacturer’s Instructions: Always refer to the manufacturer’s instructions for specific maintenance recommendations and guidelines for your table saw model.

Conclusion

Trunnions are essential components of a table saw, providing stability, precision, and adjustability to the tabletop. They enable users to make a variety of cuts and ensure the longevity of the saw. Understanding trunnions and their function enhances your woodworking experience by allowing you to maximize the capabilities of your table saw. By properly maintaining the trunnions, you can ensure their smooth operation and optimize the performance of your table saw for years to come.

Key Takeaways: What Are Trunnions on a Table Saw?

- Trunnions are a vital component of a table saw, supporting the weight of the motor and determining its angle.

- They act as pivot points, allowing the blade to tilt for angled cuts or be set at 90 degrees for straight cuts.

- Properly adjusted trunnions ensure accurate and precise cuts on a table saw.

- Regular maintenance of trunnions is important to keep the table saw functioning optimally.

- Understanding how trunnions work can help improve safety and efficiency when using a table saw.

Frequently Asked Questions

Here are some common questions about trunnions on a table saw:

Why are trunnions important in a table saw?

Trunnions are crucial components of a table saw because they provide stability and support for the saw blade and the entire cutting mechanism. They are responsible for holding the arbor, which is the shaft that the saw blade attaches to. The trunnions allow for precise alignment of the blade, ensuring accurate and safe cuts.

By securely holding the arbor, trunnions prevent any wobbling or movement of the blade during operation. They also allow for adjustments to the blade’s angle and height, allowing woodworkers to cut at different angles and depths. In short, trunnions play a vital role in maintaining the overall performance and functionality of a table saw.

How do trunnions work in a table saw?

Trunnions work by providing a pivot point for the arbor assembly of a table saw. The arbor assembly, including the saw blade, is attached to the trunnions, allowing it to tilt and raise or lower along with the entire cutting mechanism. The trunnions are equipped with gears or mechanisms that allow for adjustments to the blade’s angle and height.

When the user adjusts the angle or height of the blade, the trunnions pivot, tilting or raising the arbor assembly accordingly. This allows for precise and controlled cutting, as the user can set the blade at the desired angle or height for different woodworking techniques. Trunnions provide the flexibility and stability needed for accurate cuts with a table saw.

Are trunnions the same as arbor bearings?

No, trunnions and arbor bearings are not the same. Trunnions are the components that hold the arbor assembly and allow for adjustments to the blade’s angle and height. They provide stability and support for the entire cutting mechanism of a table saw.

On the other hand, arbor bearings are the bearings that support the arbor shaft itself. They reduce friction and ensure smooth rotation of the arbor, allowing the blade to spin freely. While both trunnions and arbor bearings are important for the functioning of a table saw, they have different roles and functions within the saw’s structure.

Can trunnions be replaced or upgraded on a table saw?

Yes, trunnions can be replaced or upgraded on a table saw. If the trunnions on your table saw are damaged, worn out or not functioning properly, it is possible to replace them with new trunnions. This can enhance the performance and accuracy of your table saw.

Upgrading trunnions is also an option for some table saw models. Upgraded trunnions may offer improved features, such as smoother adjustments, increased stability, or better precision. However, it’s important to check if the upgraded trunnions are compatible with your specific table saw model before making any changes. Consulting the manufacturer’s instructions or seeking professional advice is recommended to ensure proper installation and compatibility.

What should I do if the trunnions on my table saw are misaligned?

If the trunnions on your table saw are misaligned, it can affect the accuracy and safety of your cuts. To correct this issue, start by unplugging the table saw and removing the saw blade. Then, check the trunnions for any visible signs of misalignment, such as uneven gaps or irregularities.

You can try adjusting the trunnions by loosening the bolts that secure them and carefully repositioning them to align properly. It may take some trial and error to achieve the correct alignment. Once the trunnions are aligned, tighten the bolts securely but be careful not to over-tighten. Finally, reassemble the saw blade and test the alignment by making a test cut on a scrap piece of wood. If you’re unsure or uncomfortable with making adjustments yourself, it’s best to consult a professional or the manufacturer’s instructions for guidance.

Table Saw Tuneup – Trunnion Adjustment

Summary

Trunnions on a table saw are important parts that help the blade move up and down. They are like the hinge on a door, allowing the blade to tilt for making angled cuts. Trunnions have gears that work together to control the blade’s movements, ensuring accuracy and safety. These mechanisms are crucial for the overall functionality of the table saw.

Understanding how trunnions work can help you operate a table saw more effectively. By knowing how to tilt the blade for different cuts and adjust the height, you can achieve precise and professional results. Trunnions play a significant role in making the table saw a versatile tool for woodworking projects. So the next time you use a table saw, remember the importance of trunnions in making your cuts reliable and accurate.