Are you wondering what bandsaw blade to use for stainless steel? Well, you’re in the right place! Choosing the right blade for your bandsaw can make all the difference when it comes to cutting through stainless steel like a hot knife through butter. So, let’s dive in and discover the best blade for the job!

When it comes to cutting stainless steel, it’s crucial to select a bandsaw blade that can tackle this tough material with ease. But don’t worry, we’ve got you covered! In this guide, we’ll walk you through the various types of bandsaw blades available and help you determine the ideal one for cutting stainless steel like a pro.

Cutting stainless steel requires the right combination of tooth pitch, material, and blade width. But fear not, because we’re here to simplify it all for you! By the end of this article, you’ll be equipped with the knowledge to choose the perfect bandsaw blade for all your stainless steel cutting needs. So, let’s get started!

- Choose a bi-metal bandsaw blade for stainless steel due to its high durability.

- Ensure the blade has a fine tooth pitch, as this helps maintain control and reduce the risk of chipping or breaking.

- Select a blade with a high cutting speed to efficiently cut through the stainless steel.

- Consider using a variable tooth pattern blade for smooth and precise cuts.

- Remember to use the appropriate cutting fluid to keep the blade cool and extend its lifespan.

What Bandsaw Blade to Use for Stainless Steel?

Choosing the right bandsaw blade for stainless steel cutting is crucial for achieving clean, precise, and efficient results. Stainless steel is a tough and hard material that requires a specially designed blade to withstand its resistance and provide optimal performance. In this article, we will explore the different factors to consider when selecting a bandsaw blade for stainless steel, including tooth pitch, blade material, and blade thickness. With the right blade, you can achieve smooth cuts, minimize waste, and extend the lifespan of your bandsaw.

Factors to Consider When Choosing a Bandsaw Blade for Stainless Steel

1. Tooth Pitch:

When cutting stainless steel, it is important to select the appropriate tooth pitch on your bandsaw blade. The tooth pitch refers to the distance between each tooth on the blade. For stainless steel, a finer tooth pitch is recommended to ensure a smoother cut and to reduce heat buildup during the cutting process. A fine tooth pitch will also help prevent the blade from becoming clogged with chips and debris, ensuring better cutting efficiency.

The number of teeth per inch (TPI) is an important consideration. Blades with a higher TPI, such as 18 or 24, are ideal for stainless steel cutting. These blades have more teeth, which means each tooth takes a smaller bite, resulting in a cleaner and more precise cut.

2. Blade Material:

Choosing the right blade material is essential for cutting stainless steel effectively. Carbon steel blades are not suitable for cutting stainless steel as they lack the necessary hardness and durability to withstand the material’s toughness. Instead, opt for bi-metal or carbide-tipped bandsaw blades specifically designed for stainless steel cutting.

Benefits of Using the Right Bandsaw Blade for Stainless Steel

1. Clean and precise cuts:

Using a bandsaw blade that is specifically designed for stainless steel cutting will ensure clean and precise cuts. The fine tooth pitch and appropriate blade material will minimize the risk of chips or rough edges, resulting in smooth and accurate cuts.

2. Increased efficiency:

The right bandsaw blade will increase cutting efficiency by reducing heat buildup and preventing clogging. This means you can complete your cuts faster and with less effort, saving valuable time and increasing productivity.

3. Extended blade lifespan:

Investing in a high-quality bandsaw blade for stainless steel will result in a longer lifespan for your blade. The blade’s durability and resistance to wear and tear will reduce the need for frequent blade replacements, saving you money in the long run.

Different Types of Bandsaw Blades for Stainless Steel Cutting

1. Bi-Metal Blades:

Bi-metal blades are the most commonly used blades for cutting stainless steel. These blades are made from two different metals: a high-speed steel cutting edge and a flexible carbon steel body. The combination of these materials provides the blade with both hardness and flexibility, making it ideal for stainless steel cutting.

2. Carbide-Tipped Blades:

Carbide-tipped blades are another excellent option for cutting stainless steel. These blades are made from a combination of high-carbon steel and carbide, a highly durable compound. Carbide-tipped blades offer exceptional cutting performance and longevity for heavy-duty stainless steel cutting applications.

