Ah, the wonders of a scroll saw! Have you ever wondered what you can’t do with this versatile tool? Well, you’re in for a treat because in this article, we’ll explore just that. So, sit tight, grab a snack, and let’s dive into the world of scroll saws!

Now, you might be thinking, “What can you not do with a scroll saw?” It’s a fair question, my friend. While scroll saws are incredibly useful for a wide range of projects, there are a few things they’re not cut out for (pun intended). But fear not, because we’re here to shed some light on this topic.

Whether you’re a seasoned woodworker or just starting out, it’s important to know the limitations of your tools. Understanding what a scroll saw can’t do will not only save you time and effort, but it will also help you make informed decisions when tackling your next project. So, let’s get started and uncover the secrets of the scroll saw!

What Can You Not Do with a Scroll Saw?

Scroll saws are versatile and powerful tools that allow woodworkers to create intricate and detailed cuts in various materials. However, there are certain limitations to what a scroll saw can accomplish. In this article, we will explore the things that you cannot do with a scroll saw, including the materials that are not suitable for cutting, the types of cuts that are challenging to achieve, and the limitations of the scroll saw design.

1. Cutting Metal and Hardened Materials

Scroll saws are primarily designed for cutting wood and other soft materials such as plastic and certain types of soft metals like aluminum. However, they are not well-suited for cutting hard metals like steel or hardened materials such as hardened carbon fiber. These materials are too tough for the delicate and precise action of the scroll saw blade, and attempting to cut them may result in damage to the blade or the saw itself.

While it is possible to cut thin sheets of soft metals like aluminum on a scroll saw, it is essential to use the appropriate blade and take precautions to prevent heat buildup, which can cause the metal to deform or the blade to break. Always consult the manufacturer’s guidelines to ensure that you are using the scroll saw within its intended capabilities.

In summary, if you need to cut hard metals or hardened materials, it is best to use a different tool that is specifically designed for those purposes, such as a bandsaw or a metal-cutting circular saw.

2. Long and Wide Cuts

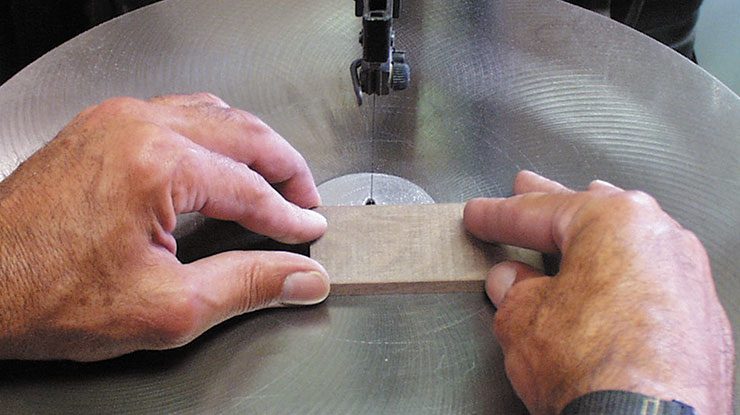

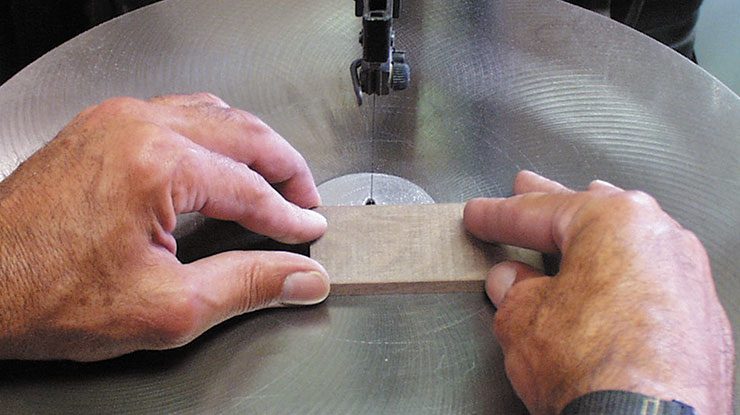

While scroll saws excel at making intricate and detailed cuts, they are not ideal for long and wide cuts. The design of the scroll saw, with its narrow throat and small work table, limits the length and width of the materials that can be effectively cut. Attempting to make long or wide cuts on a scroll saw can result in instability and difficulty maneuvering the material, leading to inaccurate cuts or potential safety hazards.

