Hey there! Ever wondered what causes a circular saw to kick back? Well, let’s dive into this fascinating topic and find out together!

A circular saw is a handy tool that makes woodworking projects a breeze. But sometimes, it can surprise us with a sudden jolt or kickback. So, what exactly causes this kickback?

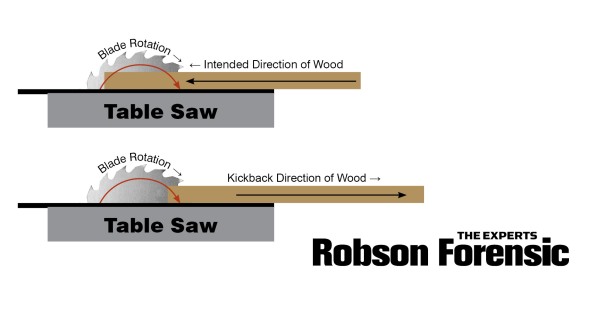

When a circular saw kicks back, it means that the saw’s blade suddenly stops or gets jammed. This can happen if the material you’re cutting pinches the blade or if there’s a misalignment between the saw’s base and the material being cut. Curious to learn more? Let’s keep going!

So, what are the factors that contribute to kickback? We’ll explore them in detail and also provide you with some useful tips on how to prevent it. Ready? Let’s get into the nitty-gritty of why circular saws kick back and how to stay safe while using them.

Circular saw kickback can occur due to several factors. One common cause is incorrect blade alignment, so ensure it is properly aligned before cutting. Another possible reason is feeding the material too quickly through the saw. Maintain a steady pace to prevent kickback. Additionally, a dull or damaged blade can lead to kickback, so regularly check and replace your blades as needed. Finally, using excessive force or not using a saw guide can contribute to kickback. Be mindful of these factors to prevent kickback incidents.

What Causes a Circular Saw to Kick Back?

Kickback is a common hazard that can occur when using a circular saw. It happens when the saw blade gets stuck or jams, causing the saw to violently kick back towards the user. This can result in serious injuries, including lacerations and even amputations. Understanding the causes of kickback and how to prevent it is crucial for the safe use of a circular saw. In this article, we will explore the various factors that can lead to kickback and provide tips on how to avoid it.

Improper Blade Alignment

One of the main causes of kickback is improper blade alignment. If the saw blade is not correctly aligned with the cut line or if the blade is dull or damaged, it can lead to kickback. When the blade is misaligned, it can get pinched in the material being cut, causing the saw to jerk back towards the operator. To prevent this, always ensure that the blade is properly aligned and in good condition before making any cuts. Using a sharp blade with the correct teeth configuration for the material being cut can greatly reduce the risk of kickback.

In addition to blade alignment, it is important to use the appropriate cutting technique. Pushing the saw too quickly or applying excessive downward pressure can increase the likelihood of kickback. Instead, use a steady and controlled cutting motion, allowing the blade to do the work gradually.

Tips to prevent kickback due to improper blade alignment:

- Check blade alignment before starting any cuts.

- Regularly sharpen and maintain the blade.

- Use the correct blade for the material being cut.

- Apply steady and controlled force when pushing the saw.

Inadequate Saw Control

Another common cause of kickback is inadequate saw control. This can happen when the operator loses control of the saw or when the material being cut binds or pinches the blade. To maintain proper control, it is essential to use both hands to grip the saw firmly and maintain a stable stance. Avoid overreaching or standing in an unstable position, as it can compromise your ability to control the saw.

