Are you wondering what bandsaw blade is best for resawing? Well, you’ve come to the right place! In this article, we’ll explore the different types of bandsaw blades and help you find the perfect one for your resawing needs.

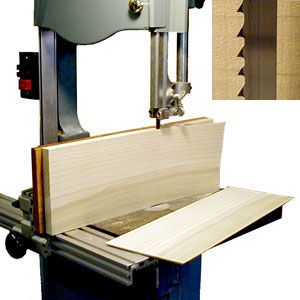

Resawing is a woodworking technique where you cut a thick piece of lumber into thinner boards. It’s a great way to get the most out of your wood and create beautiful, uniform pieces for your projects. But to achieve clean and efficient cuts, you need the right bandsaw blade.

With so many options available, choosing the best bandsaw blade for resawing can be a bit overwhelming. But fear not! We’re here to break it down for you and simplify the process. By the end of this article, you’ll have a clear understanding of the different blade styles and be equipped to make an informed decision. So let’s dive in!

What Bandsaw Blade is Best for Resawing?

Resawing is a technique in woodworking where a thick piece of wood is sliced into thinner boards. It’s a great way to maximize the use of your lumber and create unique pieces with beautiful bookmatched grains. However, to achieve precise and clean cuts, you need the right bandsaw blade for the job. In this article, we will explore the different types of bandsaw blades and guide you in choosing the best one for resawing.

The Benefits of Resawing

Before discussing the bandsaw blades, let’s briefly touch upon the benefits of resawing. Resawing allows you to create veneer, thin boards for box making, or even resculpt the shape of the wood. It also gives you the opportunity to showcase the natural beauty of the wood’s grain pattern by creating bookmatched boards. Resawing is a valuable technique for both professional woodworkers and hobbyists, as it opens up a world of design possibilities and maximizes the use of your materials.

Choosing the Right Blade Width

The width of the bandsaw blade is crucial for achieving clean and accurate resawing cuts. Generally, wider blades are recommended for resawing as they provide more stability and reduce blade deflection. A blade with a width between 3/4″ to 1-1/2″ is ideal for most resawing tasks. This width allows for efficient cutting while minimizing the risk of the blade wandering off-course.

Additionally, the blade’s thickness should be taken into consideration. Thicker blades are less prone to bending and are ideal for resawing thicker stock. On the other hand, thinner blades are more flexible and can cut tighter curves. Consider the type of wood you’ll be working with and the desired outcome before selecting the blade thickness.

Types of Blades for Resawing

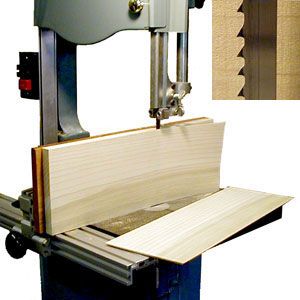

There are two main types of bandsaw blades for resawing: hook-tooth blades and skip-tooth blades. Let’s explore both options:

1. Hook-Tooth Blades

Hook-tooth blades have deep gullets and large teeth with a positive rake angle. Their aggressive tooth pattern allows for fast cutting and easy chip removal. These blades are ideal for resawing thick stock and hardwoods. The deep gullets prevent the blade from clogging, resulting in cleaner cuts. However, hook-tooth blades can leave a rough surface finish, which may require additional sanding or planing.

2. Skip-Tooth Blades

Skip-tooth blades have wide gullets and widely spaced teeth with a neutral or negative rake angle. These blades are excellent for resawing thinner stock and softer woods. The wider gullets help clear away the sawdust efficiently. Skip-tooth blades also produce smoother surface finishes compared to hook-tooth blades. They are less aggressive but offer more control and precision. If you’re working with delicate materials or need to minimize sanding, a skip-tooth blade is a great choice.

The Importance of Blade Tension and Tooth Set

When resawing, proper blade tension and tooth set play vital roles in achieving accurate and clean cuts. It’s essential to ensure your bandsaw is properly set up and adjusted for resawing.

Blade Tension

Proper blade tension ensures the blade stays on track and doesn’t wander during the cut. Insufficient tension can cause the blade to twist or veer off-course, resulting in uneven cuts. On the other hand, excessive tension can lead to premature blade wear. Check your bandsaw’s manual for the recommended blade tension and adjust accordingly.

Tooth Set

The tooth set refers to the alternating bending of teeth left and right to create a wider kerf and allow the blade to pass through the wood smoothly. Too much set can cause excessive material removal, while too little set can lead to binding or burning. Most bandsaw blades come with the appropriate tooth set for the intended purpose. However, it’s essential to periodically inspect and adjust the tooth set if needed.

Tips for Successful Resawing

Resawing can be a challenging task, especially for beginners. Here are a few tips to help you achieve successful resawing:

1. Use a Fence or Bandsaw Resawing Jig

A fence or a bandsaw resawing jig provides support and helps guide the wood through the blade, ensuring straight and accurate cuts. It eliminates the need for constant hand control and reduces the risk of the wood drifting off-course.

2. Take It Slow and Steady

When resawing, patience is key. Take your time and let the blade do the cutting. Applying excessive force or pushing the wood too quickly can result in rough cuts and may cause the blade to deflect or break.