For long and straight cuts, a table saw or a circular saw with a guide system would be a better choice. These tools provide a larger cutting surface and are designed to handle longer and wider materials more effectively.

However, if you need to make a curved or intricate cut in a long and wide material, you can use the scroll saw by working in sections or by using a technique called “stack cutting.” Stack cutting involves stacking multiple layers of the material and cutting them simultaneously, allowing you to achieve a consistent and accurate cut along the entire length or width of the material.

3. Rough or Aggressive Cuts

Scroll saws are known for their precision and ability to make intricate cuts with smooth edges. However, they are not designed for rough or aggressive cuts. The fine teeth of the scroll saw blade are delicate and can easily break or become damaged if forced to cut too aggressively or in materials that are too dense or thick.

It is important to let the scroll saw blade do the work and avoid pushing or forcing the material through the blade. If you need to remove a substantial amount of material or make rough cuts, it is recommended to use a different tool, such as a jigsaw or a bandsaw, which are better suited for these types of cuts.

When using a scroll saw, it is best to focus on precision and finesse, taking your time to guide the material carefully and allowing the blade to cut at its own pace. This will result in cleaner and more accurate cuts while preserving the longevity of the scroll saw blade.

4. Non-Perpendicular Cuts

While scroll saws are capable of making angled cuts, they are not well-suited for non-perpendicular cuts, such as compound angles or bevel cuts. The nature of the scroll saw’s design and the limited adjustability of the table and blade make it challenging to achieve precise and consistent non-perpendicular cuts.

If you need to make non-perpendicular cuts, it is recommended to use a different tool, such as a miter saw or a table saw, which offer more precise and adjustable cutting angles. These tools are specifically designed for making accurate angled cuts and provide better stability and control compared to a scroll saw.

However, if you need to create unique or intricate shapes with curved and non-perpendicular lines, the scroll saw can still be a valuable tool. By using a technique called “stack cutting” or by making multiple small cuts and carefully shaping the material, you can achieve the desired angles and shapes.

5. Sanding and Smoothing

While a scroll saw can create precise and detailed cuts, it is not designed for sanding or smoothing the cut surfaces. The scroll saw blade leaves behind a relatively rough and jagged edge, which may require additional finishing to achieve a smooth and polished result.

To achieve a smooth finish, it is recommended to use sandpaper or other sanding tools appropriate for the material you are working with. Start with a coarse grit sandpaper to remove any rough edges or imperfections, then gradually work your way up to finer grits for a smoother finish.

If you frequently need to sand or smooth the cut surfaces, consider investing in a disk or belt sander, which can expedite the sanding process and provide more consistent results.

6. Large and Heavy Materials

Scroll saws are typically designed for smaller and lightweight materials, such as thin pieces of wood or plastic. Trying to cut large and heavy materials on a scroll saw can lead to instability and safety hazards.

It is important to consider the size and weight of the material before attempting to cut it on a scroll saw. If the material is too large or heavy to handle comfortably and safely, it is best to use a different tool that is more suitable for larger and heavier materials, such as a bandsaw or a circular saw.

If you absolutely need to cut a large or heavy material on a scroll saw, ensure that you have proper support and secure the material to prevent movement or instability. Exercise caution and follow all safety precautions to minimize the risk of accidents or injuries.

7. Large-Scale Production

While a scroll saw can be a valuable tool for intricate and detailed work, it is not efficient for large-scale production. The nature of the scroll saw’s design and the precision required for each cut make it impractical and time-consuming for mass-producing multiple identical pieces.

