Are you wondering what bandsaw blade to use for cutting aluminum? Well, you’ve come to the right place! Finding the right blade for your bandsaw can make all the difference in achieving clean, precise cuts. So, let’s dive in and discover the best blade to tackle your aluminum cutting projects.

When it comes to cutting aluminum, you want a bandsaw blade that can handle the unique properties of this versatile metal. Aluminum is known for being soft, lightweight, and prone to gummy build-up during cutting. That’s why it’s crucial to choose a blade specifically designed to cut through aluminum like a hot knife through butter.

With the right bandsaw blade, you’ll be able to effortlessly slice through aluminum sheets, bars, or tubes with accuracy and ease. Whether you’re a DIY enthusiast or a seasoned metalworker, understanding which blade to use can save you time, money, and frustration. So, let’s explore the different types of bandsaw blades suited for cutting aluminum and find the perfect match for your project.

- Choose a blade with a small tooth pitch, such as 10-14 TPI.

- Opt for a bi-metal blade for its durability and heat resistance.

- Ensure the blade has a variable tooth set to prevent clogging.

- Consider a blade with a high positive rake angle for effective chip removal.

- Lastly, select a blade width that suits your specific cutting needs.

Remember to prioritize safety precautions and consult the manufacturer’s recommendations. Happy cutting!

What Bandsaw Blade to Use for Aluminum: A Comprehensive Guide

When it comes to cutting aluminum, using the right bandsaw blade is crucial for achieving clean and precise cuts. With the wide variety of blades available in the market, it can be overwhelming to determine which one is the best fit for your needs. In this comprehensive guide, we will explore the factors you should consider when selecting a bandsaw blade for cutting aluminum, tips for maximizing performance and blade longevity, and the different types of blades available. Whether you are a professional metalworker or a DIY enthusiast, this guide will help you make an informed decision.

Factors to Consider When Selecting a Bandsaw Blade for Aluminum

Before diving into the different types of bandsaw blades available for cutting aluminum, it is essential to understand the factors that should influence your decision. Let’s take a closer look at these crucial considerations:

Blade Material and Construction

The material and construction of the bandsaw blade play a significant role in its performance when cutting aluminum. The most common blade material for cutting aluminum is high-carbon steel or bimetal. High-carbon steel blades are affordable and provide good cutting performance. Bimetal blades, on the other hand, consist of a high-speed steel tooth edge welded to a steel back, offering enhanced cutting speed and durability.

The blade construction is also essential. Look for blades with a high tooth count per inch (TPI) for smoother cuts and a variable tooth set pattern to reduce clogging. Additionally, pay attention to the blade’s thickness, as a thinner blade allows for tighter radius cuts. However, thicker blades generally offer more stability and are suitable for heavier-duty applications.

Teeth Per Inch (TPI)

The TPI refers to the number of teeth on the blade per inch. Choosing the right TPI depends on the thickness of the aluminum you are cutting. For thicker materials, a lower TPI (around 4-6) is recommended as it provides more tooth contact and greater chip clearance. Thinner materials, on the other hand, require a higher TPI (around 14-24) for more teeth engaged in the cut and smoother finishes.

Blade Width

The width of the blade affects the overall stability and cutting performance. Narrow blades (1/8″ to 1/4″) are suitable for intricate cuts, while wider blades (1/2″ to 1″) are ideal for straight-line cuts and more substantial materials. Consider the specific cuts you will be making and select the blade width accordingly.

Blade Coating

Some bandsaw blades come with special coatings that provide additional benefits. For cutting aluminum, blades with a TiN (Titanium Nitride) or TiCN (Titanium Carbonitride) coating are popular choices. These coatings reduce friction, improve the blade’s durability, and prevent the material from sticking to the blade.

Feed Rates and Speeds

Feeding the material at the appropriate rate and using the correct cutting speed are vital for achieving optimal results. Consult the manufacturer’s recommendations or refer to reference guides to determine the appropriate feed rates and speeds for cutting aluminum with specific blades. Adjusting the speed and feed rate can help prevent premature blade wear and overheating.

