Do you love working with stainless steel? Are you wondering what bandsaw blade you need to tackle this tough material? Well, you’ve come to the right place! In this guide, we’ll explore the world of bandsaw blades and help you find the perfect one for cutting through stainless steel. So, let’s dive in and discover the secrets to successful stainless steel cutting. Get ready to take your metalworking skills to the next level!

Finding the right bandsaw blade for stainless steel can be a bit tricky, but fear not, my young metalworking enthusiast! We’re here to simplify things for you. Stainless steel is known for its durability and resistance to corrosion, which makes it a popular choice for a wide range of projects. However, cutting through this mighty material requires a specialized bandsaw blade. With the right blade, you can achieve clean and precise cuts, saving you time and effort.

Now, you might be wondering, “What type of bandsaw blade do I need for stainless steel?” Well, my eager learner, there’s no one-size-fits-all answer. The ideal blade for cutting stainless steel depends on various factors, such as the thickness of the material, the type of stainless steel, and the desired cut quality. But don’t worry—we’ll walk you through the different types of blades and their applications, helping you make an informed decision. So, let’s get ready to slice through stainless steel like a pro!

What Bandsaw Blade Do I Need for Stainless Steel?

Stainless steel is a durable and popular material used in various industries, from construction to automotive. When it comes to cutting stainless steel, using the right bandsaw blade is crucial to achieve clean and precise cuts. With the wide variety of bandsaw blades available, it can be overwhelming to determine which one is best suited for cutting stainless steel. In this guide, we will explore the factors to consider when choosing a bandsaw blade for stainless steel, as well as some of the top options available in the market.

Factors to Consider When Choosing a Bandsaw Blade for Stainless Steel

When selecting a bandsaw blade for stainless steel, there are several factors to take into consideration:

1. Blade Material: Opt for a blade made from high-speed steel (HSS) or carbide-tipped, as these materials are specifically designed to cut through stainless steel efficiently. They offer exceptional hardness and resistance to heat and wear.

2. Tooth Pitch: The tooth pitch refers to the distance between each tooth on the blade. For stainless steel, a finer tooth pitch is recommended, as it allows for smoother and more controlled cuts. Aim for a tooth pitch between 10 and 18 teeth per inch (TPI).

3. Blade Hardness: Stainless steel is a tough material, so it’s important to select a bandsaw blade with a high hardness rating. Look for blades with a Rockwell hardness (HRC) of 62 or higher. This ensures that the blade can withstand the pressures of cutting through stainless steel without dulling or breaking.

Top Bandsaw Blades for Cutting Stainless Steel

1. Bosch BS6412-24M 64-1/2-Inch by 1/2-Inch by 24TPI Metal Bandsaw Blade: This blade is made from high-speed steel and is specifically designed for cutting stainless steel. It features a fine tooth pitch for smooth and precise cuts.

2. LENOX Tools Bi-Metal Band Saw Blade: With its bi-metal construction, this bandsaw blade offers a combination of durability and flexibility. It has a tooth pitch of 10-14 TPI, making it ideal for cutting stainless steel.

3. DEWALT DW3986C 14/18 TPI Portable Band Saw Blade: This portable bandsaw blade from DEWALT is designed for cutting a variety of materials, including stainless steel. It has a tooth pitch that ranges from 14 to 18 TPI, providing versatility for different cutting needs.

4. MK Morse M71 Bi-Metal Bandsaw Blade: This blade is made from high-speed steel and offers excellent heat and wear resistance. It has a tooth pitch of 10-14 TPI, making it suitable for cutting stainless steel.

Benefits of Using the Right Bandsaw Blade for Stainless Steel

Using the right bandsaw blade for cutting stainless steel comes with several benefits:

1. Precise and Clean Cuts: A proper bandsaw blade ensures clean and accurate cuts on stainless steel, reducing the need for additional finishing or cleanup.

2. Extended Blade Life: Stainless steel is a challenging material to cut, but using a blade specifically designed for it will increase the blade’s lifespan, saving you time and money on frequent blade replacements.