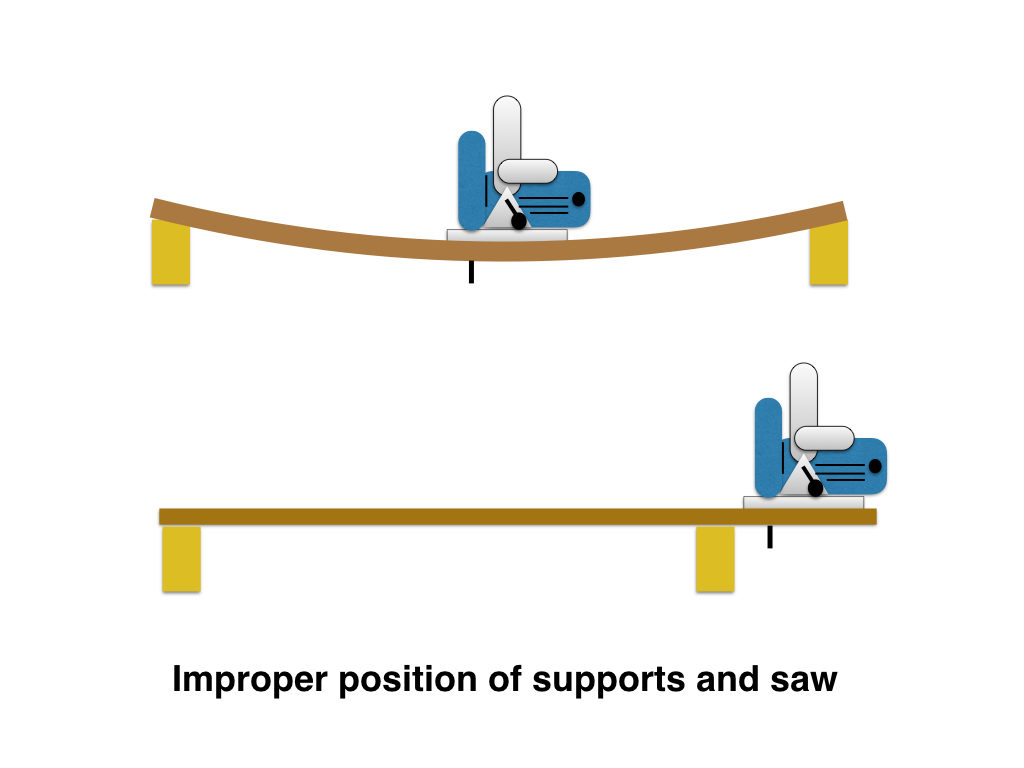

In some cases, kickback can occur due to the material being cut binding or pinching the blade. This often happens when the piece being cut is unstable or unsupported. To prevent this, always ensure that the material is properly secured and supported throughout the cutting process. Using clamps or a cutting guide can help provide stability and reduce the risk of kickback.

Tips to improve saw control and prevent kickback:

- Grip the saw firmly with both hands.

- Maintain a stable stance and avoid overreaching.

- Ensure the material being cut is properly secured and supported.

- Use clamps or a cutting guide for added stability.

Incorrect Blade Depth and Angle

The depth and angle of the blade can also contribute to kickback. If the blade is set too deep or if the cutting angle is incorrect, it can cause the saw to bind or twist in the material, leading to kickback. It is important to adjust the blade depth according to the thickness of the material being cut, allowing for a clean and efficient cut without excessive resistance. Additionally, using the correct cutting angle for the specific task at hand can help prevent kickback.

Take the time to properly set the blade depth and angle before starting any cuts. Use the appropriate adjustments based on the material being cut and the desired outcome. If you are unsure about the correct settings, consult the manufacturer’s guidelines or seek guidance from a knowledgeable professional.

Tips for proper blade depth and angle to prevent kickback:

- Adjust the blade depth according to the thickness of the material.

- Use the correct cutting angle for the task at hand.

- Refer to the manufacturer’s guidelines or seek professional advice if unsure.

Dulled or Damaged Blade

A dulled or damaged blade is not only less effective at cutting, but it can also increase the risk of kickback. A blade that is worn out or has missing or chipped teeth can easily get stuck or bind in the material, causing the saw to kick back. Regularly inspecting the blade for signs of wear and tear and promptly replacing it when necessary is essential for safety.

Additionally, using the correct blade for the material being cut can help prevent kickback. Different materials require different blade specifications, such as tooth count and type. Using the wrong blade can lead to kickback and produce poor results. Always ensure you are using the appropriate blade for the task at hand.

Tips for preventing kickback due to a dulled or damaged blade:

- Regularly inspect the blade for wear and damage.

