If you’re wondering what bandsaw blade to use for cutting aluminum, you’ve come to the right place! Let’s dive into the world of metalworking and explore the best options for tackling this task.

Cutting aluminum with a bandsaw requires a specialized blade that can handle its unique properties. We’ll discuss the different types of bandsaw blades available and help you find the perfect fit for your cutting needs.

So, grab your safety goggles and join us as we unravel the mystery of choosing the right bandsaw blade for cutting aluminum!

1. Consider the blade material: Opt for a bi-metal blade for durability and heat resistance.

2. Choose the correct TPI (teeth per inch): For cutting aluminum, a 10-14 TPI blade is recommended.

3. Select the appropriate blade width: A narrower blade provides better control for precise cuts.

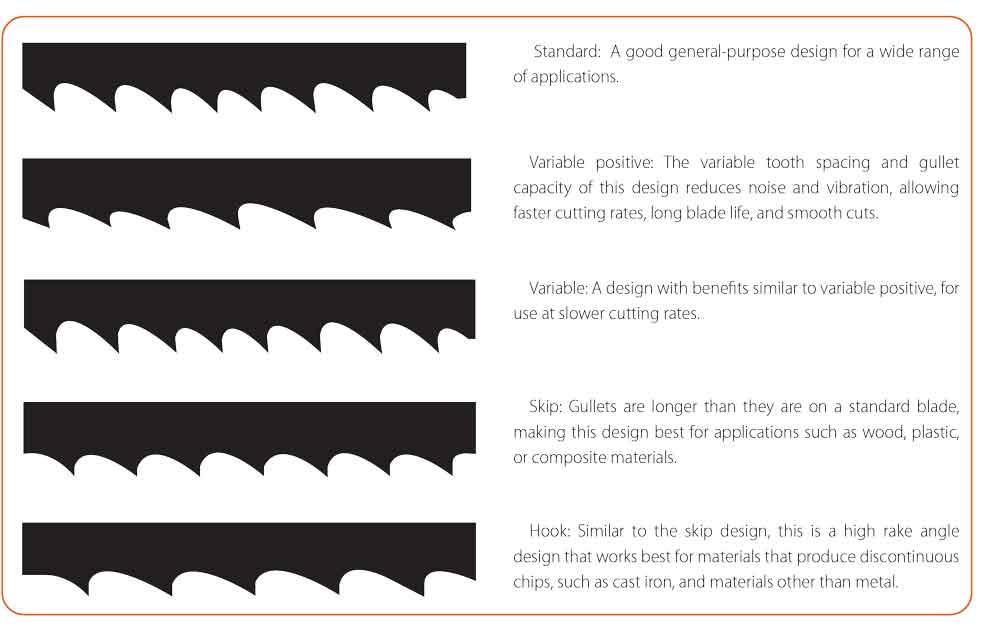

4. Check the blade’s tooth configuration: Look for a skip-tooth or hook-tooth configuration for smooth cutting.

5. Consider the blade’s thickness: Thicker blades offer more stability during cutting.

Follow these tips to select the perfect bandsaw blade for cutting aluminum!

What Bandsaw Blade to Cut Aluminum?