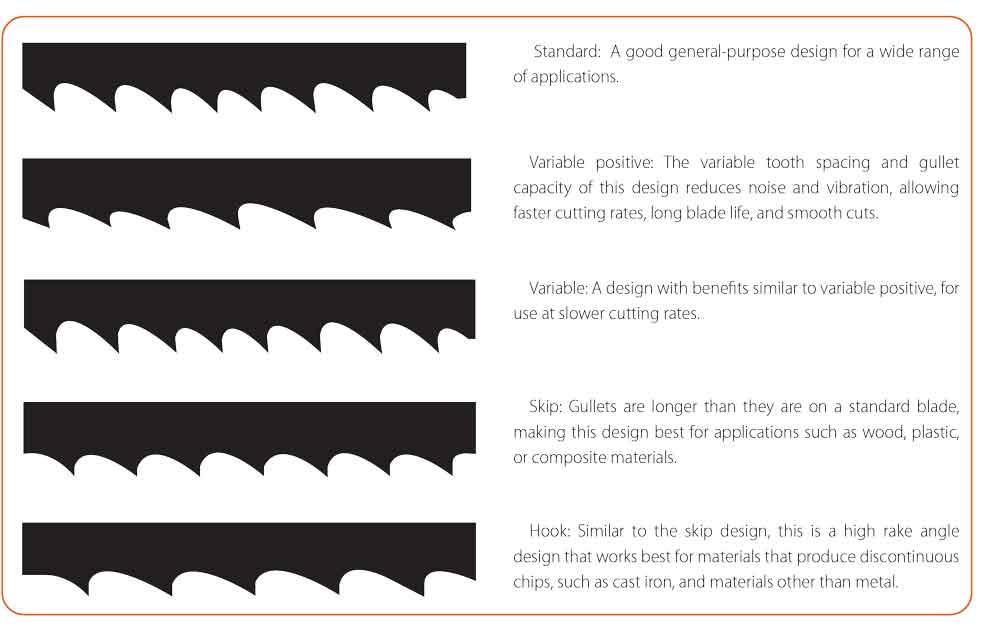

3. Variable Pitch Blades:

Variable pitch blades have teeth with varying tooth pitches along the length of the blade. These blades are designed to provide a smooth and efficient cutting experience for a wide range of materials, including stainless steel. The varying tooth pitch helps prevent vibration and reduces heat generation, resulting in cleaner cuts and longer blade life.

Tips for Maximizing the Performance of Your Bandsaw Blade

1. Proper blade tension:

Ensuring the proper tension on your bandsaw blade is crucial for optimal performance. Too much tension can result in premature blade wear or breakage, while too little tension can cause poor cutting quality and blade instability. Follow the manufacturer’s guidelines for tensioning the blade to achieve the best results.

2. Lubrication:

Using a suitable lubricant during the cutting process is essential for reducing friction and heat buildup. Apply a lubricant designed for stainless steel cutting to enhance the blade’s performance and extend its lifespan.

3. Slow and steady feeding rate:

When cutting stainless steel, it is important to feed the material at a slow and steady rate. This allows the blade to make continuous, even cuts, reducing the risk of blade damage and ensuring a clean, accurate cut.

The Importance of Choosing the Right Bandsaw Blade for Stainless Steel

Choosing the right bandsaw blade for stainless steel cutting is crucial for achieving optimal results. Using the wrong blade can result in poor cutting performance, including rough cuts, blade dullness, and wasted material. By selecting the appropriate tooth pitch, blade material, and blade thickness, you can ensure clean, precise, and efficient stainless steel cuts. Remember to follow proper usage and maintenance practices, such as maintaining the correct blade tension and using appropriate lubrication, to maximize the lifespan and performance of your bandsaw blade.

Key Takeaways:

- A bandsaw blade with a high-speed steel (HSS) tooth material is ideal for cutting stainless steel.

- Choose a blade with a fine tooth pitch for stainless steel to ensure clean and precise cuts.

- Opt for a bi-metal blade made of HSS and cobalt for increased durability and cutting performance.