- Replace the blade when signs of wear or damage are present.

- Use the correct blade for the specific material being cut.

Incorrect Use of Safety Features

Circular saws are equipped with various safety features to protect the user from kickback and other hazards. However, if these features are not used correctly or are disabled, the risk of kickback increases. Always ensure that the saw’s safety features, such as blade guards and anti-kickback devices, are in good working condition and properly engaged before making any cuts.

It is also essential to familiarize yourself with the specific safety features and operating instructions of the circular saw you are using. Different models may have different safety mechanisms, and understanding how they work will help you use the tool safely and effectively.

Tips for correctly using safety features to prevent kickback:

- Inspect and maintain the saw’s safety features regularly.

- Ensure safety features are engaged and functioning correctly before use.

- Familiarize yourself with the safety features and operating instructions of your specific circular saw.

Improper Workpiece Support

Inadequate support for the workpiece can also contribute to kickback. If the material being cut is not properly supported or if it is allowed to move or vibrate during the cutting process, it can cause the blade to bind or twist, resulting in kickback. It is crucial to provide proper support for the workpiece throughout the entire cut.

Using clamps or a cutting guide to secure the material can help prevent movement and reduce the risk of kickback. Additionally, ensuring that the work surface is clean and free from obstacles that could interfere with the cutting process is important for safe and efficient cutting.

Tips for proper workpiece support to prevent kickback:

- Secure the workpiece with clamps or a cutting guide.

- Ensure the work surface is clean and free from obstacles.

- Provide continuous support for the workpiece throughout the cut.

Insufficient Operator Training

All the factors mentioned above can contribute to kickback, but ultimately, insufficient operator training and experience can significantly increase the risk. It is essential to receive proper training on the safe use of a circular saw and to understand the potential hazards and risk mitigation strategies.

If you are new to using a circular saw or are unfamiliar with the specific model you are using, it is recommended to seek training or guidance from a professional. Familiarize yourself with the user manual and safety guidelines provided by the manufacturer, and always prioritize safety when operating a circular saw.

Preventing Kickback: Additional Tips and Best Practices

Now that we have covered the various causes of kickback, let’s delve into some additional tips and best practices to help prevent kickback and ensure safe use of a circular saw.

Select the Right Blade

Using the correct blade for the specific material and task is crucial for both performance and safety. Different blades are designed for different purposes, and using the wrong blade can increase the risk of kickback. When selecting a blade, consider factors such as tooth count, tooth type, and blade diameter. Refer to the manufacturer’s guidelines or consult with an expert to ensure you are using the appropriate blade for the job.

Keep the Saw in Good Condition

Maintaining your circular saw in good working condition is essential for safe operation. Regularly inspect the saw for any signs of wear, damage, or malfunction. Keep the blade sharp and replace it when necessary. Lubricate the moving parts, and ensure that the safety features are functioning correctly. Proper maintenance will not only reduce the risk of kickback but also extend the lifespan and performance of your saw.

Use Protective Gear

Wearing appropriate personal protective equipment (PPE) is crucial when using a circular saw or any power tool. This includes safety glasses or goggles to protect your eyes from flying debris, earmuffs or earplugs to protect your hearing from the loud noise, and gloves to provide a secure grip and protect your hands. Never operate a circular saw without the necessary PPE. Your safety should always be a top priority.

Conclusion

Kickback is a serious hazard when using a circular saw, but it can be prevented by understanding the causes and taking appropriate precautions. By ensuring proper blade alignment, maintaining good saw control, using the correct blade depth and angle, and following safety guidelines and best practices, you can significantly reduce the risk of kickback. Always prioritize safety, receive proper training, and use your circular saw responsibly. Happy and safe cutting!

Key Takeaways: What Causes a Circular Saw to Kick Back?

- A circular saw can kick back when the blade binds or gets stuck in the material being cut.

- Using a dull or damaged saw blade can increase the risk of kickback.

- Inadequate support for the material being cut can cause the saw to kick back.

- Not properly adjusting the depth of cut can lead to kickback.

- Poor technique, such as improper positioning or not maintaining a firm grip, can result in kickback.