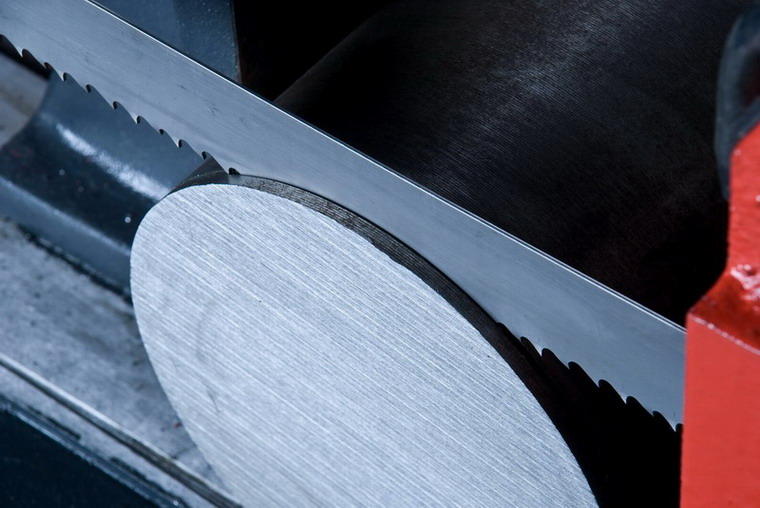

When it comes to cutting aluminum, using the right bandsaw blade is crucial for achieving clean and accurate cuts. Aluminum is a soft metal, but it can still present challenges due to its tendency to gum up blades and create excessive heat. In this article, we will explore the different types of bandsaw blades available and discuss their characteristics, benefits, and applications. Whether you’re a professional woodworker, metalworker, or a hobbyist, understanding which bandsaw blade is best for cutting aluminum will help you achieve optimal results.

The Benefits of a Carbide-Tipped Bandsaw Blade

One of the most popular choices for cutting aluminum is a carbide-tipped bandsaw blade. Carbide is a high-performance material known for its hardness and durability. Carbide-tipped blades are designed to withstand the abrasiveness of cutting aluminum and provide clean, precise cuts. The carbide tips on these blades offer a longer lifespan compared to traditional steel blades, making them cost-effective in the long run. Additionally, carbide-tipped blades are known for their resistance to heat buildup, reducing the risk of blade dulling and warping.

Carbide-tipped blades also have a unique tooth geometry that helps dissipate heat and prevent aluminum chips from sticking to the blade. The tooth design allows for efficient chip removal, reducing the chances of blade damage or material burning. Whether you’re cutting thin sheets or thick aluminum blocks, a carbide-tipped blade will provide excellent cutting performance and ensure a smooth finish.

Choosing the Right Tooth Pitch

When selecting a bandsaw blade for cutting aluminum, the tooth pitch is an important factor to consider. The tooth pitch refers to the number of teeth per inch (TPI) on the blade. The appropriate tooth pitch will depend on the thickness of the aluminum you are cutting. For thinner materials, a higher TPI blade with finer teeth is recommended. This allows for more teeth to engage with the material, resulting in a smoother and more controlled cut.

On the other hand, when cutting thicker aluminum, a lower TPI blade with larger teeth is preferred. Coarser teeth remove material at a faster rate, making the cut more efficient. However, it’s important to strike a balance, as using too coarse of a blade may result in a rough finish or excessive vibrations. Consider the thickness of your aluminum stock and choose a blade with the appropriate tooth pitch to ensure optimal cutting performance.

Aluminum Cutting Tips

While using the right bandsaw blade is essential for cutting aluminum, there are a few additional tips to keep in mind for a successful cutting process. Firstly, it’s important to use an appropriate feed rate that matches the blade’s speed. Feeding too aggressively can cause the blade to deflect or break, while feeding too slowly can result in material buildup and heat generation.

Additionally, using a coolant or lubricant can greatly improve the cutting process. Aluminum has a tendency to produce chips that stick to the blade, leading to reduced cutting efficiency. Applying a coolant, such as a mix of water and cutting oil, helps reduce friction and keeps the blade clean. This not only extends the blade’s lifespan but also ensures more accurate and reliable cuts.

Conclusion

Choosing the right bandsaw blade is essential for achieving clean and accurate cuts when working with aluminum. A carbide-tipped blade offers excellent performance and durability, making it the go-to choice for many professionals. Consider the tooth pitch based on the thickness of your aluminum stock to ensure optimal cutting efficiency. Additionally, following cutting tips such as maintaining an appropriate feed rate and using a coolant will further enhance your results. With the right bandsaw blade and proper techniques, cutting aluminum can be a precise and satisfying process.

Key Takeaways: What Bandsaw Blade to Cut Aluminum?

- Choose a bandsaw blade with a high tooth count for cutting aluminum.

- Opt for a blade with a low cutting speed to prevent the aluminum from melting.

- Ensure the blade is made of a material suitable for cutting non-ferrous metals like aluminum.

- Consider using a variable tooth pitch blade for cutting aluminum of different thicknesses.