- Consider using a variable tooth pitch blade for better control and versatility when cutting different thicknesses of stainless steel.

- Proper blade tension and lubrication are crucial for maximizing the lifespan and performance of the bandsaw blade when cutting stainless steel.

Frequently Asked Questions

Whether you’re a beginner or experienced woodworker, choosing the right bandsaw blade for stainless steel can be challenging. Below are some common questions to help guide you in selecting the optimal bandsaw blade for cutting stainless steel.

1. What factors should I consider when choosing a bandsaw blade for stainless steel?

When selecting a bandsaw blade for stainless steel, there are several factors to consider. First, look at the blade’s material and tooth configuration. Opt for a bimetal blade with high-speed steel teeth, as they are specifically designed for cutting stainless steel. Additionally, consider the blade’s width and pitch. A wider blade will provide greater stability and reduce the chance of blade flexing during the cut. As for pitch, a lower pitch blade with fewer teeth per inch is generally preferred for stainless steel, as it can clear the chips more effectively.

It’s also important to consider the blade’s TPI (teeth per inch) and tooth set. A lower TPI with a variable tooth set will help prevent clogging and improve the cutting efficiency. Lastly, take into account the blade’s durability and cost. Look for a blade that balances cost-effectiveness with long-lasting performance.

2. Can I use a regular bandsaw blade for cutting stainless steel?

While it’s technically possible to use a regular bandsaw blade for cutting stainless steel, it is not recommended. Regular blades are typically designed for cutting wood or soft materials and are not suitable for the hardness and abrasiveness of stainless steel. Using a regular blade for stainless steel can result in premature wear, blade damage, and poor cut quality.

Investing in a specific bandsaw blade designed for cutting stainless steel will help ensure clean, accurate cuts and prolong the life of your blade. These blades are engineered with the necessary hardness, tooth geometry, and edge sharpness to tackle the challenges of cutting stainless steel.

3. What is the ideal blade speed for cutting stainless steel on a bandsaw?

The ideal blade speed for cutting stainless steel on a bandsaw depends on the thickness and hardness of the material. As a general guideline, aim for a slower blade speed when cutting thicker stainless steel and a faster speed for thinner material.

It’s important to consult the manufacturer’s guidelines for the specific bandsaw blade you are using. If you don’t have access to this information, a common rule of thumb is to start with a blade speed of around 100 to 350 feet per minute for stainless steel.

4. How often should I replace the bandsaw blade when cutting stainless steel?

The frequency of blade replacement when cutting stainless steel depends on several factors, including the blade quality, cutting conditions, and the thickness of the material being cut. Generally, as soon as you notice a decrease in cut quality or the blade starts to dull, it’s a good idea to replace it.

Sawing stainless steel generates high heat and puts significant stress on the blade, which can lead to faster wear. To maximize blade life, ensure you are using the appropriate blade for stainless steel and follow proper cutting techniques, including maintaining the correct blade speed and feed rate.

5. Are there any safety precautions I should take when using a bandsaw to cut stainless steel?

Yes, there are several safety precautions you should always follow when using a bandsaw to cut stainless steel. Firstly, wear appropriate personal protective equipment, such as safety glasses, gloves, and a face shield to protect yourself from metal chips and sparks.

Additionally, ensure the bandsaw is properly set up and adjusted, with the blade tensioned correctly. Keep your fingers and hands clear of the blade during operation, and use a push stick or other suitable tools to feed the stainless steel into the blade. Finally, work in a well-ventilated area and be mindful of the heat generated during cutting, as stainless steel can become hot to the touch.

Summary

To choose the right bandsaw blade for cutting stainless steel, remember these key points. Firstly, opt for a bi-metal blade as it is durable and has high heat resistance. Secondly, consider the tooth pitch – a finer pitch is suitable for thin stainless steel, while a coarse pitch is better for thicker material. Lastly, pay attention to the blade’s thickness, as a thicker blade reduces the risk of breaking or flexing.

In conclusion, when working with stainless steel, use a bi-metal bandsaw blade with the appropriate tooth pitch and thickness for optimal cutting performance. Happy cutting!