Frequently Asked Questions

Welcome to our FAQ section on the causes of circular saw kickback! Below, we have answered some common questions about why a circular saw may kick back. Read on to learn more about this issue and how to avoid it.

1. How can I prevent kickback when using a circular saw?

Preventing kickback starts with using a properly maintained and adjusted circular saw. Ensure that the blade is sharp, that the blade guard is in good condition, and that the saw is properly aligned and calibrated. Additionally, always use the appropriate blade for the material you are cutting. When cutting, make sure to use both hands to maintain control of the saw, and maintain a secure and stable stance to minimize the risk of kickback. Finally, consider using auxiliary tools like a rip guide or a featherboard to help support and guide the workpiece.

Remember, kickback can also be caused by binding or pinching of the blade, so it is crucial to pay attention to the cutting process and make sure the workpiece is properly supported and free from obstructions. By following these guidelines, you can significantly reduce the likelihood of kickback while using a circular saw.

2. Can the type of material being cut affect the risk of kickback?

Absolutely. The type of material being cut can significantly affect the risk of kickback. Dense or thick materials, such as hardwoods or wet lumber, can put more strain on the blade and increase the chance of kickback. Similarly, knots or irregularities in the wood can cause the blade to bind or deflect, leading to kickback. It is crucial to be extra cautious when cutting these types of materials.

Additionally, certain materials, such as laminates or plastics, can cause the blade to grab or catch, increasing the risk of kickback. It’s important to choose the appropriate blade for the material you are cutting and adjust your cutting technique, if necessary, to minimize the chance of kickback.

3. What are some common mistakes that can lead to kickback when using a circular saw?

Some common mistakes that can result in kickback when using a circular saw include improper blade alignment, not using a riving knife or splitter, using a dull blade, and not using a blade guard. Blade misalignment can cause the blade to bind and kick back. A riving knife or splitter helps prevent the material from closing in on the back of the blade, reducing the risk of kickback.

Using a dull blade can cause the saw to work harder, increasing the chance of the blade grabbing the material and resulting in kickback. Lastly, always use a blade guard to protect against contact with the blade and minimize the risk of kickback.

4. Can kickback be a result of improper cutting technique?

Absolutely. Using improper cutting techniques can increase the risk of kickback. For example, applying too much force or pushing the material too quickly through the saw can cause the blade to grab or bind, leading to kickback. To avoid this, it’s important to let the saw move through the material at its own pace and avoid forcing it. Also, ensure you are using the appropriate cutting technique for the type of material being cut. Following recommended cutting practices can help minimize the risk of kickback.

Proper body positioning and stability are also vital for preventing kickback. Maintaining a secure grip on the saw and using both hands to control it can help you keep the saw steady and reduce the chance of kickback. Additionally, wearing appropriate safety gear, such as safety glasses and hearing protection, is essential for safe operation and mitigating the risk of injury.

5. Can a circular saw kickback even if used correctly?

While using a circular saw correctly significantly reduces the risk of kickback, it is important to note that kickback can still happen even when all precautions are taken. Factors such as unexpected material defects, sudden changes in grain direction, or hidden nails or screws within the material can increase the chance of kickback. In these cases, it is crucial to be prepared for the unexpected.

Always maintain a firm grip on the saw and stay alert to any signs of blade binding or catching. If you do feel the saw starting to kick back, release the trigger immediately and allow the saw to come to a complete stop before assessing the situation and proceeding with caution. Remember, safety is the number one priority when using any power tool, and being aware of the potential for kickback can help you stay safe.

How to prevent circular saw from kickback

Summary

Circular saws can kick back when not used properly, causing injuries to the user. The main reasons for kickback are improper handling, dull blades, and trying to cut through thick or hard materials. It’s essential to follow safety guidelines and make sure the saw is in good condition to prevent kickback accidents.

To avoid kickback, keep a firm grip on the saw, position yourself correctly, and use a push stick for narrow cuts. Regularly maintain the saw by sharpening the blades and replacing them when necessary. By taking these precautions, you can enjoy safe and effective use of a circular saw.