3. Reduced Heat and Wear: The right bandsaw blade for stainless steel minimizes heat buildup, preventing overheating and extending the lifespan of both the blade and the material being cut.

In summary, choosing the right bandsaw blade when cutting stainless steel is essential for achieving accurate and clean cuts. Consider factors such as blade material, tooth pitch, and blade hardness when making your selection. Some top options include the Bosch BS6412-24M, LENOX Tools Bi-Metal, DEWALT DW3986C, and MK Morse M71. By using the correct bandsaw blade, you’ll enjoy precise cuts, extended blade life, and reduced heat and wear.

Key Takeaways: What Bandsaw Blade Do I Need for Stainless Steel?

- Choose a bi-metal bandsaw blade for cutting stainless steel.

- Opt for a blade with high-speed steel (HSS) teeth for better performance.

- Ensure the bandsaw blade has a higher tooth count per inch (TPI) for smoother cuts on stainless steel.

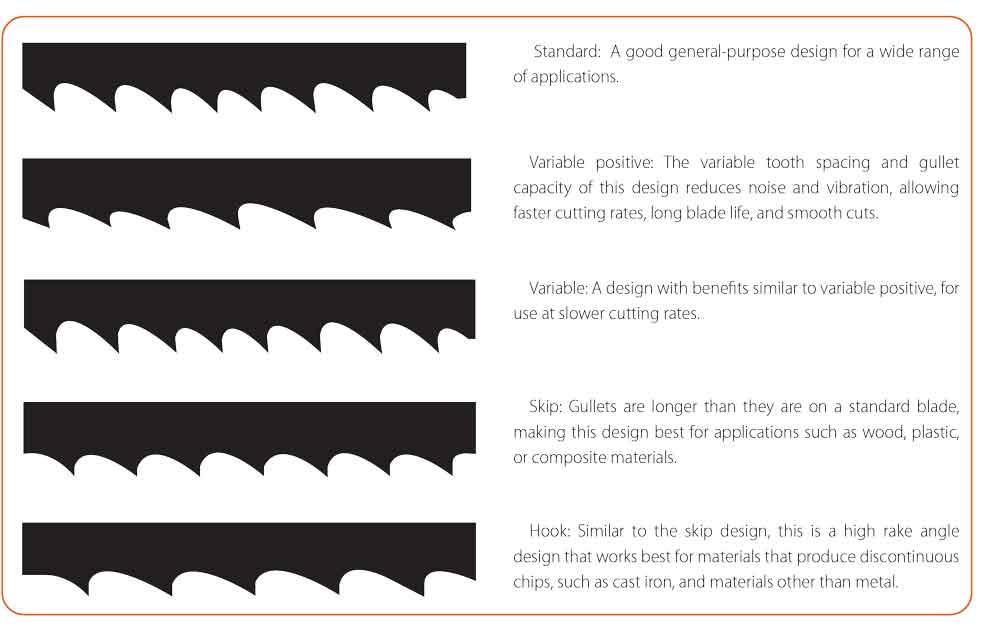

- Consider a variable pitch blade for versatile cutting of different stainless steel thicknesses.

- Regularly lubricate the bandsaw blade to prolong its lifespan and improve cutting efficiency.

Frequently Asked Questions

Are you wondering which bandsaw blade is best suited for cutting stainless steel? Look no further! We’ve compiled a list of commonly asked questions about bandsaw blades for stainless steel to help you make an informed decision.

1. How do I select the right bandsaw blade for cutting stainless steel?

Selecting the right bandsaw blade is crucial for cutting stainless steel effectively. Opt for a blade specifically designed for stainless steel cutting, featuring a high-speed steel (HSS) blade with a variable tooth pitch. This combination ensures efficient cutting and minimizes heat build-up, preventing the blade from seizing up and reducing the risk of workpiece damage. Additionally, choosing a blade with a wide set, reduced tooth rake angle, and tooth relief angles optimizes chip clearance for smoother cuts.