If you need to produce a large quantity of the same piece, it is recommended to consider other tools, such as a laser cutter or a CNC machine, which can automate and streamline the production process. These tools are specifically designed for repeatable accuracy and efficiency in large-scale production.

However, if you are creating one-of-a-kind or limited edition pieces that require the intricacy and artistry that can be achieved with a scroll saw, it remains an excellent choice.

Key Takeaways: What Can You Not Do with a Scroll Saw?

- A scroll saw cannot cut through thick or dense materials.

- It is not suitable for cutting curves with a small diameter.

- You cannot use a scroll saw for straight cuts or rip cuts.

- Scroll saws are not designed for heavy-duty or production work.

- They are not ideal for making long or continuous cuts.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we address common queries about using a scroll saw. Here you’ll find answers to some of the things you might wonder about what you can and can’t do with a scroll saw. Read on to learn more!

Can I use a scroll saw to cut metal?

No, a scroll saw is not designed for cutting metal. It is primarily used for making intricate cuts in wood, plastic, and other softer materials. Metal is too hard for the scroll saw’s blade, which is specifically designed for cutting through less dense materials. Attempting to cut metal with a scroll saw can damage the blade and the machine, and may result in an unsafe working environment.

If you need to cut metal, it is best to use specific tools designed for that purpose, such as a metal-cutting bandsaw or a plasma cutter. These tools are sturdier and have blades specifically engineered to handle the toughness of metal.

Can I make bevel cuts with a scroll saw?

No, the scroll saw is not suitable for making bevel cuts. A scroll saw is designed to make intricate, precise, and mostly vertical cuts. It does not have the ability to tilt the blade for angled cuts like a table saw or miter saw. If you need to make bevel cuts, it is best to use a different tool, such as a miter saw or a circular saw with a bevel adjustment feature.

The scroll saw excels in making intricate patterns and curves with its thin and narrow blade. It is best to utilize its strengths for detailed work and use other tools for tasks that require bevel cuts.

Can I cut thick materials with a scroll saw?

The scroll saw is not designed for cutting thick materials. Its thin blade is designed to make precise, intricate cuts in materials that are less than an inch thick. Attempting to cut thicker materials with a scroll saw can result in blade breakage and may cause damage to the machine itself.

If you need to cut thicker materials, it is recommended to use a different tool such as a band saw or a jigsaw, as these are better equipped to handle thicker stock and provide more stability and power for the task.

Can I use a scroll saw without a table?

While it is technically possible to use a scroll saw without a table, it is highly recommended to use one. A scroll saw table provides stability and support for your workpiece, allowing for more precise and controlled cutting. It also helps to minimize vibrations, making the cutting process safer and more efficient.

If you don’t have a dedicated scroll saw table, you can make one using a sturdy, flat surface such as a workbench or a piece of plywood securely mounted to a surface. Just ensure that the table is level and provides adequate support for your workpiece to achieve the best results.

Can I use a scroll saw for straight cuts?

While a scroll saw is not typically known for making straight cuts, it is still possible to achieve them with some practice and the right techniques. However, other saws such as a table saw or a circular saw are better suited for making long, straight cuts in materials like wood or plastic.

The primary strength of a scroll saw lies in its ability to create intricate curves and patterns. It is designed to make precise, detailed cuts that are difficult to achieve with other saws. However, with the right blade, proper setup, and patience, you can make relatively straight cuts with a scroll saw.

Summary

So, what can you not do with a scroll saw? Firstly, you should avoid cutting large, thick pieces of wood because the saw’s thin blade is not designed for heavy-duty cutting. Secondly, you should steer clear of using it for metal or other hard materials as it can damage the blade. Thirdly, intricate curves and rounded cuts may pose a challenge due to the scroll saw’s limited range of motion. Lastly, you should not expect the saw to perform straight cuts as it is primarily meant for intricate, curved designs.

In summary, a scroll saw is a versatile tool for detailed woodworking projects. However, it has its limitations. It is best suited for delicate and artistic work, while heavy-duty cutting and straight cuts are better left to other tools. Remember to prioritize your safety and the proper use of equipment when working with a scroll saw.