3. Maintain Proper Blade Tension and Sharpness

Regularly check the blade tension and ensure it’s within the manufacturer’s recommendations. Blunt blades can lead to burning, wandering, and imprecise cuts. Keep your bandsaw blades sharp and make sure to replace them when necessary to maintain optimal cutting performance.

| Bandsaw Blade Type | Advantages | Disadvantages |

|---|---|---|

| Hook-Tooth Blades | Fast cutting, good chip removal | Rough surface finish |

| Skip-Tooth Blades | Smoother surface finish, more control | Less aggressive |

Conclusion

Choosing the right bandsaw blade for resawing is essential for achieving precise, clean, and efficient cuts. Consider the width and thickness of the blade, as well as the type of blade that suits your specific needs. Proper blade tension and tooth set are crucial factors in ensuring successful resawing. Remember to take your time, use a fence or jig for guidance, and maintain the blade’s sharpness. By following these tips and selecting the appropriate bandsaw blade, you’ll be on your way to creating stunning resawn boards and unlocking endless design possibilities.

Key Takeaways: What Bandsaw Blade is Best for Resawing?

- 1. Choose a bandsaw blade with a narrow width for better control and less waste.

- 2. Opt for a blade with a low TPI (teeth per inch) count for smoother cuts on thick stock.

- 3. Look for a blade made from high-quality steel for durability.

- 4. Select a blade with a skip tooth or hook tooth design for efficient chip removal.

- 5. Consider using a blade with a variable tooth set to reduce vibration and increase cutting accuracy.

Frequently Asked Questions

Welcome to our frequently asked questions section, where we’ll be answering popular queries about finding the best bandsaw blade for resawing. Whether you’re a woodworking enthusiast or a professional carpenter, we’ve got you covered. Read on to learn more about this essential tool and find the perfect blade for your resawing needs.

1. What factors should I consider when choosing a bandsaw blade for resawing?

When selecting a bandsaw blade for resawing, there are a few key factors to keep in mind. The first is the blade’s width. For resawing, opt for a wider blade to help achieve a straighter cut and reduce the chances of the blade wandering off track. Next, consider the blade’s teeth per inch (TPI). Lower TPI blades are ideal for resawing, as they remove material more efficiently and prevent clogging. Additionally, the blade’s tooth type, such as hook or skip tooth, can impact the cutting performance and the smoothness of the resulting cut.

Other considerations include the blade’s thickness, the material you’ll be cutting, and your desired cutting speed. Taking these factors into account will help you find the best bandsaw blade for resawing.

2. Can I use the same bandsaw blade for resawing different types of wood?

While it’s possible to use the same bandsaw blade for resawing different types of wood, it’s not always the best approach. Different woods have varying densities and characteristics, which can affect the performance of the blade. For harder woods, it’s advisable to use a blade with more TPI to ensure efficient cutting. Softer woods, on the other hand, may require a blade with fewer TPI to prevent excessive tearing of the material.

If you frequently work with different types of wood, it’s recommended to have multiple bandsaw blades on hand. This way, you can switch between blades depending on the wood you’re working with, ensuring optimal results and prolonging the lifespan of your blades.

3. How often should I change the bandsaw blade used for resawing?

The frequency of blade changes for resawing depends on several factors, such as the type of material being cut, the blade’s quality, and the intensity of use. As a general guideline, it’s recommended to inspect the blade regularly for signs of wear, such as dull teeth or cracks. If you notice any visible damage or a significant decrease in cutting performance, it’s time for a blade change.

It’s essential to maintain sharp blades for resawing to achieve clean, accurate cuts. Dull blades can lead to increased strain on the motor, reduced cutting efficiency, and potentially dangerous kickbacks. By regularly inspecting and replacing worn blades, you’ll ensure optimal performance and safety in your resawing projects.

4. What maintenance steps should I take to prolong the life of my bandsaw blade for resawing?

To extend the lifespan of your bandsaw blade for resawing, proper maintenance is crucial. First, ensure that the blade is tensioned correctly. A properly tensioned blade not only improves cutting accuracy but also helps prevent premature wear and blade fatigue. Regularly inspect the blade for any signs of sawdust or pitch buildup and clean it as needed.

Additionally, using a suitable blade lubricant can reduce friction and heat buildup, extending the blade’s life. Proper storage is also vital – store your blades in a dry, cool area to prevent moisture damage and rust. Finally, remember to follow the manufacturer’s guidelines for your specific bandsaw model to ensure optimal performance and longevity.

5. Can I use a regular woodworking blade instead of a bandsaw blade for resawing?

While it’s technically possible to use a regular woodworking blade for resawing, it’s not recommended. Bandsaw blades are specifically designed for resawing, with features that allow for better control, reduced heat buildup, and improved cutting efficiency. Regular woodworking blades may not have the necessary tooth configuration or blade width to handle the demands of resawing.

Using a bandsaw blade designed for resawing will provide better results, including cleaner cuts and less material waste. Investing in a quality bandsaw blade tailored for resawing is a wise choice if you frequently work on resawing projects and want to achieve professional-level results.

Summary

So, which bandsaw blade is best for resawing? Well, it depends on the material you’re cutting. For hard, dense woods, a wide blade with fewer teeth per inch will work best. On the other hand, for softer woods or thicker cuts, a narrower blade with more teeth per inch is the way to go. Make sure to choose the right blade width and tooth configuration for your specific resawing needs. Happy woodworking!

In conclusion, the key to successful resawing lies in selecting the right bandsaw blade. Understanding the type of wood you’re cutting and the thickness of your desired cut will guide you in choosing the blade width and teeth per inch. With the appropriate blade, you’ll be able to achieve smooth and accurate resawing results. Keep experimenting and learning to become a pro at resawing!