Remember to consider the thickness of the stainless steel you will be cutting. Larger teeth with a lower TPI (teeth per inch) are ideal for thicker stock, while finer teeth with a higher TPI work better for thin stock. It’s crucial to check the manufacturer’s recommendations for the specific stainless steel grade you will be working with, as different types of stainless steel have varying hardness and require different cutting parameters.

2. Can I use a regular bandsaw blade for cutting stainless steel?

While it is possible to use a regular bandsaw blade for cutting stainless steel, it is not recommended. Stainless steel is a tough material that places significant strain on the blade, causing excessive wear and reducing its lifespan. Regular blades may struggle to handle the heat generated during the cutting process, leading to premature blade failure and poor cut quality.

To avoid these issues, invest in a bandsaw blade specifically designed for stainless steel. These blades are made from high-speed steel and have hardened teeth that can withstand the demands of cutting stainless steel. They are designed to dissipate heat effectively, ensuring a longer blade life and cleaner cuts. Using a specialized stainless steel bandsaw blade will ultimately save you time, money, and frustration in the long run.

3. What tooth configuration is best for cutting stainless steel?

The tooth configuration of a bandsaw blade plays a crucial role in cutting stainless steel effectively. For stainless steel, a variable tooth pitch blade is recommended. This means that the teeth have different distances between them. The varying tooth pitch helps to dissipate heat and prevents the blade from getting stuck in the workpiece, resulting in smoother and more efficient cuts.

Furthermore, choose a blade with a wide set, reduced tooth rake angle, and tooth relief angles. This allows for better chip clearance, reducing the risk of clogging and improving the overall cutting performance. Consulting the blade manufacturer’s recommendations for the specific stainless steel grade you’re working with is also essential for optimal tooth configuration.

4. How can I maximize the lifespan of a bandsaw blade for cutting stainless steel?

To maximize the lifespan of a bandsaw blade used for cutting stainless steel, proper blade maintenance is crucial. Firstly, ensure the blade tension is correctly adjusted, as incorrect tension can lead to premature wear or blade damage. Regularly inspect the blade for signs of wear, such as dulling or missing teeth, and replace it as needed to maintain optimal cutting performance.

Using lubrication or coolant specifically formulated for stainless steel cutting can also significantly extend blade life. These substances reduce friction and heat buildup, minimizing wear and tear on the blade. Additionally, it’s important to operate the bandsaw machine at the correct cutting speed for the stainless steel grade you are working with, as excessive speed can lead to blade damage. Finally, always follow proper cutting techniques and avoid forcing the blade through the material, which can cause unnecessary stress and accelerated blade wear.

5. Can I use the same bandsaw blade for cutting different grades of stainless steel?

While it is possible to use the same bandsaw blade for cutting different grades of stainless steel, it might not provide optimal performance. Different stainless steel grades have varying levels of hardness, which can affect the blade’s cutting efficiency and lifespan. Therefore, it is recommended to use a bandsaw blade specifically designed and recommended by the manufacturer for each stainless steel grade you work with.

Using the appropriate blade for each stainless steel grade will ensure that you achieve cleaner cuts, minimize blade wear, and prolong the life of the blade. It’s worth investing in multiple blades optimized for different stainless steel grades, as this will ultimately lead to better cutting results and a more cost-effective cutting process.

Summary

So, to cut stainless steel with a bandsaw, you need the right blade. It’s important to choose a blade with the right tooth pitch, material, and thickness. A bi-metal blade with a tooth pitch of 10-14 TPI works well for stainless steel. Make sure the blade is made of hardened steel to handle the tough stainless steel material. Lastly, choose a blade that is of the appropriate thickness for your bandsaw to ensure smooth and effective cutting.

Now that you know what bandsaw blade you need for stainless steel, you can confidently tackle your projects. Remember to always prioritize safety and use the appropriate protective gear when operating a bandsaw. Happy cutting!