Choosing the Right Blade Type

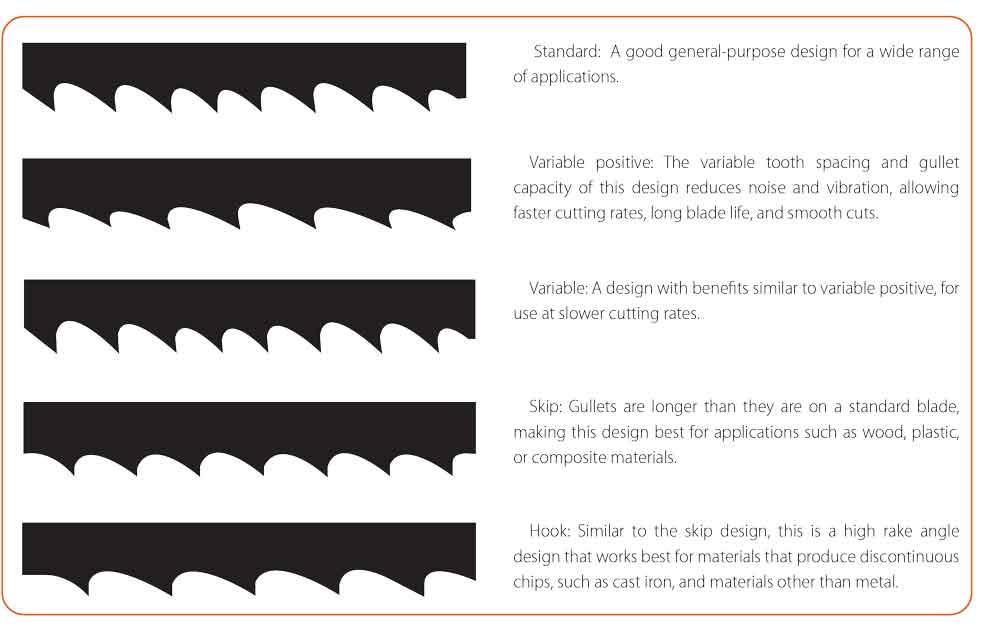

The type of blade you choose depends on the specific cutting application. Let’s explore the most common types of bandsaw blades for cutting aluminum:

1. Regular Tooth Blade

A regular tooth blade is a versatile option suitable for cutting various materials, including aluminum. It features evenly spaced teeth that provide a clean cut. This type of blade is ideal for general-purpose cutting tasks.

Benefits:

- Simple and cost-effective

- Good cutting performance for aluminum

- Suitable for a wide range of materials

2. Skip Tooth Blade

A skip tooth blade features widely spaced teeth with large gullets between them. This design helps prevent clogging and improves chip clearance. It is a popular choice for cutting softer materials such as aluminum.

Benefits:

- Excellent chip clearance

- Reduced clogging

- Smooth finish

Maintaining and Maximizing the Performance of your Bandsaw Blade

Now that we have discussed the factors to consider when selecting a bandsaw blade for cutting aluminum, let’s explore some tips for maintaining and maximizing the performance of your blade:

Proper Blade Tension

Ensure that your bandsaw blade is properly tensioned to prevent premature wear and ensure accurate cuts. Refer to your bandsaw’s manual for the recommended tension settings and regularly check and adjust the tension as needed.

Regular Blade Cleaning

Aluminum tends to stick to the blade, leading to reduced cutting performance. It is essential to clean your bandsaw blade regularly to remove any buildup. Use a brush or a blade cleaning solution to clean the blade after each use.

Coolant and Lubrication

Using a coolant or lubricant when cutting aluminum can help dissipate heat and prolong blade life. Apply a suitable coolant or lubricant to the blade while cutting to reduce friction and improve cutting performance.

Proper Cutting Technique

Adopting the correct cutting technique can make a significant difference in the performance and lifespan of your bandsaw blade. Ensure you are using the appropriate feed rate, cutting speed, and blade speed for cutting aluminum. Avoid forcing the material and let the blade do the work.

Conclusion

Choosing the right bandsaw blade for cutting aluminum is essential to achieve accurate and efficient results. Consider factors such as blade material, teeth per inch, blade width, and coating to select the most suitable blade for your specific application. Remember to adhere to manufacturer recommendations for feed rates and speeds, and maintain your blade through proper tensioning, cleaning, and lubrication. By following these guidelines, you can make clean, precise cuts in aluminum and extend the life of your bandsaw blade.

Key Takeaways: What Bandsaw Blade to Use for Aluminum?

- Choose a blade specifically designed for cutting non-ferrous metals like aluminum.

- Opt for a blade with a high tooth count, around 10 to 14 teeth per inch, for smoother cuts.

- Look for a blade made of carbide-tipped or bi-metal material for durability and longevity.

- Ensure the blade has a positive rake angle for efficient chip removal and reduced heat buildup.