- Regularly clean and lubricate the blade to ensure optimal cutting performance.

Frequently Asked Questions

Looking to cut aluminum with a bandsaw? Here are some commonly asked questions and expert answers to help you choose the right bandsaw blade for the job.

1. What type of bandsaw blade should I use to cut aluminum?

When cutting aluminum, it’s best to use a bi-metal bandsaw blade. Bi-metal blades are specially designed with a high-speed steel tooth edge and a flexible backing material. This combination allows the blade to withstand the high cutting speeds necessary for aluminum while maintaining durability and longevity. Bi-metal blades also provide better chip evacuation and heat resistance, ensuring clean cuts and preventing blade damage.

Additionally, choose a blade with a fine tooth pitch (around 10-14 TPI) for cutting aluminum. The fine tooth pitch helps control the cutting process, reducing the chance of chips sticking to the blade or workpiece.

2. Can I use a wood-cutting bandsaw blade to cut aluminum?

It is not advisable to use a wood-cutting bandsaw blade to cut aluminum. Wood-cutting blades have a different tooth geometry and a wider gullet, which is not suitable for cutting metal. These blades are designed specifically for cutting wood, and using them for aluminum can lead to poor cutting performance, premature blade wear, and potential accidents.

It is important to use a blade specifically designed for cutting metal, such as a bi-metal bandsaw blade, to ensure clean and efficient cuts in aluminum.

3. What factors should I consider when choosing a bandsaw blade for cutting aluminum?

When choosing a bandsaw blade for cutting aluminum, consider the following factors:

– Blade width: Use a blade width suitable for your bandsaw’s capacity and the desired cutting accuracy. Narrower blades provide more precise cuts, but thicker blades offer more stability.

– Blade thickness: Select a blade thickness that matches the thickness of the aluminum you’ll be cutting. Thicker blades are more rigid and suitable for cutting thicker materials.

– Tooth pitch: Choose a blade with a fine tooth pitch (around 10-14 TPI) for cutting aluminum. Fine-tooth blades reduce chip clogging and provide cleaner cuts.

– Blade material: Opt for bi-metal blades that combine high-speed steel teeth and a flexible backing material for superior performance and longevity.

4. Can I use lubrication when cutting aluminum with a bandsaw?

Yes, using lubrication when cutting aluminum with a bandsaw can improve cutting performance and prolong blade life. Applying a suitable coolant or cutting fluid helps reduce heat and friction, preventing the blade from overheating and extending its durability. It also helps flush away chips, resulting in cleaner cuts.

Consider using a water-based coolant or a specialized cutting fluid designed for cutting aluminum. Make sure to follow the manufacturer’s instructions for the proper use and application of the lubricant.

5. How can I maintain the bandsaw blade while cutting aluminum?

To maintain the bandsaw blade while cutting aluminum, follow these tips:

– Keep the blade clean: Regularly remove chips and debris from the blade to prevent them from affecting the cutting performance or damaging the blade.

– Adjust blade tension: Adequately tension the blade to ensure optimal cutting performance. Follow the manufacturer’s recommendations for the proper tension level.

– Monitor blade wear: Check the blade regularly for signs of wear or damage. Replace the blade if it becomes dull or shows signs of fatigue, such as tooth wear or cracks.

– Use proper cutting speed: Cutting aluminum at the appropriate speed helps reduce heat and prevents premature blade dulling. Consult the manufacturer’s recommendations for the recommended cutting speed.

Summary

So, to wrap it all up, when it comes to cutting aluminum with a bandsaw, it’s important to use the right blade. A blade with fewer teeth per inch (TPI) and a variable pitch will work best for this type of material. Welded bi-metal blades are also a good choice because they offer durability and efficiency. Remember to go slower and use lubrication to prevent overheating and ensure a smooth cut. Safety goggles and gloves are a must when operating a bandsaw.

Overall, cutting aluminum with a bandsaw can be done successfully as long as you have the right blade and follow the proper techniques. With a little practice and attention to safety, you’ll be able to achieve clean and accurate cuts in no time. Just remember to choose the right blade, go at a slower speed, use lubrication, and prioritize safety. Happy cutting!