- Consider using a coolant or lubricant during the cutting process to prolong blade life and prevent overheating.

Frequently Asked Questions

Welcome to our frequently asked questions section about choosing the right bandsaw blade for cutting aluminum. Here, we will address some common queries to help you make an informed decision.

1. What factors should I consider when selecting a bandsaw blade for cutting aluminum?

When choosing a bandsaw blade for cutting aluminum, there are a few key factors to consider. Firstly, the blade material is important. Look for blades made from bi-metal or carbide-tipped materials, as these are specifically designed for cutting aluminum. Secondly, consider the tooth pattern. Blades with a skip-tooth or hook-tooth configuration are preferable for aluminum, as they help prevent clogging and provide a smoother cut. Lastly, pay attention to the blade’s width and length, ensuring it is suitable for your specific bandsaw model.

By considering these factors in tandem, you can select a bandsaw blade that is optimal for cutting aluminum and achieve precise, clean cuts every time.

2. Can I use a regular steel bandsaw blade for cutting aluminum?

While it is technically possible to use a regular steel bandsaw blade for cutting aluminum, it is not recommended. Steel blades are designed for cutting through tougher materials like wood and metal, while aluminum requires a different approach. Aluminum is a softer metal, which means it reacts differently to cutting forces. Using a regular steel blade can result in poor performance, blade dulling, and rough cuts.

To achieve accurate and clean cuts in aluminum, it is best to use a bandsaw blade specifically designed for cutting this material. Blades made from bi-metal or carbide-tipped materials are engineered to handle the unique properties of aluminum, ensuring optimal performance and longevity.

3. What are the advantages of using a bi-metal blade for cutting aluminum?

Bi-metal blades offer several advantages when it comes to cutting aluminum. Firstly, they are known for their durability and longevity. Bi-metal blades consist of two different materials: the teeth are made from high-speed steel, while the back of the blade is constructed from a flexible alloy steel. This combination provides the perfect balance of cutting power and flexibility, ensuring a smooth cutting experience without compromising blade strength or integrity.

Additionally, bi-metal blades are specifically engineered to resist heat buildup, which is crucial when cutting aluminum. The high-speed steel teeth have excellent heat resistance properties, preventing premature blade dulling and extending the blade’s lifespan. The combination of durability, flexibility, and heat resistance makes bi-metal blades an excellent choice for cutting aluminum.

4. Is it necessary to lubricate the bandsaw blade when cutting aluminum?

Yes, it is highly recommended to lubricate the bandsaw blade when cutting aluminum. Aluminum has a tendency to create chips and residue during the cutting process, which can lead to increased friction and heat buildup on the blade. Applying a suitable cutting fluid or lubricant helps reduce heat and prolongs the blade’s life by reducing wear. Additionally, lubrication improves cutting efficiency and promotes cleaner cuts by minimizing chip buildup on the blade’s teeth.

There are various types of lubricants available specifically designed for cutting aluminum. It is important to refer to the manufacturer’s guidelines for the recommended lubrication method and ensure proper application to achieve optimal results.

5. How do I determine the correct blade speed for cutting aluminum?

Determining the correct blade speed for cutting aluminum involves finding the right balance between cutting efficiency and heat buildup. Ideally, the blade speed should be set at a rate that allows for efficient chip removal without excessive friction. If the blade speed is too high, it can lead to premature blade wear, while a speed that is too slow can cause increased heat buildup, resulting in poor cutting performance.

To determine the correct blade speed, you should consult the bandsaw manufacturer’s guidelines or refer to the blade manufacturer’s recommendations for cutting aluminum. These guidelines will provide you with the optimal blade speed range based on the blade type, material, and thickness of the aluminum you are cutting. Adjusting the blade speed accordingly will help ensure cleaner cuts, prolong blade life, and enhance cutting efficiency.

Summary

So, to wrap things up, when it comes to choosing a bandsaw blade for aluminum:

First, make sure to select a blade with a high tooth count, preferably 18 to 24 teeth per inch, as this will give you a smoother cut and prevent chattering.

Next, consider a blade made from carbon steel or bi-metal, as these materials are durable and can handle the demands of cutting through aluminum.

Additionally, it’s important to check the blade tension and make sure it is properly adjusted for optimal performance.

Remember, safety is key, so always wear protective gear like goggles and gloves when operating the bandsaw.

Lastly, take your time, be patient, and let the blade do the work for you. Happy cutting!